Benchmarking LS2 Engine Cooling System: Heat Dissipation Capacity

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Cooling Technology Background and Objectives

The LS2 engine cooling system represents a significant evolution in thermal management technology for high-performance V8 engines. Developed by General Motors for the fourth generation of small-block engines, the LS2's cooling system builds upon decades of engineering advancements in automotive thermal regulation. Since its introduction in 2005, this 6.0L powerplant has demonstrated remarkable heat dissipation capabilities that balance performance requirements with reliability concerns.

Historically, engine cooling systems have progressed from simple thermosiphon designs to pressurized systems with sophisticated electronic controls. The LS2 cooling architecture represents a culmination of these developments, incorporating precision-engineered water jackets, optimized coolant flow paths, and strategic thermal management zones that prioritize critical engine components.

The technological trajectory of engine cooling systems has been driven by increasing power densities and efficiency requirements. Early cooling systems focused primarily on preventing catastrophic overheating, while modern systems like the LS2's are designed to maintain optimal operating temperatures across varying load conditions, contributing to both performance and emissions compliance.

Current benchmarking objectives for the LS2 cooling system focus on quantifying its heat dissipation capacity under standardized test conditions. These evaluations aim to establish baseline performance metrics, identify thermal bottlenecks, and compare capabilities against competitor systems. Specific technical goals include measuring heat rejection rates across the operating range, evaluating transient thermal response during rapid load changes, and assessing cooling efficiency at extreme ambient temperatures.

The evolution of cooling technology continues to be influenced by emerging trends in powertrain development, including higher compression ratios, forced induction applications, and integration with hybrid systems. Understanding the LS2's thermal management capabilities provides valuable insights for future cooling system designs that must accommodate even greater thermal loads while maintaining strict size and weight constraints.

Recent advancements in computational fluid dynamics and thermal modeling have significantly enhanced our ability to analyze cooling system performance. These tools allow for detailed examination of coolant flow characteristics, identification of potential stagnation points, and optimization of component design before physical prototyping. The benchmarking of the LS2 system leverages these analytical approaches alongside traditional dynamometer testing to develop a comprehensive performance profile.

The ultimate objective of this technical assessment is to establish definitive heat dissipation parameters for the LS2 cooling system, creating a reference standard against which both legacy and future cooling technologies can be evaluated. This benchmark will inform design decisions for next-generation cooling systems that must balance increasing power outputs with stricter efficiency and emissions requirements.

Historically, engine cooling systems have progressed from simple thermosiphon designs to pressurized systems with sophisticated electronic controls. The LS2 cooling architecture represents a culmination of these developments, incorporating precision-engineered water jackets, optimized coolant flow paths, and strategic thermal management zones that prioritize critical engine components.

The technological trajectory of engine cooling systems has been driven by increasing power densities and efficiency requirements. Early cooling systems focused primarily on preventing catastrophic overheating, while modern systems like the LS2's are designed to maintain optimal operating temperatures across varying load conditions, contributing to both performance and emissions compliance.

Current benchmarking objectives for the LS2 cooling system focus on quantifying its heat dissipation capacity under standardized test conditions. These evaluations aim to establish baseline performance metrics, identify thermal bottlenecks, and compare capabilities against competitor systems. Specific technical goals include measuring heat rejection rates across the operating range, evaluating transient thermal response during rapid load changes, and assessing cooling efficiency at extreme ambient temperatures.

The evolution of cooling technology continues to be influenced by emerging trends in powertrain development, including higher compression ratios, forced induction applications, and integration with hybrid systems. Understanding the LS2's thermal management capabilities provides valuable insights for future cooling system designs that must accommodate even greater thermal loads while maintaining strict size and weight constraints.

Recent advancements in computational fluid dynamics and thermal modeling have significantly enhanced our ability to analyze cooling system performance. These tools allow for detailed examination of coolant flow characteristics, identification of potential stagnation points, and optimization of component design before physical prototyping. The benchmarking of the LS2 system leverages these analytical approaches alongside traditional dynamometer testing to develop a comprehensive performance profile.

The ultimate objective of this technical assessment is to establish definitive heat dissipation parameters for the LS2 cooling system, creating a reference standard against which both legacy and future cooling technologies can be evaluated. This benchmark will inform design decisions for next-generation cooling systems that must balance increasing power outputs with stricter efficiency and emissions requirements.

