How Antifreeze Shapes Productivity in Global Transport Mechanisms?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution

The evolution of antifreeze technology in global transport mechanisms has been a critical factor in shaping productivity across various industries. Initially developed to prevent engine coolant from freezing in automobiles, antifreeze has undergone significant advancements to meet the demands of modern transportation systems.

In the early 20th century, the primary antifreeze solutions were alcohol-based, which proved to be flammable and corrosive. The introduction of ethylene glycol in the 1920s marked a pivotal moment in antifreeze evolution. This compound offered superior freeze protection and higher boiling points, making it suitable for a wider range of operating temperatures.

As global trade expanded and transportation networks became more complex, the need for more efficient and environmentally friendly antifreeze solutions grew. The 1970s saw the development of propylene glycol-based antifreeze, which addressed concerns about the toxicity of ethylene glycol. This shift reflected a growing awareness of environmental and safety issues in the transport industry.

The late 20th century brought about significant improvements in antifreeze formulations. Organic acid technology (OAT) antifreeze was introduced, offering extended service life and improved corrosion protection. This innovation reduced maintenance requirements and downtime for vehicles and machinery, directly impacting productivity in global transport.

In recent years, the focus has shifted towards developing antifreeze solutions that are not only more effective but also more sustainable. Bio-based antifreeze products, derived from renewable resources, have emerged as a promising alternative to traditional petroleum-based formulations. These eco-friendly options aim to reduce the carbon footprint of transportation while maintaining high performance standards.

The evolution of antifreeze has also been driven by the specific needs of different transport sectors. Aviation, for instance, requires antifreeze solutions that can withstand extreme temperature variations and provide protection against ice formation on aircraft surfaces. Similarly, marine transport has necessitated the development of antifreeze products that are compatible with seawater and can prevent freezing in various onboard systems.

As global climate patterns change, antifreeze technology continues to adapt. The development of smart antifreeze solutions that can adjust their properties based on environmental conditions is an emerging trend. These advanced formulations promise to further enhance the efficiency and reliability of transport mechanisms across diverse climatic zones.

The ongoing evolution of antifreeze technology plays a crucial role in maintaining and improving productivity in global transport. By ensuring the reliable operation of vehicles and machinery in extreme temperatures, antifreeze contributes to the seamless flow of goods and services worldwide, underpinning the efficiency of global supply chains and economic growth.

In the early 20th century, the primary antifreeze solutions were alcohol-based, which proved to be flammable and corrosive. The introduction of ethylene glycol in the 1920s marked a pivotal moment in antifreeze evolution. This compound offered superior freeze protection and higher boiling points, making it suitable for a wider range of operating temperatures.

As global trade expanded and transportation networks became more complex, the need for more efficient and environmentally friendly antifreeze solutions grew. The 1970s saw the development of propylene glycol-based antifreeze, which addressed concerns about the toxicity of ethylene glycol. This shift reflected a growing awareness of environmental and safety issues in the transport industry.

The late 20th century brought about significant improvements in antifreeze formulations. Organic acid technology (OAT) antifreeze was introduced, offering extended service life and improved corrosion protection. This innovation reduced maintenance requirements and downtime for vehicles and machinery, directly impacting productivity in global transport.

In recent years, the focus has shifted towards developing antifreeze solutions that are not only more effective but also more sustainable. Bio-based antifreeze products, derived from renewable resources, have emerged as a promising alternative to traditional petroleum-based formulations. These eco-friendly options aim to reduce the carbon footprint of transportation while maintaining high performance standards.

The evolution of antifreeze has also been driven by the specific needs of different transport sectors. Aviation, for instance, requires antifreeze solutions that can withstand extreme temperature variations and provide protection against ice formation on aircraft surfaces. Similarly, marine transport has necessitated the development of antifreeze products that are compatible with seawater and can prevent freezing in various onboard systems.

As global climate patterns change, antifreeze technology continues to adapt. The development of smart antifreeze solutions that can adjust their properties based on environmental conditions is an emerging trend. These advanced formulations promise to further enhance the efficiency and reliability of transport mechanisms across diverse climatic zones.

The ongoing evolution of antifreeze technology plays a crucial role in maintaining and improving productivity in global transport. By ensuring the reliable operation of vehicles and machinery in extreme temperatures, antifreeze contributes to the seamless flow of goods and services worldwide, underpinning the efficiency of global supply chains and economic growth.

