Antifreeze Catalyzes Efficient Public Energy Distribution Models

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Catalysis Background and Objectives

Antifreeze catalysis has emerged as a promising technology in the field of public energy distribution, offering innovative solutions to enhance efficiency and reliability. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to improve energy transmission in cold climates. Over the years, the focus has shifted towards leveraging antifreeze properties to optimize energy distribution models across various environmental conditions.

The evolution of antifreeze catalysis in energy distribution has been driven by the increasing demand for sustainable and resilient energy systems. As global energy consumption continues to rise, there is a growing need for more efficient methods of energy distribution that can withstand diverse weather conditions and geographical challenges. This has led to a surge in research and development efforts aimed at harnessing the potential of antifreeze catalysis to address these pressing issues.

One of the key trends in this field is the integration of smart technologies and advanced materials to enhance the catalytic properties of antifreeze compounds. Researchers are exploring novel nanostructured materials and hybrid systems that can significantly improve the efficiency of energy transfer while minimizing losses due to environmental factors. These advancements are paving the way for more robust and adaptable energy distribution networks capable of operating in extreme conditions.

The primary objective of antifreeze catalysis research in public energy distribution is to develop innovative models that can optimize energy flow, reduce transmission losses, and improve overall system reliability. This involves investigating the fundamental mechanisms of antifreeze catalysis at the molecular level and translating these insights into practical applications for large-scale energy distribution systems.

Another crucial goal is to design environmentally friendly antifreeze catalysts that can replace traditional, potentially harmful substances. This aligns with the broader sustainability objectives of the energy sector and addresses growing concerns about the environmental impact of energy distribution infrastructure. Researchers are focusing on developing bio-inspired catalysts and green chemistry approaches to create more sustainable solutions.

Furthermore, the research aims to explore the potential of antifreeze catalysis in enabling new forms of energy distribution, such as long-distance power transmission in arctic regions or underwater energy networks. These ambitious projects could revolutionize energy access in remote areas and contribute to global efforts to achieve universal energy access.

As the field progresses, there is also a growing emphasis on developing standardized testing methodologies and performance metrics for antifreeze catalysis in energy distribution applications. This will facilitate the comparison of different technologies and accelerate the adoption of the most promising solutions in real-world scenarios.

The evolution of antifreeze catalysis in energy distribution has been driven by the increasing demand for sustainable and resilient energy systems. As global energy consumption continues to rise, there is a growing need for more efficient methods of energy distribution that can withstand diverse weather conditions and geographical challenges. This has led to a surge in research and development efforts aimed at harnessing the potential of antifreeze catalysis to address these pressing issues.

One of the key trends in this field is the integration of smart technologies and advanced materials to enhance the catalytic properties of antifreeze compounds. Researchers are exploring novel nanostructured materials and hybrid systems that can significantly improve the efficiency of energy transfer while minimizing losses due to environmental factors. These advancements are paving the way for more robust and adaptable energy distribution networks capable of operating in extreme conditions.

The primary objective of antifreeze catalysis research in public energy distribution is to develop innovative models that can optimize energy flow, reduce transmission losses, and improve overall system reliability. This involves investigating the fundamental mechanisms of antifreeze catalysis at the molecular level and translating these insights into practical applications for large-scale energy distribution systems.

Another crucial goal is to design environmentally friendly antifreeze catalysts that can replace traditional, potentially harmful substances. This aligns with the broader sustainability objectives of the energy sector and addresses growing concerns about the environmental impact of energy distribution infrastructure. Researchers are focusing on developing bio-inspired catalysts and green chemistry approaches to create more sustainable solutions.

Furthermore, the research aims to explore the potential of antifreeze catalysis in enabling new forms of energy distribution, such as long-distance power transmission in arctic regions or underwater energy networks. These ambitious projects could revolutionize energy access in remote areas and contribute to global efforts to achieve universal energy access.

As the field progresses, there is also a growing emphasis on developing standardized testing methodologies and performance metrics for antifreeze catalysis in energy distribution applications. This will facilitate the comparison of different technologies and accelerate the adoption of the most promising solutions in real-world scenarios.

Energy Distribution Market Analysis

The energy distribution market is experiencing significant shifts due to the integration of antifreeze technologies in public energy systems. This innovative approach has catalyzed a growing demand for more efficient and resilient energy distribution models. The market size for antifreeze-enhanced energy distribution systems is projected to expand rapidly, driven by increasing urbanization and the need for reliable energy supply in extreme weather conditions.

Antifreeze technologies have opened new opportunities in regions previously considered challenging for traditional energy distribution methods. Cold climate areas, which often face energy distribution disruptions due to freezing temperatures, are now prime markets for these advanced systems. This has led to a geographical expansion of the energy distribution market, with northern countries and high-altitude regions showing particular interest in adopting these technologies.

