Antifreeze's Role in Climate Control Technologies

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution

Antifreeze has played a pivotal role in the evolution of climate control technologies, marking significant milestones in the development of efficient heating and cooling systems. The journey of antifreeze in this domain began in the early 20th century, primarily as a solution to prevent engine freezing in automobiles. However, its application quickly expanded to various climate control systems, revolutionizing both residential and industrial temperature management.

In the 1930s, ethylene glycol emerged as the predominant antifreeze compound, replacing earlier, less effective solutions. This breakthrough allowed for more reliable operation of heating systems in colder climates, extending the functionality of climate control technologies to previously challenging environments. The 1950s saw the introduction of propylene glycol, a less toxic alternative, which broadened the application of antifreeze in climate control systems where safety was a primary concern.

The 1970s marked a significant shift in antifreeze technology with the development of more sophisticated heat transfer fluids. These advanced formulations not only prevented freezing but also enhanced heat transfer efficiency, leading to more effective and energy-efficient climate control systems. This period also saw the integration of corrosion inhibitors into antifreeze solutions, addressing the long-standing issue of system degradation and extending the lifespan of climate control equipment.

The late 20th century witnessed the advent of environmentally friendly antifreeze solutions, responding to growing ecological concerns. These new formulations reduced the environmental impact of climate control systems while maintaining or even improving their performance. Simultaneously, the development of nano-engineered antifreeze particles in the early 2000s represented a quantum leap in heat transfer efficiency, enabling the creation of more compact and powerful climate control units.

Recent years have seen a focus on smart antifreeze solutions that can adapt to changing environmental conditions. These intelligent fluids can alter their properties based on temperature fluctuations, optimizing system performance across a wide range of operating conditions. Additionally, the integration of antifreeze technologies with renewable energy systems has opened new frontiers in sustainable climate control, allowing for more efficient heat storage and transfer in solar thermal and geothermal applications.

Looking ahead, the evolution of antifreeze in climate control technologies is poised to continue its trajectory of innovation. Research into bio-based antifreeze compounds promises to further reduce environmental impact, while advancements in material science may lead to antifreeze solutions with unprecedented thermal properties. As climate change presents new challenges, the role of antifreeze in adapting and optimizing climate control technologies remains more critical than ever, driving ongoing research and development in this field.

In the 1930s, ethylene glycol emerged as the predominant antifreeze compound, replacing earlier, less effective solutions. This breakthrough allowed for more reliable operation of heating systems in colder climates, extending the functionality of climate control technologies to previously challenging environments. The 1950s saw the introduction of propylene glycol, a less toxic alternative, which broadened the application of antifreeze in climate control systems where safety was a primary concern.

The 1970s marked a significant shift in antifreeze technology with the development of more sophisticated heat transfer fluids. These advanced formulations not only prevented freezing but also enhanced heat transfer efficiency, leading to more effective and energy-efficient climate control systems. This period also saw the integration of corrosion inhibitors into antifreeze solutions, addressing the long-standing issue of system degradation and extending the lifespan of climate control equipment.

The late 20th century witnessed the advent of environmentally friendly antifreeze solutions, responding to growing ecological concerns. These new formulations reduced the environmental impact of climate control systems while maintaining or even improving their performance. Simultaneously, the development of nano-engineered antifreeze particles in the early 2000s represented a quantum leap in heat transfer efficiency, enabling the creation of more compact and powerful climate control units.

Recent years have seen a focus on smart antifreeze solutions that can adapt to changing environmental conditions. These intelligent fluids can alter their properties based on temperature fluctuations, optimizing system performance across a wide range of operating conditions. Additionally, the integration of antifreeze technologies with renewable energy systems has opened new frontiers in sustainable climate control, allowing for more efficient heat storage and transfer in solar thermal and geothermal applications.

Looking ahead, the evolution of antifreeze in climate control technologies is poised to continue its trajectory of innovation. Research into bio-based antifreeze compounds promises to further reduce environmental impact, while advancements in material science may lead to antifreeze solutions with unprecedented thermal properties. As climate change presents new challenges, the role of antifreeze in adapting and optimizing climate control technologies remains more critical than ever, driving ongoing research and development in this field.

