Phenolphthalein in the Development of Time-Temperature Indicators

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein TTI Background and Objectives

Time-Temperature Indicators (TTIs) have emerged as crucial tools in monitoring the quality and safety of perishable products throughout the supply chain. Among various TTI technologies, the use of phenolphthalein has gained significant attention due to its unique properties and potential applications. This research aims to explore the development and implementation of phenolphthalein-based TTIs, addressing the growing demand for reliable and cost-effective temperature monitoring solutions.

The evolution of TTI technology can be traced back to the mid-20th century, with early attempts focusing on simple chemical reactions. However, the incorporation of phenolphthalein into TTI systems represents a more recent advancement, leveraging its well-known pH-sensitive color-changing properties. Phenolphthalein, traditionally used as an acid-base indicator, has found a new purpose in the realm of temperature monitoring, offering a visual representation of time-temperature exposure.

The primary objective of this research is to comprehensively investigate the potential of phenolphthalein in developing advanced TTI systems. This includes understanding the underlying mechanisms of phenolphthalein's response to temperature changes, optimizing its performance for various temperature ranges, and exploring methods to enhance its stability and longevity in practical applications.

Furthermore, this study aims to address the current limitations of existing TTI technologies, such as limited temperature range, poor visibility, and high production costs. By focusing on phenolphthalein-based solutions, we seek to develop TTIs that offer improved accuracy, broader temperature sensitivity, and enhanced visual clarity, all while maintaining cost-effectiveness for widespread adoption across industries.

Another key objective is to explore the integration of phenolphthalein TTIs with smart packaging technologies and IoT systems. This convergence has the potential to revolutionize supply chain management by providing real-time temperature monitoring and data analytics capabilities, enabling more informed decision-making and proactive quality control measures.

As environmental concerns continue to grow, this research also aims to investigate the eco-friendly aspects of phenolphthalein-based TTIs. We will explore biodegradable formulations and sustainable production methods to align with the increasing demand for environmentally responsible packaging solutions.

Ultimately, this research seeks to contribute to the advancement of food safety, pharmaceutical integrity, and overall quality assurance in temperature-sensitive supply chains. By developing innovative phenolphthalein-based TTI technologies, we aim to provide industries with more reliable tools to monitor and maintain product quality, reduce waste, and enhance consumer trust in perishable goods.

The evolution of TTI technology can be traced back to the mid-20th century, with early attempts focusing on simple chemical reactions. However, the incorporation of phenolphthalein into TTI systems represents a more recent advancement, leveraging its well-known pH-sensitive color-changing properties. Phenolphthalein, traditionally used as an acid-base indicator, has found a new purpose in the realm of temperature monitoring, offering a visual representation of time-temperature exposure.

The primary objective of this research is to comprehensively investigate the potential of phenolphthalein in developing advanced TTI systems. This includes understanding the underlying mechanisms of phenolphthalein's response to temperature changes, optimizing its performance for various temperature ranges, and exploring methods to enhance its stability and longevity in practical applications.

Furthermore, this study aims to address the current limitations of existing TTI technologies, such as limited temperature range, poor visibility, and high production costs. By focusing on phenolphthalein-based solutions, we seek to develop TTIs that offer improved accuracy, broader temperature sensitivity, and enhanced visual clarity, all while maintaining cost-effectiveness for widespread adoption across industries.

Another key objective is to explore the integration of phenolphthalein TTIs with smart packaging technologies and IoT systems. This convergence has the potential to revolutionize supply chain management by providing real-time temperature monitoring and data analytics capabilities, enabling more informed decision-making and proactive quality control measures.

As environmental concerns continue to grow, this research also aims to investigate the eco-friendly aspects of phenolphthalein-based TTIs. We will explore biodegradable formulations and sustainable production methods to align with the increasing demand for environmentally responsible packaging solutions.

Ultimately, this research seeks to contribute to the advancement of food safety, pharmaceutical integrity, and overall quality assurance in temperature-sensitive supply chains. By developing innovative phenolphthalein-based TTI technologies, we aim to provide industries with more reliable tools to monitor and maintain product quality, reduce waste, and enhance consumer trust in perishable goods.