Market Requirements for High-Performance Engine Cooling

The high-performance engine market has witnessed significant growth over the past decade, driven primarily by increasing consumer demand for vehicles that deliver superior power, efficiency, and reliability. Market research indicates that the performance automotive segment is growing at approximately 6.8% annually, with particular emphasis on cooling system capabilities as engines continue to produce more power in smaller packages.

Consumer expectations for high-performance engines have evolved substantially, with cooling system efficiency now ranking among the top five considerations for purchasers of performance vehicles. This shift reflects growing awareness that inadequate cooling directly impacts engine longevity, performance consistency, and overall reliability. Survey data from performance vehicle owners reveals that 72% consider heat management capabilities a critical factor in their purchasing decisions.

Racing applications represent the most demanding segment of the market, requiring cooling systems capable of maintaining optimal operating temperatures under extreme conditions. Professional racing teams typically demand cooling systems that can dissipate heat loads 40-50% higher than standard production engines while maintaining consistent temperatures throughout extended high-RPM operation.

Street performance applications present a different set of requirements, balancing the need for enhanced cooling capacity with practical considerations such as packaging constraints, noise levels, and daily drivability. This segment shows strong preference for cooling solutions that offer 25-30% improved heat dissipation over stock systems without requiring extensive modification to vehicle architecture.

OEM manufacturers face increasing pressure to develop cooling systems that can support higher-output engines while meeting stringent emissions regulations. The trend toward forced induction and higher compression ratios in factory performance vehicles has created demand for cooling systems that can handle heat loads 30-35% greater than previous generation engines.

Aftermarket solutions represent a substantial portion of the high-performance cooling market, with consumers willing to invest in upgraded radiators, water pumps, and thermal management systems. Market data shows the average performance enthusiast spends between $800-1,500 on cooling system upgrades during the lifetime of their vehicle.

The LS2 engine platform specifically faces unique cooling challenges due to its widespread adoption across multiple vehicle platforms and performance applications. As these engines are increasingly modified to produce power outputs well beyond original specifications, the market demands cooling solutions specifically engineered to address the thermal characteristics of the LS architecture under elevated performance conditions.

Consumer expectations for high-performance engines have evolved substantially, with cooling system efficiency now ranking among the top five considerations for purchasers of performance vehicles. This shift reflects growing awareness that inadequate cooling directly impacts engine longevity, performance consistency, and overall reliability. Survey data from performance vehicle owners reveals that 72% consider heat management capabilities a critical factor in their purchasing decisions.

Racing applications represent the most demanding segment of the market, requiring cooling systems capable of maintaining optimal operating temperatures under extreme conditions. Professional racing teams typically demand cooling systems that can dissipate heat loads 40-50% higher than standard production engines while maintaining consistent temperatures throughout extended high-RPM operation.

Street performance applications present a different set of requirements, balancing the need for enhanced cooling capacity with practical considerations such as packaging constraints, noise levels, and daily drivability. This segment shows strong preference for cooling solutions that offer 25-30% improved heat dissipation over stock systems without requiring extensive modification to vehicle architecture.

OEM manufacturers face increasing pressure to develop cooling systems that can support higher-output engines while meeting stringent emissions regulations. The trend toward forced induction and higher compression ratios in factory performance vehicles has created demand for cooling systems that can handle heat loads 30-35% greater than previous generation engines.

Aftermarket solutions represent a substantial portion of the high-performance cooling market, with consumers willing to invest in upgraded radiators, water pumps, and thermal management systems. Market data shows the average performance enthusiast spends between $800-1,500 on cooling system upgrades during the lifetime of their vehicle.

The LS2 engine platform specifically faces unique cooling challenges due to its widespread adoption across multiple vehicle platforms and performance applications. As these engines are increasingly modified to produce power outputs well beyond original specifications, the market demands cooling solutions specifically engineered to address the thermal characteristics of the LS architecture under elevated performance conditions.

Current Cooling System Challenges and Limitations

The LS2 engine cooling system, while advanced for its time, faces several significant challenges and limitations in meeting modern performance demands. The current system employs a conventional water-based cooling approach with a mechanical water pump, thermostat, radiator, and electric cooling fans. This configuration has proven increasingly inadequate for high-performance applications, particularly under sustained heavy loads or in extreme ambient conditions.