Market Demand Analysis

The market demand for antifreeze in climate control technologies has been steadily increasing due to the growing need for efficient heating, ventilation, and air conditioning (HVAC) systems across various sectors. As global temperatures continue to fluctuate and extreme weather events become more frequent, the importance of reliable climate control solutions has become paramount.

In the automotive industry, antifreeze plays a crucial role in maintaining optimal engine performance and preventing damage from freezing or overheating. With the rise of electric vehicles (EVs), the demand for specialized antifreeze formulations has surged. These new formulations are designed to meet the unique cooling requirements of EV batteries and power electronics, ensuring their longevity and efficiency.

The construction sector has also witnessed a significant uptick in demand for antifreeze-based climate control solutions. Modern buildings require sophisticated HVAC systems to maintain comfortable indoor temperatures year-round. Antifreeze compounds are essential in these systems, particularly in regions experiencing harsh winters or extreme temperature variations.

Industrial applications represent another substantial market for antifreeze in climate control technologies. Manufacturing processes, data centers, and cold storage facilities all rely on precise temperature regulation. The use of antifreeze in these settings ensures uninterrupted operations and protects valuable equipment from temperature-related damage.

The renewable energy sector has emerged as a new frontier for antifreeze applications in climate control. Solar thermal systems and geothermal heat pumps utilize antifreeze solutions to transfer heat efficiently, even in sub-zero temperatures. As the adoption of these renewable technologies accelerates, so does the demand for specialized antifreeze products.

Market analysts project robust growth in the antifreeze sector, driven by technological advancements and increasing awareness of energy efficiency. The development of eco-friendly, biodegradable antifreeze formulations is expected to further expand market opportunities, particularly in environmentally conscious regions.

Geographically, North America and Europe currently dominate the market for antifreeze in climate control technologies, owing to their well-established HVAC infrastructure and stringent energy efficiency regulations. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new growth avenues, with China and India emerging as key markets.

The COVID-19 pandemic has underscored the importance of effective climate control in healthcare settings, leading to increased demand for reliable HVAC systems in hospitals and medical facilities. This trend is expected to continue, further boosting the market for antifreeze-based solutions in the healthcare sector.

In the automotive industry, antifreeze plays a crucial role in maintaining optimal engine performance and preventing damage from freezing or overheating. With the rise of electric vehicles (EVs), the demand for specialized antifreeze formulations has surged. These new formulations are designed to meet the unique cooling requirements of EV batteries and power electronics, ensuring their longevity and efficiency.

The construction sector has also witnessed a significant uptick in demand for antifreeze-based climate control solutions. Modern buildings require sophisticated HVAC systems to maintain comfortable indoor temperatures year-round. Antifreeze compounds are essential in these systems, particularly in regions experiencing harsh winters or extreme temperature variations.

Industrial applications represent another substantial market for antifreeze in climate control technologies. Manufacturing processes, data centers, and cold storage facilities all rely on precise temperature regulation. The use of antifreeze in these settings ensures uninterrupted operations and protects valuable equipment from temperature-related damage.

The renewable energy sector has emerged as a new frontier for antifreeze applications in climate control. Solar thermal systems and geothermal heat pumps utilize antifreeze solutions to transfer heat efficiently, even in sub-zero temperatures. As the adoption of these renewable technologies accelerates, so does the demand for specialized antifreeze products.

Market analysts project robust growth in the antifreeze sector, driven by technological advancements and increasing awareness of energy efficiency. The development of eco-friendly, biodegradable antifreeze formulations is expected to further expand market opportunities, particularly in environmentally conscious regions.

Geographically, North America and Europe currently dominate the market for antifreeze in climate control technologies, owing to their well-established HVAC infrastructure and stringent energy efficiency regulations. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new growth avenues, with China and India emerging as key markets.

