Antifreeze's Role in Multinational Sustainable Solutions Innovations

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Technology Evolution and Objectives

Antifreeze technology has evolved significantly over the past century, driven by the need for more efficient and environmentally friendly solutions. Initially developed to prevent water-based coolants from freezing in automotive engines, antifreeze has since found applications in various industries, including aerospace, renewable energy, and sustainable infrastructure.

The evolution of antifreeze technology can be traced back to the early 1900s when ethylene glycol was first used as a coolant in automobiles. This marked a significant improvement over earlier water-based solutions, which were prone to freezing in cold climates. As environmental concerns grew in the latter half of the 20th century, propylene glycol emerged as a less toxic alternative, gaining popularity in food processing and pharmaceutical applications.

In recent decades, the focus has shifted towards developing more sustainable and eco-friendly antifreeze solutions. This has led to the exploration of bio-based alternatives, such as glycerin derived from renewable sources like vegetable oils. These bio-based antifreezes offer comparable performance to traditional petroleum-based products while reducing environmental impact and carbon footprint.

The objectives of modern antifreeze technology extend beyond mere freeze protection. Today's solutions aim to provide enhanced heat transfer efficiency, corrosion protection, and compatibility with a wide range of materials. This is particularly crucial in the context of multinational sustainable solutions, where antifreeze plays a vital role in various applications, from solar thermal systems to geothermal heat pumps.

One of the key objectives in antifreeze technology development is to create formulations that can withstand extreme temperature fluctuations while maintaining long-term stability. This is essential for applications in renewable energy systems, where antifreeze solutions must perform reliably in diverse climatic conditions across different geographical regions.

Another important goal is to develop antifreeze solutions that are non-toxic, biodegradable, and recyclable. This aligns with global sustainability initiatives and helps companies meet increasingly stringent environmental regulations. Researchers are exploring novel additives and formulations that can achieve these objectives without compromising performance or cost-effectiveness.

As multinational corporations expand their sustainable solutions portfolios, the demand for advanced antifreeze technologies continues to grow. The industry is now focusing on developing smart antifreeze systems that can adapt to changing conditions and integrate with IoT platforms for real-time monitoring and optimization. These innovations aim to enhance energy efficiency, reduce maintenance requirements, and extend the lifespan of equipment across various sustainable applications.

The evolution of antifreeze technology can be traced back to the early 1900s when ethylene glycol was first used as a coolant in automobiles. This marked a significant improvement over earlier water-based solutions, which were prone to freezing in cold climates. As environmental concerns grew in the latter half of the 20th century, propylene glycol emerged as a less toxic alternative, gaining popularity in food processing and pharmaceutical applications.

In recent decades, the focus has shifted towards developing more sustainable and eco-friendly antifreeze solutions. This has led to the exploration of bio-based alternatives, such as glycerin derived from renewable sources like vegetable oils. These bio-based antifreezes offer comparable performance to traditional petroleum-based products while reducing environmental impact and carbon footprint.

The objectives of modern antifreeze technology extend beyond mere freeze protection. Today's solutions aim to provide enhanced heat transfer efficiency, corrosion protection, and compatibility with a wide range of materials. This is particularly crucial in the context of multinational sustainable solutions, where antifreeze plays a vital role in various applications, from solar thermal systems to geothermal heat pumps.

One of the key objectives in antifreeze technology development is to create formulations that can withstand extreme temperature fluctuations while maintaining long-term stability. This is essential for applications in renewable energy systems, where antifreeze solutions must perform reliably in diverse climatic conditions across different geographical regions.

Another important goal is to develop antifreeze solutions that are non-toxic, biodegradable, and recyclable. This aligns with global sustainability initiatives and helps companies meet increasingly stringent environmental regulations. Researchers are exploring novel additives and formulations that can achieve these objectives without compromising performance or cost-effectiveness.

As multinational corporations expand their sustainable solutions portfolios, the demand for advanced antifreeze technologies continues to grow. The industry is now focusing on developing smart antifreeze systems that can adapt to changing conditions and integrate with IoT platforms for real-time monitoring and optimization. These innovations aim to enhance energy efficiency, reduce maintenance requirements, and extend the lifespan of equipment across various sustainable applications.

Global Market Demand for Sustainable Antifreeze Solutions

The global market for sustainable antifreeze solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations across various industries. This demand is particularly pronounced in automotive, industrial, and renewable energy sectors, where the need for eco-friendly cooling and heat transfer solutions is paramount.

