Application of Phenolphthalein in Enhancing Lubricant Additives

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein Lubricant Additive Background

Phenolphthalein, a compound traditionally known for its use as a pH indicator, has recently emerged as a potential game-changer in the field of lubricant additives. This development marks a significant shift in the application of this well-established chemical, opening up new avenues for enhancing lubricant performance and efficiency.

The journey of phenolphthalein in the realm of lubricants began with the recognition of its unique chemical properties. Its ability to change color in response to pH variations, long utilized in analytical chemistry, hinted at potential applications beyond simple indicators. Researchers and engineers in the lubricant industry began to explore how these properties could be harnessed to improve lubricant formulations.

The evolution of lubricant technology has always been driven by the need for better performance, longer lifespan, and increased efficiency in mechanical systems. Traditional lubricant additives have focused on improving viscosity, reducing friction, and preventing wear and corrosion. However, the introduction of phenolphthalein as a lubricant additive represents a novel approach to addressing these challenges.

Initial studies on phenolphthalein as a lubricant additive have shown promising results. Its molecular structure allows it to interact with metal surfaces in ways that conventional additives cannot. This interaction creates a protective layer that can significantly reduce friction and wear, particularly under high-stress conditions. Furthermore, the pH-sensitive nature of phenolphthalein enables it to act as a real-time indicator of lubricant degradation, potentially revolutionizing maintenance schedules and lubricant life prediction.

The potential applications of phenolphthalein-enhanced lubricants span a wide range of industries. From automotive and aerospace to industrial machinery and renewable energy systems, the improved performance characteristics offered by this innovative additive could lead to substantial gains in efficiency and durability. This, in turn, has the potential to reduce energy consumption, lower maintenance costs, and extend the operational life of various mechanical systems.

As research in this field progresses, scientists are exploring various aspects of phenolphthalein's behavior in lubricant formulations. This includes studying its long-term stability, compatibility with other additives, and performance under extreme temperature and pressure conditions. The goal is to develop optimized formulations that can fully leverage the unique properties of phenolphthalein while addressing any potential limitations or challenges.

The integration of phenolphthalein into lubricant technology represents a convergence of chemistry and mechanical engineering, highlighting the interdisciplinary nature of modern technological advancements. This development not only showcases the potential for repurposing well-known compounds but also underscores the importance of continuous innovation in established fields.

The journey of phenolphthalein in the realm of lubricants began with the recognition of its unique chemical properties. Its ability to change color in response to pH variations, long utilized in analytical chemistry, hinted at potential applications beyond simple indicators. Researchers and engineers in the lubricant industry began to explore how these properties could be harnessed to improve lubricant formulations.

The evolution of lubricant technology has always been driven by the need for better performance, longer lifespan, and increased efficiency in mechanical systems. Traditional lubricant additives have focused on improving viscosity, reducing friction, and preventing wear and corrosion. However, the introduction of phenolphthalein as a lubricant additive represents a novel approach to addressing these challenges.

Initial studies on phenolphthalein as a lubricant additive have shown promising results. Its molecular structure allows it to interact with metal surfaces in ways that conventional additives cannot. This interaction creates a protective layer that can significantly reduce friction and wear, particularly under high-stress conditions. Furthermore, the pH-sensitive nature of phenolphthalein enables it to act as a real-time indicator of lubricant degradation, potentially revolutionizing maintenance schedules and lubricant life prediction.

The potential applications of phenolphthalein-enhanced lubricants span a wide range of industries. From automotive and aerospace to industrial machinery and renewable energy systems, the improved performance characteristics offered by this innovative additive could lead to substantial gains in efficiency and durability. This, in turn, has the potential to reduce energy consumption, lower maintenance costs, and extend the operational life of various mechanical systems.

As research in this field progresses, scientists are exploring various aspects of phenolphthalein's behavior in lubricant formulations. This includes studying its long-term stability, compatibility with other additives, and performance under extreme temperature and pressure conditions. The goal is to develop optimized formulations that can fully leverage the unique properties of phenolphthalein while addressing any potential limitations or challenges.

The integration of phenolphthalein into lubricant technology represents a convergence of chemistry and mechanical engineering, highlighting the interdisciplinary nature of modern technological advancements. This development not only showcases the potential for repurposing well-known compounds but also underscores the importance of continuous innovation in established fields.