The COVID-19 pandemic has underscored the importance of effective climate control in healthcare settings, leading to increased demand for reliable HVAC systems in hospitals and medical facilities. This trend is expected to continue, further boosting the market for antifreeze-based solutions in the healthcare sector.

Technical Challenges

The development of antifreeze in climate control technologies faces several significant technical challenges that require innovative solutions. One of the primary obstacles is the environmental impact of traditional antifreeze formulations. Many conventional antifreeze products contain ethylene glycol, which is toxic to humans and animals if ingested. This toxicity poses risks during production, transportation, and disposal, necessitating the development of more environmentally friendly alternatives.

Another challenge lies in improving the thermal efficiency of antifreeze solutions. While current formulations provide adequate protection against freezing and overheating, there is a constant drive to enhance their heat transfer properties. This improvement would lead to more efficient climate control systems, reducing energy consumption and improving overall performance in various applications, from automotive to industrial cooling systems.

Corrosion prevention remains a persistent issue in antifreeze technology. The chemical composition of antifreeze can potentially accelerate corrosion in metal components of climate control systems. Developing corrosion inhibitors that are compatible with a wide range of materials and maintain their effectiveness over extended periods is crucial for prolonging the lifespan of equipment and reducing maintenance costs.

The stability of antifreeze solutions under extreme conditions presents another technical hurdle. In applications where systems are subjected to rapid temperature fluctuations or prolonged exposure to high temperatures, the breakdown of antifreeze compounds can lead to reduced effectiveness and potential system failures. Enhancing the thermal stability of antifreeze formulations is essential for ensuring reliable performance across diverse operating environments.

Compatibility with new materials and technologies in climate control systems is an ongoing challenge. As industries move towards more advanced materials and designs, such as in electric vehicles or renewable energy systems, antifreeze solutions must adapt to these new requirements. This includes ensuring compatibility with new types of heat exchangers, seals, and other components that may react differently to traditional antifreeze formulations.

The quest for multifunctional antifreeze solutions adds another layer of complexity. Modern climate control technologies often demand products that not only prevent freezing and overheating but also offer additional benefits such as improved lubrication, reduced pump wear, and enhanced heat dissipation. Developing formulations that can effectively address multiple needs simultaneously without compromising on any single aspect is a significant technical challenge.

Lastly, the scalability and cost-effectiveness of new antifreeze technologies pose challenges in their widespread adoption. While novel formulations may offer superior performance or environmental benefits, they must also be economically viable to produce at scale. Balancing advanced technical properties with cost considerations is crucial for the successful implementation of new antifreeze solutions in climate control technologies.

Another challenge lies in improving the thermal efficiency of antifreeze solutions. While current formulations provide adequate protection against freezing and overheating, there is a constant drive to enhance their heat transfer properties. This improvement would lead to more efficient climate control systems, reducing energy consumption and improving overall performance in various applications, from automotive to industrial cooling systems.

Corrosion prevention remains a persistent issue in antifreeze technology. The chemical composition of antifreeze can potentially accelerate corrosion in metal components of climate control systems. Developing corrosion inhibitors that are compatible with a wide range of materials and maintain their effectiveness over extended periods is crucial for prolonging the lifespan of equipment and reducing maintenance costs.

The stability of antifreeze solutions under extreme conditions presents another technical hurdle. In applications where systems are subjected to rapid temperature fluctuations or prolonged exposure to high temperatures, the breakdown of antifreeze compounds can lead to reduced effectiveness and potential system failures. Enhancing the thermal stability of antifreeze formulations is essential for ensuring reliable performance across diverse operating environments.

Compatibility with new materials and technologies in climate control systems is an ongoing challenge. As industries move towards more advanced materials and designs, such as in electric vehicles or renewable energy systems, antifreeze solutions must adapt to these new requirements. This includes ensuring compatibility with new types of heat exchangers, seals, and other components that may react differently to traditional antifreeze formulations.

