How Antifreeze Technology is Revolutionizing Space Exploration?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze in Space: Background and Objectives

Antifreeze technology has emerged as a critical component in the ongoing revolution of space exploration. The harsh, frigid environments encountered in space present significant challenges to spacecraft and equipment, necessitating innovative solutions to ensure their functionality and longevity. The development of advanced antifreeze technologies has its roots in terrestrial applications but has rapidly evolved to meet the unique demands of space missions.

The primary objective of antifreeze technology in space exploration is to prevent the formation of ice crystals in vital systems and components. In the vacuum of space, where temperatures can plummet to extreme lows, traditional fluids used in cooling systems and hydraulics are at risk of freezing, potentially leading to catastrophic failures. By implementing cutting-edge antifreeze solutions, space agencies and private companies aim to enhance the reliability and efficiency of their missions, ultimately expanding the boundaries of human exploration in the cosmos.

The evolution of antifreeze technology for space applications has been driven by a combination of scientific breakthroughs and engineering ingenuity. Early space missions relied on rudimentary heating systems and insulation to protect against freezing, but these methods were often energy-intensive and limited in their effectiveness. As our understanding of molecular interactions and material science advanced, researchers began developing specialized antifreeze compounds tailored for the unique challenges of space environments.

One of the key milestones in this field was the development of antifreeze proteins (AFPs), inspired by organisms that naturally survive in extreme cold. These proteins, first discovered in Arctic fish, have been adapted and synthesized for use in space technology. AFPs work by binding to ice crystals as they form, preventing them from growing larger and causing damage to sensitive equipment.

The current landscape of antifreeze technology in space exploration encompasses a wide range of solutions, from advanced chemical formulations to novel materials with inherent antifreeze properties. Researchers are exploring the potential of nanomaterials and smart fluids that can dynamically respond to temperature changes, providing more efficient and adaptable protection against freezing.

As space missions become more ambitious, targeting destinations like Mars and the icy moons of Jupiter and Saturn, the importance of antifreeze technology continues to grow. The ability to operate equipment reliably in extreme cold is not just a matter of convenience but a fundamental requirement for the success and safety of these missions. Consequently, the development of next-generation antifreeze solutions has become a priority for space agencies and private aerospace companies alike, driving innovation and pushing the boundaries of materials science and chemical engineering.

The primary objective of antifreeze technology in space exploration is to prevent the formation of ice crystals in vital systems and components. In the vacuum of space, where temperatures can plummet to extreme lows, traditional fluids used in cooling systems and hydraulics are at risk of freezing, potentially leading to catastrophic failures. By implementing cutting-edge antifreeze solutions, space agencies and private companies aim to enhance the reliability and efficiency of their missions, ultimately expanding the boundaries of human exploration in the cosmos.

The evolution of antifreeze technology for space applications has been driven by a combination of scientific breakthroughs and engineering ingenuity. Early space missions relied on rudimentary heating systems and insulation to protect against freezing, but these methods were often energy-intensive and limited in their effectiveness. As our understanding of molecular interactions and material science advanced, researchers began developing specialized antifreeze compounds tailored for the unique challenges of space environments.

One of the key milestones in this field was the development of antifreeze proteins (AFPs), inspired by organisms that naturally survive in extreme cold. These proteins, first discovered in Arctic fish, have been adapted and synthesized for use in space technology. AFPs work by binding to ice crystals as they form, preventing them from growing larger and causing damage to sensitive equipment.

The current landscape of antifreeze technology in space exploration encompasses a wide range of solutions, from advanced chemical formulations to novel materials with inherent antifreeze properties. Researchers are exploring the potential of nanomaterials and smart fluids that can dynamically respond to temperature changes, providing more efficient and adaptable protection against freezing.

As space missions become more ambitious, targeting destinations like Mars and the icy moons of Jupiter and Saturn, the importance of antifreeze technology continues to grow. The ability to operate equipment reliably in extreme cold is not just a matter of convenience but a fundamental requirement for the success and safety of these missions. Consequently, the development of next-generation antifreeze solutions has become a priority for space agencies and private aerospace companies alike, driving innovation and pushing the boundaries of materials science and chemical engineering.

