Antifreeze in Rapid Advancement of Resourceful Engineering Targets

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Tech Evolution

The evolution of antifreeze technology in the context of rapid advancement of resourceful engineering targets has been marked by significant milestones and innovations. Initially, the focus was on simple salt-based solutions, primarily using sodium chloride, which effectively lowered the freezing point of water but posed corrosion risks to metal components.

As engineering demands grew more sophisticated, the 1930s saw the introduction of ethylene glycol-based antifreeze. This breakthrough offered superior freeze protection and higher boiling points, addressing the dual challenges of cold starts and engine overheating. The adoption of ethylene glycol marked a pivotal shift in antifreeze technology, setting the stage for decades of refinement.

The 1960s and 1970s brought increased awareness of environmental concerns, leading to the development of propylene glycol-based antifreeze. This less toxic alternative gained traction in applications where environmental impact and safety were paramount, such as food processing and pharmaceutical industries.

Advancements in polymer science in the 1980s and 1990s led to the creation of extended-life antifreeze formulations. These products incorporated organic acid technology (OAT) and hybrid organic acid technology (HOAT), significantly extending service intervals and reducing maintenance requirements for cooling systems.

The turn of the millennium saw a surge in nanotechnology applications in antifreeze. Nanofluids, containing suspended nanoparticles, demonstrated enhanced heat transfer properties and improved freeze protection. This innovation opened new possibilities for more efficient cooling systems in various engineering applications.

Recent years have witnessed a focus on biodegradable and renewable antifreeze solutions. Bio-based glycols derived from agricultural feedstocks are being explored as sustainable alternatives to petroleum-based products. These eco-friendly options aim to reduce the carbon footprint of antifreeze production and usage.

The latest frontier in antifreeze technology involves smart materials and adaptive formulations. Research is underway to develop antifreeze solutions that can dynamically adjust their properties based on environmental conditions, potentially revolutionizing thermal management in extreme environments.

As engineering targets become more ambitious and resource-conscious, antifreeze technology continues to evolve. Current efforts are directed towards developing multi-functional antifreeze solutions that not only prevent freezing but also offer enhanced lubrication, corrosion protection, and even self-healing properties for damaged systems.

As engineering demands grew more sophisticated, the 1930s saw the introduction of ethylene glycol-based antifreeze. This breakthrough offered superior freeze protection and higher boiling points, addressing the dual challenges of cold starts and engine overheating. The adoption of ethylene glycol marked a pivotal shift in antifreeze technology, setting the stage for decades of refinement.

The 1960s and 1970s brought increased awareness of environmental concerns, leading to the development of propylene glycol-based antifreeze. This less toxic alternative gained traction in applications where environmental impact and safety were paramount, such as food processing and pharmaceutical industries.

Advancements in polymer science in the 1980s and 1990s led to the creation of extended-life antifreeze formulations. These products incorporated organic acid technology (OAT) and hybrid organic acid technology (HOAT), significantly extending service intervals and reducing maintenance requirements for cooling systems.

The turn of the millennium saw a surge in nanotechnology applications in antifreeze. Nanofluids, containing suspended nanoparticles, demonstrated enhanced heat transfer properties and improved freeze protection. This innovation opened new possibilities for more efficient cooling systems in various engineering applications.

Recent years have witnessed a focus on biodegradable and renewable antifreeze solutions. Bio-based glycols derived from agricultural feedstocks are being explored as sustainable alternatives to petroleum-based products. These eco-friendly options aim to reduce the carbon footprint of antifreeze production and usage.

The latest frontier in antifreeze technology involves smart materials and adaptive formulations. Research is underway to develop antifreeze solutions that can dynamically adjust their properties based on environmental conditions, potentially revolutionizing thermal management in extreme environments.

As engineering targets become more ambitious and resource-conscious, antifreeze technology continues to evolve. Current efforts are directed towards developing multi-functional antifreeze solutions that not only prevent freezing but also offer enhanced lubrication, corrosion protection, and even self-healing properties for damaged systems.

Market Demand Analysis

The market demand for antifreeze solutions in rapid engineering applications has been steadily growing, driven by the increasing need for efficient and reliable operations in extreme temperature conditions. This demand spans across various industries, including construction, mining, oil and gas, and aerospace, where equipment and materials must function optimally in cold environments.