The quest for multifunctional antifreeze solutions adds another layer of complexity. Modern climate control technologies often demand products that not only prevent freezing and overheating but also offer additional benefits such as improved lubrication, reduced pump wear, and enhanced heat dissipation. Developing formulations that can effectively address multiple needs simultaneously without compromising on any single aspect is a significant technical challenge.

Lastly, the scalability and cost-effectiveness of new antifreeze technologies pose challenges in their widespread adoption. While novel formulations may offer superior performance or environmental benefits, they must also be economically viable to produce at scale. Balancing advanced technical properties with cost considerations is crucial for the successful implementation of new antifreeze solutions in climate control technologies.

Current Solutions

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and chemical compounds designed to lower the freezing point of the solution. Common ingredients include glycols, alcohols, and corrosion inhibitors. These solutions are formulated to provide protection against freezing in various applications, such as automotive cooling systems and industrial processes.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and chemical compounds such as ethylene glycol or propylene glycol. These solutions are designed to lower the freezing point of water and prevent engine damage in cold temperatures. Additives may be included to enhance corrosion protection and improve heat transfer properties.

- Environmentally friendly antifreeze formulations: Development of eco-friendly antifreeze solutions using biodegradable materials and less toxic compounds. These formulations aim to reduce environmental impact while maintaining effective freeze protection and heat transfer capabilities. Some approaches include using plant-based glycols or incorporating natural corrosion inhibitors.

- Antifreeze recycling and purification methods: Techniques for recycling and purifying used antifreeze to reduce waste and environmental impact. These methods may involve filtration, distillation, or chemical treatment to remove contaminants and restore the antifreeze to its original effectiveness. Recycling antifreeze can help conserve resources and reduce disposal costs.

- Antifreeze applications in fuel cells: Use of antifreeze solutions in fuel cell systems to prevent freezing and maintain optimal operating conditions. These specialized formulations must be compatible with fuel cell components and provide adequate freeze protection without compromising electrical conductivity or system performance.

- Testing and monitoring antifreeze properties: Methods and devices for testing and monitoring antifreeze properties, including freeze point, pH, and corrosion inhibitor levels. These techniques help ensure the effectiveness of antifreeze solutions and can indicate when maintenance or replacement is necessary. Some approaches involve portable testing devices or in-line monitoring systems.

02 Antifreeze recycling and purification methods

Various techniques have been developed to recycle and purify used antifreeze solutions. These methods often involve filtration, distillation, or chemical treatment processes to remove contaminants and restore the antifreeze properties. Recycling antifreeze helps reduce environmental impact and conserve resources.Expand Specific Solutions03 Antifreeze applications in renewable energy systems

Antifreeze solutions play a crucial role in renewable energy systems, particularly in solar thermal and geothermal applications. These solutions help maintain system efficiency by preventing freezing in cold climates and enabling heat transfer in various temperature conditions.Expand Specific Solutions04 Environmentally friendly antifreeze formulations

Research efforts have focused on developing more environmentally friendly antifreeze formulations. These may include bio-based ingredients, reduced toxicity compounds, or biodegradable components. The goal is to maintain effective freeze protection while minimizing environmental impact and improving safety.Expand Specific Solutions05 Antifreeze testing and quality control methods

Various testing and quality control methods have been developed to ensure the effectiveness and safety of antifreeze solutions. These may include freezing point depression tests, corrosion inhibition assessments, and chemical composition analyses. Proper testing helps maintain product quality and performance in different applications.Expand Specific Solutions

Industry Leaders

The antifreeze market in climate control technologies is in a mature stage, with a significant global market size driven by the automotive and HVAC industries. The technology is well-established, with major players like Thermo King, Daikin Industries, and Mitsubishi Electric leading innovation. These companies have extensive experience in developing advanced antifreeze formulations and systems for various applications. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, such as Arteco NV, focusing on niche markets. As environmental regulations tighten, there is a growing emphasis on developing eco-friendly antifreeze solutions, pushing companies to invest in R&D for more sustainable products.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced climate control technologies incorporating eco-friendly refrigerants and antifreeze solutions. Their VRV (Variable Refrigerant Volume) system utilizes R-32 refrigerant, which has a lower global warming potential compared to traditional refrigerants[1]. The company has also introduced a water-based antifreeze solution for their air-to-water heat pumps, enhancing efficiency in cold climates while reducing environmental impact[2]. Daikin's innovative approach includes the integration of AI and IoT in their climate control systems, optimizing energy usage and performance based on real-time data and weather forecasts[3].