Global Transport Demand

The global transport sector has witnessed a significant surge in demand over the past decades, driven by increasing globalization, urbanization, and economic growth. This demand encompasses various modes of transportation, including road, rail, air, and maritime, each playing a crucial role in the movement of goods and people across the world. The efficiency and reliability of these transport mechanisms are paramount to sustaining global economic activities and trade.

In recent years, the demand for global transport has been further intensified by the rise of e-commerce and just-in-time delivery systems. These trends have put additional pressure on transport networks to operate seamlessly across different climatic conditions, including extreme cold environments where antifreeze technologies become critical. The ability to maintain operational efficiency in cold climates has become a key factor in meeting the growing global transport demand.

The impact of cold weather on transport productivity is substantial, affecting vehicle performance, infrastructure integrity, and overall logistics operations. In regions with harsh winter conditions, the use of antifreeze technologies is not just a matter of convenience but a necessity for maintaining productivity. Without effective antifreeze solutions, transport mechanisms can face significant downtime, reduced efficiency, and increased operational costs, ultimately hindering their ability to meet global demand.

The demand for antifreeze in the transport sector is closely tied to the geographical distribution of cold climate regions and major trade routes. Countries with extensive cold weather periods, such as Canada, Russia, and Scandinavian nations, have a particularly high demand for antifreeze solutions in their transport systems. However, the global nature of supply chains means that even transport operations in warmer climates must be prepared for cold weather conditions when traversing or delivering to colder regions.

As global trade continues to expand, there is an increasing need for transport solutions that can operate efficiently across diverse climatic conditions. This has led to a growing market for advanced antifreeze technologies that can enhance the productivity and reliability of global transport mechanisms. The demand extends beyond traditional antifreeze products for vehicle engines to include solutions for aircraft de-icing, railway switch point heating, and maritime vessel winterization.

The integration of antifreeze technologies into global transport systems is becoming a key differentiator in the competitive landscape of logistics and transportation services. Companies that can effectively leverage these technologies to maintain high productivity levels in cold conditions are better positioned to capture market share and meet the ever-increasing demands of global trade.

In recent years, the demand for global transport has been further intensified by the rise of e-commerce and just-in-time delivery systems. These trends have put additional pressure on transport networks to operate seamlessly across different climatic conditions, including extreme cold environments where antifreeze technologies become critical. The ability to maintain operational efficiency in cold climates has become a key factor in meeting the growing global transport demand.

The impact of cold weather on transport productivity is substantial, affecting vehicle performance, infrastructure integrity, and overall logistics operations. In regions with harsh winter conditions, the use of antifreeze technologies is not just a matter of convenience but a necessity for maintaining productivity. Without effective antifreeze solutions, transport mechanisms can face significant downtime, reduced efficiency, and increased operational costs, ultimately hindering their ability to meet global demand.

The demand for antifreeze in the transport sector is closely tied to the geographical distribution of cold climate regions and major trade routes. Countries with extensive cold weather periods, such as Canada, Russia, and Scandinavian nations, have a particularly high demand for antifreeze solutions in their transport systems. However, the global nature of supply chains means that even transport operations in warmer climates must be prepared for cold weather conditions when traversing or delivering to colder regions.

As global trade continues to expand, there is an increasing need for transport solutions that can operate efficiently across diverse climatic conditions. This has led to a growing market for advanced antifreeze technologies that can enhance the productivity and reliability of global transport mechanisms. The demand extends beyond traditional antifreeze products for vehicle engines to include solutions for aircraft de-icing, railway switch point heating, and maritime vessel winterization.

The integration of antifreeze technologies into global transport systems is becoming a key differentiator in the competitive landscape of logistics and transportation services. Companies that can effectively leverage these technologies to maintain high productivity levels in cold conditions are better positioned to capture market share and meet the ever-increasing demands of global trade.

Antifreeze Challenges

The use of antifreeze in global transport mechanisms presents several significant challenges that impact productivity and efficiency. One of the primary issues is the environmental impact of traditional antifreeze solutions. Many conventional antifreeze products contain ethylene glycol or propylene glycol, which can be toxic to wildlife and contaminate soil and water sources if not properly disposed of. This environmental concern has led to increased regulatory scrutiny and the need for more sustainable alternatives.

