The Role of Antifreeze in Heat Transfer Systems

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Objectives

Antifreeze has played a crucial role in heat transfer systems since the early 20th century. The evolution of antifreeze technology has been driven by the need for more efficient and environmentally friendly solutions in various applications, particularly in automotive and industrial cooling systems.

The development of antifreeze began with the use of methanol and ethanol in the 1920s. These early solutions provided basic freeze protection but were highly flammable and corrosive. The 1930s saw the introduction of ethylene glycol-based antifreeze, which marked a significant improvement in terms of safety and effectiveness. This compound quickly became the industry standard due to its superior heat transfer properties and lower freezing point.

As environmental concerns grew in the latter half of the 20th century, researchers began exploring alternatives to ethylene glycol, which is toxic to humans and animals. This led to the development of propylene glycol-based antifreeze in the 1990s, offering a less toxic option for applications where environmental impact is a primary concern.

In recent years, the focus has shifted towards enhancing the performance of antifreeze solutions while minimizing their environmental footprint. Nanotechnology has emerged as a promising avenue for improving heat transfer efficiency. Researchers are exploring the addition of nanoparticles to traditional antifreeze formulations to create nanofluids with superior thermal conductivity.

The objectives of modern antifreeze technology extend beyond mere freeze protection. Current research aims to develop multifunctional coolants that offer improved heat transfer efficiency, corrosion protection, and longevity. There is also a growing emphasis on creating biodegradable and renewable antifreeze solutions to address environmental concerns.

Another key objective is the development of smart antifreeze systems that can adapt to changing conditions. These advanced formulations may incorporate phase-change materials or thermoresponsive polymers to optimize heat transfer across a wide range of temperatures.

As we look to the future, the goals for antifreeze technology include achieving higher energy efficiency in heat transfer systems, reducing the overall environmental impact of cooling processes, and extending the lifespan of equipment. Researchers are also exploring the potential of antifreeze solutions in emerging fields such as electric vehicle battery thermal management and data center cooling.

The evolution of antifreeze technology reflects a continuous effort to balance performance, safety, and environmental responsibility. As industries strive for greater sustainability and energy efficiency, the role of antifreeze in heat transfer systems will continue to evolve, driving innovation in materials science and thermal management strategies.

The development of antifreeze began with the use of methanol and ethanol in the 1920s. These early solutions provided basic freeze protection but were highly flammable and corrosive. The 1930s saw the introduction of ethylene glycol-based antifreeze, which marked a significant improvement in terms of safety and effectiveness. This compound quickly became the industry standard due to its superior heat transfer properties and lower freezing point.

As environmental concerns grew in the latter half of the 20th century, researchers began exploring alternatives to ethylene glycol, which is toxic to humans and animals. This led to the development of propylene glycol-based antifreeze in the 1990s, offering a less toxic option for applications where environmental impact is a primary concern.

In recent years, the focus has shifted towards enhancing the performance of antifreeze solutions while minimizing their environmental footprint. Nanotechnology has emerged as a promising avenue for improving heat transfer efficiency. Researchers are exploring the addition of nanoparticles to traditional antifreeze formulations to create nanofluids with superior thermal conductivity.

The objectives of modern antifreeze technology extend beyond mere freeze protection. Current research aims to develop multifunctional coolants that offer improved heat transfer efficiency, corrosion protection, and longevity. There is also a growing emphasis on creating biodegradable and renewable antifreeze solutions to address environmental concerns.

Another key objective is the development of smart antifreeze systems that can adapt to changing conditions. These advanced formulations may incorporate phase-change materials or thermoresponsive polymers to optimize heat transfer across a wide range of temperatures.

As we look to the future, the goals for antifreeze technology include achieving higher energy efficiency in heat transfer systems, reducing the overall environmental impact of cooling processes, and extending the lifespan of equipment. Researchers are also exploring the potential of antifreeze solutions in emerging fields such as electric vehicle battery thermal management and data center cooling.