In the construction sector, there is a rising demand for antifreeze admixtures in concrete, particularly in regions with harsh winters or for projects that require year-round construction activities. These admixtures allow concrete to be poured and cured at temperatures below freezing, extending the construction season and improving project timelines. The global market for concrete admixtures, including antifreeze solutions, is projected to grow significantly in the coming years.

The mining industry also presents a substantial market for antifreeze technologies, especially in regions with extreme cold climates such as Canada, Russia, and Scandinavia. As mining operations expand into more remote and challenging environments, the need for equipment and materials that can withstand sub-zero temperatures becomes critical. This includes antifreeze solutions for drilling fluids, hydraulic systems, and other mining equipment.

In the oil and gas sector, the exploration and production activities in Arctic regions have created a niche market for specialized antifreeze products. These are essential for maintaining the flow of oil and gas through pipelines, preventing equipment failures, and ensuring the safety of personnel working in extreme cold conditions. The growing interest in Arctic oil and gas reserves is expected to further drive the demand for advanced antifreeze solutions in this sector.

The aerospace industry represents another significant market for antifreeze technologies, particularly in de-icing and anti-icing systems for aircraft. As air travel continues to grow globally, and as airlines seek to operate in a wider range of weather conditions, the demand for more effective and environmentally friendly de-icing solutions is increasing. This includes both ground-based de-icing systems and in-flight anti-icing technologies.

Furthermore, the automotive industry continues to be a major consumer of antifreeze products, with a growing emphasis on developing more efficient and environmentally friendly formulations. As electric vehicles gain market share, there is an emerging demand for specialized antifreeze solutions tailored to the unique cooling requirements of electric powertrains and battery systems.

The market for antifreeze solutions is also being shaped by environmental concerns and regulatory pressures. There is a growing demand for bio-based and less toxic antifreeze formulations that offer comparable performance to traditional products while reducing environmental impact. This trend is driving innovation in the sector and opening up new market opportunities for eco-friendly antifreeze solutions across various industries.

In the construction sector, there is a rising demand for antifreeze admixtures in concrete, particularly in regions with harsh winters or for projects that require year-round construction activities. These admixtures allow concrete to be poured and cured at temperatures below freezing, extending the construction season and improving project timelines. The global market for concrete admixtures, including antifreeze solutions, is projected to grow significantly in the coming years.

The mining industry also presents a substantial market for antifreeze technologies, especially in regions with extreme cold climates such as Canada, Russia, and Scandinavia. As mining operations expand into more remote and challenging environments, the need for equipment and materials that can withstand sub-zero temperatures becomes critical. This includes antifreeze solutions for drilling fluids, hydraulic systems, and other mining equipment.

In the oil and gas sector, the exploration and production activities in Arctic regions have created a niche market for specialized antifreeze products. These are essential for maintaining the flow of oil and gas through pipelines, preventing equipment failures, and ensuring the safety of personnel working in extreme cold conditions. The growing interest in Arctic oil and gas reserves is expected to further drive the demand for advanced antifreeze solutions in this sector.

The aerospace industry represents another significant market for antifreeze technologies, particularly in de-icing and anti-icing systems for aircraft. As air travel continues to grow globally, and as airlines seek to operate in a wider range of weather conditions, the demand for more effective and environmentally friendly de-icing solutions is increasing. This includes both ground-based de-icing systems and in-flight anti-icing technologies.

Furthermore, the automotive industry continues to be a major consumer of antifreeze products, with a growing emphasis on developing more efficient and environmentally friendly formulations. As electric vehicles gain market share, there is an emerging demand for specialized antifreeze solutions tailored to the unique cooling requirements of electric powertrains and battery systems.

The market for antifreeze solutions is also being shaped by environmental concerns and regulatory pressures. There is a growing demand for bio-based and less toxic antifreeze formulations that offer comparable performance to traditional products while reducing environmental impact. This trend is driving innovation in the sector and opening up new market opportunities for eco-friendly antifreeze solutions across various industries.

Current Challenges

The field of antifreeze research for rapid advancement of resourceful engineering targets faces several significant challenges. One of the primary obstacles is the development of antifreeze solutions that can effectively function across a wide range of temperatures without compromising the structural integrity or performance of engineering materials. Current antifreeze formulations often struggle to maintain their efficacy in extreme cold conditions, particularly in applications involving advanced materials used in aerospace, automotive, and energy sectors.