Market Demand for Time-Temperature Indicators

The market demand for time-temperature indicators (TTIs) has been steadily growing, driven by increasing concerns about food safety and quality across the global supply chain. These smart labels provide real-time information about the temperature history of perishable products, enabling better monitoring and management of cold chain logistics. The food and beverage industry represents the largest market segment for TTIs, with applications ranging from fresh produce and dairy to frozen foods and ready-to-eat meals.

In recent years, the pharmaceutical and healthcare sectors have also emerged as significant drivers of TTI demand. Temperature-sensitive medications, vaccines, and biological products require strict temperature control during storage and transportation. The COVID-19 pandemic has further accelerated this trend, highlighting the critical need for reliable temperature monitoring in vaccine distribution.

Market research indicates that the global TTI market is expected to experience robust growth in the coming years. Factors contributing to this growth include stringent food safety regulations, increasing consumer awareness about product freshness, and the expansion of cold chain infrastructure in developing economies. Additionally, the rise of e-commerce and direct-to-consumer food delivery services has created new opportunities for TTI adoption.

The integration of smart packaging technologies and the Internet of Things (IoT) is also influencing market demand. Advanced TTIs that can transmit real-time data to cloud-based platforms are gaining traction, allowing for more efficient supply chain management and traceability. This trend is particularly relevant in high-value industries such as pharmaceuticals and premium food products.

Geographically, North America and Europe currently dominate the TTI market, owing to well-established cold chain networks and stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, changing consumer preferences, and increasing investments in cold chain infrastructure.

Despite the positive outlook, several challenges may impact market demand. These include the relatively high cost of advanced TTI technologies, concerns about electronic waste generation, and the need for standardization across different TTI systems. Addressing these issues will be crucial for sustained market growth and wider adoption of TTIs across various industries.

As research on phenolphthalein in the development of TTIs progresses, it has the potential to address some of the existing market demands. Phenolphthalein-based indicators could offer cost-effective alternatives to current electronic TTIs, potentially expanding their use in price-sensitive markets. Furthermore, if these indicators prove to be more environmentally friendly and easier to dispose of, they could alleviate concerns about electronic waste and promote broader adoption in sustainable packaging initiatives.

In recent years, the pharmaceutical and healthcare sectors have also emerged as significant drivers of TTI demand. Temperature-sensitive medications, vaccines, and biological products require strict temperature control during storage and transportation. The COVID-19 pandemic has further accelerated this trend, highlighting the critical need for reliable temperature monitoring in vaccine distribution.

Market research indicates that the global TTI market is expected to experience robust growth in the coming years. Factors contributing to this growth include stringent food safety regulations, increasing consumer awareness about product freshness, and the expansion of cold chain infrastructure in developing economies. Additionally, the rise of e-commerce and direct-to-consumer food delivery services has created new opportunities for TTI adoption.

The integration of smart packaging technologies and the Internet of Things (IoT) is also influencing market demand. Advanced TTIs that can transmit real-time data to cloud-based platforms are gaining traction, allowing for more efficient supply chain management and traceability. This trend is particularly relevant in high-value industries such as pharmaceuticals and premium food products.

Geographically, North America and Europe currently dominate the TTI market, owing to well-established cold chain networks and stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, changing consumer preferences, and increasing investments in cold chain infrastructure.

Despite the positive outlook, several challenges may impact market demand. These include the relatively high cost of advanced TTI technologies, concerns about electronic waste generation, and the need for standardization across different TTI systems. Addressing these issues will be crucial for sustained market growth and wider adoption of TTIs across various industries.

As research on phenolphthalein in the development of TTIs progresses, it has the potential to address some of the existing market demands. Phenolphthalein-based indicators could offer cost-effective alternatives to current electronic TTIs, potentially expanding their use in price-sensitive markets. Furthermore, if these indicators prove to be more environmentally friendly and easier to dispose of, they could alleviate concerns about electronic waste and promote broader adoption in sustainable packaging initiatives.

Current Challenges in Phenolphthalein-based TTIs

Despite the widespread use of phenolphthalein in Time-Temperature Indicators (TTIs), several challenges persist in their development and application. One of the primary issues is the stability of phenolphthalein-based TTIs under various environmental conditions. These indicators are susceptible to factors such as humidity, light exposure, and pH fluctuations, which can affect their accuracy and reliability over time.