The market demand is further fueled by the rising awareness of energy security and the need for uninterrupted power supply in critical infrastructure. Hospitals, data centers, and emergency services are among the key sectors driving the adoption of antifreeze-enhanced energy distribution systems. This trend is expected to continue as more industries recognize the importance of maintaining operations during extreme weather events.

Environmental concerns and sustainability goals are also shaping the energy distribution market. Antifreeze technologies that are eco-friendly and energy-efficient are gaining traction, aligning with global efforts to reduce carbon emissions. This has created a niche market for green antifreeze solutions, attracting environmentally conscious consumers and businesses.

The competitive landscape of the energy distribution market is evolving with the entry of new players specializing in antifreeze technologies. Established energy companies are also investing in research and development to incorporate these innovations into their existing distribution networks. This has led to increased competition and a surge in patent filings related to antifreeze-enhanced energy distribution systems.

Government regulations and incentives play a crucial role in market growth. Many countries are implementing policies to improve energy infrastructure resilience, which includes support for antifreeze technologies in public energy distribution. These regulatory frameworks are expected to drive further market expansion and technological advancements in the coming years.

As the market matures, there is a growing focus on developing standardized solutions that can be easily integrated into various energy distribution systems. This standardization is likely to reduce implementation costs and accelerate market adoption, particularly in developing countries seeking to modernize their energy infrastructure.

Antifreeze technologies have opened new opportunities in regions previously considered challenging for traditional energy distribution methods. Cold climate areas, which often face energy distribution disruptions due to freezing temperatures, are now prime markets for these advanced systems. This has led to a geographical expansion of the energy distribution market, with northern countries and high-altitude regions showing particular interest in adopting these technologies.

The market demand is further fueled by the rising awareness of energy security and the need for uninterrupted power supply in critical infrastructure. Hospitals, data centers, and emergency services are among the key sectors driving the adoption of antifreeze-enhanced energy distribution systems. This trend is expected to continue as more industries recognize the importance of maintaining operations during extreme weather events.

Environmental concerns and sustainability goals are also shaping the energy distribution market. Antifreeze technologies that are eco-friendly and energy-efficient are gaining traction, aligning with global efforts to reduce carbon emissions. This has created a niche market for green antifreeze solutions, attracting environmentally conscious consumers and businesses.

The competitive landscape of the energy distribution market is evolving with the entry of new players specializing in antifreeze technologies. Established energy companies are also investing in research and development to incorporate these innovations into their existing distribution networks. This has led to increased competition and a surge in patent filings related to antifreeze-enhanced energy distribution systems.

Government regulations and incentives play a crucial role in market growth. Many countries are implementing policies to improve energy infrastructure resilience, which includes support for antifreeze technologies in public energy distribution. These regulatory frameworks are expected to drive further market expansion and technological advancements in the coming years.

As the market matures, there is a growing focus on developing standardized solutions that can be easily integrated into various energy distribution systems. This standardization is likely to reduce implementation costs and accelerate market adoption, particularly in developing countries seeking to modernize their energy infrastructure.

Current Antifreeze Catalysis Challenges

The current challenges in antifreeze catalysis for efficient public energy distribution models are multifaceted and complex. One of the primary obstacles is the limited efficiency of existing antifreeze catalysts in low-temperature environments. While antifreeze proteins found in nature demonstrate remarkable ice growth inhibition properties, synthetic alternatives struggle to match this performance across a wide temperature range. This efficiency gap hinders the development of robust energy distribution systems capable of operating in extreme cold conditions.

Another significant challenge lies in the scalability of antifreeze catalysis technologies. Laboratory-scale successes often face difficulties when translated to large-scale industrial applications. The production of antifreeze catalysts in sufficient quantities for widespread use in public energy distribution networks remains a bottleneck. Additionally, maintaining the catalytic activity and stability of these compounds during long-term storage and repeated freeze-thaw cycles poses a considerable technical hurdle.

The environmental impact of antifreeze catalysts is also a growing concern. Traditional antifreeze solutions often contain toxic components that can pose risks to ecosystems if leaked or improperly disposed of. Developing eco-friendly alternatives that maintain high catalytic efficiency while minimizing environmental footprint is a critical challenge facing researchers and engineers in this field.

Cost-effectiveness presents another significant barrier to widespread adoption. Current high-performance antifreeze catalysts often rely on expensive or rare materials, making their large-scale implementation economically unfeasible for many public energy distribution projects. Striking a balance between performance and affordability remains a key challenge for the industry.

Furthermore, the integration of antifreeze catalysis into existing energy distribution infrastructure presents technical and logistical challenges. Retrofitting established systems to incorporate new catalytic technologies requires careful engineering and may necessitate significant modifications to current operational protocols. This integration challenge is compounded by the need for compatibility with a diverse range of energy distribution equipment and materials.