The evolution of antifreeze technology reflects a continuous effort to balance performance, safety, and environmental responsibility. As industries strive for greater sustainability and energy efficiency, the role of antifreeze in heat transfer systems will continue to evolve, driving innovation in materials science and thermal management strategies.

Heat Transfer System Market Analysis

The heat transfer system market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, HVAC, and industrial processes. The global market size for heat transfer systems was valued at approximately $16.5 billion in 2020 and is projected to reach $23.2 billion by 2026, growing at a CAGR of 5.8% during the forecast period.

The automotive sector represents a substantial portion of the heat transfer system market, with the rising production of vehicles and the growing trend towards electric and hybrid vehicles contributing to increased demand. The HVAC industry also plays a crucial role in market growth, particularly in commercial and residential buildings, where energy efficiency and environmental regulations are driving the adoption of advanced heat transfer solutions.

In the context of antifreeze in heat transfer systems, the market has seen a shift towards more environmentally friendly and efficient solutions. Traditional ethylene glycol-based antifreeze products are gradually being replaced by propylene glycol and other organic alternatives due to their lower toxicity and improved performance characteristics. This trend is particularly evident in regions with stringent environmental regulations, such as Europe and North America.

The Asia-Pacific region is expected to witness the highest growth rate in the heat transfer system market, fueled by rapid industrialization, urbanization, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with a focus on technological advancements and energy-efficient solutions driving demand for innovative heat transfer systems and antifreeze products.

Key market players in the heat transfer system industry include Alfa Laval, Kelvion Holdings GmbH, SPX Corporation, and Danfoss A/S. These companies are investing heavily in research and development to improve the efficiency and sustainability of their products, with a particular emphasis on developing advanced antifreeze formulations that offer superior heat transfer properties and corrosion protection.

The COVID-19 pandemic has had a mixed impact on the heat transfer system market. While some sectors experienced temporary slowdowns due to supply chain disruptions and reduced industrial activity, others, such as the healthcare and food processing industries, saw increased demand for heat transfer solutions. As economies recover and industrial activities resume, the market is expected to regain its growth trajectory, with a renewed focus on energy-efficient and sustainable heat transfer technologies.

The automotive sector represents a substantial portion of the heat transfer system market, with the rising production of vehicles and the growing trend towards electric and hybrid vehicles contributing to increased demand. The HVAC industry also plays a crucial role in market growth, particularly in commercial and residential buildings, where energy efficiency and environmental regulations are driving the adoption of advanced heat transfer solutions.

In the context of antifreeze in heat transfer systems, the market has seen a shift towards more environmentally friendly and efficient solutions. Traditional ethylene glycol-based antifreeze products are gradually being replaced by propylene glycol and other organic alternatives due to their lower toxicity and improved performance characteristics. This trend is particularly evident in regions with stringent environmental regulations, such as Europe and North America.

The Asia-Pacific region is expected to witness the highest growth rate in the heat transfer system market, fueled by rapid industrialization, urbanization, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with a focus on technological advancements and energy-efficient solutions driving demand for innovative heat transfer systems and antifreeze products.

Key market players in the heat transfer system industry include Alfa Laval, Kelvion Holdings GmbH, SPX Corporation, and Danfoss A/S. These companies are investing heavily in research and development to improve the efficiency and sustainability of their products, with a particular emphasis on developing advanced antifreeze formulations that offer superior heat transfer properties and corrosion protection.

The COVID-19 pandemic has had a mixed impact on the heat transfer system market. While some sectors experienced temporary slowdowns due to supply chain disruptions and reduced industrial activity, others, such as the healthcare and food processing industries, saw increased demand for heat transfer solutions. As economies recover and industrial activities resume, the market is expected to regain its growth trajectory, with a renewed focus on energy-efficient and sustainable heat transfer technologies.

