How Antifreeze Battles Challenges in Heat Transfer Innovation Area?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution

The evolution of antifreeze technology in heat transfer innovation has been marked by significant advancements over the years. Initially, simple salt solutions were used to lower the freezing point of water, but these proved corrosive and inefficient for modern applications. The introduction of ethylene glycol in the 1920s marked a pivotal moment, offering improved thermal properties and corrosion resistance.

As automotive and industrial cooling demands increased, propylene glycol emerged as a less toxic alternative, gaining popularity in food processing and HVAC systems. The 1970s saw the development of more sophisticated antifreeze formulations, incorporating corrosion inhibitors and pH buffers to extend the lifespan of cooling systems and improve heat transfer efficiency.

The late 20th century brought about a shift towards environmentally friendly options. Organic acid technology (OAT) antifreeze was introduced, providing longer-lasting protection and reduced environmental impact. This was followed by hybrid organic acid technology (HOAT), which combined the benefits of traditional coolants with OAT's extended life properties.

Recent years have witnessed the emergence of nanofluids in antifreeze technology. These advanced formulations incorporate nanoparticles to enhance thermal conductivity and heat transfer capabilities. Research has shown promising results in improving the overall efficiency of cooling systems, particularly in high-performance applications.

The push for sustainability has led to the development of bio-based antifreeze solutions derived from renewable resources. These eco-friendly alternatives aim to reduce reliance on petroleum-based products while maintaining or improving performance characteristics.

Current research focuses on smart antifreeze systems that can adapt to changing environmental conditions. These innovations include self-healing additives that can repair minor system damage and phase-change materials that provide more stable temperature control.

The evolution of antifreeze technology continues to be driven by the need for improved heat transfer efficiency, environmental sustainability, and system longevity. As industries face increasingly complex cooling challenges, the development of advanced antifreeze solutions remains crucial in addressing the demands of modern heat transfer applications.

As automotive and industrial cooling demands increased, propylene glycol emerged as a less toxic alternative, gaining popularity in food processing and HVAC systems. The 1970s saw the development of more sophisticated antifreeze formulations, incorporating corrosion inhibitors and pH buffers to extend the lifespan of cooling systems and improve heat transfer efficiency.

The late 20th century brought about a shift towards environmentally friendly options. Organic acid technology (OAT) antifreeze was introduced, providing longer-lasting protection and reduced environmental impact. This was followed by hybrid organic acid technology (HOAT), which combined the benefits of traditional coolants with OAT's extended life properties.

Recent years have witnessed the emergence of nanofluids in antifreeze technology. These advanced formulations incorporate nanoparticles to enhance thermal conductivity and heat transfer capabilities. Research has shown promising results in improving the overall efficiency of cooling systems, particularly in high-performance applications.

The push for sustainability has led to the development of bio-based antifreeze solutions derived from renewable resources. These eco-friendly alternatives aim to reduce reliance on petroleum-based products while maintaining or improving performance characteristics.

Current research focuses on smart antifreeze systems that can adapt to changing environmental conditions. These innovations include self-healing additives that can repair minor system damage and phase-change materials that provide more stable temperature control.

The evolution of antifreeze technology continues to be driven by the need for improved heat transfer efficiency, environmental sustainability, and system longevity. As industries face increasingly complex cooling challenges, the development of advanced antifreeze solutions remains crucial in addressing the demands of modern heat transfer applications.

Heat Transfer Market

The heat transfer market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, HVAC, and electronics. This market encompasses a wide range of products and technologies designed to facilitate efficient heat exchange and thermal management. The global heat transfer market size was valued at approximately $16.5 billion in 2020 and is projected to reach $24.3 billion by 2026, growing at a CAGR of 6.7% during the forecast period.

One of the key factors driving market growth is the rising need for energy-efficient solutions in industrial processes and consumer applications. As environmental regulations become more stringent and energy costs continue to rise, companies are increasingly focusing on optimizing their heat transfer systems to reduce energy consumption and operational costs. This trend has led to the development of advanced heat exchangers, cooling systems, and thermal management solutions that offer improved performance and efficiency.

