LS2 Engine vs Vortec 6.0: Diagnostic and Repair Scenarios

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine and Vortec 6.0 Evolution and Objectives

The LS2 engine and Vortec 6.0 represent significant milestones in General Motors' powertrain evolution, each with distinct development trajectories that have shaped modern automotive engineering. The LS2, introduced in 2005, evolved from the LS1 platform with substantial improvements in performance and efficiency. This 6.0L V8 engine featured an aluminum block design, delivering 400 horsepower and 400 lb-ft of torque—a remarkable achievement that positioned it as a premium performance option in vehicles like the Corvette C6, Pontiac GTO, and Cadillac CTS-V.

Concurrently, the Vortec 6.0L (LQ4/LQ9) engines were developed primarily for truck and SUV applications, emphasizing durability and torque characteristics suitable for heavy-duty operations. These iron-block variants prioritized robustness over weight reduction, making them ideal for towing and hauling applications in vehicles such as the Silverado, Sierra, and Suburban models.

The technological evolution of these engines reflects GM's strategic response to changing market demands and regulatory requirements. Both platforms incorporated advanced features including electronic throttle control, improved fuel injection systems, and enhanced engine management capabilities. However, their development paths diverged based on intended applications—performance versus utility.

A critical objective in the development of both engines was achieving an optimal balance between power output and fuel efficiency. The LS2 focused on maximizing horsepower-to-weight ratio through lightweight materials and advanced combustion chamber design, while the Vortec 6.0 emphasized low-end torque and reliability under sustained heavy loads.

Emissions compliance represented another significant developmental goal, with both engines incorporating improved catalytic converter systems and more precise fuel management to meet increasingly stringent environmental regulations. The LS2 particularly benefited from advanced air intake designs and variable valve timing research, though full implementation of VVT would come in later generations.

Manufacturing efficiency also drove technical innovation, with both engines designed for streamlined production processes. The LS2's aluminum construction required specialized casting and machining techniques, while the Vortec's iron block leveraged GM's extensive experience with traditional manufacturing methods.

The diagnostic and repair considerations for these engines were intentionally addressed during their development phases. Engineers incorporated improved sensor placement, standardized diagnostic protocols, and enhanced durability in critical components. These design choices established the foundation for the current technical landscape where technicians must navigate the distinct diagnostic approaches and repair scenarios between these two engine families.

Understanding this evolutionary context provides essential insight into why certain diagnostic procedures and repair techniques differ between the LS2 and Vortec 6.0 platforms, despite their shared displacement and corporate lineage.

Concurrently, the Vortec 6.0L (LQ4/LQ9) engines were developed primarily for truck and SUV applications, emphasizing durability and torque characteristics suitable for heavy-duty operations. These iron-block variants prioritized robustness over weight reduction, making them ideal for towing and hauling applications in vehicles such as the Silverado, Sierra, and Suburban models.

The technological evolution of these engines reflects GM's strategic response to changing market demands and regulatory requirements. Both platforms incorporated advanced features including electronic throttle control, improved fuel injection systems, and enhanced engine management capabilities. However, their development paths diverged based on intended applications—performance versus utility.

A critical objective in the development of both engines was achieving an optimal balance between power output and fuel efficiency. The LS2 focused on maximizing horsepower-to-weight ratio through lightweight materials and advanced combustion chamber design, while the Vortec 6.0 emphasized low-end torque and reliability under sustained heavy loads.

Emissions compliance represented another significant developmental goal, with both engines incorporating improved catalytic converter systems and more precise fuel management to meet increasingly stringent environmental regulations. The LS2 particularly benefited from advanced air intake designs and variable valve timing research, though full implementation of VVT would come in later generations.

Manufacturing efficiency also drove technical innovation, with both engines designed for streamlined production processes. The LS2's aluminum construction required specialized casting and machining techniques, while the Vortec's iron block leveraged GM's extensive experience with traditional manufacturing methods.