Antifreeze Technology Status and Challenges

Antifreeze technology in heat transfer systems has seen significant advancements in recent years, yet it still faces several challenges. The current state of antifreeze technology is characterized by a balance between performance, environmental impact, and cost-effectiveness. Traditional ethylene glycol-based antifreeze remains widely used due to its excellent heat transfer properties and low cost. However, concerns about its toxicity have led to increased adoption of propylene glycol-based alternatives, particularly in applications where environmental safety is paramount.

One of the primary challenges in antifreeze technology is the development of more environmentally friendly formulations without compromising performance. Researchers are exploring bio-based antifreeze solutions derived from renewable sources, such as glycerol from biodiesel production. These alternatives show promise in reducing the carbon footprint of heat transfer systems but currently lag behind traditional options in terms of thermal efficiency and freeze protection.

Corrosion inhibition remains a critical aspect of antifreeze technology. While modern formulations incorporate advanced corrosion inhibitors, the long-term effectiveness of these additives in diverse operating conditions is an ongoing concern. The increasing use of aluminum and other lightweight metals in heat exchangers has necessitated the development of more specialized corrosion protection strategies.

Another significant challenge is the optimization of heat transfer properties. Current antifreeze solutions, while effective, still introduce a thermal penalty compared to water alone. Researchers are investigating nanofluid additives and novel molecular structures to enhance thermal conductivity and heat capacity, potentially revolutionizing the efficiency of heat transfer systems.

The global distribution of antifreeze technology is uneven, with more advanced formulations and research concentrated in regions with harsh winter climates or developed automotive industries. North America, Europe, and parts of Asia lead in innovation and adoption of cutting-edge antifreeze technologies. However, emerging markets are rapidly catching up, driven by increasing industrialization and automotive sector growth.

Regulatory pressures present both a challenge and an opportunity for antifreeze technology. Stricter environmental regulations are pushing for the phase-out of toxic formulations, driving innovation in safer alternatives. However, navigating the complex landscape of international standards and regional requirements poses a significant hurdle for manufacturers and researchers alike.

Lastly, the integration of antifreeze technology with emerging trends in heat transfer systems, such as electric vehicle thermal management and renewable energy applications, presents new frontiers for innovation. Adapting antifreeze formulations to meet the unique demands of these evolving technologies is a key focus area for current research and development efforts.

One of the primary challenges in antifreeze technology is the development of more environmentally friendly formulations without compromising performance. Researchers are exploring bio-based antifreeze solutions derived from renewable sources, such as glycerol from biodiesel production. These alternatives show promise in reducing the carbon footprint of heat transfer systems but currently lag behind traditional options in terms of thermal efficiency and freeze protection.

Corrosion inhibition remains a critical aspect of antifreeze technology. While modern formulations incorporate advanced corrosion inhibitors, the long-term effectiveness of these additives in diverse operating conditions is an ongoing concern. The increasing use of aluminum and other lightweight metals in heat exchangers has necessitated the development of more specialized corrosion protection strategies.

Another significant challenge is the optimization of heat transfer properties. Current antifreeze solutions, while effective, still introduce a thermal penalty compared to water alone. Researchers are investigating nanofluid additives and novel molecular structures to enhance thermal conductivity and heat capacity, potentially revolutionizing the efficiency of heat transfer systems.

The global distribution of antifreeze technology is uneven, with more advanced formulations and research concentrated in regions with harsh winter climates or developed automotive industries. North America, Europe, and parts of Asia lead in innovation and adoption of cutting-edge antifreeze technologies. However, emerging markets are rapidly catching up, driven by increasing industrialization and automotive sector growth.

Regulatory pressures present both a challenge and an opportunity for antifreeze technology. Stricter environmental regulations are pushing for the phase-out of toxic formulations, driving innovation in safer alternatives. However, navigating the complex landscape of international standards and regional requirements poses a significant hurdle for manufacturers and researchers alike.

Lastly, the integration of antifreeze technology with emerging trends in heat transfer systems, such as electric vehicle thermal management and renewable energy applications, presents new frontiers for innovation. Adapting antifreeze formulations to meet the unique demands of these evolving technologies is a key focus area for current research and development efforts.