In the automotive industry, the shift towards electric vehicles (EVs) has created a new market segment for sustainable antifreeze products. EVs require specialized cooling systems for battery thermal management, and environmentally friendly antifreeze solutions are essential to meet sustainability goals. Major automotive manufacturers are actively seeking alternatives to traditional ethylene glycol-based antifreeze, which is toxic and non-biodegradable.

The industrial sector, including manufacturing, chemical processing, and food production, is another key driver of demand for sustainable antifreeze solutions. Companies are increasingly adopting green practices to reduce their environmental footprint and comply with stricter regulations on chemical usage and disposal. This has led to a growing interest in biodegradable and non-toxic antifreeze formulations that can maintain operational efficiency while minimizing environmental impact.

Renewable energy installations, such as solar thermal systems and geothermal heat pumps, represent a rapidly expanding market for sustainable antifreeze solutions. These systems often require heat transfer fluids that can withstand extreme temperatures while being environmentally benign. The growth of renewable energy projects worldwide is thus creating substantial opportunities for innovative antifreeze products.

Geographically, North America and Europe are leading the demand for sustainable antifreeze solutions, largely due to advanced environmental regulations and consumer awareness. However, emerging economies in Asia-Pacific and Latin America are showing increasing interest as they modernize their industries and implement stricter environmental policies.

The market is also seeing a trend towards customized solutions tailored to specific industry needs. This includes antifreeze formulations designed for particular temperature ranges, compatibility with specific materials, and enhanced longevity to reduce replacement frequency and waste generation.

Despite the growing demand, challenges remain in terms of performance parity with traditional antifreeze products and cost-effectiveness. Manufacturers are investing heavily in research and development to address these issues and create sustainable alternatives that match or exceed the performance of conventional products while remaining economically viable.

In the automotive industry, the shift towards electric vehicles (EVs) has created a new market segment for sustainable antifreeze products. EVs require specialized cooling systems for battery thermal management, and environmentally friendly antifreeze solutions are essential to meet sustainability goals. Major automotive manufacturers are actively seeking alternatives to traditional ethylene glycol-based antifreeze, which is toxic and non-biodegradable.

The industrial sector, including manufacturing, chemical processing, and food production, is another key driver of demand for sustainable antifreeze solutions. Companies are increasingly adopting green practices to reduce their environmental footprint and comply with stricter regulations on chemical usage and disposal. This has led to a growing interest in biodegradable and non-toxic antifreeze formulations that can maintain operational efficiency while minimizing environmental impact.

Renewable energy installations, such as solar thermal systems and geothermal heat pumps, represent a rapidly expanding market for sustainable antifreeze solutions. These systems often require heat transfer fluids that can withstand extreme temperatures while being environmentally benign. The growth of renewable energy projects worldwide is thus creating substantial opportunities for innovative antifreeze products.

Geographically, North America and Europe are leading the demand for sustainable antifreeze solutions, largely due to advanced environmental regulations and consumer awareness. However, emerging economies in Asia-Pacific and Latin America are showing increasing interest as they modernize their industries and implement stricter environmental policies.

The market is also seeing a trend towards customized solutions tailored to specific industry needs. This includes antifreeze formulations designed for particular temperature ranges, compatibility with specific materials, and enhanced longevity to reduce replacement frequency and waste generation.

Despite the growing demand, challenges remain in terms of performance parity with traditional antifreeze products and cost-effectiveness. Manufacturers are investing heavily in research and development to address these issues and create sustainable alternatives that match or exceed the performance of conventional products while remaining economically viable.

Current Challenges in Eco-friendly Antifreeze Development

The development of eco-friendly antifreeze solutions faces several significant challenges in the current technological landscape. One of the primary obstacles is the need to balance environmental sustainability with performance efficiency. Traditional antifreeze formulations, often based on ethylene glycol or propylene glycol, have proven effective but pose environmental risks due to their toxicity and slow biodegradation.

Researchers and manufacturers are grappling with the challenge of developing alternative compounds that offer comparable or superior freeze protection while minimizing ecological impact. This involves exploring novel materials and formulations that are biodegradable, non-toxic, and derived from renewable resources. However, achieving the same level of performance as conventional antifreeze without compromising environmental standards remains a complex task.