The automotive sector represents a significant portion of the heat transfer market, with the increasing adoption of electric vehicles (EVs) and hybrid vehicles creating new opportunities for thermal management solutions. As battery technology advances and charging speeds increase, efficient heat dissipation becomes crucial for maintaining optimal performance and extending battery life. This has led to the development of specialized cooling systems and thermal interface materials tailored for EV applications.

In the industrial sector, the demand for heat transfer solutions is driven by the need to improve process efficiency and reduce energy consumption in manufacturing, chemical processing, and power generation. Advanced heat exchangers, such as plate heat exchangers and spiral heat exchangers, are gaining popularity due to their compact design and high thermal efficiency. Additionally, the growing focus on waste heat recovery systems is creating new opportunities for heat transfer technologies in industrial applications.

The HVAC industry is another major contributor to the heat transfer market, with increasing demand for energy-efficient heating and cooling systems in both residential and commercial buildings. The adoption of smart building technologies and the integration of IoT-enabled devices are driving innovation in HVAC heat transfer solutions, leading to the development of more responsive and efficient systems.

As the heat transfer market continues to evolve, manufacturers are investing in research and development to create innovative solutions that address emerging challenges. This includes the development of new materials with enhanced thermal properties, such as nanofluids and phase change materials, as well as the integration of advanced manufacturing techniques like 3D printing to create more complex and efficient heat transfer geometries.

One of the key factors driving market growth is the rising need for energy-efficient solutions in industrial processes and consumer applications. As environmental regulations become more stringent and energy costs continue to rise, companies are increasingly focusing on optimizing their heat transfer systems to reduce energy consumption and operational costs. This trend has led to the development of advanced heat exchangers, cooling systems, and thermal management solutions that offer improved performance and efficiency.

The automotive sector represents a significant portion of the heat transfer market, with the increasing adoption of electric vehicles (EVs) and hybrid vehicles creating new opportunities for thermal management solutions. As battery technology advances and charging speeds increase, efficient heat dissipation becomes crucial for maintaining optimal performance and extending battery life. This has led to the development of specialized cooling systems and thermal interface materials tailored for EV applications.

In the industrial sector, the demand for heat transfer solutions is driven by the need to improve process efficiency and reduce energy consumption in manufacturing, chemical processing, and power generation. Advanced heat exchangers, such as plate heat exchangers and spiral heat exchangers, are gaining popularity due to their compact design and high thermal efficiency. Additionally, the growing focus on waste heat recovery systems is creating new opportunities for heat transfer technologies in industrial applications.

The HVAC industry is another major contributor to the heat transfer market, with increasing demand for energy-efficient heating and cooling systems in both residential and commercial buildings. The adoption of smart building technologies and the integration of IoT-enabled devices are driving innovation in HVAC heat transfer solutions, leading to the development of more responsive and efficient systems.

As the heat transfer market continues to evolve, manufacturers are investing in research and development to create innovative solutions that address emerging challenges. This includes the development of new materials with enhanced thermal properties, such as nanofluids and phase change materials, as well as the integration of advanced manufacturing techniques like 3D printing to create more complex and efficient heat transfer geometries.

Antifreeze Challenges

Antifreeze solutions have long been a critical component in heat transfer systems, particularly in automotive and industrial applications. However, as technology advances and environmental concerns grow, these solutions face several significant challenges that demand innovative approaches to overcome.

One of the primary challenges is the environmental impact of traditional antifreeze formulations. Many conventional antifreeze solutions contain ethylene glycol, which is toxic to humans and animals if ingested. This poses risks during production, transportation, and disposal. The industry is under pressure to develop more environmentally friendly alternatives that maintain or improve upon the performance of existing solutions.

Another challenge lies in the thermal efficiency of antifreeze solutions. As heat transfer systems become more compact and powerful, there is a growing need for antifreeze formulations that can provide enhanced heat transfer capabilities. This requires innovations in fluid dynamics and chemical engineering to create solutions that can more effectively absorb and dissipate heat while maintaining their protective properties against freezing and corrosion.