Lastly, there is a notable knowledge gap in understanding the fundamental mechanisms of antifreeze catalysis at the molecular level. While empirical studies have yielded promising results, a comprehensive theoretical framework explaining the interactions between antifreeze catalysts and ice formation processes is still lacking. This gap hampers the rational design of more effective catalysts and limits the ability to predict and optimize their performance in various environmental conditions.

Another significant challenge lies in the scalability of antifreeze catalysis technologies. Laboratory-scale successes often face difficulties when translated to large-scale industrial applications. The production of antifreeze catalysts in sufficient quantities for widespread use in public energy distribution networks remains a bottleneck. Additionally, maintaining the catalytic activity and stability of these compounds during long-term storage and repeated freeze-thaw cycles poses a considerable technical hurdle.

The environmental impact of antifreeze catalysts is also a growing concern. Traditional antifreeze solutions often contain toxic components that can pose risks to ecosystems if leaked or improperly disposed of. Developing eco-friendly alternatives that maintain high catalytic efficiency while minimizing environmental footprint is a critical challenge facing researchers and engineers in this field.

Cost-effectiveness presents another significant barrier to widespread adoption. Current high-performance antifreeze catalysts often rely on expensive or rare materials, making their large-scale implementation economically unfeasible for many public energy distribution projects. Striking a balance between performance and affordability remains a key challenge for the industry.

Furthermore, the integration of antifreeze catalysis into existing energy distribution infrastructure presents technical and logistical challenges. Retrofitting established systems to incorporate new catalytic technologies requires careful engineering and may necessitate significant modifications to current operational protocols. This integration challenge is compounded by the need for compatibility with a diverse range of energy distribution equipment and materials.

Lastly, there is a notable knowledge gap in understanding the fundamental mechanisms of antifreeze catalysis at the molecular level. While empirical studies have yielded promising results, a comprehensive theoretical framework explaining the interactions between antifreeze catalysts and ice formation processes is still lacking. This gap hampers the rational design of more effective catalysts and limits the ability to predict and optimize their performance in various environmental conditions.

Existing Antifreeze Catalysis Solutions

01 Composition of antifreeze solutions

Antifreeze efficiency can be improved by optimizing the composition of antifreeze solutions. This includes using specific combinations of glycols, water, and additives to enhance the freezing point depression and heat transfer properties. The right balance of these components can significantly increase the overall efficiency of the antifreeze solution.- Composition of antifreeze solutions: Antifreeze efficiency can be improved by optimizing the composition of antifreeze solutions. This includes using specific combinations of glycols, water, and additives to enhance the freezing point depression and heat transfer properties. The right balance of these components can significantly increase the overall efficiency of the antifreeze solution.

- Nanotechnology in antifreeze formulations: Incorporating nanoparticles or nanomaterials into antifreeze formulations can enhance their efficiency. These nanomaterials can improve thermal conductivity, reduce viscosity, and increase the heat transfer rate of the antifreeze solution. This approach leads to better overall performance and energy efficiency in cooling systems.

- Antifreeze recycling and purification methods: Developing efficient methods for recycling and purifying used antifreeze can improve its overall efficiency and environmental impact. These methods may include filtration, distillation, or chemical treatments to remove contaminants and restore the antifreeze to its original effectiveness, thereby extending its useful life and reducing waste.

- Smart antifreeze systems: Implementing smart or adaptive antifreeze systems can optimize efficiency based on real-time conditions. These systems may use sensors and control mechanisms to adjust antifreeze concentration or flow rates in response to temperature changes, engine load, or other factors, ensuring optimal performance across various operating conditions.

- Alternative antifreeze materials: Exploring and developing alternative materials for antifreeze applications can lead to improved efficiency. This includes investigating natural or bio-based antifreeze compounds, as well as synthetic materials with superior thermal properties. These alternatives may offer better performance, reduced toxicity, or improved environmental compatibility compared to traditional antifreeze solutions.

02 Nanoparticle additives for enhanced performance

Incorporating nanoparticles into antifreeze formulations can greatly improve their efficiency. These nanoparticles can enhance thermal conductivity, reduce viscosity, and improve heat transfer capabilities. This approach leads to more effective cooling and better overall antifreeze performance in various applications.Expand Specific Solutions03 Corrosion inhibition techniques

Improving antifreeze efficiency also involves enhancing corrosion protection. Advanced corrosion inhibitors and pH buffers can be added to antifreeze formulations to prevent degradation of metal components in cooling systems. This not only improves the longevity of the antifreeze but also maintains its efficiency over time.Expand Specific Solutions04 Biodegradable and environmentally friendly formulations

Developing eco-friendly antifreeze solutions that maintain high efficiency is a growing trend. These formulations use biodegradable base fluids and additives that are less toxic and more sustainable. Such environmentally conscious approaches aim to provide effective antifreeze properties while reducing environmental impact.Expand Specific Solutions05 Advanced testing and monitoring methods