Another critical challenge lies in the scalability and cost-effectiveness of eco-friendly antifreeze solutions. While promising alternatives have been identified in laboratory settings, translating these innovations into commercially viable products presents significant hurdles. The production processes for these new formulations often require substantial investments in research, development, and manufacturing infrastructure, which can drive up costs and limit widespread adoption.

Regulatory compliance and standardization pose additional challenges in the development of eco-friendly antifreeze. Different countries and regions have varying environmental regulations and performance standards for antifreeze products. Developing solutions that meet these diverse requirements while maintaining consistent performance across different climates and applications is a complex undertaking.

The automotive industry, a major consumer of antifreeze products, presents unique challenges for eco-friendly alternatives. Modern vehicles have increasingly complex cooling systems that demand specific performance characteristics from antifreeze solutions. Ensuring that environmentally friendly formulations can meet these stringent requirements without compromising engine efficiency or longevity is a significant technical challenge.

Furthermore, the disposal and recycling of eco-friendly antifreeze present their own set of challenges. While these products may be less harmful to the environment, developing efficient recycling processes and establishing proper disposal protocols are essential to maximize their environmental benefits. This requires collaboration between manufacturers, waste management facilities, and regulatory bodies to create comprehensive end-of-life solutions for these products.

Lastly, consumer education and market acceptance remain significant hurdles. Despite growing environmental awareness, there is still a need to educate consumers and industry professionals about the benefits and proper use of eco-friendly antifreeze solutions. Overcoming skepticism and changing established practices in various industries that rely on antifreeze products require sustained efforts in marketing, demonstration, and education.

Researchers and manufacturers are grappling with the challenge of developing alternative compounds that offer comparable or superior freeze protection while minimizing ecological impact. This involves exploring novel materials and formulations that are biodegradable, non-toxic, and derived from renewable resources. However, achieving the same level of performance as conventional antifreeze without compromising environmental standards remains a complex task.

Another critical challenge lies in the scalability and cost-effectiveness of eco-friendly antifreeze solutions. While promising alternatives have been identified in laboratory settings, translating these innovations into commercially viable products presents significant hurdles. The production processes for these new formulations often require substantial investments in research, development, and manufacturing infrastructure, which can drive up costs and limit widespread adoption.

Regulatory compliance and standardization pose additional challenges in the development of eco-friendly antifreeze. Different countries and regions have varying environmental regulations and performance standards for antifreeze products. Developing solutions that meet these diverse requirements while maintaining consistent performance across different climates and applications is a complex undertaking.

The automotive industry, a major consumer of antifreeze products, presents unique challenges for eco-friendly alternatives. Modern vehicles have increasingly complex cooling systems that demand specific performance characteristics from antifreeze solutions. Ensuring that environmentally friendly formulations can meet these stringent requirements without compromising engine efficiency or longevity is a significant technical challenge.

Furthermore, the disposal and recycling of eco-friendly antifreeze present their own set of challenges. While these products may be less harmful to the environment, developing efficient recycling processes and establishing proper disposal protocols are essential to maximize their environmental benefits. This requires collaboration between manufacturers, waste management facilities, and regulatory bodies to create comprehensive end-of-life solutions for these products.

Lastly, consumer education and market acceptance remain significant hurdles. Despite growing environmental awareness, there is still a need to educate consumers and industry professionals about the benefits and proper use of eco-friendly antifreeze solutions. Overcoming skepticism and changing established practices in various industries that rely on antifreeze products require sustained efforts in marketing, demonstration, and education.

Existing Eco-friendly Antifreeze Formulations

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and chemical compounds designed to lower the freezing point of the solution. Common ingredients include glycols, such as ethylene glycol or propylene glycol, which are effective in preventing freezing in cold temperatures. These solutions may also contain additives to prevent corrosion and improve heat transfer properties.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and chemical compounds such as ethylene glycol or propylene glycol. These solutions are designed to lower the freezing point of water and prevent it from freezing in vehicle cooling systems and other applications. The composition may also include additives to enhance performance and protect against corrosion.

- Recycling and purification of used antifreeze: Methods for recycling and purifying used antifreeze have been developed to reduce waste and environmental impact. These processes often involve filtration, distillation, or chemical treatment to remove contaminants and restore the antifreeze to its original effectiveness. Recycled antifreeze can be reused in vehicles or other applications, reducing the need for new production.