Corrosion prevention remains a persistent challenge in antifreeze technology. The diverse materials used in modern heat transfer systems, including aluminum, copper, and various alloys, require antifreeze solutions that can protect against galvanic corrosion and chemical degradation across a wide range of operating conditions. Developing formulations that offer comprehensive corrosion protection without compromising heat transfer efficiency is a complex balancing act.

The increasing electrification of vehicles and industrial systems introduces new challenges for antifreeze solutions. Electric and hybrid vehicles have different cooling requirements compared to traditional internal combustion engines. Antifreeze formulations must be adapted to meet the specific needs of battery thermal management systems and power electronics cooling, which often operate at different temperature ranges and have unique material compatibility requirements.

Longevity and stability of antifreeze solutions under extreme conditions pose another significant challenge. As systems are designed to operate in more diverse and demanding environments, antifreeze solutions must maintain their performance characteristics over extended periods and across a wider range of temperatures. This requires innovations in additive technology and formulation stability to prevent degradation and maintain consistent protection.

Lastly, the challenge of cost-effectiveness cannot be overlooked. As the automotive and industrial sectors seek to optimize their operations, there is constant pressure to develop antifreeze solutions that offer improved performance at competitive prices. This economic factor drives the need for innovations in production processes and raw material sourcing to create high-performance, environmentally friendly antifreeze solutions that remain economically viable for widespread adoption.

One of the primary challenges is the environmental impact of traditional antifreeze formulations. Many conventional antifreeze solutions contain ethylene glycol, which is toxic to humans and animals if ingested. This poses risks during production, transportation, and disposal. The industry is under pressure to develop more environmentally friendly alternatives that maintain or improve upon the performance of existing solutions.

Another challenge lies in the thermal efficiency of antifreeze solutions. As heat transfer systems become more compact and powerful, there is a growing need for antifreeze formulations that can provide enhanced heat transfer capabilities. This requires innovations in fluid dynamics and chemical engineering to create solutions that can more effectively absorb and dissipate heat while maintaining their protective properties against freezing and corrosion.

Corrosion prevention remains a persistent challenge in antifreeze technology. The diverse materials used in modern heat transfer systems, including aluminum, copper, and various alloys, require antifreeze solutions that can protect against galvanic corrosion and chemical degradation across a wide range of operating conditions. Developing formulations that offer comprehensive corrosion protection without compromising heat transfer efficiency is a complex balancing act.

The increasing electrification of vehicles and industrial systems introduces new challenges for antifreeze solutions. Electric and hybrid vehicles have different cooling requirements compared to traditional internal combustion engines. Antifreeze formulations must be adapted to meet the specific needs of battery thermal management systems and power electronics cooling, which often operate at different temperature ranges and have unique material compatibility requirements.

Longevity and stability of antifreeze solutions under extreme conditions pose another significant challenge. As systems are designed to operate in more diverse and demanding environments, antifreeze solutions must maintain their performance characteristics over extended periods and across a wider range of temperatures. This requires innovations in additive technology and formulation stability to prevent degradation and maintain consistent protection.

Lastly, the challenge of cost-effectiveness cannot be overlooked. As the automotive and industrial sectors seek to optimize their operations, there is constant pressure to develop antifreeze solutions that offer improved performance at competitive prices. This economic factor drives the need for innovations in production processes and raw material sourcing to create high-performance, environmentally friendly antifreeze solutions that remain economically viable for widespread adoption.

Current Solutions

01 Antifreeze compositions for heat transfer fluids

Development of antifreeze compositions specifically designed for heat transfer applications. These compositions typically include a base fluid, such as ethylene glycol or propylene glycol, along with various additives to enhance thermal properties, prevent corrosion, and improve overall performance in heating and cooling systems.- Composition of antifreeze heat transfer fluids: Antifreeze heat transfer fluids are typically composed of a mixture of water and glycol-based compounds. These fluids are designed to lower the freezing point and raise the boiling point of the solution, making them effective for use in various temperature ranges. Additional additives may be included to enhance corrosion protection, lubrication, and thermal stability.

