How Antifreeze Implements Advanced Structural Technology Assets?

Antifreeze Tech Evolution

The evolution of antifreeze technology has been marked by significant advancements in structural technology assets over the past decades. Initially, antifreeze solutions were simple mixtures of water and ethylene glycol, primarily focused on lowering the freezing point of liquids in automotive cooling systems.

As environmental concerns grew, propylene glycol emerged as a less toxic alternative, sparking a shift towards more eco-friendly formulations. This transition marked the beginning of a new era in antifreeze technology, where performance and environmental impact became equally important considerations.

The late 20th century saw the introduction of organic acid technology (OAT) antifreeze. This innovation represented a major leap forward, offering extended service life and improved corrosion protection. OAT formulations utilized advanced carboxylic acid-based inhibitors, which formed a thin, protective layer on metal surfaces, significantly reducing corrosion and scaling.

In the early 2000s, hybrid organic acid technology (HOAT) antifreeze emerged, combining the benefits of OAT with traditional inhibitors. This hybrid approach provided enhanced protection for aluminum components, addressing the growing use of lightweight materials in automotive design.

Recent years have witnessed the development of nanomaterial-enhanced antifreeze solutions. These cutting-edge formulations incorporate nanoparticles, such as graphene or carbon nanotubes, to improve thermal conductivity and enhance heat transfer efficiency. This nanotechnology integration represents a significant structural advancement, allowing for better performance in extreme temperature conditions.

The latest frontier in antifreeze technology involves smart materials and self-healing additives. These innovative components can detect and respond to changes in temperature or pH levels, automatically adjusting the antifreeze properties as needed. Self-healing additives can repair minor damage to the protective layers formed by the antifreeze, extending the lifespan of the solution and the protected systems.

Furthermore, the integration of IoT sensors and data analytics has enabled real-time monitoring of antifreeze performance. This technological leap allows for predictive maintenance and optimization of antifreeze solutions in various applications, from automotive to industrial cooling systems.

As environmental regulations continue to tighten, the focus has shifted towards developing biodegradable and renewable antifreeze solutions. Research into bio-based glycols and natural corrosion inhibitors is paving the way for more sustainable antifreeze technologies, aligning with global efforts to reduce environmental impact.

Market Demand Analysis

The market demand for advanced antifreeze technologies implementing structural assets has been steadily growing in recent years. This growth is primarily driven by the increasing need for more efficient and environmentally friendly cooling solutions across various industries. The automotive sector, in particular, has shown a significant interest in these technologies as vehicle manufacturers strive to improve engine performance and fuel efficiency while reducing environmental impact.

In the automotive industry, the global antifreeze market is projected to expand at a compound annual growth rate (CAGR) of around 6% over the next five years. This growth is attributed to the rising production of vehicles worldwide and the increasing adoption of electric and hybrid vehicles, which require specialized cooling systems. The demand for advanced antifreeze solutions is also being fueled by the trend towards more compact and powerful engines, which generate higher temperatures and require more effective cooling mechanisms.

The construction industry is another key driver of market demand for advanced antifreeze technologies. As urbanization continues to accelerate globally, there is a growing need for concrete that can withstand extreme temperatures and freeze-thaw cycles. This has led to increased interest in antifreeze admixtures that can enhance the durability and performance of concrete structures in cold climates.

In the renewable energy sector, the demand for antifreeze solutions is rising due to the expansion of solar thermal and geothermal energy systems. These technologies often require efficient heat transfer fluids that can operate in a wide range of temperatures, including sub-zero conditions. The market for such specialized antifreeze products is expected to grow as renewable energy adoption increases worldwide.

The aerospace industry is also contributing to the demand for advanced antifreeze technologies. With the development of more fuel-efficient aircraft and the exploration of electric propulsion systems, there is a need for innovative cooling solutions that can handle the unique challenges of aviation environments. This includes antifreeze formulations that can maintain their effectiveness at high altitudes and extreme temperatures.

Furthermore, the growing focus on sustainability and environmental regulations is shaping the market demand for eco-friendly antifreeze solutions. There is an increasing preference for propylene glycol-based antifreeze over traditional ethylene glycol formulations due to its lower toxicity and biodegradability. This shift is driving research and development efforts to create more sustainable antifreeze products that incorporate advanced structural technology assets.

As industries continue to evolve and face new challenges related to temperature management and material performance, the demand for innovative antifreeze solutions is expected to grow. This presents significant opportunities for companies investing in research and development of advanced structural technology assets in antifreeze formulations, as they can potentially capture a larger share of this expanding market.

Current Challenges

The implementation of advanced structural technology assets in antifreeze solutions faces several significant challenges in the current landscape. One of the primary obstacles is the complexity of developing materials that can maintain their structural integrity across a wide range of temperatures. Antifreeze solutions must not only prevent freezing but also preserve the mechanical properties of the structures they protect, which requires a delicate balance of chemical composition and material science.

Another challenge lies in the scalability of advanced antifreeze technologies. While laboratory-scale experiments may yield promising results, translating these innovations into large-scale industrial applications presents considerable difficulties. Issues such as cost-effectiveness, production efficiency, and compatibility with existing infrastructure must be addressed to ensure widespread adoption.