- Antifreeze applications in renewable energy systems: Antifreeze solutions are used in renewable energy systems such as solar thermal collectors and geothermal heat pumps. These applications require specialized formulations that can withstand high temperatures and provide efficient heat transfer. The antifreeze used in these systems often includes corrosion inhibitors and other additives to protect the equipment and maintain performance.

- Environmentally friendly antifreeze alternatives: Research has been conducted to develop more environmentally friendly antifreeze alternatives. These include bio-based antifreeze solutions derived from renewable resources, as well as formulations with reduced toxicity. Some alternatives use propylene glycol instead of ethylene glycol, as it is less toxic to humans and animals. These eco-friendly options aim to provide effective freeze protection while minimizing environmental impact.

- Antifreeze testing and quality control methods: Various testing and quality control methods have been developed for antifreeze solutions. These include techniques for measuring freezing point, boiling point, pH levels, and the concentration of active ingredients. Advanced testing methods may use spectroscopy or chromatography to analyze the composition and detect contaminants. Quality control procedures ensure that antifreeze products meet industry standards and perform effectively in their intended applications.

02 Environmentally friendly antifreeze formulations

There is a growing trend towards developing more environmentally friendly antifreeze formulations. These may include biodegradable compounds or renewable resources as base materials. Some formulations aim to reduce toxicity and improve safety for both humans and wildlife, while maintaining effective freeze protection and heat transfer properties.Expand Specific Solutions03 Antifreeze recycling and purification methods

Various methods have been developed for recycling and purifying used antifreeze solutions. These processes aim to remove contaminants, restore the original properties of the antifreeze, and extend its usable life. Techniques may include filtration, distillation, ion exchange, or chemical treatments to separate and purify the active ingredients.Expand Specific Solutions04 Antifreeze applications in specific industries

Antifreeze solutions are used in various industries beyond automotive applications. Specialized formulations have been developed for use in solar panels, wind turbines, and other renewable energy systems. In the food industry, food-grade antifreeze solutions are used in refrigeration systems. Some antifreeze formulations are designed for use in extreme conditions, such as in aerospace or polar research.Expand Specific Solutions05 Antifreeze monitoring and testing systems

Advanced systems have been developed for monitoring and testing antifreeze solutions in various applications. These may include sensors to detect the concentration and effectiveness of antifreeze in real-time, as well as portable testing devices for field use. Some systems are designed to automatically adjust antifreeze levels or alert users when maintenance is required.Expand Specific Solutions

Key Players in Sustainable Antifreeze Industry

The antifreeze industry is in a mature stage, with a global market size estimated to reach $7.7 billion by 2027. The technology for antifreeze solutions is well-established, but innovations are ongoing, particularly in sustainable and eco-friendly formulations. Key players like BASF Corp., Clariant Produkte, and Arteco NV are driving advancements in this field. These companies are focusing on developing antifreeze products that are not only effective in thermal management but also align with multinational sustainable solutions initiatives. The competitive landscape is characterized by a mix of established chemical giants and specialized antifreeze manufacturers, all striving to balance performance, environmental impact, and cost-effectiveness in their product offerings.

BASF Corp.

Technical Solution: BASF has developed innovative antifreeze solutions that contribute to sustainable practices in various industries. Their Glysantin® G40® coolant technology offers extended service life and improved protection against corrosion, cavitation, and deposits in cooling systems[1]. This advanced formulation reduces the need for frequent coolant changes, minimizing waste and environmental impact. BASF has also introduced bio-based antifreeze products, utilizing renewable resources to create more environmentally friendly alternatives to traditional petroleum-based options[2]. These products maintain high performance while reducing carbon footprint and dependence on fossil fuels.

Strengths: Global reach and extensive R&D capabilities allow for rapid innovation and adaptation to market needs. Weaknesses: Higher costs associated with developing and producing sustainable antifreeze solutions may impact price competitiveness in some markets.

Clariant Produkte (Deutschland) GmbH

Technical Solution: Clariant has developed a range of sustainable antifreeze solutions under their "EcoTain" label, focusing on environmental compatibility and performance. Their innovative approach includes the use of bio-based raw materials and advanced additive packages that enhance the efficiency and longevity of antifreeze products[3]. Clariant's antifreeze solutions incorporate corrosion inhibitors that are free from nitrites, amines, and phosphates, addressing environmental concerns while maintaining excellent heat transfer properties[4]. The company has also invested in developing antifreeze formulations that are readily biodegradable, reducing the environmental impact of potential spills or improper disposal.