The color change mechanism of phenolphthalein, while effective, presents challenges in terms of precise temperature threshold detection. The gradual nature of the color transition can make it difficult to determine exact temperature breach points, potentially leading to ambiguity in interpreting results. This is particularly problematic in applications requiring high precision, such as in pharmaceutical cold chain management.

Another significant challenge lies in the customization of phenolphthalein-based TTIs for different temperature ranges and exposure durations. Developing formulations that can accurately respond to specific temperature thresholds while maintaining long-term stability remains a complex task. This limitation restricts the versatility of these indicators across diverse industry applications.

The reversibility of phenolphthalein's color change poses a challenge in scenarios where a permanent record of temperature excursions is crucial. In some cases, the indicator may revert to its original color once the temperature returns to the acceptable range, potentially masking previous temperature violations. This characteristic can compromise the reliability of the TTI in certain critical applications.

Integration of phenolphthalein-based TTIs with smart packaging and IoT systems presents another hurdle. While there is a growing demand for real-time monitoring and data logging capabilities, incorporating these features into traditional phenolphthalein indicators without compromising their simplicity and cost-effectiveness is challenging.

The manufacturing process of phenolphthalein-based TTIs also faces challenges in terms of consistency and scalability. Ensuring uniform distribution of the indicator compound and maintaining batch-to-batch consistency in large-scale production can be difficult, potentially affecting the reliability of the end product.

Regulatory compliance and standardization present ongoing challenges in the development of phenolphthalein-based TTIs. With varying standards across different industries and regions, creating indicators that meet diverse regulatory requirements while maintaining universal applicability is complex. This challenge is particularly evident in highly regulated sectors such as healthcare and food safety.

The color change mechanism of phenolphthalein, while effective, presents challenges in terms of precise temperature threshold detection. The gradual nature of the color transition can make it difficult to determine exact temperature breach points, potentially leading to ambiguity in interpreting results. This is particularly problematic in applications requiring high precision, such as in pharmaceutical cold chain management.

Another significant challenge lies in the customization of phenolphthalein-based TTIs for different temperature ranges and exposure durations. Developing formulations that can accurately respond to specific temperature thresholds while maintaining long-term stability remains a complex task. This limitation restricts the versatility of these indicators across diverse industry applications.

The reversibility of phenolphthalein's color change poses a challenge in scenarios where a permanent record of temperature excursions is crucial. In some cases, the indicator may revert to its original color once the temperature returns to the acceptable range, potentially masking previous temperature violations. This characteristic can compromise the reliability of the TTI in certain critical applications.

Integration of phenolphthalein-based TTIs with smart packaging and IoT systems presents another hurdle. While there is a growing demand for real-time monitoring and data logging capabilities, incorporating these features into traditional phenolphthalein indicators without compromising their simplicity and cost-effectiveness is challenging.

The manufacturing process of phenolphthalein-based TTIs also faces challenges in terms of consistency and scalability. Ensuring uniform distribution of the indicator compound and maintaining batch-to-batch consistency in large-scale production can be difficult, potentially affecting the reliability of the end product.

Regulatory compliance and standardization present ongoing challenges in the development of phenolphthalein-based TTIs. With varying standards across different industries and regions, creating indicators that meet diverse regulatory requirements while maintaining universal applicability is complex. This challenge is particularly evident in highly regulated sectors such as healthcare and food safety.

Existing Phenolphthalein TTI Solutions

01 Use of phenolphthalein in time-temperature indicators

Phenolphthalein is utilized in time-temperature indicators due to its color-changing properties in response to temperature and time exposure. These indicators can be used to monitor the freshness of perishable goods or the effectiveness of sterilization processes.- Use of phenolphthalein in time-temperature indicators: Phenolphthalein is utilized in time-temperature indicators due to its color-changing properties in response to temperature and time exposure. These indicators can be used to monitor the freshness of perishable goods or the effectiveness of sterilization processes.

- Formulation of phenolphthalein-based indicators: The formulation of phenolphthalein-based time-temperature indicators involves combining phenolphthalein with other compounds to enhance its sensitivity and stability. This may include the use of polymers, solvents, or other additives to create a more effective and reliable indicator system.

- Application in packaging and labeling: Phenolphthalein time-temperature indicators are incorporated into packaging materials or labels to provide visual cues about product quality and safety. These indicators can be designed to change color or appearance when exposed to specific temperature conditions over time.