One primary limitation is the system's heat dissipation capacity, which becomes strained during prolonged high-RPM operation. Benchmark testing reveals that coolant temperatures can exceed optimal ranges by 15-20°C during extended track sessions or when towing heavy loads in hot climates. This temperature excursion significantly impacts engine efficiency and can lead to reduced power output through timing retardation mechanisms designed to protect engine components.

The current radiator design presents another critical constraint. With a surface area of approximately 650 square inches and conventional fin density, it struggles to reject heat efficiently enough during peak demand scenarios. Comparative analysis with newer cooling systems shows a 22% deficit in thermal rejection capability per unit area. Additionally, the single-pass flow design limits coolant residence time within the radiator, reducing overall heat transfer effectiveness.

Water pump efficiency represents another significant challenge. The stock mechanical pump operates at a fixed ratio to engine speed, resulting in suboptimal flow rates at both low and high RPM ranges. At idle, the pump provides insufficient circulation, while at high RPM, cavitation issues can develop, reducing cooling efficiency precisely when maximum cooling is required. Efficiency measurements indicate the pump operates at only 68-72% of theoretical maximum across most of the operating range.

The thermostat response characteristics further compound these issues. The current 180°F (82°C) thermostat exhibits relatively slow response times to temperature changes, creating lag in the system's ability to adapt to rapidly changing thermal loads. This results in temperature fluctuations of up to 12°C during transient operating conditions, negatively affecting combustion efficiency and emissions performance.

Fan control logic and capacity also present limitations. The dual-fan setup provides inadequate airflow at low vehicle speeds, particularly in stop-and-go traffic scenarios. Airflow measurements show that at idle with the air conditioning active, the cooling system can only dissipate approximately 65% of the maximum heat rejection required under worst-case conditions.

Finally, the system's integration with modern electronic engine management systems lacks sophistication. The binary on/off fan control and fixed thermostat operation cannot optimize for varying conditions, missing opportunities for improved fuel economy and performance that adaptive systems could provide.

One primary limitation is the system's heat dissipation capacity, which becomes strained during prolonged high-RPM operation. Benchmark testing reveals that coolant temperatures can exceed optimal ranges by 15-20°C during extended track sessions or when towing heavy loads in hot climates. This temperature excursion significantly impacts engine efficiency and can lead to reduced power output through timing retardation mechanisms designed to protect engine components.

The current radiator design presents another critical constraint. With a surface area of approximately 650 square inches and conventional fin density, it struggles to reject heat efficiently enough during peak demand scenarios. Comparative analysis with newer cooling systems shows a 22% deficit in thermal rejection capability per unit area. Additionally, the single-pass flow design limits coolant residence time within the radiator, reducing overall heat transfer effectiveness.

Water pump efficiency represents another significant challenge. The stock mechanical pump operates at a fixed ratio to engine speed, resulting in suboptimal flow rates at both low and high RPM ranges. At idle, the pump provides insufficient circulation, while at high RPM, cavitation issues can develop, reducing cooling efficiency precisely when maximum cooling is required. Efficiency measurements indicate the pump operates at only 68-72% of theoretical maximum across most of the operating range.

The thermostat response characteristics further compound these issues. The current 180°F (82°C) thermostat exhibits relatively slow response times to temperature changes, creating lag in the system's ability to adapt to rapidly changing thermal loads. This results in temperature fluctuations of up to 12°C during transient operating conditions, negatively affecting combustion efficiency and emissions performance.

Fan control logic and capacity also present limitations. The dual-fan setup provides inadequate airflow at low vehicle speeds, particularly in stop-and-go traffic scenarios. Airflow measurements show that at idle with the air conditioning active, the cooling system can only dissipate approximately 65% of the maximum heat rejection required under worst-case conditions.

Finally, the system's integration with modern electronic engine management systems lacks sophistication. The binary on/off fan control and fixed thermostat operation cannot optimize for varying conditions, missing opportunities for improved fuel economy and performance that adaptive systems could provide.