- Heat transfer systems using antifreeze solutions: Heat transfer systems incorporating antifreeze solutions are designed to efficiently transfer heat in various applications, such as automotive cooling systems, HVAC systems, and industrial processes. These systems often include specialized components like heat exchangers, pumps, and temperature control mechanisms to optimize heat transfer performance while preventing freezing or overheating.

- Environmentally friendly antifreeze formulations: Recent developments in antifreeze technology focus on creating more environmentally friendly formulations. These may include the use of bio-based glycols, natural corrosion inhibitors, and biodegradable additives. Such formulations aim to reduce environmental impact while maintaining or improving heat transfer efficiency and freeze protection properties.

- Nanofluid-based antifreeze solutions: Nanofluid-based antifreeze solutions incorporate nanoparticles to enhance heat transfer properties. These advanced formulations can improve thermal conductivity, heat capacity, and overall heat transfer efficiency compared to traditional antifreeze fluids. Research in this area focuses on optimizing nanoparticle types, sizes, and concentrations for various applications.

- Antifreeze heat transfer in renewable energy systems: Antifreeze heat transfer fluids play a crucial role in renewable energy systems, such as solar thermal collectors and geothermal heat pumps. These applications require specialized antifreeze formulations that can withstand extreme temperatures, provide long-term stability, and offer excellent heat transfer properties to maximize energy efficiency in sustainable energy production.

02 Heat transfer systems utilizing antifreeze solutions

Design and implementation of heat transfer systems that incorporate antifreeze solutions. These systems may include components such as heat exchangers, pumps, and piping specifically engineered to work efficiently with antifreeze fluids, ensuring optimal heat transfer and system protection in various temperature conditions.Expand Specific Solutions03 Nanofluid-based antifreeze for enhanced heat transfer

Incorporation of nanoparticles into antifreeze solutions to create nanofluids with improved heat transfer properties. These advanced fluids can offer enhanced thermal conductivity and heat capacity compared to traditional antifreeze solutions, potentially leading to more efficient heat transfer systems.Expand Specific Solutions04 Environmentally friendly antifreeze heat transfer fluids

Development of eco-friendly antifreeze solutions for heat transfer applications. These formulations may use biodegradable base fluids, renewable resources, or alternative chemicals to reduce environmental impact while maintaining effective heat transfer and freeze protection properties.Expand Specific Solutions05 Antifreeze heat transfer devices and equipment

Innovation in devices and equipment specifically designed for use with antifreeze heat transfer fluids. This includes specialized heat exchangers, pumps, valves, and monitoring systems that are optimized for the unique properties of antifreeze solutions, ensuring efficient and reliable operation in various applications.Expand Specific Solutions

Heat Transfer Players

The antifreeze heat transfer innovation sector is in a mature growth phase, with a global market size expected to reach $7.7 billion by 2025. Technological advancements are driving competition among key players like Carrier Corp., DAIKIN INDUSTRIES Ltd., and Danfoss A/S. These companies are focusing on developing eco-friendly, energy-efficient solutions to address environmental concerns and regulatory pressures. The industry is characterized by high R&D investments, with companies like NEC Corp. and IBM exploring novel materials and AI-driven optimization techniques. Emerging players such as Sunamp Ltd. are introducing innovative phase change materials, challenging established firms to adapt and innovate continuously in this evolving landscape.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed a range of innovative heat transfer solutions, focusing on environmentally friendly refrigerants and energy-efficient systems. Their VRV (Variable Refrigerant Volume) technology allows for simultaneous heating and cooling in different zones, optimizing energy usage [1]. DAIKIN has also introduced low-GWP (Global Warming Potential) refrigerants, such as R-32, which offer improved heat transfer properties and reduced environmental impact [3]. The company's inverter technology in air conditioning systems provides precise temperature control and energy savings by adjusting compressor speed based on demand [5]. Additionally, DAIKIN has developed microchannel heat exchangers that enhance heat transfer efficiency and reduce refrigerant charge in their systems [7].