- Integration with smart packaging technologies: Advanced time-temperature indicators using phenolphthalein are being integrated with smart packaging technologies. This includes the development of sensors, RFID tags, or QR codes that can provide more detailed information about temperature history and product quality.

- Customization for specific applications: Phenolphthalein-based time-temperature indicators are being customized for specific applications in various industries. This includes tailoring the indicators for use in pharmaceuticals, food products, or medical devices, with adjustments made to the formulation to meet specific temperature thresholds and time requirements.

02 Formulation of phenolphthalein-based indicators

The formulation of phenolphthalein-based time-temperature indicators involves combining phenolphthalein with other compounds to enhance its sensitivity and stability. This may include the use of polymers, solvents, or other additives to create a more effective indicator system.Expand Specific Solutions03 Application in packaging and labeling

Phenolphthalein time-temperature indicators are incorporated into packaging materials or labels to provide visual cues about product quality and storage conditions. This technology is particularly useful in the food, pharmaceutical, and medical industries.Expand Specific Solutions04 Integration with smart packaging systems

Advanced time-temperature indicators using phenolphthalein are being integrated into smart packaging systems. These systems may include electronic components or other advanced materials to provide more accurate and detailed information about temperature exposure over time.Expand Specific Solutions05 Development of reversible indicators

Research is being conducted on developing reversible phenolphthalein-based time-temperature indicators. These indicators can potentially reset or change color multiple times, allowing for more complex monitoring of temperature fluctuations throughout a product's lifecycle.Expand Specific Solutions

Key Players in TTI and Food Packaging Industry

The research on phenolphthalein in time-temperature indicators is in an early development stage, with a growing market potential as food safety and quality control become increasingly important. The global time-temperature indicator market is expected to expand significantly in the coming years, driven by demand in pharmaceuticals, food, and logistics sectors. Technologically, the field is still evolving, with various approaches being explored. Companies like Temptime Corp., Keep-it Technologies AS, and 3M Innovative Properties Co. are at the forefront, developing innovative solutions. However, the technology is not yet fully mature, with ongoing research to improve accuracy, reliability, and cost-effectiveness of these indicators.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced time-temperature indicators (TTIs) using phenolphthalein as a key component. Their approach involves encapsulating phenolphthalein in a polymer matrix, which changes color irreversibly when exposed to specific time-temperature conditions[1]. The company has optimized the formulation to achieve precise control over the color change rate, allowing for customization based on different product shelf-life requirements[3]. BASF's TTIs also incorporate stabilizers to prevent premature activation and ensure accuracy across various environmental conditions[5].

Strengths: Customizable for different products, high accuracy, and stability. Weaknesses: May require specialized manufacturing processes, potentially higher cost compared to simpler indicators.

Temptime Corp.

Technical Solution: Temptime Corp. has pioneered the use of phenolphthalein in their HEATmarker® line of TTIs. Their technology employs a proprietary blend of phenolphthalein and other reagents in a microcrystalline wax matrix[2]. As temperature increases, the wax softens, allowing controlled diffusion of the indicator compounds, resulting in a gradual color change[4]. Temptime's TTIs are designed to mimic the degradation kinetics of various perishable products, providing a visual representation of cumulative temperature exposure over time[6]. The company has also developed a range of activation temperatures to suit different cold chain requirements[8].

Strengths: Proven technology with wide adoption in pharmaceutical and food industries, versatile product range. Weaknesses: May be more suitable for longer-term monitoring rather than rapid temperature fluctuations.

Core Innovations in Phenolphthalein-based TTIs

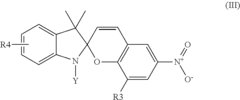

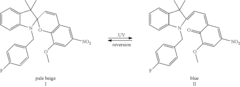

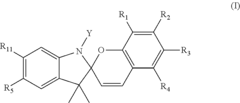

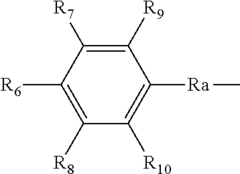

Optimized time temperature indicator

PatentInactiveUS20110217786A1

Innovation

- Incorporating a modifier that forms mixed solids with spiropyrans, such as esters, alcohols, or metal complexes, to control the coloration and decoloration kinetics of spiropyran-based time-temperature indicators, allowing for adjustment of bleaching behavior to match the shelf life of perishable goods.