Another critical challenge lies in the environmental impact of traditional antifreeze compounds. Many conventional antifreeze solutions contain toxic chemicals that pose significant risks to ecosystems and human health. As environmental regulations become increasingly stringent, there is a pressing need to develop eco-friendly alternatives that offer comparable or superior performance without the associated environmental hazards.

The rapid pace of technological advancement in engineering also presents a unique challenge for antifreeze research. As new materials and technologies emerge, antifreeze solutions must evolve to meet the specific requirements of these innovations. This necessitates a continuous cycle of research and development to ensure compatibility and effectiveness with cutting-edge engineering materials and systems.

Furthermore, the scalability of antifreeze production for large-scale industrial applications remains a significant hurdle. While some promising antifreeze compounds have shown excellent results in laboratory settings, translating these successes into cost-effective, mass-producible solutions for real-world applications has proven challenging. This gap between research findings and practical implementation continues to be a major obstacle in the field.

The multidisciplinary nature of antifreeze research also presents challenges in terms of collaboration and knowledge integration. Effective solutions often require expertise from diverse fields such as materials science, chemistry, biology, and engineering. Coordinating research efforts across these disciplines and ensuring effective communication and knowledge transfer can be complex and time-consuming.

Lastly, the development of smart or adaptive antifreeze systems that can respond dynamically to changing environmental conditions represents a frontier challenge in the field. Such systems would need to incorporate advanced sensing technologies and responsive materials, pushing the boundaries of current scientific and engineering capabilities. Overcoming these challenges will be crucial for advancing the field of antifreeze research and meeting the evolving needs of resourceful engineering targets in rapidly advancing technological landscapes.

Another critical challenge lies in the environmental impact of traditional antifreeze compounds. Many conventional antifreeze solutions contain toxic chemicals that pose significant risks to ecosystems and human health. As environmental regulations become increasingly stringent, there is a pressing need to develop eco-friendly alternatives that offer comparable or superior performance without the associated environmental hazards.

The rapid pace of technological advancement in engineering also presents a unique challenge for antifreeze research. As new materials and technologies emerge, antifreeze solutions must evolve to meet the specific requirements of these innovations. This necessitates a continuous cycle of research and development to ensure compatibility and effectiveness with cutting-edge engineering materials and systems.

Furthermore, the scalability of antifreeze production for large-scale industrial applications remains a significant hurdle. While some promising antifreeze compounds have shown excellent results in laboratory settings, translating these successes into cost-effective, mass-producible solutions for real-world applications has proven challenging. This gap between research findings and practical implementation continues to be a major obstacle in the field.

The multidisciplinary nature of antifreeze research also presents challenges in terms of collaboration and knowledge integration. Effective solutions often require expertise from diverse fields such as materials science, chemistry, biology, and engineering. Coordinating research efforts across these disciplines and ensuring effective communication and knowledge transfer can be complex and time-consuming.

Lastly, the development of smart or adaptive antifreeze systems that can respond dynamically to changing environmental conditions represents a frontier challenge in the field. Such systems would need to incorporate advanced sensing technologies and responsive materials, pushing the boundaries of current scientific and engineering capabilities. Overcoming these challenges will be crucial for advancing the field of antifreeze research and meeting the evolving needs of resourceful engineering targets in rapidly advancing technological landscapes.

Existing Solutions

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and chemicals such as ethylene glycol or propylene glycol. These solutions lower the freezing point of water and raise its boiling point, providing protection against both freezing and overheating in various applications, including automotive cooling systems.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and chemicals such as ethylene glycol or propylene glycol. These solutions lower the freezing point of water and raise its boiling point, making them effective in preventing freezing in automotive cooling systems and other applications. Additives may be included to enhance corrosion protection and improve heat transfer properties.

- Environmentally friendly antifreeze formulations: Development of eco-friendly antifreeze solutions using biodegradable materials or renewable resources. These formulations aim to reduce environmental impact while maintaining effective freeze protection. They may incorporate plant-based glycols or other natural compounds as alternatives to traditional petroleum-based ingredients.

- Antifreeze recycling and purification methods: Techniques for recycling used antifreeze to reduce waste and environmental impact. These methods involve removing contaminants, adjusting chemical composition, and restoring the antifreeze to its original effectiveness. Purification processes may include filtration, distillation, or chemical treatments to remove impurities and extend the life of the antifreeze.