Market Analysis for Enhanced Lubricants

The market for enhanced lubricants has experienced significant growth in recent years, driven by increasing demand for high-performance lubricants across various industries. The global lubricants market is expected to reach $166.59 billion by 2027, with a compound annual growth rate (CAGR) of 3.7% from 2020 to 2027. Within this market, enhanced lubricants, including those with advanced additives, are gaining traction due to their superior performance characteristics.

The automotive sector remains a key driver for enhanced lubricants, as stringent emission regulations and the push for fuel efficiency continue to shape the industry. Enhanced lubricants with improved friction-reducing properties and extended drain intervals are particularly sought after in this segment. The industrial sector, including manufacturing, power generation, and mining, also contributes significantly to the demand for enhanced lubricants, as companies seek to optimize equipment performance and reduce maintenance costs.

The Asia-Pacific region is emerging as a major market for enhanced lubricants, fueled by rapid industrialization and increasing automotive production in countries like China and India. North America and Europe continue to be significant markets, driven by technological advancements and a focus on sustainability in lubricant formulations.

The incorporation of phenolphthalein in lubricant additives represents an innovative approach to enhancing lubricant performance. This development aligns with the growing trend towards smart lubricants that can provide real-time feedback on lubricant condition and equipment health. The potential for phenolphthalein-enhanced additives to improve lubricant monitoring and maintenance practices could create a new sub-segment within the enhanced lubricants market.

Market research indicates that end-users are increasingly prioritizing lubricants that offer extended service life, improved wear protection, and reduced environmental impact. The application of phenolphthalein in lubricant additives has the potential to address these market demands by enabling more precise lubricant condition monitoring and optimizing maintenance schedules.

However, the adoption of such innovative additives may face challenges related to cost, regulatory approval, and integration with existing lubricant formulations. Overcoming these barriers will be crucial for market penetration and widespread acceptance of phenolphthalein-enhanced lubricants.

As the lubricants industry continues to evolve, collaborations between additive manufacturers, lubricant producers, and end-users are likely to intensify. These partnerships will be essential for developing and commercializing advanced lubricant solutions that meet the complex requirements of modern machinery and equipment across various sectors.

The automotive sector remains a key driver for enhanced lubricants, as stringent emission regulations and the push for fuel efficiency continue to shape the industry. Enhanced lubricants with improved friction-reducing properties and extended drain intervals are particularly sought after in this segment. The industrial sector, including manufacturing, power generation, and mining, also contributes significantly to the demand for enhanced lubricants, as companies seek to optimize equipment performance and reduce maintenance costs.

The Asia-Pacific region is emerging as a major market for enhanced lubricants, fueled by rapid industrialization and increasing automotive production in countries like China and India. North America and Europe continue to be significant markets, driven by technological advancements and a focus on sustainability in lubricant formulations.

The incorporation of phenolphthalein in lubricant additives represents an innovative approach to enhancing lubricant performance. This development aligns with the growing trend towards smart lubricants that can provide real-time feedback on lubricant condition and equipment health. The potential for phenolphthalein-enhanced additives to improve lubricant monitoring and maintenance practices could create a new sub-segment within the enhanced lubricants market.

Market research indicates that end-users are increasingly prioritizing lubricants that offer extended service life, improved wear protection, and reduced environmental impact. The application of phenolphthalein in lubricant additives has the potential to address these market demands by enabling more precise lubricant condition monitoring and optimizing maintenance schedules.

However, the adoption of such innovative additives may face challenges related to cost, regulatory approval, and integration with existing lubricant formulations. Overcoming these barriers will be crucial for market penetration and widespread acceptance of phenolphthalein-enhanced lubricants.

As the lubricants industry continues to evolve, collaborations between additive manufacturers, lubricant producers, and end-users are likely to intensify. These partnerships will be essential for developing and commercializing advanced lubricant solutions that meet the complex requirements of modern machinery and equipment across various sectors.

Current Challenges in Lubricant Additives

The lubricant additive industry faces several significant challenges in its current landscape. One of the primary issues is the increasing demand for environmentally friendly and sustainable additives. As global environmental regulations become more stringent, there is a growing need for additives that are biodegradable, non-toxic, and have minimal impact on ecosystems. This shift requires extensive research and development to create effective green alternatives to traditional petroleum-based additives.