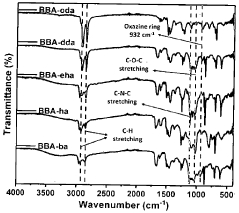

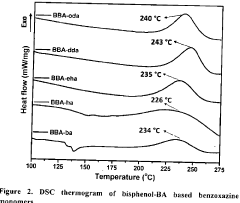

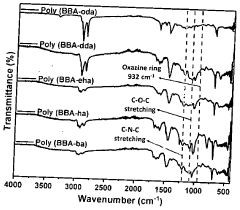

Production of extreme range of PH indicators from benzoxazines

PatentActiveIN202341027342A

Innovation

- Development of bisphenol-BA/aliphatic amine based hydrophobic polybenzoxazines coated on cellulose paper, synthesized through Mannich condensation, which exhibit distinct color changes across a wide pH range from -1.8 to 14, offering thermal stability and repeated use capability.

Food Safety Regulations and TTI Standards

The development and implementation of Time-Temperature Indicators (TTIs) in food packaging are subject to various regulations and standards to ensure food safety and consumer protection. These regulations and standards play a crucial role in guiding the research and application of phenolphthalein-based TTIs.

In the United States, the Food and Drug Administration (FDA) oversees the use of TTIs in food packaging. The FDA's Food Contact Substance Notification (FCN) program requires manufacturers to submit detailed information about the safety and effectiveness of TTIs before they can be used in food packaging. This includes data on the chemical composition, migration potential, and toxicological profile of the TTI components, including phenolphthalein.

The European Union has established regulations through the European Food Safety Authority (EFSA) for the use of intelligent packaging technologies, including TTIs. The EU Regulation No. 1935/2004 on materials and articles intended to come into contact with food provides a framework for the safety assessment of TTIs. Manufacturers must demonstrate that the TTI components, such as phenolphthalein, do not migrate into food at levels that could endanger human health or change the composition of the food.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for TTIs. ISO 22119:2011 provides guidelines for the performance testing of TTIs used in food packaging. This standard outlines methods for evaluating the accuracy, reliability, and consistency of TTI responses under various temperature conditions.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has developed guidelines for the use of temperature control devices in food transport and storage. These guidelines indirectly influence the development and application of phenolphthalein-based TTIs by setting requirements for temperature monitoring in the food supply chain.

Industry-specific standards also exist, such as those developed by the American Society for Testing and Materials (ASTM). ASTM F1416-16 provides standard methods for determining the time-temperature sensitivity of TTIs, which is crucial for validating the performance of phenolphthalein-based indicators.

Compliance with these regulations and standards is essential for the commercial success of phenolphthalein-based TTIs. Researchers and manufacturers must consider these regulatory requirements throughout the development process, from initial concept to final product design. This ensures that the TTIs not only function effectively but also meet the stringent safety and performance criteria set by regulatory bodies worldwide.

In the United States, the Food and Drug Administration (FDA) oversees the use of TTIs in food packaging. The FDA's Food Contact Substance Notification (FCN) program requires manufacturers to submit detailed information about the safety and effectiveness of TTIs before they can be used in food packaging. This includes data on the chemical composition, migration potential, and toxicological profile of the TTI components, including phenolphthalein.

The European Union has established regulations through the European Food Safety Authority (EFSA) for the use of intelligent packaging technologies, including TTIs. The EU Regulation No. 1935/2004 on materials and articles intended to come into contact with food provides a framework for the safety assessment of TTIs. Manufacturers must demonstrate that the TTI components, such as phenolphthalein, do not migrate into food at levels that could endanger human health or change the composition of the food.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for TTIs. ISO 22119:2011 provides guidelines for the performance testing of TTIs used in food packaging. This standard outlines methods for evaluating the accuracy, reliability, and consistency of TTI responses under various temperature conditions.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has developed guidelines for the use of temperature control devices in food transport and storage. These guidelines indirectly influence the development and application of phenolphthalein-based TTIs by setting requirements for temperature monitoring in the food supply chain.

Industry-specific standards also exist, such as those developed by the American Society for Testing and Materials (ASTM). ASTM F1416-16 provides standard methods for determining the time-temperature sensitivity of TTIs, which is crucial for validating the performance of phenolphthalein-based indicators.