Space Exploration Market Analysis

The space exploration market has been experiencing significant growth in recent years, driven by technological advancements, increased private sector involvement, and renewed government interest. This market encompasses various segments, including satellite manufacturing, launch services, ground equipment, and space-based services. The global space economy was valued at approximately $447 billion in 2020, with projections indicating continued expansion in the coming years.

Antifreeze technology is emerging as a crucial factor in revolutionizing space exploration, addressing key challenges in spacecraft design and operation. The demand for advanced thermal management solutions in space applications is growing, as missions become more complex and long-duration. This technology is particularly relevant for missions to extreme environments, such as Mars or the outer solar system, where temperature fluctuations can be severe.

The market for antifreeze technologies in space exploration is closely tied to the broader space industry trends. As space agencies and private companies plan more ambitious missions, the need for robust thermal protection systems increases. This demand is driving innovation in materials science and engineering, creating new opportunities for specialized companies in the space sector.

Key market drivers include the growing number of satellite launches, plans for lunar and Mars missions, and the development of reusable spacecraft. These factors contribute to a higher demand for advanced thermal management solutions, including antifreeze technologies. The market is also influenced by international space cooperation and competition, as nations seek to establish technological leadership in space exploration.

The commercial space sector, particularly companies focused on space tourism and private space stations, represents a significant potential market for antifreeze technologies. As these ventures aim to make space more accessible, ensuring the safety and comfort of passengers and crew becomes paramount, further driving the need for advanced thermal management systems.

Geographically, the market for space exploration antifreeze technologies is concentrated in countries with established space programs, such as the United States, Russia, China, and European Union member states. However, emerging space nations are also showing increased interest in developing their capabilities, potentially expanding the market for these technologies.

Challenges in this market include high development costs, stringent regulatory requirements, and the need for extensive testing in simulated space environments. Despite these obstacles, the potential applications and benefits of antifreeze technologies in space exploration continue to attract investment and research efforts, indicating a promising future for this specialized sector within the broader space industry.

Antifreeze technology is emerging as a crucial factor in revolutionizing space exploration, addressing key challenges in spacecraft design and operation. The demand for advanced thermal management solutions in space applications is growing, as missions become more complex and long-duration. This technology is particularly relevant for missions to extreme environments, such as Mars or the outer solar system, where temperature fluctuations can be severe.

The market for antifreeze technologies in space exploration is closely tied to the broader space industry trends. As space agencies and private companies plan more ambitious missions, the need for robust thermal protection systems increases. This demand is driving innovation in materials science and engineering, creating new opportunities for specialized companies in the space sector.

Key market drivers include the growing number of satellite launches, plans for lunar and Mars missions, and the development of reusable spacecraft. These factors contribute to a higher demand for advanced thermal management solutions, including antifreeze technologies. The market is also influenced by international space cooperation and competition, as nations seek to establish technological leadership in space exploration.

The commercial space sector, particularly companies focused on space tourism and private space stations, represents a significant potential market for antifreeze technologies. As these ventures aim to make space more accessible, ensuring the safety and comfort of passengers and crew becomes paramount, further driving the need for advanced thermal management systems.

Geographically, the market for space exploration antifreeze technologies is concentrated in countries with established space programs, such as the United States, Russia, China, and European Union member states. However, emerging space nations are also showing increased interest in developing their capabilities, potentially expanding the market for these technologies.

Challenges in this market include high development costs, stringent regulatory requirements, and the need for extensive testing in simulated space environments. Despite these obstacles, the potential applications and benefits of antifreeze technologies in space exploration continue to attract investment and research efforts, indicating a promising future for this specialized sector within the broader space industry.

Current Antifreeze Tech in Space: Challenges

The current antifreeze technology in space exploration faces several significant challenges that hinder its effectiveness and widespread application. One of the primary issues is the extreme temperature fluctuations encountered in space environments. Spacecraft and equipment must withstand temperatures ranging from -270°C in deep space to over 120°C in direct sunlight, placing immense stress on antifreeze systems.