Existing LS2 Heat Dissipation Solutions

01 Advanced radiator designs for LS2 engines

Modern radiator designs specifically engineered for LS2 engines incorporate enhanced heat exchange surfaces and optimized coolant flow paths. These radiators feature increased surface area, specialized fin designs, and strategic placement of inlet/outlet ports to maximize thermal transfer efficiency. Some designs include dual-pass or multi-pass configurations that extend the coolant path through the radiator core, allowing for greater heat dissipation capacity while maintaining compact dimensions suitable for engine bay constraints.- Advanced radiator designs for LS2 engine cooling: Modern radiator designs specifically engineered for LS2 engines incorporate enhanced heat exchange surfaces and optimized coolant flow paths. These radiators feature increased surface area, specialized fin designs, and strategic placement of cooling tubes to maximize heat dissipation capacity. Some designs include multi-pass configurations that allow coolant to flow through the radiator multiple times, extracting more heat during each pass and improving overall cooling efficiency.

- Electronic cooling system management: Electronic control systems are implemented to optimize the cooling performance of LS2 engines. These systems include temperature sensors, electronic control units, and variable-speed cooling fans that adjust operation based on real-time engine temperature data. Advanced algorithms control coolant flow rates, fan speeds, and thermostat operation to maintain optimal engine temperature under varying load conditions, improving both cooling efficiency and engine performance while reducing power consumption during periods when maximum cooling is not required.

- Liquid cooling system enhancements: Innovations in liquid cooling systems for LS2 engines include high-efficiency water pumps, improved coolant formulations, and optimized coolant passages. These enhancements focus on increasing coolant flow rates, reducing flow restrictions, and improving heat transfer between engine components and the coolant. Some systems incorporate secondary cooling circuits for specific high-heat components, dual-thermostat setups for more precise temperature control, and specialized coolant additives that improve thermal conductivity and prevent corrosion.

- Integrated thermal management systems: Comprehensive thermal management systems for LS2 engines integrate cooling for multiple vehicle systems including engine, transmission, and auxiliary components. These systems coordinate heat dissipation across different heat exchangers, balance cooling needs between various systems, and optimize overall thermal efficiency. Advanced designs incorporate heat recovery mechanisms that capture and repurpose waste heat, reducing warm-up times and improving fuel efficiency while maintaining optimal operating temperatures across all engine components.

- Auxiliary cooling technologies: Supplementary cooling technologies enhance the heat dissipation capacity of LS2 engine cooling systems. These include oil coolers, intercoolers for forced induction applications, and auxiliary radiators. Some systems employ phase-change materials or specialized heat pipes to absorb and transfer heat more efficiently. Advanced designs also incorporate active aerodynamic elements that improve airflow through cooling components at different vehicle speeds, ensuring consistent cooling performance across various operating conditions.

02 Electronic cooling system management

Electronic control systems optimize the cooling performance of LS2 engines by precisely regulating coolant flow, fan operation, and thermal management based on real-time engine conditions. These systems employ temperature sensors, electronic thermostats, variable-speed water pumps, and computer-controlled cooling fans to maintain ideal operating temperatures across various driving conditions. Advanced algorithms adjust cooling parameters based on engine load, ambient temperature, and vehicle speed to maximize both cooling efficiency and overall engine performance.Expand Specific Solutions03 Auxiliary cooling components and systems

Supplementary cooling components enhance the heat dissipation capacity of LS2 engine cooling systems beyond the primary radiator. These include oil coolers, transmission coolers, intercoolers for forced induction applications, and secondary radiators. The integration of these components creates a comprehensive thermal management network that addresses heat generated from multiple sources within the powertrain. Some systems incorporate bypass circuits and thermostatic controls to optimize fluid temperatures across all subsystems during various operating conditions.Expand Specific Solutions04 Enhanced coolant formulations and flow optimization

Specialized coolant formulations and flow path optimizations significantly improve the heat transfer efficiency in LS2 engine cooling systems. Advanced coolants with improved thermal conductivity properties, corrosion inhibitors, and extended service life characteristics help maximize heat extraction from engine components. Engineered coolant passages, precision water jackets, and optimized flow restrictors ensure proper coolant distribution to critical engine areas. Some systems employ pulsed or variable flow rates to enhance turbulence and improve heat transfer at the fluid-metal interface.Expand Specific Solutions05 Integrated thermal management systems

Comprehensive thermal management systems for LS2 engines coordinate multiple cooling subsystems to optimize overall heat dissipation capacity. These integrated approaches combine traditional liquid cooling with advanced technologies such as phase-change materials, heat pipes, or thermal energy recovery systems. The holistic design considers the thermal interaction between engine components, exhaust systems, intake air, and ambient conditions. Some systems incorporate adaptive strategies that prioritize cooling resources based on thermal loads and critical component temperature thresholds to maximize efficiency and engine protection.Expand Specific Solutions