Strengths: Energy-efficient systems, environmentally friendly refrigerants, and advanced temperature control. Weaknesses: Higher initial costs for advanced systems and potential compatibility issues with existing infrastructure.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed Solstice®, a line of low-GWP refrigerants and blowing agents that address heat transfer challenges while minimizing environmental impact. Their Solstice® yf refrigerant, designed for automotive air conditioning, offers improved energy efficiency and reduced carbon footprint compared to traditional refrigerants [2]. Honeywell has also introduced Solstice® N41, a non-flammable refrigerant for stationary air conditioning applications, providing enhanced safety and performance [4]. The company's thermal management solutions incorporate advanced phase change materials (PCMs) that absorb and release heat at specific temperatures, improving temperature control in various applications [6]. Additionally, Honeywell has developed smart HVAC control systems that optimize heat transfer and energy consumption in buildings through predictive algorithms and real-time monitoring [8].

Strengths: Low environmental impact, improved energy efficiency, and advanced thermal management solutions. Weaknesses: Potential higher costs for new refrigerant adoption and the need for system modifications in some applications.

Key Innovations

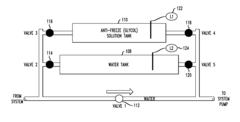

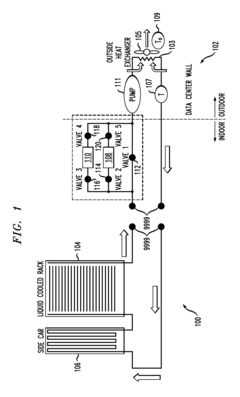

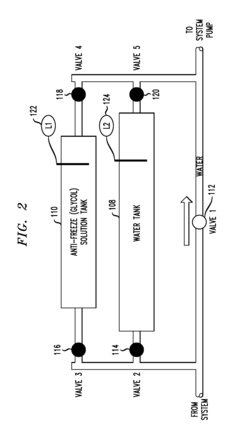

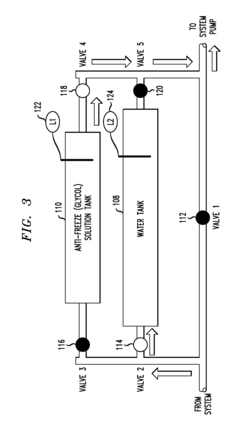

Data center coolant switch

PatentInactiveUS9151543B2

Innovation

- A data center cooling system that switches between a high-performance heat transfer fluid, such as water, and a low-performance antifreeze fluid, like glycol, based on outdoor air temperature, using a coolant switch arrangement with shut-off or three-way valves to manage the fluid switch, allowing for efficient operation in both winter and summer without freezing issues.

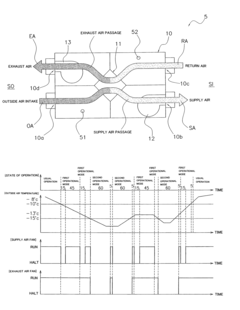

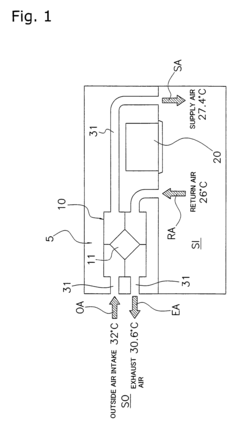

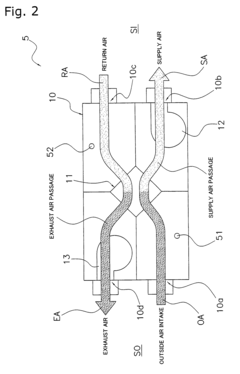

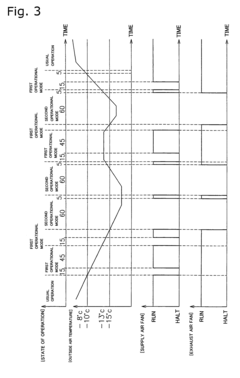

Heat exchanger unit

PatentInactiveUS6983794B2

Innovation

- A heat exchanger unit with a control system that executes a first and second freeze inhibit control mode based on outside air temperature, where the second mode further inhibits freezing by intermittently stopping both supply and exhaust air fans, allowing the heat exchange element to store heat from the indoor space and reducing exposure to cold outside air.