Strengths: Strong focus on sustainability and eco-friendly product development aligns well with global environmental initiatives. Weaknesses: May face challenges in markets where traditional, less expensive antifreeze products are still preferred.

Breakthrough Technologies in Green Antifreeze

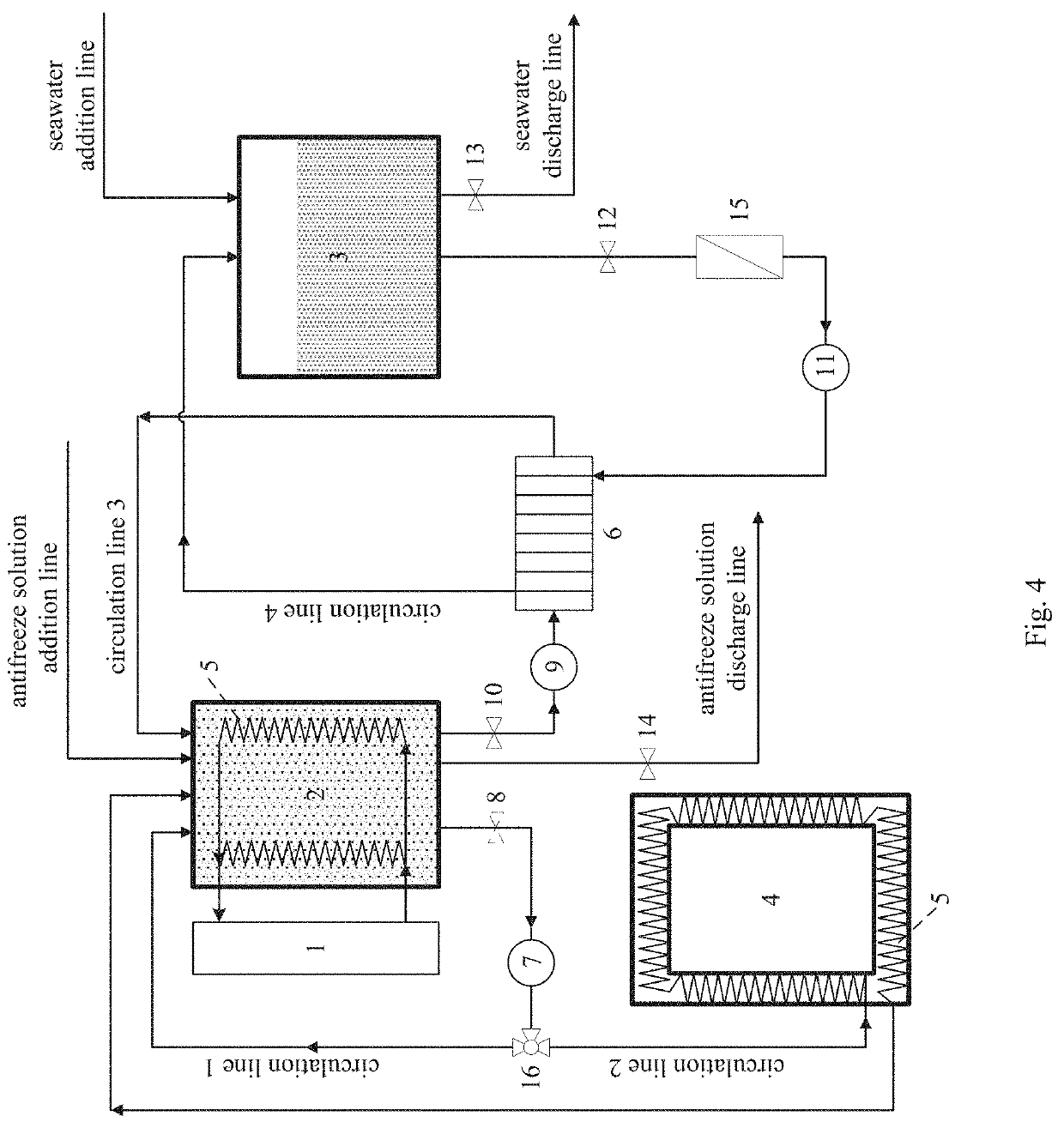

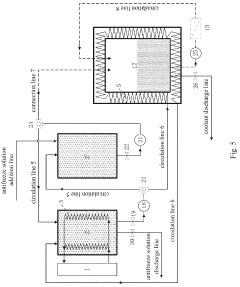

Method of green and safe preservation for aquatic products at sea

PatentActiveUS20190387760A1

Innovation

- A method using an on-board refrigeration system with an antifreeze solution composed of edible alcohol, propylene glycol, glycerin, calcium chloride, sodium chloride, Antarctic krill protein hydrolysate, and surfactants to rapidly cool aquatic products, inhibiting microbial growth and enzyme activity without mechanical damage, and reducing energy consumption and costs.