- Antifreeze applications in non-automotive industries: Use of antifreeze solutions in various industries beyond automotive, such as HVAC systems, solar panels, and industrial processes. These applications may require specialized formulations to meet specific requirements for temperature range, compatibility with materials, or regulatory compliance.

- Antifreeze testing and quality control methods: Development of techniques for testing antifreeze properties and ensuring quality control in production. These methods may include measuring freezing point depression, boiling point elevation, corrosion protection, and other key performance indicators. Advanced analytical tools and standardized testing procedures are employed to maintain consistent product quality.

02 Environmentally friendly antifreeze formulations

Development of eco-friendly antifreeze formulations that reduce environmental impact and toxicity. These may include biodegradable components, natural additives, or alternative chemicals that provide similar antifreeze properties with less harm to the environment.Expand Specific Solutions03 Antifreeze recycling and purification methods

Techniques for recycling and purifying used antifreeze to extend its lifespan and reduce waste. This may involve filtration, chemical treatment, or other processes to remove contaminants and restore the antifreeze to a usable condition.Expand Specific Solutions04 Antifreeze additives for enhanced performance

Incorporation of additives into antifreeze formulations to improve performance characteristics such as corrosion inhibition, heat transfer efficiency, and long-term stability. These additives can extend the life of cooling systems and improve overall antifreeze effectiveness.Expand Specific Solutions05 Application-specific antifreeze solutions

Development of specialized antifreeze formulations tailored for specific applications beyond automotive use, such as industrial processes, renewable energy systems, or extreme temperature environments. These solutions may have unique properties or compositions to meet specific requirements of different industries or operating conditions.Expand Specific Solutions

Key Industry Players

The research on antifreeze in rapid advancement of resourceful engineering targets is in a nascent stage, with the market showing significant growth potential. The technology is still evolving, with varying levels of maturity across different applications. Companies like BASF Corp., Kaneka Corp., and Clariant Produkte (Deutschland) GmbH are leading the charge in developing innovative antifreeze solutions. Academic institutions such as Arizona State University and Massachusetts Institute of Technology are contributing to fundamental research. The competitive landscape is diverse, with both established chemical companies and emerging startups vying for market share. As the technology matures, we can expect increased collaboration between industry and academia, driving further advancements in this field.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced antifreeze solutions for rapid engineering applications. Their research focuses on creating environmentally friendly and highly efficient antifreeze formulations. BASF's latest antifreeze technology incorporates nano-additives that enhance heat transfer properties, allowing for faster cooling and improved performance in extreme conditions[1]. The company has also introduced bio-based antifreeze products, derived from renewable resources, which offer comparable performance to traditional petroleum-based solutions while reducing environmental impact[2]. BASF's antifreeze solutions are designed to provide extended protection against corrosion and cavitation, ensuring longer equipment life in various industrial applications[3].

Strengths: Industry-leading research capabilities, eco-friendly formulations, and enhanced heat transfer properties. Weaknesses: Potentially higher costs compared to traditional antifreeze solutions and limited field testing data for newer formulations.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have made significant advancements in antifreeze technology for rapid engineering applications. They have developed a novel antifreeze protein-based solution that mimics the natural antifreeze properties found in certain fish species[4]. This biomimetic approach allows for more effective ice crystal inhibition at lower concentrations compared to traditional antifreeze chemicals. MIT's research also includes the development of smart antifreeze materials that can respond to temperature changes, providing adaptive protection in varying environmental conditions[5]. Additionally, their work on nanostructured surfaces has led to the creation of ice-phobic coatings that can significantly reduce ice formation and adhesion in critical engineering systems[6].

Strengths: Cutting-edge biomimetic solutions, adaptive smart materials, and innovative ice-phobic coatings. Weaknesses: Potential scalability issues for mass production and higher costs associated with advanced technologies.