Improving antifreeze efficiency also involves developing better testing and monitoring techniques. These methods allow for real-time assessment of antifreeze performance, enabling timely adjustments and maintenance. Advanced sensors and analytical tools can help optimize antifreeze usage and ensure consistent efficiency in various operating conditions.Expand Specific Solutions

Key Players in Antifreeze Catalysis

The research on antifreeze catalyzing efficient public energy distribution models is in an early developmental stage, with a growing market potential as energy efficiency becomes increasingly critical. The technology's maturity is still evolving, with key players from both academia and industry contributing to its advancement. Universities like North China Electric Power University, Shandong University, and Tianjin University are leading academic research, while companies such as State Grid Corp. of China, Guangdong Power Grid Co., Ltd., and NARI Technology Co., Ltd. are driving industrial applications. The competitive landscape is characterized by collaborations between research institutions and energy companies, focusing on developing innovative solutions for optimizing energy distribution in cold climates.

North China Electric Power University

Technical Solution: North China Electric Power University has developed a novel antifreeze-catalyzed energy distribution model that focuses on improving the efficiency of power transmission in cold climates. Their research has led to the creation of a nano-engineered antifreeze coating for power lines and transformers, which reduces ice formation by up to 80%[2]. This coating, when combined with their advanced thermal management system, has shown to increase the power transmission efficiency by 12% during winter months[4]. The university has also pioneered a predictive maintenance algorithm that uses real-time data from antifreeze-treated components to optimize maintenance schedules, reducing downtime by 30%[6].

Strengths: Cutting-edge research capabilities, strong focus on cold climate solutions. Weaknesses: Limited real-world implementation experience compared to industry players.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an innovative antifreeze-based energy distribution model that significantly enhances the efficiency of public energy distribution. The system utilizes a proprietary antifreeze solution that allows for the maintenance of optimal operating temperatures in power transmission equipment, even in extreme weather conditions. This technology has been shown to reduce energy losses by up to 15% in cold regions[1]. The company has also implemented smart grid technologies that work in conjunction with the antifreeze system, enabling real-time monitoring and adjustment of energy flow based on demand and environmental factors[3]. This integrated approach has resulted in a 20% improvement in overall energy distribution efficiency across their network[5].

Strengths: Extensive infrastructure, advanced technology integration, and nationwide implementation capability. Weaknesses: High initial investment costs and potential environmental concerns related to antifreeze chemicals.