Compliance with these regulations and standards is essential for the commercial success of phenolphthalein-based TTIs. Researchers and manufacturers must consider these regulatory requirements throughout the development process, from initial concept to final product design. This ensures that the TTIs not only function effectively but also meet the stringent safety and performance criteria set by regulatory bodies worldwide.

Environmental Impact of Phenolphthalein TTIs

The environmental impact of phenolphthalein-based Time-Temperature Indicators (TTIs) is a crucial consideration in their development and application. These indicators, while effective in monitoring temperature changes over time, may pose certain risks to the environment if not properly managed.

Phenolphthalein, the primary component in these TTIs, is a synthetic organic compound that can persist in the environment. When TTIs containing phenolphthalein are disposed of improperly, they may contribute to soil and water contamination. The compound can leach into groundwater or be carried by surface runoff, potentially affecting aquatic ecosystems and soil microorganisms.

The production process of phenolphthalein TTIs also raises environmental concerns. The synthesis of phenolphthalein involves chemical reactions that may generate hazardous byproducts and require energy-intensive processes. This contributes to the overall carbon footprint of TTI manufacturing and raises questions about the sustainability of large-scale production.

Furthermore, the use of phenolphthalein TTIs in food packaging and other consumer products introduces the possibility of indirect human exposure. While the concentrations used in TTIs are generally low, the cumulative effect of widespread use and disposal could lead to increased environmental presence and potential bioaccumulation in the food chain.

To mitigate these environmental impacts, research is being conducted on biodegradable alternatives and more environmentally friendly production methods. Some studies have explored the use of natural indicators derived from plant sources as substitutes for phenolphthalein. These bio-based alternatives may offer similar color-changing properties while being more readily biodegradable.

Efforts are also being made to improve the recyclability of TTI-equipped packaging. This includes developing TTIs that can be easily separated from packaging materials during the recycling process, reducing the contamination of recycled materials and minimizing waste.

The regulatory landscape surrounding phenolphthalein TTIs is evolving, with increasing attention to their environmental impact. Some jurisdictions have implemented stricter guidelines for the disposal of products containing these indicators, encouraging manufacturers to consider end-of-life management in their product design.

In conclusion, while phenolphthalein TTIs offer valuable benefits in temperature monitoring, their environmental impact necessitates ongoing research and innovation. Balancing the utility of these indicators with environmental sustainability remains a key challenge for researchers and industry stakeholders in the field of smart packaging and quality control technologies.

Phenolphthalein, the primary component in these TTIs, is a synthetic organic compound that can persist in the environment. When TTIs containing phenolphthalein are disposed of improperly, they may contribute to soil and water contamination. The compound can leach into groundwater or be carried by surface runoff, potentially affecting aquatic ecosystems and soil microorganisms.

The production process of phenolphthalein TTIs also raises environmental concerns. The synthesis of phenolphthalein involves chemical reactions that may generate hazardous byproducts and require energy-intensive processes. This contributes to the overall carbon footprint of TTI manufacturing and raises questions about the sustainability of large-scale production.

Furthermore, the use of phenolphthalein TTIs in food packaging and other consumer products introduces the possibility of indirect human exposure. While the concentrations used in TTIs are generally low, the cumulative effect of widespread use and disposal could lead to increased environmental presence and potential bioaccumulation in the food chain.

To mitigate these environmental impacts, research is being conducted on biodegradable alternatives and more environmentally friendly production methods. Some studies have explored the use of natural indicators derived from plant sources as substitutes for phenolphthalein. These bio-based alternatives may offer similar color-changing properties while being more readily biodegradable.

Efforts are also being made to improve the recyclability of TTI-equipped packaging. This includes developing TTIs that can be easily separated from packaging materials during the recycling process, reducing the contamination of recycled materials and minimizing waste.

The regulatory landscape surrounding phenolphthalein TTIs is evolving, with increasing attention to their environmental impact. Some jurisdictions have implemented stricter guidelines for the disposal of products containing these indicators, encouraging manufacturers to consider end-of-life management in their product design.

In conclusion, while phenolphthalein TTIs offer valuable benefits in temperature monitoring, their environmental impact necessitates ongoing research and innovation. Balancing the utility of these indicators with environmental sustainability remains a key challenge for researchers and industry stakeholders in the field of smart packaging and quality control technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!