Current Antifreeze Formulations and Applications

01 Antifreeze compositions for heat transfer fluids

Development of specialized antifreeze compositions designed to enhance heat transfer efficiency in various systems. These formulations typically include a mixture of glycols, corrosion inhibitors, and other additives to improve thermal conductivity and prevent freezing at low temperatures.- Antifreeze compositions for heat transfer fluids: Development of antifreeze compositions specifically designed for heat transfer applications. These compositions typically include a base fluid, such as ethylene glycol or propylene glycol, combined with various additives to enhance thermal properties, prevent corrosion, and improve overall performance in heating and cooling systems.

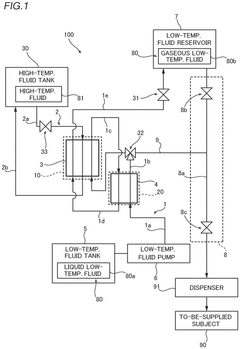

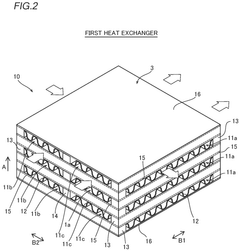

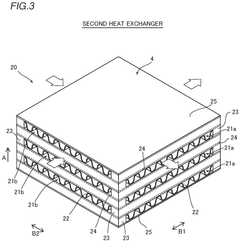

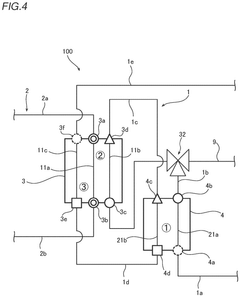

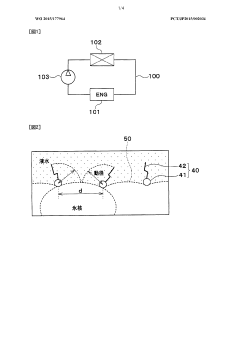

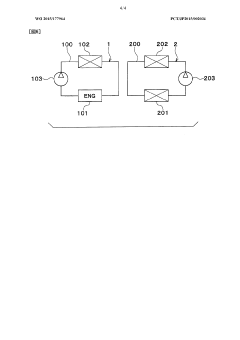

- Heat transfer systems utilizing antifreeze solutions: Design and implementation of heat transfer systems that incorporate antifreeze solutions. These systems are engineered to efficiently transfer heat while preventing freezing in low-temperature environments. They may include specialized components such as heat exchangers, pumps, and control mechanisms optimized for use with antifreeze fluids.

- Eco-friendly and biodegradable antifreeze formulations: Development of environmentally friendly antifreeze formulations that maintain effective heat transfer properties while reducing environmental impact. These formulations may utilize bio-based materials, natural additives, or easily biodegradable components to achieve both performance and sustainability goals.

- Nanofluid-based antifreeze solutions for enhanced heat transfer: Incorporation of nanoparticles into antifreeze solutions to improve heat transfer efficiency. These nanofluids can enhance thermal conductivity, specific heat capacity, and overall heat transfer performance compared to traditional antifreeze formulations.

- Antifreeze heat transfer systems for specific applications: Specialized antifreeze heat transfer solutions designed for particular industries or applications, such as automotive cooling systems, HVAC systems, industrial processes, or renewable energy installations. These tailored solutions address unique requirements and operating conditions specific to each application.

02 Heat exchange systems utilizing antifreeze solutions

Design and implementation of heat exchange systems that incorporate antifreeze solutions for improved thermal management. These systems may include specialized components and configurations to optimize heat transfer while preventing freezing and corrosion.Expand Specific Solutions03 Environmentally friendly antifreeze formulations

Development of eco-friendly antifreeze solutions that maintain effective heat transfer properties while reducing environmental impact. These formulations may utilize biodegradable materials or renewable resources as alternatives to traditional glycol-based antifreezes.Expand Specific Solutions04 Nanofluid-based antifreeze for enhanced heat transfer