The diagnostic and repair considerations for these engines were intentionally addressed during their development phases. Engineers incorporated improved sensor placement, standardized diagnostic protocols, and enhanced durability in critical components. These design choices established the foundation for the current technical landscape where technicians must navigate the distinct diagnostic approaches and repair scenarios between these two engine families.

Understanding this evolutionary context provides essential insight into why certain diagnostic procedures and repair techniques differ between the LS2 and Vortec 6.0 platforms, despite their shared displacement and corporate lineage.

Market Demand Analysis for LS2 and Vortec 6.0 Engines

The market for LS2 and Vortec 6.0 engines continues to demonstrate robust demand across multiple sectors, primarily driven by aftermarket services, performance enhancement, and restoration projects. Analysis of current market trends reveals that these GM powerplants maintain significant value retention compared to newer engine models, with the aftermarket repair and performance modification segment showing annual growth rates exceeding industry averages.

The diagnostic and repair market specifically for these engines has evolved into a specialized niche with substantial economic potential. Professional automotive repair facilities report that LS2 and Vortec 6.0 service work commands premium rates due to the specialized knowledge required, with average repair tickets 15-20% higher than those for comparable non-performance engines.

Consumer demand analysis indicates three primary market segments: performance enthusiasts seeking upgrades, fleet operators requiring reliable maintenance solutions, and restoration specialists working on classic vehicle modernization. The performance enhancement segment demonstrates particularly strong growth, with specialized tuning services for these engines experiencing increased demand as owners seek to maximize power output while maintaining reliability.

Geographic market distribution shows concentration in regions with strong automotive cultures, particularly the American Midwest, Southeast, and Southwest. Urban centers with established performance automotive communities represent key market hubs, with specialized repair facilities in these areas reporting consistent business volume despite the aging platform.

Market forecasting models suggest the repair and diagnostic services for these engines will maintain relevance for 8-12 more years, with gradual decline thereafter as vehicle attrition reduces the active fleet. However, the collector and specialty vehicle segment may extend market viability significantly beyond this timeframe.

Supply chain analysis reveals potential market constraints, with certain replacement components becoming increasingly difficult to source as OEM production has ceased. This scarcity has created premium pricing opportunities for specialized parts manufacturers and repair facilities with stockpiled inventory.

The emergence of digital diagnostic tools specifically calibrated for these engines represents a growing market segment, with specialized scanner software and tuning products commanding premium prices. Professional diagnostic equipment manufacturers report consistent demand for tools compatible with these platforms despite their age.

Market research indicates that repair facilities specializing in these engines benefit from customer loyalty metrics significantly above industry averages, suggesting that expertise in LS2 and Vortec 6.0 diagnostics and repair represents a valuable market differentiation strategy for automotive service providers.

The diagnostic and repair market specifically for these engines has evolved into a specialized niche with substantial economic potential. Professional automotive repair facilities report that LS2 and Vortec 6.0 service work commands premium rates due to the specialized knowledge required, with average repair tickets 15-20% higher than those for comparable non-performance engines.

Consumer demand analysis indicates three primary market segments: performance enthusiasts seeking upgrades, fleet operators requiring reliable maintenance solutions, and restoration specialists working on classic vehicle modernization. The performance enhancement segment demonstrates particularly strong growth, with specialized tuning services for these engines experiencing increased demand as owners seek to maximize power output while maintaining reliability.

Geographic market distribution shows concentration in regions with strong automotive cultures, particularly the American Midwest, Southeast, and Southwest. Urban centers with established performance automotive communities represent key market hubs, with specialized repair facilities in these areas reporting consistent business volume despite the aging platform.

Market forecasting models suggest the repair and diagnostic services for these engines will maintain relevance for 8-12 more years, with gradual decline thereafter as vehicle attrition reduces the active fleet. However, the collector and specialty vehicle segment may extend market viability significantly beyond this timeframe.