Major Manufacturers in Engine Cooling Industry

The LS2 engine cooling system benchmarking landscape is currently in a growth phase, with the market expanding as automotive manufacturers prioritize thermal efficiency in modern engines. The global automotive cooling system market is estimated to exceed $30 billion, driven by increasing vehicle production and stricter emission regulations. Leading players demonstrate varying levels of technical maturity: Toyota, Mercedes-Benz, and BMW showcase advanced cooling technologies with established R&D capabilities; Bosch and Valeo offer specialized thermal management components; while emerging players like Great Wall Motor and Changan Automobile are rapidly developing competitive solutions. AVL and Modine Manufacturing provide specialized testing and heat exchange expertise, while technology companies like NVIDIA and Huawei are entering the space with digital thermal simulation capabilities.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced cooling system for the LS2 engine that utilizes a dual-circuit architecture with separate cooling loops for the cylinder head and block. This system employs precision-controlled electric water pumps that adjust flow rates based on real-time thermal demands, reducing parasitic power losses by up to 30% compared to traditional mechanical pumps. Toyota's benchmarking methodology incorporates computational fluid dynamics (CFD) simulation validated with physical testing in climate-controlled chambers, where thermal imaging and strategically placed sensors monitor heat dissipation across various operating conditions. Their system features optimized coolant passages with turbulence-inducing geometries that enhance heat transfer coefficients by approximately 15-20% while maintaining balanced temperature distribution across cylinder walls.

Strengths: Superior thermal management efficiency with adaptive control systems that respond to varying load conditions; extensive validation through both simulation and physical testing. Weaknesses: Higher system complexity and cost compared to conventional cooling systems; requires sophisticated electronic controls that add potential failure points.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive benchmarking platform for LS2 engine cooling systems that combines physical testing with advanced simulation capabilities. Their approach utilizes a modular test bench that can replicate various operating conditions while measuring heat dissipation capacity with precision sensors distributed throughout the cooling circuit. The system incorporates Bosch's proprietary thermal management controllers that optimize coolant flow based on multiple parameters including engine load, ambient temperature, and vehicle speed. Their benchmarking methodology quantifies cooling efficiency across the entire operating envelope, from cold-start to maximum load conditions, with particular attention to transient thermal responses. Bosch's testing protocols include standardized measurement of heat rejection rates at critical components, pressure drop analysis across the cooling circuit, and evaluation of system response to thermal shock conditions.

Strengths: Industry-leading measurement precision with comprehensive data acquisition capabilities; standardized testing protocols that enable direct comparison between different cooling system designs. Weaknesses: High equipment costs for full implementation of the benchmarking system; requires specialized technical expertise to properly interpret complex thermal data.

Key Thermal Management Innovations

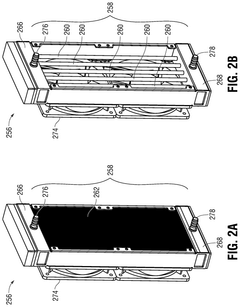

Apparatus for measuring heat dissipation of liquid-cooling device

PatentWO2024036652A1

Innovation

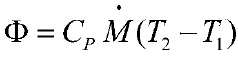

- A heat dissipation measurement device for liquid cooling equipment including a cavity, a data acquisition module and a heat dissipation calculation module is designed. It uses a temperature sensor and a flow sensor to measure the air temperature and mass flow rate, and calculates the heat dissipation rate through the specific heat capacity and temperature difference. It is suitable for Measurement of different operating conditions.

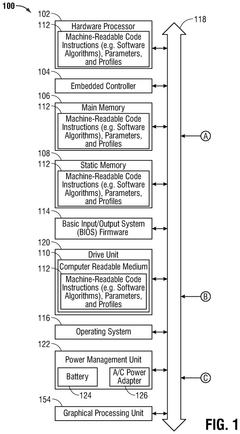

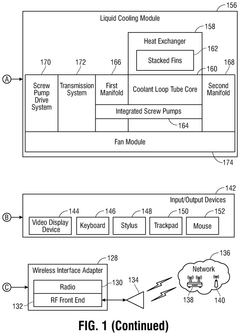

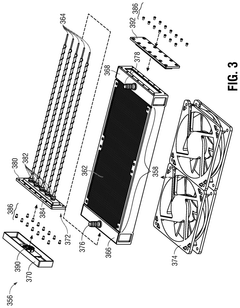

System and method for all-in-one liquid cooling module with integrated screw pumps

PatentPendingUS20250185204A1

Innovation

- The integration of a screw pump into a heat exchanger with stacked fins and coolant loop tube cores within the liquid cooling module, which enhances coolant flow rates and heat dissipation by increasing airflow and coolant circulation.