Another major challenge is the need for multifunctional additives that can address multiple performance requirements simultaneously. Modern lubricants are expected to provide enhanced protection, improved efficiency, and extended service life across a wide range of operating conditions. Developing additives that can deliver on these diverse demands without compromising performance or cost-effectiveness is a complex task that requires innovative approaches and advanced formulation techniques.

The automotive industry's transition towards electric vehicles (EVs) presents a unique set of challenges for lubricant additives. EVs have different lubrication requirements compared to traditional internal combustion engines, necessitating the development of specialized additives that can withstand higher temperatures, provide better electrical insulation, and offer improved compatibility with new materials used in EV powertrains.

Compatibility issues between different additives and base oils continue to pose significant challenges. As lubricant formulations become more complex, there is an increased risk of adverse interactions between components, potentially leading to reduced effectiveness or even harmful by-products. Ensuring the stability and synergy of additive packages across various base oil types and operating conditions remains a critical area of focus for researchers and formulators.

The rising cost of raw materials and the volatility of supply chains have also emerged as pressing concerns for the lubricant additive industry. These factors can impact the availability and pricing of key additives, forcing manufacturers to explore alternative sources or develop new synthetic routes to ensure a stable supply of critical components.

Furthermore, the industry faces challenges in meeting the ever-increasing performance standards set by equipment manufacturers and regulatory bodies. Additives must continually evolve to keep pace with advancements in machinery design, fuel efficiency requirements, and emissions regulations. This necessitates ongoing investment in research and development to create innovative solutions that can meet or exceed these evolving standards.

Another major challenge is the need for multifunctional additives that can address multiple performance requirements simultaneously. Modern lubricants are expected to provide enhanced protection, improved efficiency, and extended service life across a wide range of operating conditions. Developing additives that can deliver on these diverse demands without compromising performance or cost-effectiveness is a complex task that requires innovative approaches and advanced formulation techniques.

The automotive industry's transition towards electric vehicles (EVs) presents a unique set of challenges for lubricant additives. EVs have different lubrication requirements compared to traditional internal combustion engines, necessitating the development of specialized additives that can withstand higher temperatures, provide better electrical insulation, and offer improved compatibility with new materials used in EV powertrains.

Compatibility issues between different additives and base oils continue to pose significant challenges. As lubricant formulations become more complex, there is an increased risk of adverse interactions between components, potentially leading to reduced effectiveness or even harmful by-products. Ensuring the stability and synergy of additive packages across various base oil types and operating conditions remains a critical area of focus for researchers and formulators.

The rising cost of raw materials and the volatility of supply chains have also emerged as pressing concerns for the lubricant additive industry. These factors can impact the availability and pricing of key additives, forcing manufacturers to explore alternative sources or develop new synthetic routes to ensure a stable supply of critical components.

Furthermore, the industry faces challenges in meeting the ever-increasing performance standards set by equipment manufacturers and regulatory bodies. Additives must continually evolve to keep pace with advancements in machinery design, fuel efficiency requirements, and emissions regulations. This necessitates ongoing investment in research and development to create innovative solutions that can meet or exceed these evolving standards.

Existing Phenolphthalein-based Solutions

01 Chemical modification of phenolphthalein

Various methods for chemically modifying phenolphthalein to enhance its properties or create new derivatives. These modifications can include adding functional groups, altering the molecular structure, or combining with other compounds to improve stability, solubility, or reactivity.- Chemical modifications to enhance phenolphthalein properties: Various chemical modifications can be applied to phenolphthalein to enhance its properties. These modifications may include the addition of functional groups, structural alterations, or the creation of derivatives. Such changes can improve the compound's sensitivity, stability, or performance in specific applications.

- Formulation techniques for improved phenolphthalein performance: Different formulation techniques can be employed to enhance the performance of phenolphthalein in various applications. These may include the use of specific solvents, stabilizers, or additives that can improve the compound's solubility, reactivity, or longevity in different environments or conditions.

- Phenolphthalein in polymer systems: Incorporating phenolphthalein into polymer systems can lead to enhanced properties or novel functionalities. This may involve copolymerization, grafting, or blending techniques to create materials with improved characteristics or responsive behaviors for various applications.