Traditional antifreeze solutions, such as ethylene glycol or propylene glycol, have limitations in their performance under these extreme conditions. They may become ineffective at very low temperatures or degrade rapidly at high temperatures, compromising their ability to protect vital systems. Additionally, the low pressure environment of space can cause these liquids to evaporate or sublimate, reducing their long-term effectiveness.

Another challenge is the weight and volume constraints of space missions. Every gram of payload is crucial, and bulky antifreeze systems can significantly impact mission parameters. This necessitates the development of more compact and lightweight antifreeze solutions that can provide adequate protection without adding excessive mass to the spacecraft.

The potential for contamination is also a major concern. In the event of a leak, traditional antifreeze chemicals could interfere with sensitive scientific instruments or compromise the integrity of extraterrestrial samples. This risk is particularly significant for missions focused on the search for extraterrestrial life or the study of planetary environments.

Radiation exposure in space presents another hurdle for antifreeze technology. High-energy particles can degrade antifreeze compounds over time, reducing their effectiveness and potentially creating harmful byproducts. Developing radiation-resistant antifreeze solutions is crucial for long-duration space missions, especially those venturing beyond Earth's protective magnetosphere.

The need for multi-functional antifreeze systems adds complexity to their development. Ideally, these systems should not only prevent freezing but also offer thermal management capabilities, act as a radiation shield, and potentially serve as a power source through thermoelectric conversion. Balancing these diverse requirements while maintaining reliability and efficiency is a significant engineering challenge.

Lastly, the long-term stability and reliability of antifreeze systems in space remain a concern. Space missions can last for years or even decades, and antifreeze solutions must maintain their properties throughout this extended period without maintenance or replacement. Ensuring this level of durability under the harsh conditions of space is a formidable task that requires ongoing research and innovation in materials science and engineering.

Traditional antifreeze solutions, such as ethylene glycol or propylene glycol, have limitations in their performance under these extreme conditions. They may become ineffective at very low temperatures or degrade rapidly at high temperatures, compromising their ability to protect vital systems. Additionally, the low pressure environment of space can cause these liquids to evaporate or sublimate, reducing their long-term effectiveness.

Another challenge is the weight and volume constraints of space missions. Every gram of payload is crucial, and bulky antifreeze systems can significantly impact mission parameters. This necessitates the development of more compact and lightweight antifreeze solutions that can provide adequate protection without adding excessive mass to the spacecraft.

The potential for contamination is also a major concern. In the event of a leak, traditional antifreeze chemicals could interfere with sensitive scientific instruments or compromise the integrity of extraterrestrial samples. This risk is particularly significant for missions focused on the search for extraterrestrial life or the study of planetary environments.

Radiation exposure in space presents another hurdle for antifreeze technology. High-energy particles can degrade antifreeze compounds over time, reducing their effectiveness and potentially creating harmful byproducts. Developing radiation-resistant antifreeze solutions is crucial for long-duration space missions, especially those venturing beyond Earth's protective magnetosphere.

The need for multi-functional antifreeze systems adds complexity to their development. Ideally, these systems should not only prevent freezing but also offer thermal management capabilities, act as a radiation shield, and potentially serve as a power source through thermoelectric conversion. Balancing these diverse requirements while maintaining reliability and efficiency is a significant engineering challenge.

Lastly, the long-term stability and reliability of antifreeze systems in space remain a concern. Space missions can last for years or even decades, and antifreeze solutions must maintain their properties throughout this extended period without maintenance or replacement. Ensuring this level of durability under the harsh conditions of space is a formidable task that requires ongoing research and innovation in materials science and engineering.

Existing Antifreeze Solutions for Space

01 Antifreeze compositions and additives

Development of novel antifreeze compositions and additives to improve freezing point depression and heat transfer properties. These may include organic compounds, inorganic salts, or combinations thereof, designed to enhance the overall performance of antifreeze solutions in various applications.- Antifreeze compositions and additives: Development of novel antifreeze compositions and additives to improve freezing point depression and heat transfer properties. These may include organic compounds, inorganic salts, or combinations thereof, designed to enhance the performance of antifreeze solutions in various applications.