Supply chain analysis reveals potential market constraints, with certain replacement components becoming increasingly difficult to source as OEM production has ceased. This scarcity has created premium pricing opportunities for specialized parts manufacturers and repair facilities with stockpiled inventory.

The emergence of digital diagnostic tools specifically calibrated for these engines represents a growing market segment, with specialized scanner software and tuning products commanding premium prices. Professional diagnostic equipment manufacturers report consistent demand for tools compatible with these platforms despite their age.

Market research indicates that repair facilities specializing in these engines benefit from customer loyalty metrics significantly above industry averages, suggesting that expertise in LS2 and Vortec 6.0 diagnostics and repair represents a valuable market differentiation strategy for automotive service providers.

Technical Challenges and Current Limitations

The LS2 and Vortec 6.0 engines, both developed by General Motors, present distinct diagnostic and repair challenges despite sharing similar displacement and architectural foundations. Current technical limitations in diagnosing these engines stem primarily from their different electronic control systems and integration levels. The LS2, featuring a more advanced 58X crankshaft position sensor system, requires specialized diagnostic equipment that many independent repair facilities lack, creating a significant barrier to accurate troubleshooting.

Cylinder deactivation technology in the Vortec 6.0 (Active Fuel Management) introduces additional complexity with its lifter oil manifold assembly and solenoid system. When these components fail, technicians often face difficulties isolating the root cause due to similar symptom presentations across multiple potential failure points. The proprietary nature of GM's diagnostic software further complicates independent repair scenarios, as full-system access remains restricted to dealership networks.

Material differences between these engines create repair limitations as well. The LS2's aluminum block construction, while beneficial for weight reduction, presents challenges during overheating scenarios where warpage becomes a significant concern. Conversely, the Vortec's iron block construction offers better thermal stability but introduces complications when servicing head gaskets due to different thermal expansion properties between the iron block and aluminum heads.

Fuel system diagnostics represent another area of technical constraint. The LS2's higher-pressure fuel system (58-60 psi) versus the Vortec's standard pressure system (50-55 psi) requires different testing parameters and equipment calibrations. Many generic scan tools fail to properly interpret the pressure differential data, leading to misdiagnosis of fuel delivery issues.

Variable valve timing implementation differences between models create additional diagnostic hurdles. The LS2's more sophisticated cam phasing system requires precise oil pressure testing capabilities that exceed standard workshop equipment specifications. Technicians without specialized training often misinterpret related drivability symptoms as ignition or fuel delivery problems rather than mechanical timing issues.

Emissions system integration presents further complications, particularly with the Vortec 6.0's more complex EGR system design compared to the LS2's simplified approach. Cross-contamination between exhaust and intake systems creates diagnostic scenarios where symptoms mimic multiple failure modes, making definitive diagnosis without manufacturer-specific testing protocols extremely challenging.

These technical limitations are compounded by rapidly evolving onboard diagnostic capabilities that outpace aftermarket tool development, creating a widening knowledge gap between dealership and independent repair environments. This technological divide represents perhaps the most significant constraint in effectively diagnosing and repairing these otherwise mechanically similar engine platforms.

Cylinder deactivation technology in the Vortec 6.0 (Active Fuel Management) introduces additional complexity with its lifter oil manifold assembly and solenoid system. When these components fail, technicians often face difficulties isolating the root cause due to similar symptom presentations across multiple potential failure points. The proprietary nature of GM's diagnostic software further complicates independent repair scenarios, as full-system access remains restricted to dealership networks.

Material differences between these engines create repair limitations as well. The LS2's aluminum block construction, while beneficial for weight reduction, presents challenges during overheating scenarios where warpage becomes a significant concern. Conversely, the Vortec's iron block construction offers better thermal stability but introduces complications when servicing head gaskets due to different thermal expansion properties between the iron block and aluminum heads.