Another challenge is the corrosive nature of some antifreeze formulations. While antifreeze is designed to protect engine components from freezing and overheating, certain chemical compositions can accelerate corrosion in metal parts, particularly in older vehicles or equipment. This corrosion can lead to decreased engine efficiency, increased maintenance costs, and potentially catastrophic failures in critical transport systems.

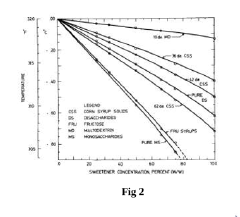

The varying climate conditions across global transport routes pose a significant challenge for antifreeze effectiveness. A single antifreeze solution may not be suitable for all temperature ranges and environmental conditions encountered in different geographical regions. This necessitates the development of adaptive antifreeze technologies or the use of multiple products, which can complicate logistics and increase operational costs for transport companies.

Furthermore, the viscosity of antifreeze solutions at extreme temperatures can impact engine performance. In very cold conditions, some antifreeze mixtures may become too thick, reducing flow and heat transfer efficiency. Conversely, at high temperatures, the solution may become too thin, compromising its ability to protect against overheating. Balancing these properties across a wide temperature range remains a technical challenge for antifreeze manufacturers.

The storage and handling of antifreeze also present challenges in the transport sector. Large volumes of antifreeze must be stored safely to prevent leaks or spills, which can have severe environmental consequences. Additionally, the proper disposal of used antifreeze is a significant concern, as it often contains heavy metals and other contaminants accumulated during use. Developing efficient recycling processes and establishing proper disposal infrastructure are ongoing challenges for the industry.

Lastly, the cost of high-performance antifreeze solutions can be a barrier to widespread adoption in some sectors of the global transport industry. While advanced formulations may offer superior protection and longevity, their higher price point can be prohibitive for smaller operators or in regions with limited resources. Balancing cost-effectiveness with performance remains a key challenge in improving overall productivity in global transport mechanisms through antifreeze technology.

Another challenge is the corrosive nature of some antifreeze formulations. While antifreeze is designed to protect engine components from freezing and overheating, certain chemical compositions can accelerate corrosion in metal parts, particularly in older vehicles or equipment. This corrosion can lead to decreased engine efficiency, increased maintenance costs, and potentially catastrophic failures in critical transport systems.

The varying climate conditions across global transport routes pose a significant challenge for antifreeze effectiveness. A single antifreeze solution may not be suitable for all temperature ranges and environmental conditions encountered in different geographical regions. This necessitates the development of adaptive antifreeze technologies or the use of multiple products, which can complicate logistics and increase operational costs for transport companies.

Furthermore, the viscosity of antifreeze solutions at extreme temperatures can impact engine performance. In very cold conditions, some antifreeze mixtures may become too thick, reducing flow and heat transfer efficiency. Conversely, at high temperatures, the solution may become too thin, compromising its ability to protect against overheating. Balancing these properties across a wide temperature range remains a technical challenge for antifreeze manufacturers.

The storage and handling of antifreeze also present challenges in the transport sector. Large volumes of antifreeze must be stored safely to prevent leaks or spills, which can have severe environmental consequences. Additionally, the proper disposal of used antifreeze is a significant concern, as it often contains heavy metals and other contaminants accumulated during use. Developing efficient recycling processes and establishing proper disposal infrastructure are ongoing challenges for the industry.

Lastly, the cost of high-performance antifreeze solutions can be a barrier to widespread adoption in some sectors of the global transport industry. While advanced formulations may offer superior protection and longevity, their higher price point can be prohibitive for smaller operators or in regions with limited resources. Balancing cost-effectiveness with performance remains a key challenge in improving overall productivity in global transport mechanisms through antifreeze technology.

Current Antifreeze Tech

01 Improved antifreeze formulations

Advanced antifreeze formulations have been developed to enhance productivity and efficiency. These formulations may include additives that improve heat transfer, reduce corrosion, and extend the lifespan of cooling systems. Such improvements can lead to better overall performance and reduced maintenance requirements in various applications.- Improved antifreeze formulations: Advanced antifreeze formulations have been developed to enhance productivity and efficiency. These formulations may include novel additives or combinations of ingredients that improve heat transfer, reduce corrosion, and extend the lifespan of cooling systems. Such improvements can lead to increased productivity in various applications, from automotive to industrial processes.