- Antifreeze recycling and purification methods: Techniques for recycling and purifying used antifreeze solutions to extend their lifespan and reduce environmental impact. This includes filtration systems, chemical treatments, and distillation processes to remove contaminants and restore antifreeze properties.

- Antifreeze systems for specific applications: Specialized antifreeze technologies tailored for specific industries or applications, such as automotive, aerospace, or renewable energy systems. These solutions address unique challenges and requirements of different operating environments.

- Smart antifreeze monitoring and control systems: Integration of sensors and control systems to monitor antifreeze performance, detect leaks, and automatically adjust antifreeze concentrations. These technologies enhance efficiency and safety in various cooling and heating applications.

- Environmentally friendly antifreeze solutions: Development of biodegradable and non-toxic antifreeze formulations to reduce environmental impact. These solutions may utilize plant-based ingredients or other eco-friendly compounds as alternatives to traditional ethylene glycol-based antifreeze.

02 Antifreeze recycling and purification methods

Techniques for recycling and purifying used antifreeze solutions to extend their lifespan and reduce environmental impact. This includes filtration systems, chemical treatments, and distillation processes to remove contaminants and restore the antifreeze to its original effectiveness.Expand Specific Solutions03 Antifreeze systems for specific applications

Specialized antifreeze technologies tailored for specific industries or applications, such as automotive, aerospace, or renewable energy systems. These solutions address unique challenges and requirements of different operating environments and equipment types.Expand Specific Solutions04 Smart antifreeze monitoring and control systems

Integration of sensors and control systems to monitor antifreeze performance, detect leaks, and automatically adjust concentration levels. These technologies aim to optimize antifreeze efficiency and prevent system failures in real-time.Expand Specific Solutions05 Environmentally friendly antifreeze alternatives

Research and development of eco-friendly antifreeze solutions using biodegradable materials or renewable resources. These alternatives aim to reduce the environmental impact of traditional antifreeze chemicals while maintaining or improving performance characteristics.Expand Specific Solutions

Key Players in Space Antifreeze Industry

The antifreeze technology market in space exploration is in its early growth stage, with increasing demand driven by the expanding space industry. While the market size is relatively small, it's projected to grow significantly as space missions become more frequent and complex. The technology's maturity varies across applications, with some areas more advanced than others. Key players like NASA, Boeing, and China Academy of Space Technology are leading research and development efforts, while companies such as Mitsubishi Heavy Industries and Airbus Defence & Space are contributing to technological advancements. Universities and research institutes, including the University of Florida and Beijing Institute of Technology, are also playing crucial roles in pushing the boundaries of antifreeze technology for space applications.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries (MHI) has been innovating in the field of antifreeze technology for space exploration, with a focus on advanced thermal management systems for satellites and spacecraft. Their approach includes the development of highly efficient loop heat pipes using proprietary working fluids that remain operational at extremely low temperatures. These systems provide reliable heat transfer in microgravity environments, crucial for maintaining optimal temperatures in sensitive electronic components[11]. MHI has also made progress in developing smart radiator systems that can adapt their heat rejection capabilities based on the varying thermal loads and environmental conditions encountered during space missions. These systems utilize advanced antifreeze solutions in combination with shape-memory alloys to create dynamically adjustable radiator surfaces[12].

Strengths: Strong expertise in thermal engineering and spacecraft systems, proven track record in international space projects. Weaknesses: May face challenges in scaling technologies for larger space exploration vehicles beyond satellite applications.

The Boeing Co.

Technical Solution: Boeing has been at the forefront of developing antifreeze technologies for space exploration, particularly focusing on thermal management systems for spacecraft. Their approach involves using advanced phase-change materials (PCMs) that can absorb or release large amounts of energy during melting or freezing processes. These PCMs are integrated into the spacecraft's structure to provide passive thermal control, reducing the need for active heating or cooling systems[4]. Boeing has also developed innovative heat pipe technologies that use specialized antifreeze solutions to efficiently transfer heat across spacecraft components, ensuring optimal temperature regulation in the harsh space environment[5].