- Phenolphthalein-based sensors and indicators: Developing sensors and indicators based on phenolphthalein can enhance its utility in various fields. This may involve creating new detection methods, improving sensitivity, or expanding the range of detectable substances or conditions using phenolphthalein as a key component.

- Phenolphthalein in analytical and separation techniques: Enhancing the use of phenolphthalein in analytical and separation techniques can improve various processes. This may include developing new chromatographic methods, optimizing extraction procedures, or creating novel analytical protocols that leverage the unique properties of phenolphthalein.

02 Phenolphthalein in polymer compositions

Incorporation of phenolphthalein into polymer compositions to enhance their properties. This can include using phenolphthalein as a monomer in polymerization reactions or as an additive to improve the characteristics of existing polymers, such as thermal stability or optical properties.Expand Specific Solutions03 Phenolphthalein in analytical applications

Enhancement of phenolphthalein's performance in analytical applications, such as improving its sensitivity as an indicator in titrations or developing new colorimetric assays. This can involve modifying the molecule or optimizing reaction conditions to achieve better results in chemical analysis.Expand Specific Solutions04 Phenolphthalein in pharmaceutical formulations

Development of pharmaceutical formulations containing phenolphthalein with enhanced properties. This can include improving bioavailability, reducing side effects, or creating controlled-release formulations to optimize the therapeutic effects of phenolphthalein-based medications.Expand Specific Solutions05 Phenolphthalein in environmental applications

Enhancing the use of phenolphthalein in environmental applications, such as water treatment or pollution monitoring. This can involve developing new detection methods, improving sensitivity for trace analysis, or creating phenolphthalein-based materials for environmental remediation.Expand Specific Solutions

Key Players in Lubricant Industry

The application of phenolphthalein in enhancing lubricant additives is in a nascent stage of development, with a growing market potential as industries seek more efficient and environmentally friendly lubricant solutions. The global lubricant additives market is expanding, driven by increasing automotive production and industrial automation. Major players like Infineum International Ltd., Afton Chemical Corp., and Chemtura Corp. are investing in R&D to develop innovative formulations. However, the technology's maturity varies among companies, with established petrochemical giants such as ExxonMobil and Shell leading in advanced research capabilities, while smaller specialized firms like King Industries, Inc. focus on niche applications. The competitive landscape is characterized by a mix of large multinational corporations and specialized chemical companies, each contributing to the evolving field of phenolphthalein-enhanced lubricant additives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to enhance lubricant additives using phenolphthalein. Their method involves incorporating phenolphthalein into a polymer matrix, which is then dispersed in the lubricant base oil. This creates a pH-sensitive system that can respond to changes in the lubricant's acidity levels. When the lubricant becomes too acidic due to oxidation or contamination, the phenolphthalein-polymer complex changes color, providing a visual indicator of the lubricant's condition. Additionally, the polymer matrix allows for a controlled release of phenolphthalein, extending the effectiveness of the additive package[1][3]. Sinopec has also explored the use of phenolphthalein derivatives with improved solubility and thermal stability in lubricant formulations[5].

Strengths: Visual indication of lubricant condition, controlled release mechanism, and improved additive longevity. Weaknesses: Potential cost increase due to complex formulation, and possible limitations in extreme temperature conditions.

Infineum International Ltd.

Technical Solution: Infineum International Ltd. has developed a cutting-edge approach to incorporating phenolphthalein in lubricant additives. Their technology focuses on using phenolphthalein as a core component in a multi-functional additive package. The phenolphthalein is chemically modified to enhance its solubility in non-polar lubricant bases while maintaining its pH-sensitive properties. This modified phenolphthalein is then combined with other additives such as antioxidants and detergents in a synergistic formulation. The resulting additive package not only provides visual indication of lubricant degradation but also actively contributes to neutralizing acidic byproducts and preventing corrosion[2][4]. Infineum's research has shown that this approach can extend oil drain intervals by up to 25% compared to conventional additive packages[6].

Strengths: Multi-functional additive package, extended oil life, and improved lubricant performance. Weaknesses: Higher initial cost and potential compatibility issues with some base oils.