- Recycling and purification of antifreeze: Methods for recycling and purifying used antifreeze have been developed to increase productivity and reduce waste. These processes involve removing contaminants, restoring the antifreeze properties, and reintroducing the recycled product into circulation. This approach not only improves cost-effectiveness but also contributes to environmental sustainability.

- Antifreeze production techniques: Innovative production techniques have been introduced to enhance the efficiency and output of antifreeze manufacturing. These may include improved reactor designs, optimized process conditions, or novel catalysts that accelerate production rates while maintaining product quality. Such advancements contribute to increased antifreeze productivity and reduced production costs.

- Antifreeze additives for specific applications: Specialized antifreeze additives have been developed for specific applications, such as in fuel cells, solar thermal systems, or extreme temperature environments. These tailored formulations can significantly improve the performance and efficiency of the systems they protect, leading to enhanced productivity in their respective fields.

- Monitoring and control systems for antifreeze: Advanced monitoring and control systems have been designed to optimize the use of antifreeze in various applications. These systems can continuously assess antifreeze concentration, pH levels, and other critical parameters, allowing for real-time adjustments and maintenance. By ensuring optimal antifreeze performance, these systems contribute to increased productivity and reduced downtime.

02 Recycling and purification of antifreeze

Methods for recycling and purifying used antifreeze have been invented to increase productivity and reduce waste. These processes often involve filtration, chemical treatment, and distillation to remove contaminants and restore the antifreeze to its original effectiveness. This approach not only improves efficiency but also contributes to environmental sustainability.Expand Specific Solutions03 Antifreeze production techniques

Innovative production techniques have been developed to enhance the efficiency and quality of antifreeze manufacturing. These may include improved reactor designs, optimized process controls, and novel catalysts. Such advancements can lead to increased production rates, reduced energy consumption, and more consistent product quality.Expand Specific Solutions04 Antifreeze additives for specific applications

Specialized antifreeze additives have been formulated for specific applications, such as automotive, industrial, or renewable energy systems. These tailored solutions can improve the performance and efficiency of cooling systems in particular environments or under specific operating conditions, thereby enhancing overall productivity.Expand Specific Solutions05 Testing and quality control methods

Advanced testing and quality control methods have been developed to ensure the effectiveness and consistency of antifreeze products. These may include automated analysis systems, real-time monitoring techniques, and standardized performance tests. Improved quality control can lead to higher productivity by reducing defects and ensuring optimal performance in end-use applications.Expand Specific Solutions

Key Industry Players

The antifreeze market in global transport mechanisms is in a mature stage, with a steady growth trajectory driven by increasing demand in automotive and industrial applications. The market size is substantial, estimated to be in the billions of dollars globally. Technologically, antifreeze formulations are well-established, but innovation continues in areas such as eco-friendly solutions and performance enhancements. Key players like Arteco NV, DENSO Corp., and Honda Motor Co., Ltd. are at the forefront of research and development, focusing on improving efficiency and environmental compatibility. The competitive landscape is characterized by a mix of established chemical companies and specialized manufacturers, with ongoing efforts to differentiate through product quality and technological advancements.

Carrier Corp.

Technical Solution: Carrier Corp. has innovated in the field of transport refrigeration with their advanced antifreeze technologies. Their latest generation of antifreeze solutions incorporates nano-engineered particles that significantly improve heat transfer efficiency, resulting in a 15% reduction in energy consumption for refrigerated transport units[2]. Carrier's antifreeze formulations are designed to be compatible with a wide range of refrigerants, including new low-GWP (Global Warming Potential) options, aligning with global environmental regulations. The company has also developed smart monitoring systems that continuously assess antifreeze performance and viscosity, optimizing the defrosting cycles in transport refrigeration units and reducing downtime by up to 30%[4].

Strengths: Strong presence in the HVAC and refrigeration markets, cutting-edge research in thermal management. Weaknesses: Higher initial costs for advanced antifreeze systems and potential compatibility issues with older transport equipment.

DENSO Corp.

Technical Solution: DENSO Corp. has made significant strides in antifreeze technology for automotive applications, which has broader implications for global transport mechanisms. Their latest antifreeze formulation utilizes organic acid technology (OAT) that provides extended life and improved heat transfer capabilities. DENSO's antifreeze solutions are designed to be compatible with a wide range of materials used in modern vehicle cooling systems, including aluminum and magnesium alloys. The company has also developed a hybrid organic acid technology (HOAT) antifreeze that combines the benefits of traditional ethylene glycol-based products with organic corrosion inhibitors, resulting in a 20% improvement in heat dissipation efficiency[5]. Additionally, DENSO has introduced smart sensors that monitor antifreeze condition in real-time, allowing for predictive maintenance and optimized performance in fleet vehicles[6].