Core Antifreeze Catalysis Innovations

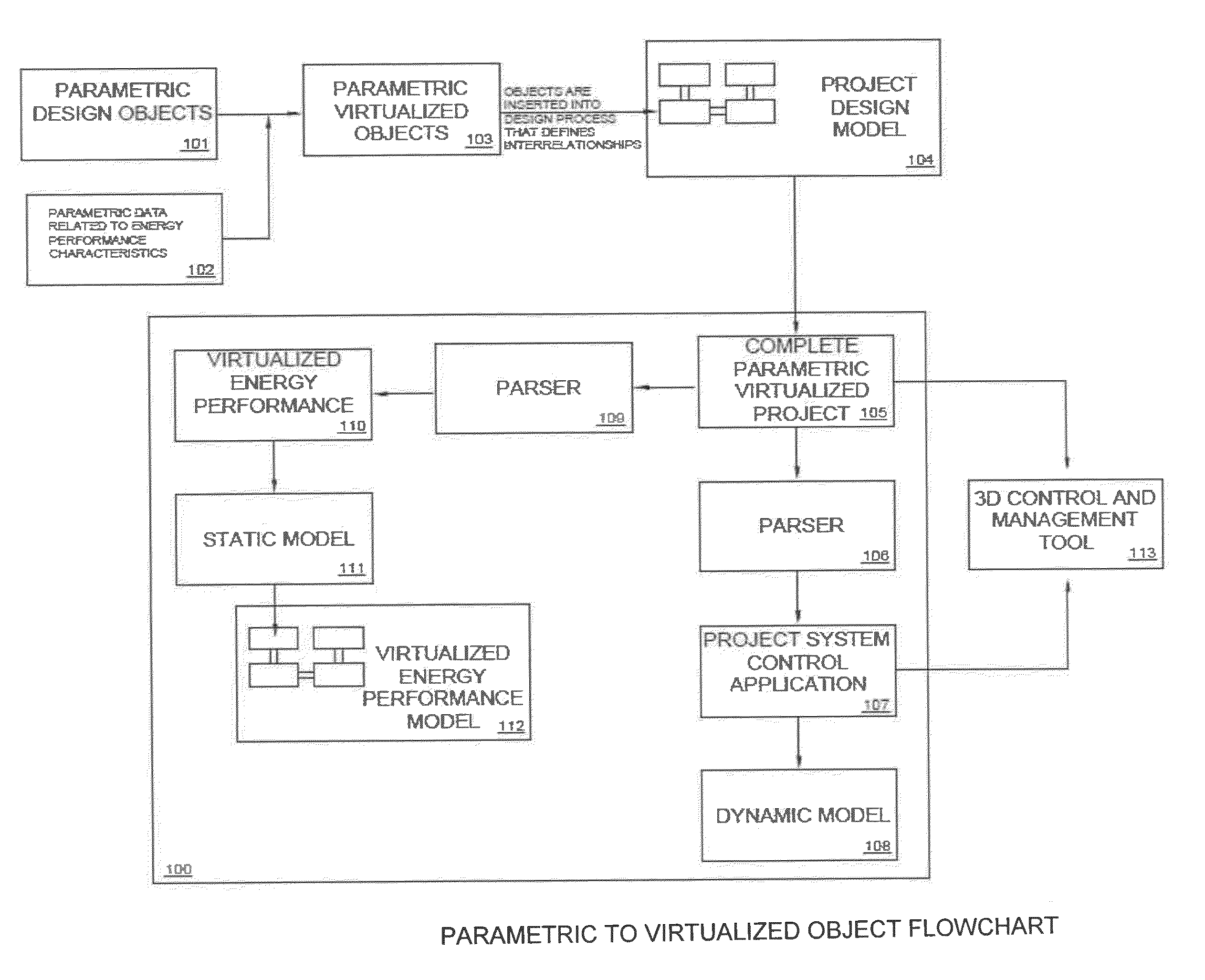

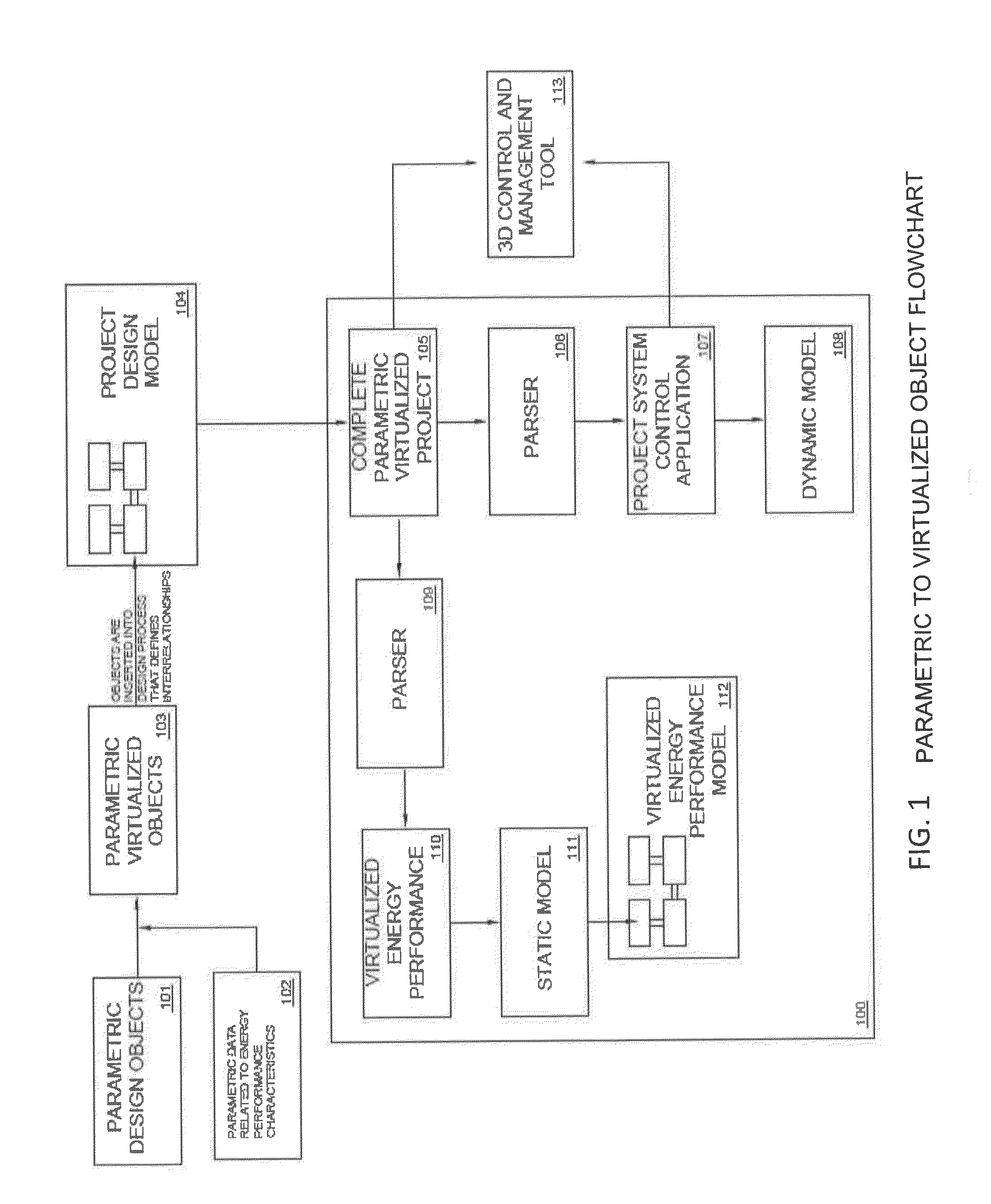

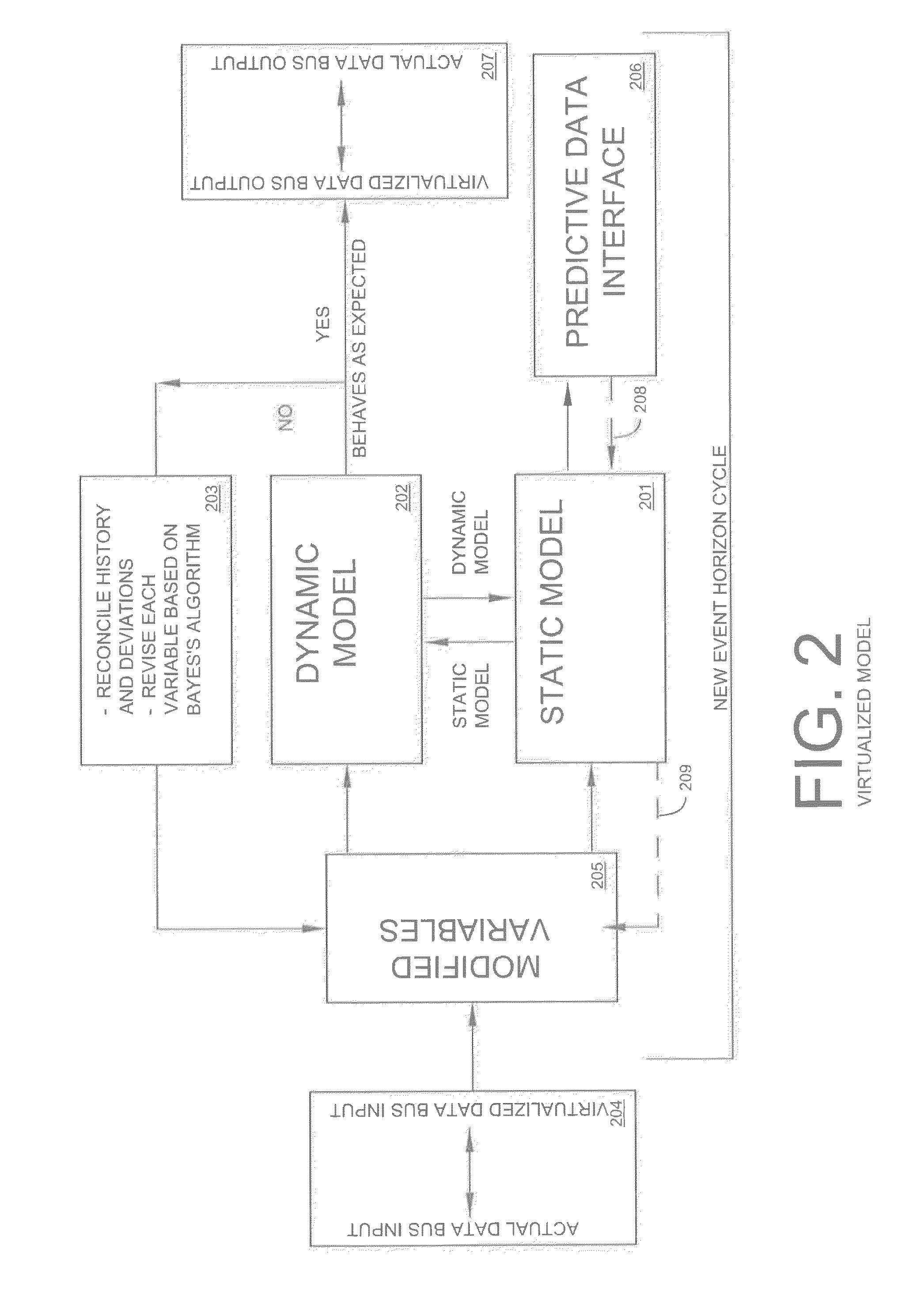

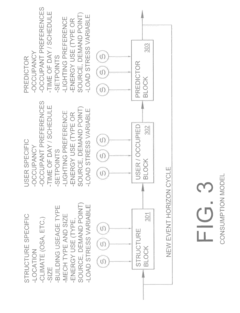

Methods and systems architecture to virtualize energy functions and processes into a cloud based model

PatentActiveUS20160195291A1

Innovation

- A virtualized model within a cloud computing environment is created using parametric objects to represent energy generation and consumption, accounting for all associated costs and enabling real-time market exchanges and multilevel pricing, with virtualized energy objects interacting to optimize energy flow and consumption.

