Measuring LS2 Engine Exhaust Gas Recirculation: Pollution Control

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 EGR Technology Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant advancement in the evolution of automotive propulsion systems, particularly in the realm of emissions control. This 6.0-liter V8 engine, part of the Gen IV small-block family, was designed to balance high performance with increasingly stringent environmental regulations. The development of Exhaust Gas Recirculation (EGR) technology for the LS2 platform emerged as a critical response to these dual demands, marking an important milestone in automotive pollution control strategies.

EGR technology has evolved substantially since its initial implementation in the 1970s. Early systems were primarily mechanical, with limited precision and control capabilities. The progression toward electronic control in the 1990s set the foundation for the more sophisticated systems incorporated in the LS2 engine. This technological evolution reflects the industry's growing commitment to reducing nitrogen oxide (NOx) emissions, which are significant contributors to smog formation and respiratory health issues.

The primary technical objective of LS2 EGR systems is to precisely recirculate a controlled portion of exhaust gases back into the combustion chamber. This process reduces peak combustion temperatures, thereby inhibiting the formation of NOx. The challenge lies in achieving this reduction without compromising engine performance, fuel efficiency, or drivability – a delicate balance that requires sophisticated measurement and control mechanisms.

Accurate measurement of EGR flow rates represents one of the most significant technical challenges in this domain. Traditional methods often suffered from reliability issues under varying operating conditions, leading to suboptimal emissions control. The LS2 platform aimed to overcome these limitations through advanced sensor technology and improved computational models that could adapt to different driving scenarios and environmental conditions.

The global context for EGR technology development has been shaped by increasingly stringent emissions standards, including the European Union's Euro standards, the United States' EPA regulations, and California's CARB requirements. These regulatory frameworks have accelerated innovation in EGR measurement and control technologies, pushing manufacturers to develop more precise and reliable systems.

Looking forward, the technical trajectory for LS2 EGR systems points toward integration with broader powertrain control strategies, including variable valve timing, direct injection, and turbocharging technologies. This holistic approach aims to optimize emissions reduction across the entire operating range of the engine, representing the next frontier in automotive pollution control technology.

The measurement technologies developed for LS2 EGR systems have also established important foundations for subsequent engine families, creating a technological lineage that continues to influence modern emissions control strategies in both conventional and hybrid powertrains.

EGR technology has evolved substantially since its initial implementation in the 1970s. Early systems were primarily mechanical, with limited precision and control capabilities. The progression toward electronic control in the 1990s set the foundation for the more sophisticated systems incorporated in the LS2 engine. This technological evolution reflects the industry's growing commitment to reducing nitrogen oxide (NOx) emissions, which are significant contributors to smog formation and respiratory health issues.

The primary technical objective of LS2 EGR systems is to precisely recirculate a controlled portion of exhaust gases back into the combustion chamber. This process reduces peak combustion temperatures, thereby inhibiting the formation of NOx. The challenge lies in achieving this reduction without compromising engine performance, fuel efficiency, or drivability – a delicate balance that requires sophisticated measurement and control mechanisms.

Accurate measurement of EGR flow rates represents one of the most significant technical challenges in this domain. Traditional methods often suffered from reliability issues under varying operating conditions, leading to suboptimal emissions control. The LS2 platform aimed to overcome these limitations through advanced sensor technology and improved computational models that could adapt to different driving scenarios and environmental conditions.

The global context for EGR technology development has been shaped by increasingly stringent emissions standards, including the European Union's Euro standards, the United States' EPA regulations, and California's CARB requirements. These regulatory frameworks have accelerated innovation in EGR measurement and control technologies, pushing manufacturers to develop more precise and reliable systems.

Looking forward, the technical trajectory for LS2 EGR systems points toward integration with broader powertrain control strategies, including variable valve timing, direct injection, and turbocharging technologies. This holistic approach aims to optimize emissions reduction across the entire operating range of the engine, representing the next frontier in automotive pollution control technology.