Core Innovations

Antifreeze

PatentInactiveUS6881355B2

Innovation

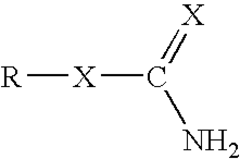

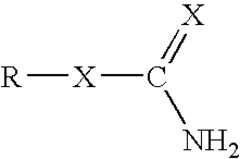

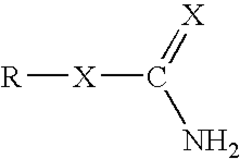

- An antifreeze concentrate combining sulfonated or sulfated polyglycols, carbamates, amines, and triazoles, along with other additives, is used to create a novel aqueous cooling medium that enhances corrosion inhibition in magnesium and aluminum alloys, maintaining effective heat transfer without excessive material deposition.

Plant extract containing antifreeze substance and method for producing same

PatentInactiveUS20110278492A1

Innovation

- Improving antifreeze activity by drying plants and using adsorbents to selectively remove unwanted matter from plant extracts, thereby enhancing purification and reducing costs, using methods like freeze-drying, through-flow drying, and treating extracts with adsorbents such as activated carbon.

Environmental Impact

The environmental impact of antifreeze research and development in rapid advancement of resourceful engineering targets is a critical aspect that demands thorough consideration. The use of antifreeze compounds, while essential for various engineering applications, can have significant implications for ecosystems and natural resources.

One of the primary environmental concerns associated with antifreeze is its potential for contamination of soil and water systems. Traditional antifreeze formulations often contain ethylene glycol or propylene glycol, which can be toxic to plants, animals, and microorganisms if released into the environment. When these substances leach into groundwater or surface water, they can disrupt aquatic ecosystems and pose risks to wildlife.

Furthermore, the production and disposal of antifreeze materials contribute to the overall environmental footprint of engineering projects. The manufacturing process of antifreeze compounds typically involves energy-intensive operations and the use of petrochemical-based raw materials, which can lead to increased carbon emissions and resource depletion.

To address these environmental challenges, researchers are exploring more sustainable alternatives to conventional antifreeze formulations. Bio-based antifreeze solutions derived from renewable resources, such as plant extracts or agricultural by-products, are gaining attention as potential eco-friendly options. These alternatives aim to reduce the reliance on fossil fuel-derived ingredients and minimize the environmental impact of antifreeze production.

Additionally, advancements in antifreeze technology are focusing on improving the biodegradability and recyclability of these materials. Developing antifreeze compounds that can be easily broken down by natural processes or efficiently recovered and reused can significantly reduce their long-term environmental impact. This approach aligns with the principles of circular economy and sustainable resource management.

The environmental impact of antifreeze research also extends to its role in enhancing the efficiency and durability of engineering systems. By improving the performance of machinery and infrastructure in extreme temperature conditions, effective antifreeze solutions can indirectly contribute to reduced energy consumption and extended equipment lifespan. This, in turn, can lead to decreased resource utilization and waste generation over time.

As the field of antifreeze research continues to evolve, it is crucial to prioritize environmental considerations alongside technical performance. Integrating life cycle assessments and environmental impact studies into the research and development process can help identify potential ecological risks and guide the development of more sustainable antifreeze technologies. By balancing technological advancements with environmental stewardship, the rapid advancement of resourceful engineering targets can be achieved in a manner that minimizes negative impacts on the planet's ecosystems.

One of the primary environmental concerns associated with antifreeze is its potential for contamination of soil and water systems. Traditional antifreeze formulations often contain ethylene glycol or propylene glycol, which can be toxic to plants, animals, and microorganisms if released into the environment. When these substances leach into groundwater or surface water, they can disrupt aquatic ecosystems and pose risks to wildlife.

Furthermore, the production and disposal of antifreeze materials contribute to the overall environmental footprint of engineering projects. The manufacturing process of antifreeze compounds typically involves energy-intensive operations and the use of petrochemical-based raw materials, which can lead to increased carbon emissions and resource depletion.

To address these environmental challenges, researchers are exploring more sustainable alternatives to conventional antifreeze formulations. Bio-based antifreeze solutions derived from renewable resources, such as plant extracts or agricultural by-products, are gaining attention as potential eco-friendly options. These alternatives aim to reduce the reliance on fossil fuel-derived ingredients and minimize the environmental impact of antifreeze production.

Additionally, advancements in antifreeze technology are focusing on improving the biodegradability and recyclability of these materials. Developing antifreeze compounds that can be easily broken down by natural processes or efficiently recovered and reused can significantly reduce their long-term environmental impact. This approach aligns with the principles of circular economy and sustainable resource management.

