How Antifreeze Pioneers Developments in Energy Conservation Strategies?

Antifreeze Evolution

The evolution of antifreeze technology has played a crucial role in advancing energy conservation strategies. Initially developed to prevent engine coolant from freezing in cold climates, antifreeze has undergone significant transformations to address broader energy efficiency concerns.

In the early 20th century, the primary focus of antifreeze was simply to lower the freezing point of water in vehicle cooling systems. Methanol and ethylene glycol emerged as the dominant antifreeze compounds due to their effectiveness and relatively low cost. However, these early formulations had limitations, including toxicity and corrosive properties.

As environmental awareness grew in the latter half of the 20th century, antifreeze manufacturers began exploring more eco-friendly alternatives. Propylene glycol, a less toxic option, gained popularity in certain applications. This shift marked the beginning of antifreeze's role in promoting sustainability and energy conservation.

The late 20th and early 21st centuries saw a paradigm shift in antifreeze technology. Researchers began to focus on developing advanced formulations that not only prevented freezing but also enhanced heat transfer efficiency. These new antifreeze solutions incorporated nanomaterials and other additives to improve thermal conductivity, leading to more efficient cooling systems in vehicles and industrial applications.

One significant breakthrough came with the development of organic acid technology (OAT) antifreeze. OAT formulations offered extended service life and improved protection against corrosion, reducing the frequency of coolant changes and minimizing waste. This innovation aligned with growing efforts to reduce resource consumption and environmental impact.

The pursuit of energy conservation led to the creation of antifreeze solutions specifically designed for renewable energy systems. In solar thermal applications, for instance, specialized antifreeze formulations were developed to withstand high temperatures and provide optimal heat transfer, enhancing the overall efficiency of solar collectors.

Recent advancements have focused on integrating smart technologies into antifreeze systems. Intelligent coolant management systems now utilize sensors and data analytics to optimize coolant performance, predict maintenance needs, and further reduce energy consumption in various applications, from automotive to industrial processes.

The evolution of antifreeze has also extended to phase change materials (PCMs) for thermal energy storage. These innovative materials, which can absorb and release large amounts of energy during phase transitions, are being incorporated into advanced antifreeze solutions to enhance energy storage and thermal management in buildings and industrial processes.

As we look to the future, the ongoing evolution of antifreeze technology continues to push the boundaries of energy conservation. Research into bio-based antifreeze compounds and advanced nanofluid formulations promises to deliver even greater efficiency gains and environmental benefits, further cementing antifreeze's role as a key player in sustainable energy strategies.

Energy Market Demand

The global energy market is experiencing a significant shift towards more sustainable and efficient solutions, driven by increasing environmental concerns and the need for energy conservation. This trend has created a growing demand for innovative technologies that can improve energy efficiency across various sectors, including residential, commercial, and industrial applications. Antifreeze, traditionally used in automotive and industrial cooling systems, is now being explored for its potential in energy conservation strategies.

The demand for energy-efficient solutions has been steadily rising, with the global energy efficiency market expected to reach substantial growth in the coming years. This growth is fueled by stringent government regulations, rising energy costs, and increasing awareness of the environmental impact of energy consumption. In this context, antifreeze technologies are gaining attention for their ability to enhance the performance of heating, ventilation, and air conditioning (HVAC) systems, as well as improve the efficiency of renewable energy technologies such as solar thermal systems.

One of the key areas where antifreeze is making significant contributions to energy conservation is in the development of more efficient heat transfer fluids. These advanced fluids, based on antifreeze formulations, can improve the overall efficiency of heating and cooling systems by reducing energy losses and enabling better heat exchange. This has led to increased demand from industries seeking to optimize their energy consumption and reduce operational costs.

The residential sector is also showing growing interest in antifreeze-based energy conservation solutions. Homeowners are increasingly adopting geothermal heat pump systems, which utilize antifreeze solutions to transfer heat between the ground and the home. This technology offers significant energy savings compared to traditional heating and cooling methods, driving demand for specialized antifreeze products in this market segment.