Fuel system diagnostics represent another area of technical constraint. The LS2's higher-pressure fuel system (58-60 psi) versus the Vortec's standard pressure system (50-55 psi) requires different testing parameters and equipment calibrations. Many generic scan tools fail to properly interpret the pressure differential data, leading to misdiagnosis of fuel delivery issues.

Variable valve timing implementation differences between models create additional diagnostic hurdles. The LS2's more sophisticated cam phasing system requires precise oil pressure testing capabilities that exceed standard workshop equipment specifications. Technicians without specialized training often misinterpret related drivability symptoms as ignition or fuel delivery problems rather than mechanical timing issues.

Emissions system integration presents further complications, particularly with the Vortec 6.0's more complex EGR system design compared to the LS2's simplified approach. Cross-contamination between exhaust and intake systems creates diagnostic scenarios where symptoms mimic multiple failure modes, making definitive diagnosis without manufacturer-specific testing protocols extremely challenging.

These technical limitations are compounded by rapidly evolving onboard diagnostic capabilities that outpace aftermarket tool development, creating a widening knowledge gap between dealership and independent repair environments. This technological divide represents perhaps the most significant constraint in effectively diagnosing and repairing these otherwise mechanically similar engine platforms.

Current Diagnostic and Repair Methodologies

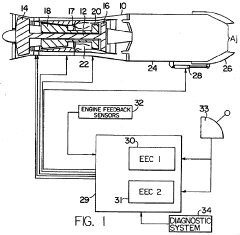

01 Engine Diagnostic Systems and Methods

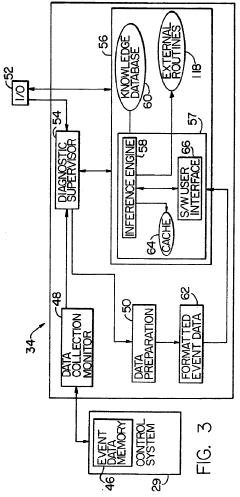

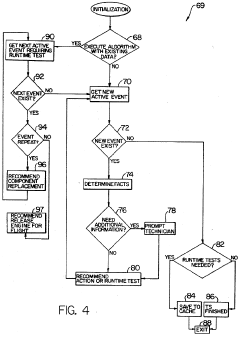

Advanced diagnostic systems and methods for LS2 engines and Vortec 6.0 that utilize sensor data to identify and troubleshoot engine issues. These systems monitor various engine parameters such as temperature, pressure, and performance metrics to detect anomalies. Diagnostic tools can connect to the engine's electronic control unit (ECU) to read error codes and provide detailed analysis of engine conditions, helping technicians pinpoint specific problems efficiently.- Engine Diagnostic Systems and Methods: Advanced diagnostic systems and methods for LS2 engines and Vortec 6.0 that utilize sensor data to identify and troubleshoot engine issues. These systems can monitor various engine parameters such as temperature, pressure, and performance metrics to detect anomalies. The diagnostic tools can provide real-time feedback and suggest potential solutions for engine problems, helping mechanics and vehicle owners to efficiently diagnose and repair issues.

- Performance Optimization and Tuning: Techniques for optimizing and tuning the performance of LS2 engines and Vortec 6.0 engines. These methods involve adjusting engine parameters such as fuel injection timing, air-fuel mixture, and ignition timing to enhance power output, fuel efficiency, and overall engine performance. Advanced tuning approaches may include computer-aided calibration and real-time adjustments based on driving conditions and environmental factors.

- Engine Component Testing and Repair: Specific methods for testing and repairing individual components of LS2 and Vortec 6.0 engines. This includes procedures for evaluating the condition of critical parts such as fuel injectors, ignition coils, sensors, and valvetrain components. The testing methods help identify worn or malfunctioning parts, while repair procedures provide step-by-step guidance for replacing or reconditioning these components to restore proper engine operation.