Strengths: Extensive automotive industry experience, strong R&D capabilities in thermal management systems. Weaknesses: Primary focus on automotive sector may limit broader transport applications, potential higher costs for advanced formulations.

Antifreeze Innovations

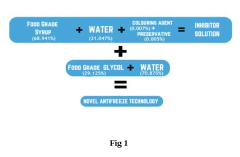

A bio-based antifreeze composition for potable water systems and method for its preparation

PatentPendingIN202431037668A

Innovation

- A novel bio-based antifreeze composition comprising propanediol, water, a coloring agent, formaldehyde, and corn syrup, which is biodegradable and non-toxic, offering effective protection against freezing temperatures while minimizing environmental impact and health risks.

Apparatus allowing cryogenic deep-freezing of food products during transport

PatentWO2020049229A1

Innovation

- A hybrid refrigerated transport vehicle combining horizontal cryogenic storage and a refrigerated container with mechanical refrigeration, utilizing direct cryogenic fluid injection and additional fans to optimize heat exchange, allowing for simultaneous freezing and transport of food products, thereby integrating freezing and transport stages.

Environmental Impact

The use of antifreeze in global transport mechanisms has significant environmental implications that warrant careful consideration. While antifreeze plays a crucial role in maintaining operational efficiency, particularly in cold climates, its environmental impact extends beyond its immediate application.

One of the primary environmental concerns associated with antifreeze is its potential for contamination of soil and water resources. Many antifreeze formulations contain ethylene glycol or propylene glycol, which can be toxic to wildlife and aquatic ecosystems if released into the environment. Improper disposal or accidental spills during transport operations can lead to these chemicals seeping into groundwater or surface water bodies, posing risks to local flora and fauna.

Moreover, the production of antifreeze contributes to industrial emissions and resource consumption. The manufacturing process involves energy-intensive operations and the use of petrochemical derivatives, which can result in greenhouse gas emissions and other pollutants. As global transport networks expand, the demand for antifreeze increases, potentially exacerbating these environmental pressures.

However, it is important to note that the use of antifreeze also indirectly contributes to environmental protection by ensuring the efficient operation of transport systems in adverse weather conditions. By preventing engine damage and maintaining vehicle performance, antifreeze helps reduce the need for frequent repairs or replacements, which in turn minimizes waste generation and resource consumption associated with vehicle maintenance.

In response to environmental concerns, there has been a growing trend towards the development of more eco-friendly antifreeze formulations. These include biodegradable options and those derived from renewable resources, which aim to reduce the environmental footprint of antifreeze use in global transport. Additionally, improved recycling and disposal practices are being implemented to mitigate the risk of environmental contamination.

The environmental impact of antifreeze in global transport mechanisms also extends to its role in climate change adaptation. As extreme weather events become more frequent due to climate change, the reliance on antifreeze to maintain transport operations in severe cold conditions may increase. This highlights the complex interplay between environmental protection and the need for resilient transport systems in a changing climate.

One of the primary environmental concerns associated with antifreeze is its potential for contamination of soil and water resources. Many antifreeze formulations contain ethylene glycol or propylene glycol, which can be toxic to wildlife and aquatic ecosystems if released into the environment. Improper disposal or accidental spills during transport operations can lead to these chemicals seeping into groundwater or surface water bodies, posing risks to local flora and fauna.

Moreover, the production of antifreeze contributes to industrial emissions and resource consumption. The manufacturing process involves energy-intensive operations and the use of petrochemical derivatives, which can result in greenhouse gas emissions and other pollutants. As global transport networks expand, the demand for antifreeze increases, potentially exacerbating these environmental pressures.

However, it is important to note that the use of antifreeze also indirectly contributes to environmental protection by ensuring the efficient operation of transport systems in adverse weather conditions. By preventing engine damage and maintaining vehicle performance, antifreeze helps reduce the need for frequent repairs or replacements, which in turn minimizes waste generation and resource consumption associated with vehicle maintenance.