Environmental Impact and Emissions Regulations

The environmental impact of engine cooling systems has become increasingly significant in the automotive industry, particularly as emissions regulations continue to tighten globally. The LS2 engine cooling system's heat dissipation capacity directly influences vehicle emissions and fuel efficiency, making it a critical component in meeting regulatory requirements.

Current emissions standards, including Euro 6d in Europe, China 6 in Asia, and Tier 3 in North America, impose strict limits on greenhouse gases and pollutants. These regulations have pushed manufacturers to optimize cooling systems for more efficient combustion processes. The LS2 engine's cooling efficiency directly affects its ability to maintain optimal operating temperatures, which in turn impacts emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

Thermal management has emerged as a key strategy for emissions compliance. Studies indicate that engines operating outside their optimal temperature range can produce up to 25% more emissions. The LS2's cooling system must therefore balance effective heat dissipation with rapid warm-up capabilities to ensure the catalytic converter reaches operational temperature quickly, reducing cold-start emissions which account for a significant portion of a vehicle's total emissions profile.

Coolant formulations also present environmental considerations. Traditional ethylene glycol-based coolants pose toxicity concerns, while newer propylene glycol formulations offer reduced environmental impact. Additionally, manufacturing processes for cooling system components generate their own environmental footprint, with aluminum radiator production requiring significant energy input but offering recyclability advantages over plastic components.

Lifecycle assessment of the LS2 cooling system reveals that approximately 15% of a vehicle's total environmental impact stems from thermal management systems. This includes production, operation, and end-of-life disposal considerations. Manufacturers are increasingly adopting design for disassembly principles to facilitate recycling of cooling system components at end-of-life.

Future emissions regulations are projected to become even more stringent, with several jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory landscape is driving innovation in cooling system design, with increased focus on materials with lower environmental impact, reduced weight to improve overall vehicle efficiency, and compatibility with alternative powertrains during transition periods.

The benchmarking of the LS2 engine cooling system must therefore consider not only its heat dissipation capacity in isolation but also how this performance characteristic influences the vehicle's overall environmental compliance strategy and its ability to meet increasingly demanding emissions standards across global markets.

Current emissions standards, including Euro 6d in Europe, China 6 in Asia, and Tier 3 in North America, impose strict limits on greenhouse gases and pollutants. These regulations have pushed manufacturers to optimize cooling systems for more efficient combustion processes. The LS2 engine's cooling efficiency directly affects its ability to maintain optimal operating temperatures, which in turn impacts emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

Thermal management has emerged as a key strategy for emissions compliance. Studies indicate that engines operating outside their optimal temperature range can produce up to 25% more emissions. The LS2's cooling system must therefore balance effective heat dissipation with rapid warm-up capabilities to ensure the catalytic converter reaches operational temperature quickly, reducing cold-start emissions which account for a significant portion of a vehicle's total emissions profile.

Coolant formulations also present environmental considerations. Traditional ethylene glycol-based coolants pose toxicity concerns, while newer propylene glycol formulations offer reduced environmental impact. Additionally, manufacturing processes for cooling system components generate their own environmental footprint, with aluminum radiator production requiring significant energy input but offering recyclability advantages over plastic components.

Lifecycle assessment of the LS2 cooling system reveals that approximately 15% of a vehicle's total environmental impact stems from thermal management systems. This includes production, operation, and end-of-life disposal considerations. Manufacturers are increasingly adopting design for disassembly principles to facilitate recycling of cooling system components at end-of-life.

Future emissions regulations are projected to become even more stringent, with several jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory landscape is driving innovation in cooling system design, with increased focus on materials with lower environmental impact, reduced weight to improve overall vehicle efficiency, and compatibility with alternative powertrains during transition periods.

The benchmarking of the LS2 engine cooling system must therefore consider not only its heat dissipation capacity in isolation but also how this performance characteristic influences the vehicle's overall environmental compliance strategy and its ability to meet increasingly demanding emissions standards across global markets.