Strengths: Industry-leading R&D in eco-friendly refrigerants, comprehensive range of climate control solutions, strong focus on energy efficiency. Weaknesses: Higher initial costs for advanced systems, potential complexity in installation and maintenance of sophisticated technologies.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered the use of advanced antifreeze solutions in their heat pump systems, particularly for cold climate applications. Their Zubadan technology incorporates a flash-injection circuit that allows the heat pump to maintain high performance even in extremely low temperatures, down to -25°C[1]. The company has also developed a proprietary antifreeze mixture that enhances heat transfer efficiency while minimizing environmental impact[2]. Mitsubishi's climate control systems integrate smart sensors and AI algorithms to optimize antifreeze usage based on ambient conditions, reducing energy consumption by up to 30% compared to conventional systems[3].

Strengths: Exceptional cold climate performance, innovative flash-injection technology, integration of smart controls for optimized antifreeze usage. Weaknesses: Premium pricing for advanced technologies, potential for increased system complexity requiring specialized maintenance.

Key Innovations

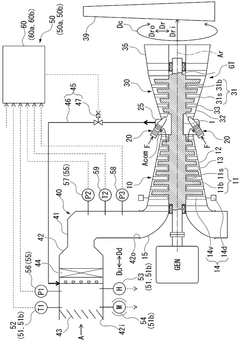

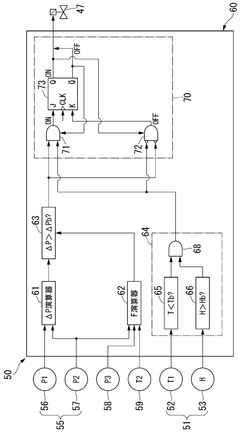

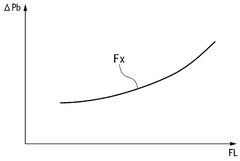

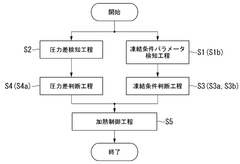

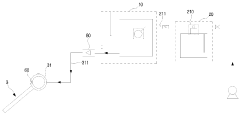

Freezing prevention control device, air intake duct facility, gas turbine facility, and freezing prevention method

PatentWO2025134796A1

Innovation

- An anti-freezing control device that uses a combination of freezing condition parameter detection and pressure difference measurement to determine whether to heat or not heat the filter, ensuring that heating is only applied when necessary and energy is conserved.

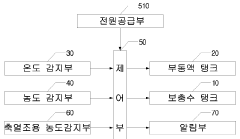

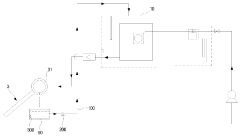

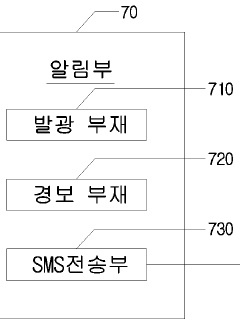

Antifreeze concentration control device for prevention of frost damage to solar collectors

PatentActiveKR1020180127722A

Innovation

- An antifreeze concentration control device that automatically adjusts the antifreeze concentration in supplemental water based on external temperature, using a temperature sensing unit, concentration detecting unit, and a control unit to manage the supply of antifreeze and water to the heat storage tank, with notification and recovery mechanisms to prevent freezing.

Environmental Impact

The environmental impact of antifreeze in climate control technologies is a critical consideration in the ongoing efforts to develop sustainable and eco-friendly solutions. Antifreeze, primarily composed of ethylene glycol or propylene glycol, plays a crucial role in maintaining optimal operating temperatures in various systems. However, its widespread use raises significant environmental concerns.