Strengths: Extensive experience in aerospace engineering and spacecraft design, strong integration capabilities for complex systems. Weaknesses: Primarily focused on large-scale spacecraft, may have limitations in adapting technologies for smaller, more agile space vehicles.

Innovative Antifreeze Patents for Space

Apparatus for supercooling and the method for defrosting an electrode of the same

PatentWO2008004770A1

Innovation

- An apparatus with a defrosting device for electrodes within a cooling chamber, which prevents frost from disrupting the electric field and maintains a stable non-freezing state by controlling the electrode's frost through a sensor and control unit, ensuring efficient cooling and extended storage without freezing.

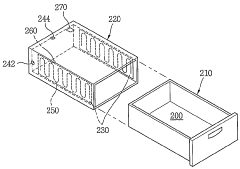

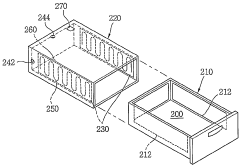

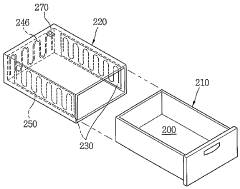

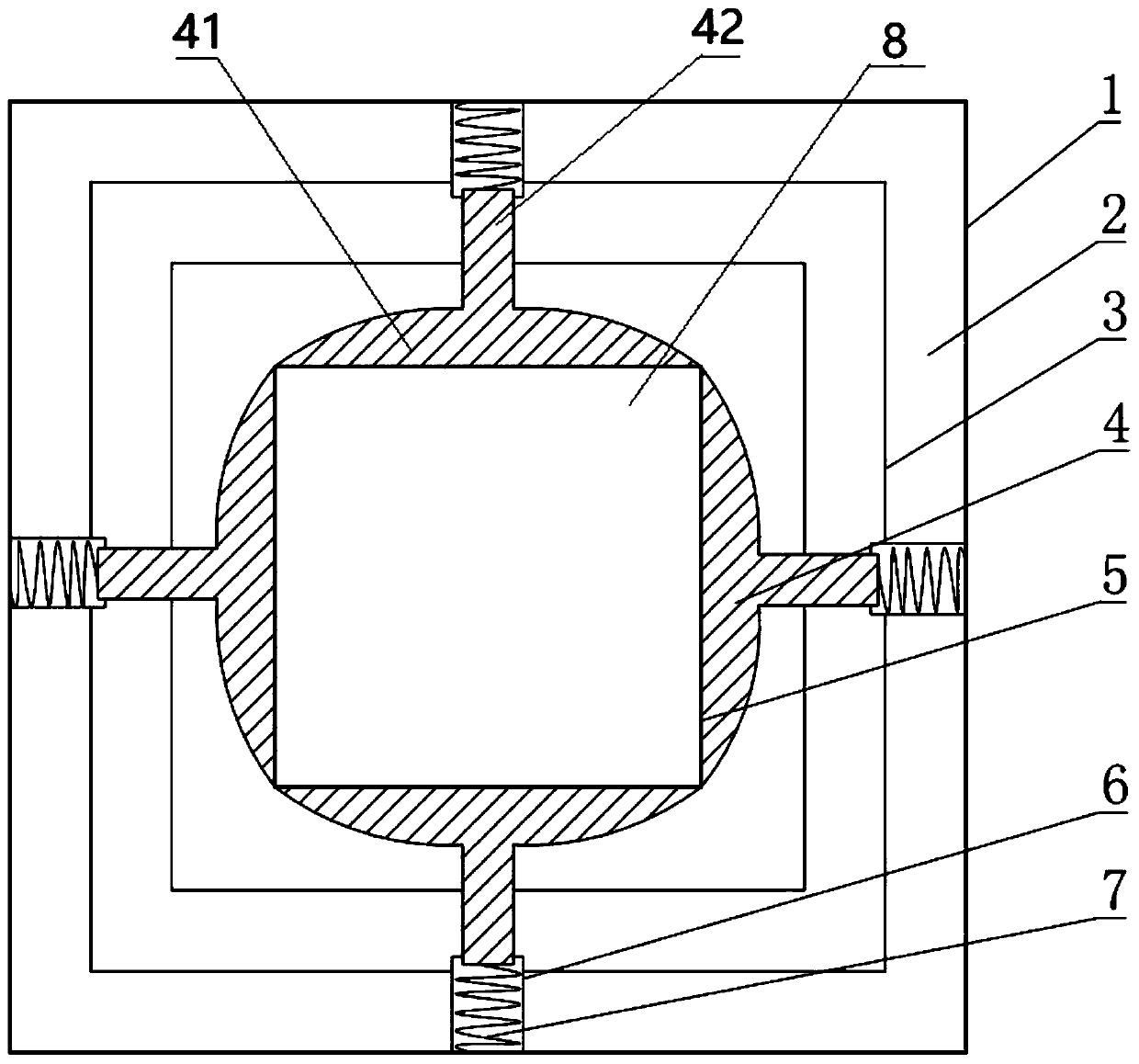

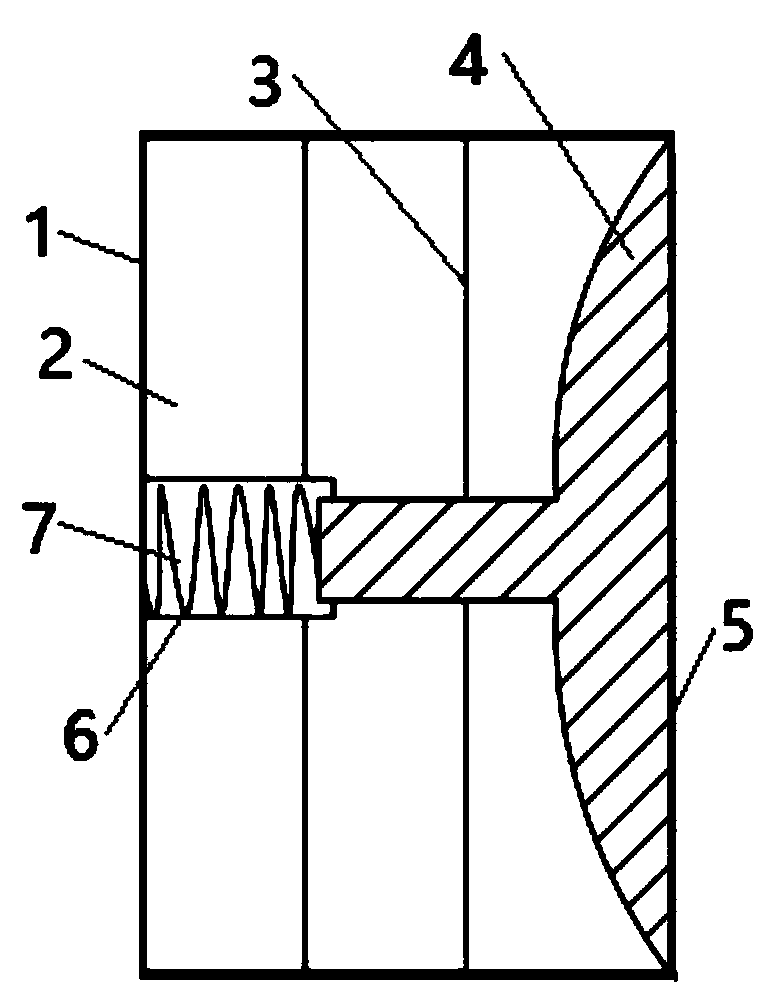

High-efficiency heat-insulation storage device and structure for space station

PatentActiveCN109578753A

Innovation

- A high-efficiency thermal insulation storage device is designed, which uses trumpet-shaped supports and low thermal conductivity gas-filled closed spaces, combined with multi-layer vacuum insulation layers and protective layers, which reduces solid and gas thermal conductivity, improves thermal insulation efficiency, and uses springs and The mount optimizes structural heat transfer paths, reducing weight and thickness requirements.