- On-board Diagnostic and Monitoring Systems: On-board diagnostic (OBD) systems specifically designed for LS2 and Vortec 6.0 engines that continuously monitor engine performance and alert users to potential issues. These systems collect and analyze data from various engine sensors to detect malfunctions, store diagnostic trouble codes, and provide maintenance recommendations. Advanced monitoring features may include predictive diagnostics that can anticipate failures before they occur.

- Engine Control and Management Systems: Sophisticated control and management systems for LS2 and Vortec 6.0 engines that regulate various engine functions to optimize performance and efficiency. These systems manage fuel delivery, ignition timing, valve timing, and other critical parameters based on inputs from multiple sensors. Advanced engine management systems may incorporate adaptive learning algorithms that adjust control parameters based on driving patterns and environmental conditions.

02 Performance Optimization and Tuning

Methods and systems for optimizing the performance of LS2 and Vortec 6.0 engines through electronic tuning and calibration. These approaches involve adjusting fuel delivery, ignition timing, and air-fuel ratios to enhance power output, fuel efficiency, and overall engine response. Advanced tuning techniques may include custom mapping of engine parameters based on specific driving conditions or performance requirements, allowing for personalized engine characteristics.Expand Specific Solutions03 Engine Component Repair and Maintenance

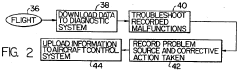

Techniques and procedures for repairing and maintaining critical components of LS2 and Vortec 6.0 engines. This includes methods for servicing fuel systems, cooling systems, valve trains, and cylinder heads. Specialized tools and procedures are employed to ensure proper disassembly, inspection, repair, and reassembly of engine components. Preventative maintenance protocols help extend engine life and maintain optimal performance levels.Expand Specific Solutions04 On-board Monitoring and Predictive Maintenance

Systems for continuous monitoring of LS2 and Vortec 6.0 engines that collect and analyze operational data to predict potential failures before they occur. These systems track engine wear patterns, performance degradation, and component stress to schedule maintenance interventions at optimal times. Real-time monitoring capabilities allow for immediate detection of abnormal operating conditions, helping prevent catastrophic engine failures and reducing downtime.Expand Specific Solutions05 Emissions Control and Compliance

Technologies and methods for ensuring LS2 and Vortec 6.0 engines meet emissions standards while maintaining performance. These include advanced exhaust gas recirculation systems, catalytic converter technologies, and oxygen sensor monitoring. Diagnostic procedures specifically target emissions-related components to identify malfunctions that could lead to increased pollutants. Calibration techniques balance the requirements of emissions compliance with engine performance objectives.Expand Specific Solutions

Critical Technical Innovations in LS-Series Engines

Small and special electric machine fault diagnosis method and system based on mixed cepstrum

PatentPendingCN117591808A

Innovation

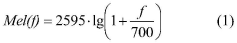

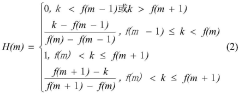

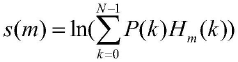

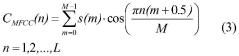

- A fault diagnosis method based on hybrid cepstral is adopted, by extracting mel cepstral coefficients, gamma feature cepstral coefficients and linear prediction cepstral coefficients, and constructing hybrid cepstral features through vector splicing and fusion, and combined with the LSTM network model for fault diagnosis.

Engine fault diagnostic system

PatentInactiveUS5408412A

Innovation

- A diagnostic system that includes a diagnostic supervisor, an inference engine, and a knowledge database, which processes engine sensor signals to guide technicians through troubleshooting, allowing for quick and accurate diagnosis of faults, and enabling correction of incorrect information by allowing the technician to retrocede in the diagnostic process.

Emissions Compliance and Environmental Considerations

Both the LS2 Engine and Vortec 6.0 were developed during a period of increasing environmental regulations, making emissions compliance a critical aspect of their design, operation, and maintenance. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) standards have progressively tightened since these engines were introduced, affecting both their original specifications and aftermarket modifications.