One of the primary environmental issues associated with antifreeze is its potential for contamination of soil and water resources. When improperly disposed of or leaked, antifreeze can seep into groundwater and surface water bodies, posing risks to aquatic ecosystems and potentially entering the food chain. The toxic nature of ethylene glycol, in particular, can have severe consequences for wildlife and vegetation.

Furthermore, the production of antifreeze contributes to carbon emissions and energy consumption. The manufacturing process involves the use of petrochemicals, which are derived from non-renewable resources and contribute to greenhouse gas emissions. This aspect of antifreeze production aligns with broader concerns about the carbon footprint of climate control technologies.

Efforts to mitigate the environmental impact of antifreeze have led to the development of more environmentally friendly alternatives. Bio-based antifreezes, derived from renewable resources such as corn or soy, offer a promising solution with reduced toxicity and improved biodegradability. These alternatives aim to maintain the performance characteristics of traditional antifreeze while minimizing ecological harm.

Recycling and proper disposal programs have also been implemented to address the end-of-life environmental impact of antifreeze. Many jurisdictions now require specialized collection and processing of used antifreeze to prevent environmental contamination and recover valuable components. These initiatives help reduce the overall environmental footprint of antifreeze use in climate control systems.

The longevity and efficiency of antifreeze in climate control systems also have indirect environmental implications. Improved formulations that extend the lifespan of antifreeze can reduce the frequency of replacement, thereby decreasing waste generation and resource consumption. Additionally, more efficient antifreeze solutions can enhance the overall energy efficiency of climate control systems, potentially reducing their operational environmental impact.

As climate change concerns intensify, the role of antifreeze in climate control technologies is under increasing scrutiny. Research and development efforts are focusing on creating more sustainable antifreeze solutions that balance performance requirements with environmental stewardship. This includes exploring novel materials and formulations that minimize toxicity, improve biodegradability, and reduce the carbon footprint associated with production and use.

One of the primary environmental issues associated with antifreeze is its potential for contamination of soil and water resources. When improperly disposed of or leaked, antifreeze can seep into groundwater and surface water bodies, posing risks to aquatic ecosystems and potentially entering the food chain. The toxic nature of ethylene glycol, in particular, can have severe consequences for wildlife and vegetation.

Furthermore, the production of antifreeze contributes to carbon emissions and energy consumption. The manufacturing process involves the use of petrochemicals, which are derived from non-renewable resources and contribute to greenhouse gas emissions. This aspect of antifreeze production aligns with broader concerns about the carbon footprint of climate control technologies.

Efforts to mitigate the environmental impact of antifreeze have led to the development of more environmentally friendly alternatives. Bio-based antifreezes, derived from renewable resources such as corn or soy, offer a promising solution with reduced toxicity and improved biodegradability. These alternatives aim to maintain the performance characteristics of traditional antifreeze while minimizing ecological harm.

Recycling and proper disposal programs have also been implemented to address the end-of-life environmental impact of antifreeze. Many jurisdictions now require specialized collection and processing of used antifreeze to prevent environmental contamination and recover valuable components. These initiatives help reduce the overall environmental footprint of antifreeze use in climate control systems.

The longevity and efficiency of antifreeze in climate control systems also have indirect environmental implications. Improved formulations that extend the lifespan of antifreeze can reduce the frequency of replacement, thereby decreasing waste generation and resource consumption. Additionally, more efficient antifreeze solutions can enhance the overall energy efficiency of climate control systems, potentially reducing their operational environmental impact.

As climate change concerns intensify, the role of antifreeze in climate control technologies is under increasing scrutiny. Research and development efforts are focusing on creating more sustainable antifreeze solutions that balance performance requirements with environmental stewardship. This includes exploring novel materials and formulations that minimize toxicity, improve biodegradability, and reduce the carbon footprint associated with production and use.