Material Science Advancements for Space

The advancements in material science have been pivotal in revolutionizing space exploration, particularly in the realm of antifreeze technology. These innovations have addressed critical challenges faced by spacecraft and equipment in the harsh conditions of outer space.

One of the most significant breakthroughs has been the development of novel antifreeze compounds that can withstand extreme temperature fluctuations. These materials are designed to prevent the formation of ice crystals in vital systems, ensuring the continued functionality of spacecraft components in sub-zero environments.

Researchers have made substantial progress in creating lightweight, yet highly durable materials that incorporate antifreeze properties. These advanced composites offer superior thermal protection while minimizing the overall mass of spacecraft, a crucial factor in reducing launch costs and improving mission efficiency.

Nanotechnology has played a crucial role in enhancing antifreeze capabilities. Scientists have engineered nanoparticles that can be integrated into various materials, providing them with self-healing properties and improved resistance to thermal stress. This innovation has significantly extended the lifespan of space equipment exposed to extreme temperature variations.

The development of smart materials with adaptive antifreeze properties has been another groundbreaking achievement. These materials can dynamically adjust their thermal characteristics in response to changing environmental conditions, offering unprecedented levels of protection for sensitive instruments and electronics aboard spacecraft.

Advancements in polymer science have led to the creation of antifreeze coatings that can be applied to external surfaces of spacecraft. These coatings not only prevent ice formation but also offer protection against space debris and radiation, thereby enhancing the overall durability of space vehicles.

The integration of antifreeze technology with energy storage systems has resulted in more efficient and reliable power sources for space missions. This has enabled the development of batteries and fuel cells that can operate effectively in extreme cold, extending the operational range of spacecraft and rovers in deep space exploration.

Material scientists have also made significant strides in developing antifreeze solutions for life support systems. These innovations are crucial for long-duration space missions and potential human colonization of other planets, as they ensure the stability of water and other essential resources in freezing conditions.

One of the most significant breakthroughs has been the development of novel antifreeze compounds that can withstand extreme temperature fluctuations. These materials are designed to prevent the formation of ice crystals in vital systems, ensuring the continued functionality of spacecraft components in sub-zero environments.

Researchers have made substantial progress in creating lightweight, yet highly durable materials that incorporate antifreeze properties. These advanced composites offer superior thermal protection while minimizing the overall mass of spacecraft, a crucial factor in reducing launch costs and improving mission efficiency.

Nanotechnology has played a crucial role in enhancing antifreeze capabilities. Scientists have engineered nanoparticles that can be integrated into various materials, providing them with self-healing properties and improved resistance to thermal stress. This innovation has significantly extended the lifespan of space equipment exposed to extreme temperature variations.

The development of smart materials with adaptive antifreeze properties has been another groundbreaking achievement. These materials can dynamically adjust their thermal characteristics in response to changing environmental conditions, offering unprecedented levels of protection for sensitive instruments and electronics aboard spacecraft.

Advancements in polymer science have led to the creation of antifreeze coatings that can be applied to external surfaces of spacecraft. These coatings not only prevent ice formation but also offer protection against space debris and radiation, thereby enhancing the overall durability of space vehicles.

The integration of antifreeze technology with energy storage systems has resulted in more efficient and reliable power sources for space missions. This has enabled the development of batteries and fuel cells that can operate effectively in extreme cold, extending the operational range of spacecraft and rovers in deep space exploration.

Material scientists have also made significant strides in developing antifreeze solutions for life support systems. These innovations are crucial for long-duration space missions and potential human colonization of other planets, as they ensure the stability of water and other essential resources in freezing conditions.

Environmental Impact of Space Antifreeze

The environmental impact of space antifreeze technology is a critical consideration in the ongoing revolution of space exploration. As spacecraft venture further into the cosmos, the need for effective antifreeze solutions becomes paramount, but this advancement comes with potential ecological consequences that must be carefully evaluated.