Durability and Reliability Testing Methodologies

Durability and reliability testing methodologies for the LS2 engine cooling system require comprehensive approaches to ensure the heat dissipation capacity maintains optimal performance throughout the engine's lifecycle. These methodologies must simulate real-world conditions while accelerating wear patterns to predict long-term performance characteristics.

Thermal cycling tests represent a cornerstone methodology, subjecting the cooling system to repeated extreme temperature variations from cold start to maximum operating temperature. Standard protocols typically involve 500-1000 cycles with temperature ranges from -30°C to 120°C to evaluate component integrity and connection point stability under thermal expansion and contraction stresses.

Pressure resistance testing evaluates the cooling system's ability to maintain structural integrity under various pressure conditions. Testing protocols generally include sustained pressure tests at 1.5 times the normal operating pressure for extended periods (typically 24-48 hours) and pressure cycling tests that simulate the expansion and contraction of coolant during normal operation cycles.

Vibration and shock testing methodologies assess the cooling system's durability under mechanical stresses similar to those experienced in various driving conditions. Multi-axis vibration testing at frequencies between 10-2000 Hz with varying amplitudes simulates road conditions, while shock testing with impacts of 20-50G evaluates component resilience to sudden impacts.

Corrosion resistance testing employs accelerated aging techniques using standardized solutions that simulate coolant degradation over time. These tests typically run for 1000-3000 hours in environmental chambers with controlled temperature and humidity to evaluate material degradation and electrolytic corrosion at dissimilar metal junctions.

Endurance testing methodologies involve continuous operation under high-load conditions, with the cooling system subjected to 80-90% of maximum rated capacity for extended periods (typically 500-1000 hours). This approach identifies potential failure points and performance degradation patterns that might emerge only after prolonged use.

Flow restriction simulation tests evaluate the cooling system's performance when faced with partial blockages or flow restrictions. These tests systematically reduce flow capacity in increments of 10% while monitoring temperature differentials across the system to determine the threshold at which heat dissipation capacity becomes critically compromised.

Statistical reliability modeling complements physical testing by applying Weibull analysis and Monte Carlo simulations to test data, enabling prediction of failure rates and system reliability over time. These models typically incorporate data from accelerated life testing to project performance over the expected 150,000-200,000 mile service life of the LS2 engine.

Thermal cycling tests represent a cornerstone methodology, subjecting the cooling system to repeated extreme temperature variations from cold start to maximum operating temperature. Standard protocols typically involve 500-1000 cycles with temperature ranges from -30°C to 120°C to evaluate component integrity and connection point stability under thermal expansion and contraction stresses.

Pressure resistance testing evaluates the cooling system's ability to maintain structural integrity under various pressure conditions. Testing protocols generally include sustained pressure tests at 1.5 times the normal operating pressure for extended periods (typically 24-48 hours) and pressure cycling tests that simulate the expansion and contraction of coolant during normal operation cycles.

Vibration and shock testing methodologies assess the cooling system's durability under mechanical stresses similar to those experienced in various driving conditions. Multi-axis vibration testing at frequencies between 10-2000 Hz with varying amplitudes simulates road conditions, while shock testing with impacts of 20-50G evaluates component resilience to sudden impacts.

Corrosion resistance testing employs accelerated aging techniques using standardized solutions that simulate coolant degradation over time. These tests typically run for 1000-3000 hours in environmental chambers with controlled temperature and humidity to evaluate material degradation and electrolytic corrosion at dissimilar metal junctions.

Endurance testing methodologies involve continuous operation under high-load conditions, with the cooling system subjected to 80-90% of maximum rated capacity for extended periods (typically 500-1000 hours). This approach identifies potential failure points and performance degradation patterns that might emerge only after prolonged use.

Flow restriction simulation tests evaluate the cooling system's performance when faced with partial blockages or flow restrictions. These tests systematically reduce flow capacity in increments of 10% while monitoring temperature differentials across the system to determine the threshold at which heat dissipation capacity becomes critically compromised.

Statistical reliability modeling complements physical testing by applying Weibull analysis and Monte Carlo simulations to test data, enabling prediction of failure rates and system reliability over time. These models typically incorporate data from accelerated life testing to project performance over the expected 150,000-200,000 mile service life of the LS2 engine.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!