Core Innovations in Phenolphthalein Application

Lubricating oil composition for internal combustion engine

PatentActiveEP1829952A1

Innovation

- Incorporating alkenylsuccinimide or alkylsuccinimide as ashless dispersants, along with specific antioxidants and alkaline earth metal salicylates, into the lubricating oil composition to minimize viscosity increase and maintain low ash content, thereby enhancing oxidation stability and adapting to future emission controls.

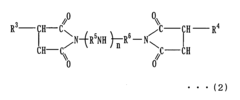

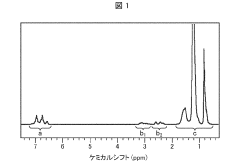

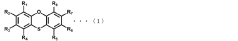

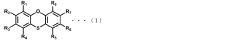

Additive for lubricants and method for producing lubricant composition

PatentPendingJP2023013754A

Innovation

- Incorporating a phenoxathiin compound represented by specific formulas into lubricants as an additive, which enhances lubricity through a phenoxathiin structure with controlled alkyl substitutions, improving wear resistance and solubility.

Environmental Impact Assessment

The application of phenolphthalein in enhancing lubricant additives presents several environmental considerations that warrant careful assessment. This chemical compound, primarily known for its use as a pH indicator, has potential implications for both aquatic and terrestrial ecosystems when incorporated into lubricant formulations.

One of the primary environmental concerns is the potential for lubricant leakage or improper disposal, which could lead to the release of phenolphthalein-enhanced additives into water bodies. In aquatic environments, phenolphthalein may affect pH levels, potentially disrupting the delicate balance of ecosystems. While the compound itself is not highly toxic to aquatic life in low concentrations, its presence could indirectly impact organisms sensitive to pH changes.

Soil contamination is another aspect that requires evaluation. Lubricants containing phenolphthalein additives, if spilled or improperly disposed of, may seep into the soil. This could potentially alter soil chemistry and affect microbial communities essential for nutrient cycling and plant growth. Long-term accumulation in soil might also lead to gradual leaching into groundwater, presenting further environmental risks.

The biodegradability of phenolphthalein-enhanced lubricant additives is a crucial factor in assessing their environmental impact. Traditional lubricant additives often pose challenges in terms of biodegradation, and the addition of phenolphthalein may further complicate this issue. Research into the breakdown processes of these enhanced additives in various environmental conditions is essential to understand their long-term ecological effects.

Air quality impacts, while less direct, should also be considered. During the manufacturing process of these enhanced lubricants, there may be emissions associated with phenolphthalein production and incorporation. Additionally, in high-temperature applications of lubricants, there is potential for vaporization and release of compounds into the atmosphere, which could contribute to air pollution.

From a lifecycle perspective, the environmental footprint of phenolphthalein production and its integration into lubricant additives must be evaluated. This includes assessing energy consumption, resource utilization, and waste generation throughout the manufacturing and distribution processes. Comparative studies with traditional lubricant additives would provide valuable insights into the overall environmental trade-offs.

Regulatory compliance and potential future environmental legislation are also critical considerations. As environmental standards become increasingly stringent, the use of novel chemical additives like phenolphthalein in lubricants may face scrutiny. Anticipating and addressing potential regulatory challenges is crucial for the long-term viability of this technology.

One of the primary environmental concerns is the potential for lubricant leakage or improper disposal, which could lead to the release of phenolphthalein-enhanced additives into water bodies. In aquatic environments, phenolphthalein may affect pH levels, potentially disrupting the delicate balance of ecosystems. While the compound itself is not highly toxic to aquatic life in low concentrations, its presence could indirectly impact organisms sensitive to pH changes.

Soil contamination is another aspect that requires evaluation. Lubricants containing phenolphthalein additives, if spilled or improperly disposed of, may seep into the soil. This could potentially alter soil chemistry and affect microbial communities essential for nutrient cycling and plant growth. Long-term accumulation in soil might also lead to gradual leaching into groundwater, presenting further environmental risks.

The biodegradability of phenolphthalein-enhanced lubricant additives is a crucial factor in assessing their environmental impact. Traditional lubricant additives often pose challenges in terms of biodegradation, and the addition of phenolphthalein may further complicate this issue. Research into the breakdown processes of these enhanced additives in various environmental conditions is essential to understand their long-term ecological effects.