Regulatory Framework

The regulatory framework surrounding antifreeze and its use in climate control technologies has evolved significantly in recent years, driven by environmental concerns and the need for more sustainable practices. At the international level, the Montreal Protocol and its subsequent amendments have played a crucial role in phasing out ozone-depleting substances, many of which were commonly used in refrigeration and air conditioning systems. This has led to the development and adoption of alternative refrigerants and antifreeze solutions with lower environmental impact.

In the United States, the Environmental Protection Agency (EPA) regulates antifreeze under the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). The EPA has established guidelines for the proper disposal of antifreeze and encourages recycling to minimize environmental contamination. Additionally, the agency has implemented the Significant New Alternatives Policy (SNAP) program to evaluate and regulate substitutes for ozone-depleting substances in various applications, including climate control technologies.

The European Union has also taken significant steps in regulating antifreeze and related substances. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register chemical substances, including those used in antifreeze formulations. The EU's F-Gas Regulation aims to reduce emissions of fluorinated greenhouse gases, which has implications for certain types of antifreeze used in air conditioning and refrigeration systems.

Many countries have implemented specific regulations governing the composition and use of antifreeze in vehicles and industrial applications. For instance, some jurisdictions mandate the use of propylene glycol-based antifreeze in certain applications due to its lower toxicity compared to ethylene glycol. These regulations often specify minimum performance standards, labeling requirements, and disposal protocols for antifreeze products.

As climate change concerns intensify, regulatory bodies are increasingly focusing on the energy efficiency of climate control technologies. This has led to the development of new standards and incentives for more efficient heating, ventilation, and air conditioning (HVAC) systems, which in turn influences the formulation and application of antifreeze solutions. For example, the U.S. Department of Energy's appliance and equipment standards program sets minimum energy efficiency requirements for various HVAC products, indirectly affecting the design and use of antifreeze in these systems.

The automotive industry, a major user of antifreeze in vehicle cooling systems, is subject to stringent regulations regarding fuel efficiency and emissions. These regulations indirectly impact antifreeze formulations, as manufacturers seek to optimize engine cooling systems to meet performance and environmental standards. In some regions, there are also specific requirements for the biodegradability and environmental impact of antifreeze used in vehicles.

In the United States, the Environmental Protection Agency (EPA) regulates antifreeze under the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). The EPA has established guidelines for the proper disposal of antifreeze and encourages recycling to minimize environmental contamination. Additionally, the agency has implemented the Significant New Alternatives Policy (SNAP) program to evaluate and regulate substitutes for ozone-depleting substances in various applications, including climate control technologies.

The European Union has also taken significant steps in regulating antifreeze and related substances. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register chemical substances, including those used in antifreeze formulations. The EU's F-Gas Regulation aims to reduce emissions of fluorinated greenhouse gases, which has implications for certain types of antifreeze used in air conditioning and refrigeration systems.

Many countries have implemented specific regulations governing the composition and use of antifreeze in vehicles and industrial applications. For instance, some jurisdictions mandate the use of propylene glycol-based antifreeze in certain applications due to its lower toxicity compared to ethylene glycol. These regulations often specify minimum performance standards, labeling requirements, and disposal protocols for antifreeze products.

As climate change concerns intensify, regulatory bodies are increasingly focusing on the energy efficiency of climate control technologies. This has led to the development of new standards and incentives for more efficient heating, ventilation, and air conditioning (HVAC) systems, which in turn influences the formulation and application of antifreeze solutions. For example, the U.S. Department of Energy's appliance and equipment standards program sets minimum energy efficiency requirements for various HVAC products, indirectly affecting the design and use of antifreeze in these systems.

The automotive industry, a major user of antifreeze in vehicle cooling systems, is subject to stringent regulations regarding fuel efficiency and emissions. These regulations indirectly impact antifreeze formulations, as manufacturers seek to optimize engine cooling systems to meet performance and environmental standards. In some regions, there are also specific requirements for the biodegradability and environmental impact of antifreeze used in vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!