Incorporation of nanoparticles into antifreeze solutions to improve thermal conductivity and heat transfer efficiency. These advanced formulations can potentially offer superior performance compared to conventional antifreeze fluids in various applications.Expand Specific Solutions05 Antifreeze heat transfer systems for specific applications

Development of specialized antifreeze heat transfer solutions tailored for specific industries or applications, such as automotive, HVAC, or industrial processes. These systems may incorporate unique design features or formulations to address the particular requirements of each application.Expand Specific Solutions

Key Antifreeze Manufacturers and Suppliers

The antifreeze market in heat transfer systems is in a mature stage, with a global market size estimated to be over $5 billion. The technology is well-established, with major players like Prestone Products Corp., Honeywell International Technologies Ltd., and Arkema France SA offering advanced formulations. These companies have developed proprietary blends that provide superior heat transfer properties and corrosion protection. Emerging trends include the development of environmentally-friendly and biodegradable antifreeze solutions, driven by increasing environmental regulations. Companies like DENSO Corp. and Nissan Motor Co., Ltd. are also investing in research to improve antifreeze performance for electric vehicle battery thermal management systems, indicating potential growth opportunities in this sector.

Prestone Products Corp.

Technical Solution: Prestone Products Corp. has developed advanced antifreeze formulations specifically designed for modern heat transfer systems. Their technology focuses on organic acid technology (OAT) based coolants, which offer extended life and improved heat transfer efficiency[1]. These formulations contain corrosion inhibitors that form a thin, protective layer on metal surfaces, preventing rust and scale buildup. Prestone's antifreeze solutions also incorporate additives that enhance thermal conductivity, allowing for more efficient heat dissipation in both automotive and industrial applications[2]. The company has invested in research to optimize the balance between freezing point depression and boiling point elevation, ensuring optimal performance across a wide temperature range.

Strengths: Long-lasting protection, improved heat transfer efficiency, and broad temperature range effectiveness. Weaknesses: Potentially higher initial cost compared to conventional antifreeze products.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed innovative heat transfer fluids for various applications, including their Genetron® series for refrigeration and air conditioning systems. Their antifreeze solutions incorporate advanced corrosion inhibitors and thermal stability enhancers[3]. Honeywell's technology focuses on environmentally friendly formulations with low global warming potential (GWP) and improved energy efficiency. They have also introduced phase-change materials (PCMs) in some of their heat transfer solutions, allowing for better temperature control and energy storage capabilities[4]. Honeywell's research extends to nanofluid-based antifreeze solutions, which have shown promising results in enhancing thermal conductivity and heat transfer coefficients in experimental settings.

Strengths: Environmentally friendly formulations, advanced thermal management capabilities. Weaknesses: Some solutions may require specialized handling or equipment.

Innovative Antifreeze Compounds and Properties

Heat exchange system

PatentPendingEP4502525A1

Innovation

- A heat exchange system comprising a first heat exchanger for transferring heat between a low-temperature fluid and a high-temperature fluid, a second heat exchanger for transferring heat between flows of the low-temperature fluid, and a heater to heat the low-temperature fluid before it enters the first heat exchanger, thereby reducing the temperature difference and preventing the high-temperature fluid from freezing.

Heat transport system

PatentWO2015177964A1

Innovation

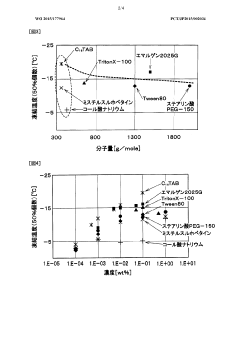

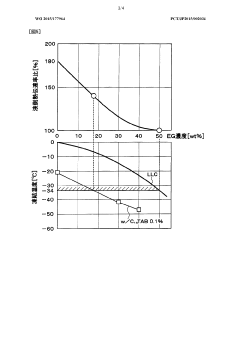

- A heat transport system employing a solvent-based heat transfer medium with specific solutes that selectively interact with the solid-liquid interface to inhibit ice nucleus growth, delaying freezing without the need for supercooling or ethylene glycol, thereby maintaining antifreeze properties and thermophysical integrity.