Environmental concerns also pose a significant challenge to the implementation of advanced antifreeze technologies. Traditional antifreeze solutions often contain toxic components that can harm ecosystems if leaked or improperly disposed of. Developing eco-friendly alternatives that maintain high performance standards is a critical area of focus for researchers and engineers in this field.

The durability and longevity of antifreeze-treated structures present another hurdle. Advanced structural technology assets must withstand repeated freeze-thaw cycles without degradation, which puts immense stress on materials. Ensuring long-term effectiveness without frequent reapplication or maintenance is crucial for practical implementation, especially in harsh environments or remote locations.

Regulatory compliance and safety standards add another layer of complexity to the development and deployment of advanced antifreeze technologies. Stringent testing and certification processes are necessary to ensure that new solutions meet or exceed existing safety requirements, which can slow down innovation and market entry.

Furthermore, the integration of smart technologies and sensors into antifreeze systems presents both opportunities and challenges. While these advancements can provide real-time monitoring and adaptive responses to changing environmental conditions, they also introduce new vulnerabilities, such as cybersecurity risks and the need for specialized maintenance.

Lastly, the diverse range of applications for antifreeze technologies, from aerospace to civil engineering, requires tailored solutions for each sector. Developing versatile yet specialized antifreeze implementations that can address the unique demands of different industries remains a significant challenge in the field.

Existing Solutions

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and chemical compounds such as ethylene glycol or propylene glycol. These solutions are designed to lower the freezing point of water and prevent engine damage in cold temperatures. Additives may be included to enhance corrosion protection and improve heat transfer properties.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and chemical compounds such as ethylene glycol or propylene glycol. These solutions lower the freezing point of water and raise its boiling point, making them effective in preventing freezing and overheating in various applications, particularly in automotive cooling systems.

- Additives for enhanced antifreeze performance: Various additives are incorporated into antifreeze formulations to improve their performance. These may include corrosion inhibitors, anti-foaming agents, and lubricants. Such additives help protect metal components, prevent foam formation, and enhance the overall efficiency of the antifreeze solution in different operating conditions.

- Environmentally friendly antifreeze alternatives: Research and development efforts are focused on creating more environmentally friendly antifreeze solutions. These alternatives aim to reduce toxicity and improve biodegradability while maintaining effective freeze protection. Some approaches include using plant-based glycols or developing new synthetic compounds with lower environmental impact.

- Antifreeze recycling and purification methods: Techniques for recycling and purifying used antifreeze have been developed to reduce waste and environmental impact. These methods often involve filtration, distillation, or chemical treatment processes to remove contaminants and restore the antifreeze to a usable condition. Recycling antifreeze helps conserve resources and minimize disposal issues.

- Specialized antifreeze for specific applications: Antifreeze solutions are tailored for specific applications beyond automotive use. These may include formulations for industrial processes, HVAC systems, or even cryogenic applications. Specialized antifreeze solutions are designed to meet the unique requirements of different operating environments and temperature ranges.

02 Environmentally friendly antifreeze formulations

Development of eco-friendly antifreeze solutions using biodegradable materials and less toxic compounds. These formulations aim to reduce environmental impact while maintaining effective freeze protection and heat transfer capabilities. Some approaches include using plant-based glycols or incorporating natural corrosion inhibitors.Expand Specific Solutions03 Antifreeze recycling and purification methods

Techniques for recycling and purifying used antifreeze to reduce waste and environmental impact. These methods may involve filtration, distillation, or chemical treatment to remove contaminants and restore the antifreeze to its original effectiveness. Recycling processes can help conserve resources and reduce the need for new antifreeze production.Expand Specific Solutions04 Antifreeze applications in renewable energy systems

Use of antifreeze solutions in renewable energy systems such as solar thermal collectors and geothermal heat pumps. These applications require specialized antifreeze formulations that can withstand high temperatures and provide long-term stability. The antifreeze helps prevent freezing and improves heat transfer efficiency in these systems.Expand Specific Solutions05 Antifreeze testing and quality control methods

Development of testing procedures and quality control measures for antifreeze solutions. These methods may include assessing freeze point depression, corrosion protection, and thermal stability. Advanced techniques such as spectroscopic analysis or electrochemical testing can be used to ensure the effectiveness and safety of antifreeze products.Expand Specific Solutions

Key Industry Players

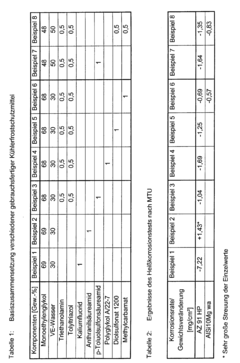

The antifreeze technology market is in a mature stage, with established players and steady growth. The global antifreeze market size is projected to reach around $6 billion by 2025, driven by increasing automotive production and industrial applications. Major companies like BASF, Clariant, and Chevron dominate the market with advanced formulations. Technological innovations focus on improving performance, environmental sustainability, and compatibility with new materials in electric vehicles. Emerging players like Arteco and Kukdong Jeyen are introducing novel solutions, while research institutions like Sichuan University contribute to advancing the field through collaborative R&D efforts.