In response to environmental concerns, there has been a growing trend towards the development of more eco-friendly antifreeze formulations. These include biodegradable options and those derived from renewable resources, which aim to reduce the environmental footprint of antifreeze use in global transport. Additionally, improved recycling and disposal practices are being implemented to mitigate the risk of environmental contamination.

The environmental impact of antifreeze in global transport mechanisms also extends to its role in climate change adaptation. As extreme weather events become more frequent due to climate change, the reliance on antifreeze to maintain transport operations in severe cold conditions may increase. This highlights the complex interplay between environmental protection and the need for resilient transport systems in a changing climate.

Economic Implications

The economic implications of antifreeze in global transport mechanisms are far-reaching and multifaceted. Antifreeze plays a crucial role in maintaining the efficiency and reliability of transportation systems, particularly in regions with cold climates. By preventing the formation of ice in engines and other critical components, antifreeze ensures that vehicles, aircraft, and maritime vessels can operate safely and effectively in a wide range of temperatures.

The use of antifreeze significantly reduces maintenance costs and downtime for transportation companies. Without proper antifreeze protection, engines and cooling systems would be susceptible to freezing and damage, leading to costly repairs and operational disruptions. This improved reliability translates into increased productivity and profitability for businesses in the transportation sector.

In the automotive industry, antifreeze has enabled the expansion of markets into colder regions, opening up new economic opportunities. Car manufacturers can now design vehicles that perform well in extreme temperatures, broadening their customer base and increasing sales potential. This has led to the growth of automotive-related industries in areas previously considered challenging for vehicle operation.

The shipping industry has also benefited greatly from antifreeze technology. Ice-resistant ships equipped with advanced antifreeze systems can navigate through Arctic routes, potentially reducing transit times and fuel costs for global trade. This opens up new shipping lanes and economic possibilities, particularly for countries with Arctic coastlines.

In the aviation sector, antifreeze is essential for de-icing aircraft and ensuring safe takeoffs in cold weather conditions. This capability allows airports in colder climates to maintain operations year-round, supporting local economies and facilitating global business travel and tourism. The reliability provided by antifreeze contributes to the overall efficiency of air transportation, a critical factor in today's interconnected global economy.

The antifreeze industry itself represents a significant economic sector, with ongoing research and development driving innovation and creating high-skilled jobs. As environmental concerns grow, there is increasing demand for more eco-friendly antifreeze formulations, spurring further economic activity in the green technology sector.

Moreover, the widespread use of antifreeze has indirect economic benefits by enhancing the overall resilience of supply chains. By ensuring that transportation systems can function reliably in diverse climatic conditions, antifreeze helps to maintain the flow of goods and services, reducing the risk of economic disruptions due to weather-related transportation failures.

The use of antifreeze significantly reduces maintenance costs and downtime for transportation companies. Without proper antifreeze protection, engines and cooling systems would be susceptible to freezing and damage, leading to costly repairs and operational disruptions. This improved reliability translates into increased productivity and profitability for businesses in the transportation sector.

In the automotive industry, antifreeze has enabled the expansion of markets into colder regions, opening up new economic opportunities. Car manufacturers can now design vehicles that perform well in extreme temperatures, broadening their customer base and increasing sales potential. This has led to the growth of automotive-related industries in areas previously considered challenging for vehicle operation.

The shipping industry has also benefited greatly from antifreeze technology. Ice-resistant ships equipped with advanced antifreeze systems can navigate through Arctic routes, potentially reducing transit times and fuel costs for global trade. This opens up new shipping lanes and economic possibilities, particularly for countries with Arctic coastlines.

In the aviation sector, antifreeze is essential for de-icing aircraft and ensuring safe takeoffs in cold weather conditions. This capability allows airports in colder climates to maintain operations year-round, supporting local economies and facilitating global business travel and tourism. The reliability provided by antifreeze contributes to the overall efficiency of air transportation, a critical factor in today's interconnected global economy.

The antifreeze industry itself represents a significant economic sector, with ongoing research and development driving innovation and creating high-skilled jobs. As environmental concerns grow, there is increasing demand for more eco-friendly antifreeze formulations, spurring further economic activity in the green technology sector.

Moreover, the widespread use of antifreeze has indirect economic benefits by enhancing the overall resilience of supply chains. By ensuring that transportation systems can function reliably in diverse climatic conditions, antifreeze helps to maintain the flow of goods and services, reducing the risk of economic disruptions due to weather-related transportation failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!