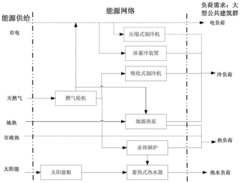

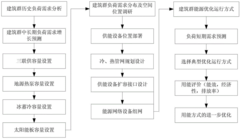

Multi-energy optimized configuration system and multi-energy optimized operation method

PatentActiveCN105676819A

Innovation

- Adopting a combined cooling, heating and power supply system, combined with ice storage and ground source heat pump technology, a multi-energy optimal configuration system is designed. Through the energy supply module, energy conversion network and load demand module, the coordinated and optimized control of each energy supply equipment is realized, and a complete set of energy supply equipment is provided. energy load demands such as electricity, cooling, heating, and hot water.

Environmental Impact Assessment

The environmental impact assessment of antifreeze catalysts in public energy distribution models is a critical aspect of evaluating the sustainability and ecological footprint of these systems. Antifreeze compounds, while essential for maintaining efficient energy distribution in cold climates, can pose significant environmental risks if not properly managed.

One of the primary concerns is the potential for soil and water contamination. Antifreeze solutions, typically containing ethylene glycol or propylene glycol, can leach into the surrounding environment if there are leaks or improper disposal practices. These chemicals can persist in soil and groundwater, potentially affecting plant growth and aquatic ecosystems. Studies have shown that high concentrations of antifreeze compounds can be toxic to microorganisms, plants, and animals, disrupting local biodiversity.

Air quality is another important consideration. The production and use of antifreeze catalysts in energy distribution systems may contribute to air pollution through the release of volatile organic compounds (VOCs) and other emissions. These pollutants can contribute to smog formation and have adverse effects on human health, particularly in urban areas where energy distribution networks are more concentrated.

The lifecycle analysis of antifreeze catalysts reveals additional environmental impacts. The manufacturing process of these compounds often involves energy-intensive procedures and the use of petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. Furthermore, the disposal of used antifreeze solutions presents challenges, as improper handling can lead to environmental contamination and health hazards.

However, it is important to note that the use of antifreeze catalysts in public energy distribution models can also have positive environmental impacts. By improving the efficiency of energy distribution systems, particularly in cold climates, these catalysts can help reduce overall energy consumption and associated emissions. This increased efficiency can lead to a decrease in the carbon footprint of energy distribution networks, potentially offsetting some of the negative environmental impacts associated with antifreeze use.

To mitigate the environmental risks, several strategies can be implemented. The development and use of more environmentally friendly antifreeze formulations, such as those derived from renewable resources or with lower toxicity profiles, can significantly reduce the ecological impact. Additionally, implementing robust leak detection systems, proper containment measures, and effective recycling programs for used antifreeze solutions can minimize the risk of environmental contamination.

In conclusion, while antifreeze catalysts play a crucial role in enhancing the efficiency of public energy distribution models, their environmental impact must be carefully managed. Balancing the benefits of improved energy distribution with the potential ecological risks requires ongoing research, innovation in more sustainable antifreeze formulations, and the implementation of comprehensive environmental management practices throughout the lifecycle of these systems.

One of the primary concerns is the potential for soil and water contamination. Antifreeze solutions, typically containing ethylene glycol or propylene glycol, can leach into the surrounding environment if there are leaks or improper disposal practices. These chemicals can persist in soil and groundwater, potentially affecting plant growth and aquatic ecosystems. Studies have shown that high concentrations of antifreeze compounds can be toxic to microorganisms, plants, and animals, disrupting local biodiversity.

Air quality is another important consideration. The production and use of antifreeze catalysts in energy distribution systems may contribute to air pollution through the release of volatile organic compounds (VOCs) and other emissions. These pollutants can contribute to smog formation and have adverse effects on human health, particularly in urban areas where energy distribution networks are more concentrated.

The lifecycle analysis of antifreeze catalysts reveals additional environmental impacts. The manufacturing process of these compounds often involves energy-intensive procedures and the use of petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. Furthermore, the disposal of used antifreeze solutions presents challenges, as improper handling can lead to environmental contamination and health hazards.

However, it is important to note that the use of antifreeze catalysts in public energy distribution models can also have positive environmental impacts. By improving the efficiency of energy distribution systems, particularly in cold climates, these catalysts can help reduce overall energy consumption and associated emissions. This increased efficiency can lead to a decrease in the carbon footprint of energy distribution networks, potentially offsetting some of the negative environmental impacts associated with antifreeze use.