In the renewable energy sector, antifreeze technologies are playing a crucial role in improving the efficiency and reliability of solar thermal systems. By preventing freezing in solar collectors during cold weather, antifreeze solutions enable these systems to operate year-round, increasing their overall energy output and economic viability. This has led to increased adoption of solar thermal technologies in regions with colder climates, expanding the market for antifreeze products in the renewable energy sector.

The industrial sector represents another significant market for antifreeze-based energy conservation strategies. Large-scale cooling systems in manufacturing plants, data centers, and other industrial facilities are increasingly utilizing advanced antifreeze solutions to improve energy efficiency and reduce operational costs. This trend is particularly pronounced in regions with extreme climates, where the demand for reliable and efficient cooling solutions is highest.

As the global focus on energy conservation intensifies, the market for antifreeze technologies in energy-efficient applications is expected to continue growing. This presents significant opportunities for innovation and development of new antifreeze formulations tailored specifically for energy conservation applications. The intersection of antifreeze technology and energy efficiency is likely to drive further research and investment in this field, as industries and consumers alike seek more sustainable and cost-effective energy solutions.

Antifreeze Challenges

Antifreeze technology, while crucial for protecting engines and systems in cold environments, presents significant challenges in the context of energy conservation strategies. One of the primary issues is the energy-intensive nature of antifreeze production and disposal processes. The manufacturing of traditional antifreeze compounds, such as ethylene glycol and propylene glycol, requires substantial energy inputs, contributing to increased carbon footprints and environmental concerns.

Moreover, the widespread use of antifreeze in various industries, particularly automotive and industrial cooling systems, leads to increased energy consumption during operation. The addition of antifreeze to cooling systems often reduces their thermal efficiency, necessitating more energy to maintain optimal operating temperatures. This efficiency loss translates to higher fuel consumption in vehicles and increased power demands in industrial applications, directly conflicting with energy conservation goals.

The disposal and recycling of antifreeze pose another set of challenges. Improper disposal can lead to environmental contamination, while recycling processes are often energy-intensive. The need for specialized treatment facilities and transportation of used antifreeze further adds to the energy expenditure associated with its lifecycle.

Additionally, the chemical composition of traditional antifreeze solutions presents environmental risks. Leaks or spills can contaminate soil and water sources, requiring energy-intensive cleanup operations. The toxicity of some antifreeze compounds also necessitates careful handling and storage, adding to the overall energy costs of their use.

The search for more environmentally friendly and energy-efficient antifreeze alternatives is ongoing but faces its own set of challenges. Developing new formulations that maintain the same level of freeze protection while reducing energy consumption throughout their lifecycle is a complex task. Balancing performance, cost-effectiveness, and environmental impact remains a significant hurdle in the advancement of antifreeze technology.

Furthermore, the integration of new antifreeze solutions into existing systems and infrastructure presents logistical and technical challenges. Retrofitting or redesigning cooling systems to accommodate more energy-efficient antifreeze compounds can be costly and time-consuming, potentially deterring widespread adoption.

As energy conservation becomes increasingly critical in the face of climate change, addressing these antifreeze challenges is paramount. The industry must innovate to develop solutions that not only provide effective freeze protection but also align with broader energy conservation strategies. This may involve exploring novel materials, improving production processes, enhancing recycling technologies, and reimagining cooling system designs to minimize the energy impact of antifreeze use across various applications.

Current Solutions

01 Antifreeze compositions for energy conservation

Improved antifreeze compositions are developed to enhance energy conservation in various systems. These formulations are designed to provide better heat transfer properties, reduce energy consumption in cooling and heating processes, and improve overall system efficiency.- Antifreeze compositions for energy conservation: Advanced antifreeze compositions are developed to improve energy efficiency in various systems. These formulations enhance heat transfer properties, reduce friction, and prevent corrosion, ultimately leading to better energy conservation in automotive, industrial, and HVAC applications.

- Energy-efficient cooling systems: Innovative cooling systems are designed to minimize energy consumption while maintaining optimal performance. These systems incorporate advanced heat exchangers, smart control algorithms, and efficient pumping mechanisms to reduce the overall energy requirements for cooling processes.