One of the primary environmental concerns associated with space antifreeze is the potential for contamination of extraterrestrial environments. As missions to Mars and other celestial bodies become more frequent, the risk of introducing foreign substances to these pristine environments increases. Antifreeze compounds, if not properly contained or disposed of, could alter the chemical composition of alien soils or atmospheres, potentially interfering with scientific studies or even harming any existing microbial life.

The production and disposal of space antifreeze materials on Earth also pose environmental challenges. Many antifreeze compounds are derived from petrochemicals, contributing to carbon emissions and resource depletion. The manufacturing process may involve hazardous chemicals and generate toxic waste, necessitating stringent environmental controls and disposal protocols.

However, advancements in green chemistry are paving the way for more environmentally friendly antifreeze solutions. Researchers are exploring bio-based alternatives and recyclable compounds that could significantly reduce the ecological footprint of space antifreeze technology. These innovations not only address environmental concerns but also align with the growing emphasis on sustainable space exploration practices.

The use of antifreeze technology in space also has potential positive environmental implications. By enabling longer-duration missions and more efficient spacecraft operations, it could lead to a reduction in the number of launches required, thereby decreasing the overall carbon footprint of space programs. Additionally, the development of advanced antifreeze solutions may yield spin-off technologies applicable to terrestrial environmental challenges, such as improved cold-weather energy storage or more efficient cooling systems for data centers.

Space agencies and private companies are increasingly incorporating environmental impact assessments into their mission planning processes. This includes evaluating the lifecycle of antifreeze materials from production to disposal, as well as considering potential mitigation strategies for any adverse effects on extraterrestrial environments. International cooperation and standardization efforts are underway to establish best practices for the use of antifreeze technology in space, with a focus on minimizing ecological risks while maximizing scientific and exploratory benefits.

As space exploration continues to push boundaries, the balance between technological advancement and environmental stewardship becomes increasingly crucial. The ongoing development of space antifreeze technology serves as a microcosm of this broader challenge, highlighting the need for innovative solutions that can propel humanity's cosmic ambitions while safeguarding the environments of both Earth and the celestial bodies we seek to explore.

One of the primary environmental concerns associated with space antifreeze is the potential for contamination of extraterrestrial environments. As missions to Mars and other celestial bodies become more frequent, the risk of introducing foreign substances to these pristine environments increases. Antifreeze compounds, if not properly contained or disposed of, could alter the chemical composition of alien soils or atmospheres, potentially interfering with scientific studies or even harming any existing microbial life.

The production and disposal of space antifreeze materials on Earth also pose environmental challenges. Many antifreeze compounds are derived from petrochemicals, contributing to carbon emissions and resource depletion. The manufacturing process may involve hazardous chemicals and generate toxic waste, necessitating stringent environmental controls and disposal protocols.

However, advancements in green chemistry are paving the way for more environmentally friendly antifreeze solutions. Researchers are exploring bio-based alternatives and recyclable compounds that could significantly reduce the ecological footprint of space antifreeze technology. These innovations not only address environmental concerns but also align with the growing emphasis on sustainable space exploration practices.

The use of antifreeze technology in space also has potential positive environmental implications. By enabling longer-duration missions and more efficient spacecraft operations, it could lead to a reduction in the number of launches required, thereby decreasing the overall carbon footprint of space programs. Additionally, the development of advanced antifreeze solutions may yield spin-off technologies applicable to terrestrial environmental challenges, such as improved cold-weather energy storage or more efficient cooling systems for data centers.

Space agencies and private companies are increasingly incorporating environmental impact assessments into their mission planning processes. This includes evaluating the lifecycle of antifreeze materials from production to disposal, as well as considering potential mitigation strategies for any adverse effects on extraterrestrial environments. International cooperation and standardization efforts are underway to establish best practices for the use of antifreeze technology in space, with a focus on minimizing ecological risks while maximizing scientific and exploratory benefits.

As space exploration continues to push boundaries, the balance between technological advancement and environmental stewardship becomes increasingly crucial. The ongoing development of space antifreeze technology serves as a microcosm of this broader challenge, highlighting the need for innovative solutions that can propel humanity's cosmic ambitions while safeguarding the environments of both Earth and the celestial bodies we seek to explore.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!