Environmental Impact

The environmental impact of antifreeze in heat transfer innovation is a critical consideration as the industry seeks to balance performance with sustainability. Traditional antifreeze solutions, often based on ethylene glycol or propylene glycol, have raised concerns due to their potential toxicity and environmental persistence. These chemicals can contaminate soil and water sources if improperly disposed of, posing risks to ecosystems and human health.

In response to these challenges, researchers and manufacturers are exploring more environmentally friendly alternatives. Bio-based antifreezes derived from renewable resources such as corn, soybeans, or other plant materials are gaining attention. These solutions offer comparable heat transfer properties while reducing the carbon footprint associated with production and disposal. Additionally, they are often biodegradable, minimizing long-term environmental impact.

Another approach focuses on improving the efficiency of heat transfer systems to reduce the overall volume of antifreeze required. This includes developing advanced heat exchanger designs and optimizing fluid dynamics to maximize heat transfer with minimal antifreeze usage. Such innovations not only decrease the environmental burden but also contribute to energy savings in various applications.

Recycling and proper disposal methods for antifreeze have also become key areas of focus. Closed-loop systems that allow for the continuous reuse of antifreeze solutions are being implemented in industrial settings, significantly reducing waste generation. Furthermore, advanced treatment technologies are being developed to purify used antifreeze, enabling its safe reintroduction into the environment or repurposing for other industrial applications.

The push for environmental sustainability has led to the exploration of novel materials and technologies in antifreeze development. Nanomaterials and advanced polymers are being investigated for their potential to enhance heat transfer properties while minimizing environmental impact. These materials could potentially replace traditional antifreeze solutions in certain applications, offering improved performance with reduced ecological consequences.

Regulatory bodies worldwide are increasingly implementing stricter guidelines on the use and disposal of antifreeze substances. This regulatory pressure is driving innovation in the industry, pushing manufacturers to develop compliant solutions that meet both performance and environmental standards. As a result, the heat transfer innovation landscape is evolving towards more sustainable practices, balancing technological advancements with ecological responsibility.

In response to these challenges, researchers and manufacturers are exploring more environmentally friendly alternatives. Bio-based antifreezes derived from renewable resources such as corn, soybeans, or other plant materials are gaining attention. These solutions offer comparable heat transfer properties while reducing the carbon footprint associated with production and disposal. Additionally, they are often biodegradable, minimizing long-term environmental impact.

Another approach focuses on improving the efficiency of heat transfer systems to reduce the overall volume of antifreeze required. This includes developing advanced heat exchanger designs and optimizing fluid dynamics to maximize heat transfer with minimal antifreeze usage. Such innovations not only decrease the environmental burden but also contribute to energy savings in various applications.

Recycling and proper disposal methods for antifreeze have also become key areas of focus. Closed-loop systems that allow for the continuous reuse of antifreeze solutions are being implemented in industrial settings, significantly reducing waste generation. Furthermore, advanced treatment technologies are being developed to purify used antifreeze, enabling its safe reintroduction into the environment or repurposing for other industrial applications.

The push for environmental sustainability has led to the exploration of novel materials and technologies in antifreeze development. Nanomaterials and advanced polymers are being investigated for their potential to enhance heat transfer properties while minimizing environmental impact. These materials could potentially replace traditional antifreeze solutions in certain applications, offering improved performance with reduced ecological consequences.

Regulatory bodies worldwide are increasingly implementing stricter guidelines on the use and disposal of antifreeze substances. This regulatory pressure is driving innovation in the industry, pushing manufacturers to develop compliant solutions that meet both performance and environmental standards. As a result, the heat transfer innovation landscape is evolving towards more sustainable practices, balancing technological advancements with ecological responsibility.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of antifreeze solutions for heat transfer innovation. As the industry continues to evolve, regulatory bodies have established stringent guidelines to ensure the safe handling, storage, and disposal of antifreeze materials.