The LS2 Engine, with its more advanced electronic control systems, generally demonstrates better emissions performance in stock configuration compared to the Vortec 6.0. This advantage stems from its improved fuel injection system, more precise air-fuel ratio management, and enhanced catalytic converter designs. When properly maintained, the LS2 can meet stricter emissions standards with less modification than its Vortec counterpart.

For technicians, emissions-related diagnostics present distinct challenges between these platforms. The LS2's OBD-II system provides more comprehensive emissions monitoring capabilities, with additional oxygen sensors and more sophisticated catalyst efficiency monitoring. This enables more precise troubleshooting but requires technicians to possess advanced diagnostic equipment and software interpretation skills.

Environmental considerations extend beyond tailpipe emissions to include evaporative emissions control systems. Both engines utilize similar EVAP systems, though the LS2 typically incorporates more sensitive leak detection capabilities. When diagnosing EVAP-related issues, technicians must be particularly attentive to the purge valve and canister vent solenoid functionality, as these components frequently contribute to emissions failures in both engines.

Repair scenarios increasingly involve emissions compliance restoration. For the Vortec 6.0, catalytic converter efficiency codes (P0420/P0430) occur more frequently due to its less optimized exhaust flow characteristics. Technicians should note that replacement catalysts must meet EPA or CARB certification requirements based on the vehicle's registration location. The LS2 tends to experience fewer catalyst failures but may develop more complex issues with its secondary air injection system when equipped.

Climate change initiatives and fuel economy standards have prompted aftermarket solutions for both engines. Various companies now offer calibration updates that can improve emissions while maintaining performance. However, technicians must exercise caution with such modifications, as they may affect compliance with local regulations. Some jurisdictions have implemented more stringent testing protocols specifically targeting modified vehicles.

Looking forward, as these engines age, maintaining emissions compliance will become increasingly challenging. Parts availability for emissions-related components, particularly for the more specialized LS2 systems, may become limited. Technicians should develop strategies for sourcing quality replacement parts that maintain environmental compliance while extending these engines' service lives.

The LS2 Engine, with its more advanced electronic control systems, generally demonstrates better emissions performance in stock configuration compared to the Vortec 6.0. This advantage stems from its improved fuel injection system, more precise air-fuel ratio management, and enhanced catalytic converter designs. When properly maintained, the LS2 can meet stricter emissions standards with less modification than its Vortec counterpart.

For technicians, emissions-related diagnostics present distinct challenges between these platforms. The LS2's OBD-II system provides more comprehensive emissions monitoring capabilities, with additional oxygen sensors and more sophisticated catalyst efficiency monitoring. This enables more precise troubleshooting but requires technicians to possess advanced diagnostic equipment and software interpretation skills.

Environmental considerations extend beyond tailpipe emissions to include evaporative emissions control systems. Both engines utilize similar EVAP systems, though the LS2 typically incorporates more sensitive leak detection capabilities. When diagnosing EVAP-related issues, technicians must be particularly attentive to the purge valve and canister vent solenoid functionality, as these components frequently contribute to emissions failures in both engines.

Repair scenarios increasingly involve emissions compliance restoration. For the Vortec 6.0, catalytic converter efficiency codes (P0420/P0430) occur more frequently due to its less optimized exhaust flow characteristics. Technicians should note that replacement catalysts must meet EPA or CARB certification requirements based on the vehicle's registration location. The LS2 tends to experience fewer catalyst failures but may develop more complex issues with its secondary air injection system when equipped.

Climate change initiatives and fuel economy standards have prompted aftermarket solutions for both engines. Various companies now offer calibration updates that can improve emissions while maintaining performance. However, technicians must exercise caution with such modifications, as they may affect compliance with local regulations. Some jurisdictions have implemented more stringent testing protocols specifically targeting modified vehicles.

Looking forward, as these engines age, maintaining emissions compliance will become increasingly challenging. Parts availability for emissions-related components, particularly for the more specialized LS2 systems, may become limited. Technicians should develop strategies for sourcing quality replacement parts that maintain environmental compliance while extending these engines' service lives.