The environmental impact of antifreeze research also extends to its role in enhancing the efficiency and durability of engineering systems. By improving the performance of machinery and infrastructure in extreme temperature conditions, effective antifreeze solutions can indirectly contribute to reduced energy consumption and extended equipment lifespan. This, in turn, can lead to decreased resource utilization and waste generation over time.

As the field of antifreeze research continues to evolve, it is crucial to prioritize environmental considerations alongside technical performance. Integrating life cycle assessments and environmental impact studies into the research and development process can help identify potential ecological risks and guide the development of more sustainable antifreeze technologies. By balancing technological advancements with environmental stewardship, the rapid advancement of resourceful engineering targets can be achieved in a manner that minimizes negative impacts on the planet's ecosystems.

Regulatory Framework

The regulatory framework surrounding antifreeze research and development in the context of rapid advancement of resourceful engineering targets is complex and multifaceted. It encompasses various levels of governance, from international agreements to national and local regulations, all aimed at ensuring safety, environmental protection, and ethical practices in this field.

At the international level, several treaties and conventions influence antifreeze research. The Montreal Protocol, for instance, regulates substances that deplete the ozone layer, which may impact certain antifreeze formulations. Similarly, the Stockholm Convention on Persistent Organic Pollutants affects the development of antifreeze solutions that might contain harmful chemicals.

National regulatory bodies play a crucial role in overseeing antifreeze research and development. In the United States, the Environmental Protection Agency (EPA) regulates antifreeze under the Toxic Substances Control Act (TSCA). The EPA mandates specific labeling requirements, disposal guidelines, and reporting of new chemical substances used in antifreeze formulations.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to antifreeze components. These regulations require manufacturers and importers to register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment.

Occupational safety regulations also impact antifreeze research. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) set standards for handling and exposure to potentially hazardous substances used in antifreeze development.

Environmental regulations are particularly relevant to antifreeze research. Many countries have implemented strict guidelines for the disposal of antifreeze solutions to prevent groundwater contamination. For example, the Resource Conservation and Recovery Act (RCRA) in the US classifies certain types of antifreeze as hazardous waste, requiring specific handling and disposal procedures.

As research in antifreeze technology advances, regulatory frameworks are evolving to keep pace. There is an increasing focus on promoting the development of more environmentally friendly antifreeze solutions. Some jurisdictions offer incentives for research into biodegradable or less toxic alternatives, while others are implementing stricter regulations on traditional antifreeze formulations.

The rapid advancement of resourceful engineering targets in antifreeze research also necessitates ongoing dialogue between researchers, industry stakeholders, and regulatory bodies. This collaboration ensures that regulations remain relevant and effective while not unduly hindering innovation in this critical field.

At the international level, several treaties and conventions influence antifreeze research. The Montreal Protocol, for instance, regulates substances that deplete the ozone layer, which may impact certain antifreeze formulations. Similarly, the Stockholm Convention on Persistent Organic Pollutants affects the development of antifreeze solutions that might contain harmful chemicals.

National regulatory bodies play a crucial role in overseeing antifreeze research and development. In the United States, the Environmental Protection Agency (EPA) regulates antifreeze under the Toxic Substances Control Act (TSCA). The EPA mandates specific labeling requirements, disposal guidelines, and reporting of new chemical substances used in antifreeze formulations.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to antifreeze components. These regulations require manufacturers and importers to register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment.

Occupational safety regulations also impact antifreeze research. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) set standards for handling and exposure to potentially hazardous substances used in antifreeze development.

Environmental regulations are particularly relevant to antifreeze research. Many countries have implemented strict guidelines for the disposal of antifreeze solutions to prevent groundwater contamination. For example, the Resource Conservation and Recovery Act (RCRA) in the US classifies certain types of antifreeze as hazardous waste, requiring specific handling and disposal procedures.

As research in antifreeze technology advances, regulatory frameworks are evolving to keep pace. There is an increasing focus on promoting the development of more environmentally friendly antifreeze solutions. Some jurisdictions offer incentives for research into biodegradable or less toxic alternatives, while others are implementing stricter regulations on traditional antifreeze formulations.

The rapid advancement of resourceful engineering targets in antifreeze research also necessitates ongoing dialogue between researchers, industry stakeholders, and regulatory bodies. This collaboration ensures that regulations remain relevant and effective while not unduly hindering innovation in this critical field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!