Environmental Impact of Antifreeze Solutions

The environmental impact of antifreeze solutions in heat transfer systems is a critical consideration for both manufacturers and end-users. Traditional antifreeze formulations, primarily based on ethylene glycol or propylene glycol, have raised concerns due to their potential ecological hazards and long-term environmental persistence.

One of the primary environmental risks associated with antifreeze solutions is groundwater contamination. When improperly disposed of or leaked, these chemicals can seep into soil and water systems, potentially affecting aquatic ecosystems and drinking water sources. Ethylene glycol, in particular, is known for its toxicity to wildlife and humans if ingested, posing a significant threat to local fauna and water quality.

Air pollution is another environmental concern linked to antifreeze use. During the production and disposal processes of antifreeze solutions, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban and industrial areas where heat transfer systems are prevalent.

The manufacturing of antifreeze solutions also carries an environmental footprint. The production process requires significant energy inputs and may involve the use of petrochemical-derived materials, contributing to carbon emissions and resource depletion. Additionally, the packaging and transportation of antifreeze products further add to their overall environmental impact through increased carbon footprint and plastic waste generation.

In response to these environmental challenges, there has been a growing trend towards the development of more eco-friendly antifreeze alternatives. Bio-based antifreeze solutions, derived from renewable resources such as corn or soy, are gaining traction in the market. These products offer improved biodegradability and reduced toxicity compared to their traditional counterparts, potentially mitigating some of the environmental risks associated with antifreeze use.

Recycling and proper disposal programs for used antifreeze have also emerged as crucial strategies for minimizing environmental impact. Many jurisdictions now require specialized handling and recycling of antifreeze to prevent improper disposal and reduce the risk of environmental contamination. These initiatives aim to create a closed-loop system where antifreeze can be reprocessed and reused, reducing the demand for new production and associated environmental costs.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing antifreeze formulations with reduced environmental impact. This includes research into non-toxic additives, improved biodegradability, and enhanced thermal efficiency to minimize the overall volume of antifreeze required in heat transfer systems. The push towards more sustainable antifreeze solutions reflects a broader industry trend of prioritizing environmental stewardship in industrial processes and product design.

One of the primary environmental risks associated with antifreeze solutions is groundwater contamination. When improperly disposed of or leaked, these chemicals can seep into soil and water systems, potentially affecting aquatic ecosystems and drinking water sources. Ethylene glycol, in particular, is known for its toxicity to wildlife and humans if ingested, posing a significant threat to local fauna and water quality.

Air pollution is another environmental concern linked to antifreeze use. During the production and disposal processes of antifreeze solutions, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban and industrial areas where heat transfer systems are prevalent.

The manufacturing of antifreeze solutions also carries an environmental footprint. The production process requires significant energy inputs and may involve the use of petrochemical-derived materials, contributing to carbon emissions and resource depletion. Additionally, the packaging and transportation of antifreeze products further add to their overall environmental impact through increased carbon footprint and plastic waste generation.

In response to these environmental challenges, there has been a growing trend towards the development of more eco-friendly antifreeze alternatives. Bio-based antifreeze solutions, derived from renewable resources such as corn or soy, are gaining traction in the market. These products offer improved biodegradability and reduced toxicity compared to their traditional counterparts, potentially mitigating some of the environmental risks associated with antifreeze use.

Recycling and proper disposal programs for used antifreeze have also emerged as crucial strategies for minimizing environmental impact. Many jurisdictions now require specialized handling and recycling of antifreeze to prevent improper disposal and reduce the risk of environmental contamination. These initiatives aim to create a closed-loop system where antifreeze can be reprocessed and reused, reducing the demand for new production and associated environmental costs.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing antifreeze formulations with reduced environmental impact. This includes research into non-toxic additives, improved biodegradability, and enhanced thermal efficiency to minimize the overall volume of antifreeze required in heat transfer systems. The push towards more sustainable antifreeze solutions reflects a broader industry trend of prioritizing environmental stewardship in industrial processes and product design.