Antifreeze agent

PatentInactiveEP1386952A3

Innovation

- An antifreeze concentrate combining sulfonated or sulfated polyglycols with additives such as aromatic amines, hydrocarbon triazoles, alkylene glycols, and specific salts to create a corrosion-inhibiting aqueous solution that maintains effective protection without causing significant metal surface deposits, even at elevated temperatures.

Environmental Regulations Impact on Antifreeze Industry

Environmental regulations have significantly impacted the antifreeze industry, driving innovation and reshaping business practices across multinational corporations. These regulations aim to mitigate the environmental risks associated with traditional antifreeze formulations, particularly those containing ethylene glycol, which is toxic to humans and wildlife.

In response to stringent environmental policies, many countries have implemented strict guidelines for the production, use, and disposal of antifreeze products. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential, requiring manufacturers to assess and manage the risks posed by chemicals used in antifreeze formulations. This has led to increased investment in research and development of more environmentally friendly alternatives.

The United States Environmental Protection Agency (EPA) has also played a crucial role in shaping the industry through regulations such as the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These regulations have mandated proper handling and disposal procedures for antifreeze, encouraging recycling and promoting the use of less harmful propylene glycol-based formulations.

As a result of these regulatory pressures, multinational companies have been compelled to innovate and develop sustainable antifreeze solutions. This has led to the emergence of bio-based and recyclable antifreeze products, which offer improved environmental performance without compromising functionality. These innovations not only help companies comply with regulations but also provide a competitive advantage in an increasingly environmentally conscious market.

The impact of environmental regulations extends beyond product formulation to manufacturing processes and supply chain management. Companies are now required to implement more efficient production methods, reduce waste, and ensure responsible sourcing of raw materials. This has resulted in the adoption of closed-loop manufacturing systems and the development of advanced recycling technologies for antifreeze products.

Furthermore, the regulatory landscape has fostered collaboration between industry players, research institutions, and regulatory bodies. This collaborative approach has accelerated the development of sustainable antifreeze solutions and helped establish industry-wide best practices for environmental stewardship.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This ongoing regulatory pressure will continue to drive innovation in the antifreeze industry, pushing companies to develop increasingly sustainable and environmentally friendly solutions. The ability to adapt to and comply with these evolving regulations will be crucial for the long-term success of multinational corporations operating in this sector.

In response to stringent environmental policies, many countries have implemented strict guidelines for the production, use, and disposal of antifreeze products. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential, requiring manufacturers to assess and manage the risks posed by chemicals used in antifreeze formulations. This has led to increased investment in research and development of more environmentally friendly alternatives.

The United States Environmental Protection Agency (EPA) has also played a crucial role in shaping the industry through regulations such as the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These regulations have mandated proper handling and disposal procedures for antifreeze, encouraging recycling and promoting the use of less harmful propylene glycol-based formulations.

As a result of these regulatory pressures, multinational companies have been compelled to innovate and develop sustainable antifreeze solutions. This has led to the emergence of bio-based and recyclable antifreeze products, which offer improved environmental performance without compromising functionality. These innovations not only help companies comply with regulations but also provide a competitive advantage in an increasingly environmentally conscious market.

The impact of environmental regulations extends beyond product formulation to manufacturing processes and supply chain management. Companies are now required to implement more efficient production methods, reduce waste, and ensure responsible sourcing of raw materials. This has resulted in the adoption of closed-loop manufacturing systems and the development of advanced recycling technologies for antifreeze products.

Furthermore, the regulatory landscape has fostered collaboration between industry players, research institutions, and regulatory bodies. This collaborative approach has accelerated the development of sustainable antifreeze solutions and helped establish industry-wide best practices for environmental stewardship.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This ongoing regulatory pressure will continue to drive innovation in the antifreeze industry, pushing companies to develop increasingly sustainable and environmentally friendly solutions. The ability to adapt to and comply with these evolving regulations will be crucial for the long-term success of multinational corporations operating in this sector.