BASF Corp.

Clariant Produkte (Deutschland) GmbH

Core Innovations

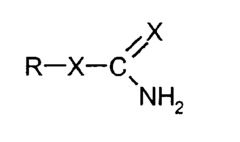

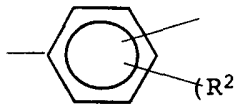

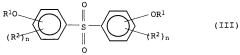

- An antifreeze concentrate containing sulfonated or sulfated polyglycols, carbamates, triazoles, amines, and other additives, which form a corrosion-inhibiting aqueous solution that protects magnesium and aluminum metals by maintaining a stable pH and preventing metal hydroxide formation, thereby enhancing corrosion inhibition and heat dissipation.

- Development of antifreeze concentrates containing a mono- or polynuclear aromatic compound with high buffering capacity as a reserve alkalinity donor, combined with alkylene glycols and corrosion inhibitors like triazoles and carboxylic acids, to enhance corrosion resistance without using silicates or borates.

Environmental Impact

The environmental impact of antifreeze implementation in advanced structural technology assets is a critical consideration in the development and deployment of these systems. Antifreeze compounds, primarily composed of ethylene glycol or propylene glycol, are essential for maintaining the operational integrity of various structures in cold environments. However, their use raises significant environmental concerns that must be addressed.

One of the primary environmental risks associated with antifreeze is its potential for soil and water contamination. When leaked or improperly disposed of, these chemicals can seep into groundwater systems, affecting both aquatic ecosystems and drinking water sources. The toxicity of ethylene glycol, in particular, poses a threat to wildlife and can lead to long-term ecological damage if not properly managed.

To mitigate these risks, advanced structural technology assets incorporating antifreeze systems often employ sophisticated containment and monitoring mechanisms. These include double-walled storage tanks, leak detection systems, and automated shut-off valves to prevent large-scale spills. Additionally, the development of biodegradable antifreeze formulations has gained traction in recent years, offering a more environmentally friendly alternative to traditional compounds.

The manufacturing process of antifreeze also contributes to its environmental footprint. The production of ethylene glycol and propylene glycol involves energy-intensive processes and the use of petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. As a result, there is a growing emphasis on developing more sustainable production methods and exploring bio-based alternatives derived from renewable resources.

In the context of advanced structural technology assets, the environmental impact of antifreeze extends beyond its chemical properties. The integration of antifreeze systems often requires additional energy consumption for pumping and circulation, potentially increasing the overall carbon footprint of the structure. To address this, engineers are focusing on optimizing system designs to maximize energy efficiency and exploring the use of renewable energy sources to power these systems.

The disposal of antifreeze at the end of its lifecycle presents another environmental challenge. Improper disposal can lead to soil and water pollution, as well as contribute to the accumulation of hazardous waste in landfills. To combat this, many jurisdictions have implemented strict regulations on antifreeze disposal, mandating recycling programs and specialized treatment facilities. Advanced structural technology assets are increasingly designed with end-of-life considerations in mind, incorporating features that facilitate the safe removal and recycling of antifreeze components.

Regulatory Compliance

The implementation of advanced structural technology assets in antifreeze products is subject to a complex web of regulatory requirements. These regulations are designed to ensure the safety, efficacy, and environmental compatibility of antifreeze formulations. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the production and use of antifreeze, particularly concerning its potential environmental impact.

One of the primary regulatory concerns is the proper disposal of antifreeze. Many jurisdictions classify used antifreeze as hazardous waste due to its potential toxicity and environmental persistence. Manufacturers must adhere to strict guidelines for labeling, handling, and disposal instructions to ensure end-users can safely manage the product throughout its lifecycle.

The incorporation of advanced structural technology assets in antifreeze must also comply with the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances, which may include novel additives or structural modifications to existing antifreeze formulations. The EPA reviews these notices to assess potential risks to human health and the environment.

Furthermore, the Clean Air Act and Clean Water Act have implications for antifreeze production and use. Manufacturers must ensure that their products do not contribute to air or water pollution, either during production or when in use. This often necessitates the development of low-volatility formulations and biodegradable components.

In the automotive sector, antifreeze must meet the standards set by the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE). These standards define the performance criteria for engine coolants, including corrosion protection, freeze point depression, and heat transfer efficiency. Any advanced structural technology incorporated into antifreeze must not compromise these essential properties.

Internationally, regulations such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) impose additional requirements on antifreeze manufacturers. REACH mandates extensive testing and documentation for chemical substances, including those used in antifreeze formulations. Compliance with REACH is essential for companies looking to market their products in the EU.

As environmental concerns grow, there is an increasing regulatory push towards more sustainable antifreeze solutions. This includes requirements for higher recycling rates, reduced toxicity, and improved biodegradability. Manufacturers implementing advanced structural technology assets must anticipate and adapt to these evolving regulatory trends to ensure long-term compliance and market viability.