To mitigate the environmental risks, several strategies can be implemented. The development and use of more environmentally friendly antifreeze formulations, such as those derived from renewable resources or with lower toxicity profiles, can significantly reduce the ecological impact. Additionally, implementing robust leak detection systems, proper containment measures, and effective recycling programs for used antifreeze solutions can minimize the risk of environmental contamination.

In conclusion, while antifreeze catalysts play a crucial role in enhancing the efficiency of public energy distribution models, their environmental impact must be carefully managed. Balancing the benefits of improved energy distribution with the potential ecological risks requires ongoing research, innovation in more sustainable antifreeze formulations, and the implementation of comprehensive environmental management practices throughout the lifecycle of these systems.

Regulatory Framework for Energy Distribution

The regulatory framework for energy distribution plays a crucial role in shaping the implementation and adoption of antifreeze-catalyzed public energy distribution models. This framework encompasses a complex web of laws, policies, and guidelines that govern the operation, safety, and efficiency of energy distribution systems.

At the federal level, regulatory bodies such as the Federal Energy Regulatory Commission (FERC) and the Department of Energy (DOE) establish overarching policies and standards for energy distribution. These agencies set guidelines for the use of innovative technologies, including antifreeze-catalyzed systems, in public energy infrastructure. They also oversee interstate energy transmission and ensure fair competition in energy markets.

State-level regulatory commissions further refine and implement these federal policies, adapting them to local needs and conditions. These commissions are responsible for approving new energy distribution technologies, setting utility rates, and ensuring the reliability and safety of energy systems within their jurisdictions. The integration of antifreeze-catalyzed models into existing energy distribution networks requires careful consideration and approval from these state-level bodies.

Environmental regulations also significantly impact the adoption of new energy distribution technologies. Agencies such as the Environmental Protection Agency (EPA) set standards for emissions, waste management, and environmental impact. Antifreeze-catalyzed systems must comply with these regulations, demonstrating their environmental benefits and addressing any potential ecological concerns.

Safety regulations form another critical component of the regulatory framework. Organizations like the Occupational Safety and Health Administration (OSHA) establish guidelines for worker safety in energy distribution facilities. The implementation of antifreeze-catalyzed systems must adhere to these safety standards, ensuring the protection of workers and the public.

The regulatory landscape also includes building codes and standards that govern the installation and operation of energy distribution systems in residential, commercial, and industrial settings. These codes, often developed by organizations like the International Code Council (ICC), must be updated to accommodate new technologies such as antifreeze-catalyzed systems.

As the energy sector evolves, regulatory frameworks must adapt to encourage innovation while maintaining safety and reliability. This requires a delicate balance between promoting technological advancements and ensuring public protection. Regulatory bodies are increasingly adopting performance-based standards rather than prescriptive rules, allowing for greater flexibility in implementing novel solutions like antifreeze-catalyzed distribution models.

At the federal level, regulatory bodies such as the Federal Energy Regulatory Commission (FERC) and the Department of Energy (DOE) establish overarching policies and standards for energy distribution. These agencies set guidelines for the use of innovative technologies, including antifreeze-catalyzed systems, in public energy infrastructure. They also oversee interstate energy transmission and ensure fair competition in energy markets.

State-level regulatory commissions further refine and implement these federal policies, adapting them to local needs and conditions. These commissions are responsible for approving new energy distribution technologies, setting utility rates, and ensuring the reliability and safety of energy systems within their jurisdictions. The integration of antifreeze-catalyzed models into existing energy distribution networks requires careful consideration and approval from these state-level bodies.

Environmental regulations also significantly impact the adoption of new energy distribution technologies. Agencies such as the Environmental Protection Agency (EPA) set standards for emissions, waste management, and environmental impact. Antifreeze-catalyzed systems must comply with these regulations, demonstrating their environmental benefits and addressing any potential ecological concerns.

Safety regulations form another critical component of the regulatory framework. Organizations like the Occupational Safety and Health Administration (OSHA) establish guidelines for worker safety in energy distribution facilities. The implementation of antifreeze-catalyzed systems must adhere to these safety standards, ensuring the protection of workers and the public.

The regulatory landscape also includes building codes and standards that govern the installation and operation of energy distribution systems in residential, commercial, and industrial settings. These codes, often developed by organizations like the International Code Council (ICC), must be updated to accommodate new technologies such as antifreeze-catalyzed systems.

As the energy sector evolves, regulatory frameworks must adapt to encourage innovation while maintaining safety and reliability. This requires a delicate balance between promoting technological advancements and ensuring public protection. Regulatory bodies are increasingly adopting performance-based standards rather than prescriptive rules, allowing for greater flexibility in implementing novel solutions like antifreeze-catalyzed distribution models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!