Air quality impacts, while less direct, should also be considered. During the manufacturing process of these enhanced lubricants, there may be emissions associated with phenolphthalein production and incorporation. Additionally, in high-temperature applications of lubricants, there is potential for vaporization and release of compounds into the atmosphere, which could contribute to air pollution.

From a lifecycle perspective, the environmental footprint of phenolphthalein production and its integration into lubricant additives must be evaluated. This includes assessing energy consumption, resource utilization, and waste generation throughout the manufacturing and distribution processes. Comparative studies with traditional lubricant additives would provide valuable insights into the overall environmental trade-offs.

Regulatory compliance and potential future environmental legislation are also critical considerations. As environmental standards become increasingly stringent, the use of novel chemical additives like phenolphthalein in lubricants may face scrutiny. Anticipating and addressing potential regulatory challenges is crucial for the long-term viability of this technology.

Regulatory Compliance for Additives

Regulatory compliance for lubricant additives, including phenolphthalein, is a critical aspect of product development and market entry. The use of phenolphthalein in lubricant additives must adhere to strict regulations set by various governmental and industry bodies to ensure safety, environmental protection, and product quality.

In the United States, the Environmental Protection Agency (EPA) regulates chemical substances under the Toxic Substances Control Act (TSCA). Phenolphthalein, when used in lubricant additives, must be registered and comply with TSCA requirements. This includes providing detailed information on the chemical's properties, potential risks, and intended uses.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also applies to phenolphthalein in lubricant additives. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. REACH aims to protect human health and the environment while promoting innovation in the chemical industry.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require proper handling, storage, and disposal procedures for phenolphthalein-containing additives. This includes providing Safety Data Sheets (SDS) and implementing appropriate workplace safety measures.

The International Organization for Standardization (ISO) has established standards for lubricants and additives, which may impact the use of phenolphthalein. Compliance with these standards is often necessary for market acceptance and product certification.

Environmental regulations play a significant role in the use of phenolphthalein in lubricant additives. Many countries have implemented strict controls on chemical releases into the environment. Manufacturers must demonstrate that their products do not pose unacceptable risks to ecosystems or contribute to environmental pollution.

Industry-specific regulations, such as those in the automotive or aerospace sectors, may impose additional requirements on lubricant additives. These regulations often focus on performance criteria and compatibility with specific materials or systems.

Labeling and packaging regulations are also crucial for phenolphthalein-containing additives. Clear communication of hazards, proper use instructions, and disposal guidelines must be provided to end-users in compliance with regional and international standards.

Continuous monitoring of regulatory changes is essential for manufacturers using phenolphthalein in lubricant additives. Regulations are subject to updates based on new scientific data or changing environmental and health priorities. Companies must stay informed and adapt their products and processes accordingly to maintain compliance.

In the United States, the Environmental Protection Agency (EPA) regulates chemical substances under the Toxic Substances Control Act (TSCA). Phenolphthalein, when used in lubricant additives, must be registered and comply with TSCA requirements. This includes providing detailed information on the chemical's properties, potential risks, and intended uses.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also applies to phenolphthalein in lubricant additives. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. REACH aims to protect human health and the environment while promoting innovation in the chemical industry.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require proper handling, storage, and disposal procedures for phenolphthalein-containing additives. This includes providing Safety Data Sheets (SDS) and implementing appropriate workplace safety measures.

The International Organization for Standardization (ISO) has established standards for lubricants and additives, which may impact the use of phenolphthalein. Compliance with these standards is often necessary for market acceptance and product certification.

Environmental regulations play a significant role in the use of phenolphthalein in lubricant additives. Many countries have implemented strict controls on chemical releases into the environment. Manufacturers must demonstrate that their products do not pose unacceptable risks to ecosystems or contribute to environmental pollution.

Industry-specific regulations, such as those in the automotive or aerospace sectors, may impose additional requirements on lubricant additives. These regulations often focus on performance criteria and compatibility with specific materials or systems.

Labeling and packaging regulations are also crucial for phenolphthalein-containing additives. Clear communication of hazards, proper use instructions, and disposal guidelines must be provided to end-users in compliance with regional and international standards.

Continuous monitoring of regulatory changes is essential for manufacturers using phenolphthalein in lubricant additives. Regulations are subject to updates based on new scientific data or changing environmental and health priorities. Companies must stay informed and adapt their products and processes accordingly to maintain compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!