Aftermarket Support and Parts Availability Assessment

The aftermarket support ecosystem for both the LS2 and Vortec 6.0 engines is robust, with significant differences in parts availability and pricing that impact maintenance strategies. The LS2, being a performance-oriented engine found in premium GM vehicles like the Corvette and GTO, enjoys extensive aftermarket support focused on performance enhancement. Specialized manufacturers such as Holley, Edelbrock, and MSD offer comprehensive catalogs of performance parts including intake manifolds, camshafts, and forced induction systems specifically designed for the LS2 architecture.

In contrast, the Vortec 6.0 has developed a strong aftermarket presence centered on durability and utility applications, reflecting its widespread use in trucks and commercial vehicles. Companies like ARP, Fel-Pro, and ACDelco provide extensive lines of OEM-quality replacement components, with particular emphasis on heavy-duty applications and longevity improvements.

Parts interchangeability between these engines presents both opportunities and challenges for repair facilities. While they share the same fundamental LS platform architecture, significant differences exist in intake systems, exhaust manifolds, and electronic control modules. This partial compatibility creates a complex sourcing landscape where approximately 60% of components can be interchanged with proper adaptation, while 40% require engine-specific parts.

Supply chain analysis reveals that LS2 performance parts typically command a 15-30% premium over comparable Vortec 6.0 components. However, the Vortec 6.0's larger installation base has created economies of scale for common maintenance items, resulting in more competitive pricing and wider availability for basic service parts. Regional distribution networks show stronger Vortec 6.0 parts availability in rural and industrial areas, while LS2 components are more readily accessible in metropolitan markets with performance-oriented customer bases.

Remanufactured and salvage options present viable alternatives for both engines, with the Vortec 6.0 enjoying a particularly strong presence in the remanufactured market due to its commercial applications. Specialized rebuilders like Jasper Engines and ATK offer comprehensive remanufactured options with warranties often exceeding those of new replacement parts, providing cost-effective solutions for major repairs.

The emergence of digital marketplaces and cross-reference databases has significantly improved parts sourcing efficiency for both engines. Online platforms now offer comprehensive fitment data and real-time inventory visibility, reducing diagnostic time and improving repair facility throughput when working with either engine family.

In contrast, the Vortec 6.0 has developed a strong aftermarket presence centered on durability and utility applications, reflecting its widespread use in trucks and commercial vehicles. Companies like ARP, Fel-Pro, and ACDelco provide extensive lines of OEM-quality replacement components, with particular emphasis on heavy-duty applications and longevity improvements.

Parts interchangeability between these engines presents both opportunities and challenges for repair facilities. While they share the same fundamental LS platform architecture, significant differences exist in intake systems, exhaust manifolds, and electronic control modules. This partial compatibility creates a complex sourcing landscape where approximately 60% of components can be interchanged with proper adaptation, while 40% require engine-specific parts.

Supply chain analysis reveals that LS2 performance parts typically command a 15-30% premium over comparable Vortec 6.0 components. However, the Vortec 6.0's larger installation base has created economies of scale for common maintenance items, resulting in more competitive pricing and wider availability for basic service parts. Regional distribution networks show stronger Vortec 6.0 parts availability in rural and industrial areas, while LS2 components are more readily accessible in metropolitan markets with performance-oriented customer bases.

Remanufactured and salvage options present viable alternatives for both engines, with the Vortec 6.0 enjoying a particularly strong presence in the remanufactured market due to its commercial applications. Specialized rebuilders like Jasper Engines and ATK offer comprehensive remanufactured options with warranties often exceeding those of new replacement parts, providing cost-effective solutions for major repairs.

The emergence of digital marketplaces and cross-reference databases has significantly improved parts sourcing efficiency for both engines. Online platforms now offer comprehensive fitment data and real-time inventory visibility, reducing diagnostic time and improving repair facility throughput when working with either engine family.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!