- Smart energy management in antifreeze systems: Intelligent energy management solutions are integrated into antifreeze systems to optimize energy usage. These solutions employ sensors, data analytics, and adaptive control strategies to adjust system parameters based on real-time conditions, resulting in significant energy savings.

- Renewable energy integration in antifreeze applications: Antifreeze systems are being designed to incorporate renewable energy sources, such as solar and geothermal energy. This integration reduces reliance on conventional energy sources and improves overall energy efficiency in various applications, including building heating and cooling systems.

- Energy-efficient antifreeze circulation and distribution: Advanced circulation and distribution systems for antifreeze fluids are developed to minimize energy losses. These systems utilize optimized piping layouts, high-efficiency pumps, and intelligent flow control mechanisms to reduce pumping power requirements and improve overall system efficiency.

02 Energy-efficient cooling systems using antifreeze

Advanced cooling systems incorporate antifreeze solutions to optimize energy usage. These systems are designed to minimize heat loss, improve thermal management, and reduce the overall energy required for cooling in various applications, including automotive and industrial processes.Expand Specific Solutions03 Smart control systems for antifreeze management

Intelligent control systems are developed to manage antifreeze usage and optimize energy conservation. These systems utilize sensors, data analysis, and automated adjustments to ensure efficient operation of antifreeze-based cooling and heating systems, reducing energy waste and improving performance.Expand Specific Solutions04 Renewable energy integration with antifreeze systems

Innovative approaches combine renewable energy sources with antifreeze-based systems to enhance energy conservation. These integrated solutions leverage solar, geothermal, or other renewable energy technologies to power and supplement antifreeze systems, reducing reliance on traditional energy sources.Expand Specific Solutions05 Nanotechnology-enhanced antifreeze for energy efficiency

Advanced antifreeze formulations incorporating nanotechnology are developed to improve energy efficiency. These nanoparticle-enhanced solutions offer superior heat transfer properties, reduced viscosity, and improved thermal conductivity, leading to enhanced energy conservation in various applications.Expand Specific Solutions

Key Industry Players

The antifreeze industry is in a mature stage, with a global market size estimated to reach $7.7 billion by 2027. The technology is well-established, but innovation continues in energy conservation strategies. Major players like Nissan, BSH Hausgeräte, and IBM are driving advancements in this field. Nissan, a leader in electric vehicles, is developing more efficient cooling systems. BSH Hausgeräte focuses on energy-efficient household appliances, while IBM contributes through its expertise in AI and data analytics for optimizing energy use. Other significant contributors include Mitsubishi Heavy Industries, Honda, and BASF, each bringing unique technological capabilities to enhance antifreeze performance and energy efficiency.

International Business Machines Corp.

Haier Smart Home Co., Ltd.

Innovative Formulations

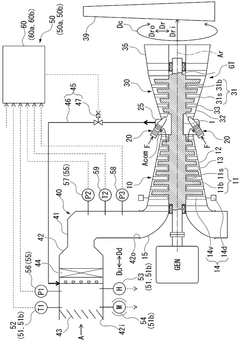

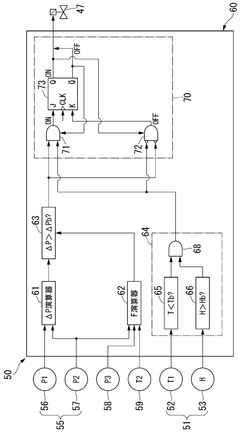

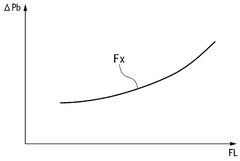

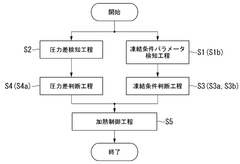

- An anti-freezing control device that uses a combination of freezing condition parameter detection and pressure difference measurement to determine whether to heat or not heat the filter, ensuring that heating is only applied when necessary and energy is conserved.