Life Cycle Assessment of Antifreeze Products

Life Cycle Assessment (LCA) of antifreeze products is a crucial component in evaluating the environmental impact and sustainability of these essential automotive fluids. This comprehensive analysis encompasses the entire lifecycle of antifreeze, from raw material extraction to production, use, and disposal.

The production phase of antifreeze involves the synthesis of ethylene glycol or propylene glycol, the primary active ingredients. This process typically requires significant energy inputs and may result in greenhouse gas emissions. Additionally, the production of additives, such as corrosion inhibitors and pH buffers, contributes to the overall environmental footprint.

During the use phase, antifreeze products play a vital role in maintaining engine efficiency and longevity. By preventing freezing and overheating, they contribute to improved fuel economy and reduced emissions over the vehicle's lifespan. However, potential leaks and improper disposal can lead to soil and water contamination, posing risks to ecosystems and human health.

The disposal and recycling stage of antifreeze products present both challenges and opportunities for sustainable practices. Proper recycling can recover a significant portion of the glycol base, reducing the need for virgin materials and minimizing waste. However, inadequate disposal methods can result in environmental pollution and resource loss.

Recent innovations in antifreeze formulations have focused on developing more environmentally friendly alternatives. These include the use of bio-based glycols derived from renewable resources, which can significantly reduce the carbon footprint of antifreeze production. Additionally, extended-life formulations have been introduced, reducing the frequency of fluid changes and associated waste generation.

The LCA of antifreeze products also considers the potential for reuse and recycling. Advanced recycling technologies can purify used antifreeze, restoring it to a quality comparable to new products. This circular economy approach not only reduces waste but also conserves energy and resources associated with new production.

Multinational corporations play a significant role in driving sustainable innovations in antifreeze products. By implementing global standards for production, use, and recycling, these companies can leverage their scale to promote environmentally responsible practices across diverse markets. Furthermore, collaboration between automotive manufacturers, chemical companies, and recycling facilities can lead to more efficient lifecycle management of antifreeze products.

In conclusion, the Life Cycle Assessment of antifreeze products reveals the complex interplay between environmental impacts and performance benefits. As the automotive industry continues to evolve towards more sustainable practices, ongoing research and innovation in antifreeze technology will be crucial in minimizing environmental footprints while maintaining essential vehicle performance and safety standards.

The production phase of antifreeze involves the synthesis of ethylene glycol or propylene glycol, the primary active ingredients. This process typically requires significant energy inputs and may result in greenhouse gas emissions. Additionally, the production of additives, such as corrosion inhibitors and pH buffers, contributes to the overall environmental footprint.

During the use phase, antifreeze products play a vital role in maintaining engine efficiency and longevity. By preventing freezing and overheating, they contribute to improved fuel economy and reduced emissions over the vehicle's lifespan. However, potential leaks and improper disposal can lead to soil and water contamination, posing risks to ecosystems and human health.

The disposal and recycling stage of antifreeze products present both challenges and opportunities for sustainable practices. Proper recycling can recover a significant portion of the glycol base, reducing the need for virgin materials and minimizing waste. However, inadequate disposal methods can result in environmental pollution and resource loss.

Recent innovations in antifreeze formulations have focused on developing more environmentally friendly alternatives. These include the use of bio-based glycols derived from renewable resources, which can significantly reduce the carbon footprint of antifreeze production. Additionally, extended-life formulations have been introduced, reducing the frequency of fluid changes and associated waste generation.

The LCA of antifreeze products also considers the potential for reuse and recycling. Advanced recycling technologies can purify used antifreeze, restoring it to a quality comparable to new products. This circular economy approach not only reduces waste but also conserves energy and resources associated with new production.

Multinational corporations play a significant role in driving sustainable innovations in antifreeze products. By implementing global standards for production, use, and recycling, these companies can leverage their scale to promote environmentally responsible practices across diverse markets. Furthermore, collaboration between automotive manufacturers, chemical companies, and recycling facilities can lead to more efficient lifecycle management of antifreeze products.

In conclusion, the Life Cycle Assessment of antifreeze products reveals the complex interplay between environmental impacts and performance benefits. As the automotive industry continues to evolve towards more sustainable practices, ongoing research and innovation in antifreeze technology will be crucial in minimizing environmental footprints while maintaining essential vehicle performance and safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!