Antifreeze Safety Regulations and Standards

The safety regulations and standards governing antifreeze in heat transfer systems are crucial for ensuring the protection of both human health and the environment. These regulations typically cover various aspects, including the composition, handling, storage, and disposal of antifreeze solutions.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating antifreeze. The EPA has established guidelines for the proper disposal of used antifreeze, classifying it as a hazardous waste due to its potential toxicity. Many states have implemented additional regulations, requiring antifreeze to be recycled or disposed of through authorized facilities.

The Occupational Safety and Health Administration (OSHA) has set standards for workplace safety related to antifreeze handling. These standards mandate proper labeling, personal protective equipment usage, and safe handling procedures to minimize exposure risks for workers.

Internationally, the European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to antifreeze components. This regulation ensures that manufacturers and importers assess and manage the risks associated with the chemicals used in antifreeze formulations.

Product safety standards, such as those developed by ASTM International, provide specifications for antifreeze and coolant quality. These standards define the physical and chemical properties that antifreeze must meet to ensure optimal performance and safety in heat transfer systems.

Many countries have adopted regulations limiting the use of certain antifreeze components, particularly ethylene glycol, due to its toxicity. There is a growing trend towards promoting the use of less toxic alternatives, such as propylene glycol-based antifreeze, especially in applications where there is a risk of human or animal exposure.

The transportation of antifreeze is subject to regulations set by agencies like the Department of Transportation (DOT) in the US and similar bodies in other countries. These regulations cover packaging, labeling, and shipping requirements to prevent spills and ensure safe transport.

As environmental concerns grow, there is an increasing focus on developing biodegradable antifreeze solutions. Regulatory bodies are encouraging research and development in this area, with some countries offering incentives for the use of more environmentally friendly antifreeze formulations.

Compliance with these regulations and standards is essential for manufacturers, distributors, and end-users of antifreeze in heat transfer systems. Regular updates to these regulations reflect ongoing research into the environmental and health impacts of antifreeze, as well as advancements in technology and safety practices in the industry.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating antifreeze. The EPA has established guidelines for the proper disposal of used antifreeze, classifying it as a hazardous waste due to its potential toxicity. Many states have implemented additional regulations, requiring antifreeze to be recycled or disposed of through authorized facilities.

The Occupational Safety and Health Administration (OSHA) has set standards for workplace safety related to antifreeze handling. These standards mandate proper labeling, personal protective equipment usage, and safe handling procedures to minimize exposure risks for workers.

Internationally, the European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to antifreeze components. This regulation ensures that manufacturers and importers assess and manage the risks associated with the chemicals used in antifreeze formulations.

Product safety standards, such as those developed by ASTM International, provide specifications for antifreeze and coolant quality. These standards define the physical and chemical properties that antifreeze must meet to ensure optimal performance and safety in heat transfer systems.

Many countries have adopted regulations limiting the use of certain antifreeze components, particularly ethylene glycol, due to its toxicity. There is a growing trend towards promoting the use of less toxic alternatives, such as propylene glycol-based antifreeze, especially in applications where there is a risk of human or animal exposure.

The transportation of antifreeze is subject to regulations set by agencies like the Department of Transportation (DOT) in the US and similar bodies in other countries. These regulations cover packaging, labeling, and shipping requirements to prevent spills and ensure safe transport.

As environmental concerns grow, there is an increasing focus on developing biodegradable antifreeze solutions. Regulatory bodies are encouraging research and development in this area, with some countries offering incentives for the use of more environmentally friendly antifreeze formulations.

Compliance with these regulations and standards is essential for manufacturers, distributors, and end-users of antifreeze in heat transfer systems. Regular updates to these regulations reflect ongoing research into the environmental and health impacts of antifreeze, as well as advancements in technology and safety practices in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!