- A method and device that utilize a multi-way gas guiding device and control system to redirect and control heat from waste heat sources, such as generator exhaust air and heat recovery devices, to maintain optimal operating temperatures in the air intake system, minimizing the need for additional heating and reducing energy losses.

Environmental Impact

The environmental impact of antifreeze in energy conservation strategies is a critical consideration as industries strive for more sustainable practices. Traditional antifreeze solutions, primarily composed of ethylene glycol or propylene glycol, have raised concerns due to their potential toxicity and environmental persistence. However, recent developments in antifreeze technology have led to more eco-friendly alternatives that contribute to energy conservation while minimizing ecological harm.

One significant advancement is the development of bio-based antifreeze solutions derived from renewable resources such as corn, soybeans, and other plant materials. These biodegradable alternatives reduce reliance on petroleum-based products and have a lower carbon footprint throughout their lifecycle. Moreover, they often exhibit improved thermal properties, enhancing energy efficiency in various applications, from automotive cooling systems to industrial heat transfer processes.

Nanotechnology has also played a crucial role in creating environmentally friendly antifreeze solutions. Nanoparticle-enhanced fluids demonstrate superior heat transfer capabilities, allowing for more efficient energy utilization in thermal management systems. These advanced formulations can potentially reduce the overall volume of antifreeze required, thereby decreasing the environmental burden associated with production, transportation, and disposal.

The shift towards more sustainable antifreeze solutions has led to innovations in closed-loop systems and recycling processes. By implementing advanced filtration and purification techniques, industries can now extend the lifespan of antifreeze fluids, reducing waste generation and the need for frequent replacements. This approach not only conserves resources but also minimizes the risk of environmental contamination through improper disposal.

Furthermore, the integration of smart monitoring systems in antifreeze applications has contributed to optimized energy usage and reduced environmental impact. These systems can detect leaks, monitor fluid quality, and adjust system parameters in real-time, ensuring optimal performance while preventing unnecessary waste and potential environmental hazards.

As antifreeze technology continues to evolve, there is a growing focus on developing solutions that not only protect against freezing but also contribute to overall energy efficiency. This holistic approach considers the entire lifecycle of antifreeze products, from production to disposal, aiming to minimize environmental impact at every stage while maximizing energy conservation benefits.

Regulatory Framework

The regulatory framework surrounding antifreeze and energy conservation strategies has evolved significantly in recent years, driven by increasing environmental concerns and the need for more sustainable practices. Governments and international organizations have implemented various policies and regulations to promote energy efficiency and reduce the environmental impact of antifreeze products.

One of the key aspects of the regulatory framework is the focus on the composition of antifreeze products. Many countries have introduced strict guidelines on the use of certain chemicals in antifreeze formulations, particularly those that pose environmental risks. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has placed restrictions on the use of certain glycols and additives commonly found in traditional antifreeze products.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal of antifreeze and has encouraged the use of more environmentally friendly alternatives. The EPA's Significant New Alternatives Policy (SNAP) program has also played a crucial role in promoting the development and adoption of safer antifreeze alternatives that contribute to energy conservation.

Energy efficiency standards have become increasingly stringent, affecting the development of antifreeze technologies. For example, the Corporate Average Fuel Economy (CAFE) standards in the United States have indirectly influenced antifreeze formulations by pushing for more efficient engine cooling systems that can operate with less antifreeze and at higher temperatures.

Many countries have implemented tax incentives and subsidies to encourage the development and adoption of energy-efficient antifreeze solutions. These financial incentives have spurred innovation in the industry, leading to the creation of advanced antifreeze products that not only protect against freezing but also contribute to overall energy conservation in various applications.

The regulatory landscape has also seen a push towards circular economy principles. Regulations promoting the recycling and proper disposal of antifreeze products have been implemented in many regions. This has led to the development of antifreeze recycling programs and the creation of more easily recyclable formulations, further contributing to energy conservation efforts.

International agreements and collaborations have played a significant role in shaping the regulatory framework. The Paris Agreement, for instance, has indirectly influenced antifreeze regulations by setting global targets for reducing greenhouse gas emissions, which has led to increased scrutiny of all aspects of energy consumption, including those related to antifreeze use.