One of the primary concerns addressed by safety regulations is the toxicity of antifreeze compounds. Many traditional antifreeze formulations contain ethylene glycol, which is highly toxic if ingested. Regulatory agencies have mandated clear labeling and packaging requirements to prevent accidental consumption, particularly by children and pets. Additionally, manufacturers are required to include bittering agents in antifreeze products to deter ingestion.

Environmental protection is another key focus of antifreeze safety regulations. The improper disposal of antifreeze can lead to soil and water contamination, posing risks to ecosystems and human health. Consequently, regulations have been implemented to govern the proper disposal methods for used antifreeze, often requiring specialized recycling or treatment processes.

In the industrial sector, safety regulations extend to the handling and storage of antifreeze in large-scale heat transfer systems. These regulations typically mandate the use of secondary containment systems, regular inspections, and maintenance protocols to prevent leaks and spills. Furthermore, workplace safety standards require proper personal protective equipment (PPE) for employees handling antifreeze materials.

As the heat transfer industry explores more innovative antifreeze solutions, regulatory bodies are adapting their guidelines to address new challenges. For instance, the development of bio-based or less toxic antifreeze formulations has prompted the need for updated safety assessments and regulatory frameworks. These emerging solutions often require extensive testing and validation to ensure they meet or exceed existing safety standards.

Regulatory compliance also extends to the transportation of antifreeze materials. Specific guidelines govern the packaging, labeling, and shipping of these substances to minimize risks during transit. This includes requirements for spill containment, emergency response procedures, and driver training for hazardous material transport.

In recent years, there has been a growing emphasis on the lifecycle management of antifreeze products. Regulations now often encompass the entire product lifecycle, from manufacturing to end-of-life disposal. This holistic approach aims to minimize environmental impact and ensure responsible resource management throughout the antifreeze supply chain.

As the heat transfer innovation area continues to advance, safety regulations will likely evolve to address new technologies and applications. This ongoing regulatory development underscores the importance of collaboration between industry stakeholders, researchers, and regulatory bodies to ensure that safety standards keep pace with technological progress in antifreeze solutions.

One of the primary concerns addressed by safety regulations is the toxicity of antifreeze compounds. Many traditional antifreeze formulations contain ethylene glycol, which is highly toxic if ingested. Regulatory agencies have mandated clear labeling and packaging requirements to prevent accidental consumption, particularly by children and pets. Additionally, manufacturers are required to include bittering agents in antifreeze products to deter ingestion.

Environmental protection is another key focus of antifreeze safety regulations. The improper disposal of antifreeze can lead to soil and water contamination, posing risks to ecosystems and human health. Consequently, regulations have been implemented to govern the proper disposal methods for used antifreeze, often requiring specialized recycling or treatment processes.

In the industrial sector, safety regulations extend to the handling and storage of antifreeze in large-scale heat transfer systems. These regulations typically mandate the use of secondary containment systems, regular inspections, and maintenance protocols to prevent leaks and spills. Furthermore, workplace safety standards require proper personal protective equipment (PPE) for employees handling antifreeze materials.

As the heat transfer industry explores more innovative antifreeze solutions, regulatory bodies are adapting their guidelines to address new challenges. For instance, the development of bio-based or less toxic antifreeze formulations has prompted the need for updated safety assessments and regulatory frameworks. These emerging solutions often require extensive testing and validation to ensure they meet or exceed existing safety standards.

Regulatory compliance also extends to the transportation of antifreeze materials. Specific guidelines govern the packaging, labeling, and shipping of these substances to minimize risks during transit. This includes requirements for spill containment, emergency response procedures, and driver training for hazardous material transport.

In recent years, there has been a growing emphasis on the lifecycle management of antifreeze products. Regulations now often encompass the entire product lifecycle, from manufacturing to end-of-life disposal. This holistic approach aims to minimize environmental impact and ensure responsible resource management throughout the antifreeze supply chain.

As the heat transfer innovation area continues to advance, safety regulations will likely evolve to address new technologies and applications. This ongoing regulatory development underscores the importance of collaboration between industry stakeholders, researchers, and regulatory bodies to ensure that safety standards keep pace with technological progress in antifreeze solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!