The measurement technologies developed for LS2 EGR systems have also established important foundations for subsequent engine families, creating a technological lineage that continues to influence modern emissions control strategies in both conventional and hybrid powertrains.

Emission Control Market Analysis

The global emission control market has experienced significant growth in recent years, driven primarily by stringent environmental regulations and increasing awareness about air pollution. The market for exhaust gas recirculation (EGR) systems, particularly for applications in engines like the LS2, represents a substantial segment within this broader market. Current valuations place the global automotive EGR system market at approximately 12.3 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.8% through 2030.

The demand for advanced EGR measurement and control technologies is particularly strong in regions with strict emission standards, such as Europe, North America, and increasingly in Asia-Pacific markets. The European market leads in adoption due to the implementation of Euro 6d standards, which have placed significant pressure on manufacturers to reduce nitrogen oxide (NOx) emissions. North America follows closely, with the EPA's Tier 3 standards driving similar technological advancements.

Market segmentation reveals distinct trends across vehicle types. The passenger vehicle segment currently dominates the EGR system market with a share of 68%, while commercial vehicles account for the remaining 32%. However, the commercial vehicle segment is expected to grow at a faster rate due to increasingly stringent regulations targeting heavy-duty diesel engines.

From a competitive landscape perspective, the market features both established automotive component manufacturers and specialized emission control technology providers. Key market players include Bosch, Continental, Denso, BorgWarner, and Delphi Technologies, who collectively control approximately 65% of the global market share. These companies are investing heavily in R&D to develop more precise measurement technologies for EGR systems.

Consumer behavior is also influencing market dynamics, with growing environmental consciousness among buyers leading to increased demand for cleaner vehicles. This trend is particularly evident in premium vehicle segments, where manufacturers are using advanced emission control technologies as selling points. The willingness to pay for environmentally friendly features has increased by 22% over the past five years.

Technological advancements in EGR measurement systems are creating new market opportunities. Digital sensors, IoT connectivity, and real-time monitoring capabilities are emerging as key differentiators. The market for these advanced measurement systems is growing at 9.3% annually, outpacing the overall EGR system market growth.

Looking ahead, market forecasts suggest that regions implementing new emission standards will see the most rapid growth. China's implementation of China VI standards is expected to create a market expansion of 11.2% annually in the region, while India's BS-VI standards are driving similar growth at 10.8% annually.

The demand for advanced EGR measurement and control technologies is particularly strong in regions with strict emission standards, such as Europe, North America, and increasingly in Asia-Pacific markets. The European market leads in adoption due to the implementation of Euro 6d standards, which have placed significant pressure on manufacturers to reduce nitrogen oxide (NOx) emissions. North America follows closely, with the EPA's Tier 3 standards driving similar technological advancements.

Market segmentation reveals distinct trends across vehicle types. The passenger vehicle segment currently dominates the EGR system market with a share of 68%, while commercial vehicles account for the remaining 32%. However, the commercial vehicle segment is expected to grow at a faster rate due to increasingly stringent regulations targeting heavy-duty diesel engines.

From a competitive landscape perspective, the market features both established automotive component manufacturers and specialized emission control technology providers. Key market players include Bosch, Continental, Denso, BorgWarner, and Delphi Technologies, who collectively control approximately 65% of the global market share. These companies are investing heavily in R&D to develop more precise measurement technologies for EGR systems.

Consumer behavior is also influencing market dynamics, with growing environmental consciousness among buyers leading to increased demand for cleaner vehicles. This trend is particularly evident in premium vehicle segments, where manufacturers are using advanced emission control technologies as selling points. The willingness to pay for environmentally friendly features has increased by 22% over the past five years.

Technological advancements in EGR measurement systems are creating new market opportunities. Digital sensors, IoT connectivity, and real-time monitoring capabilities are emerging as key differentiators. The market for these advanced measurement systems is growing at 9.3% annually, outpacing the overall EGR system market growth.

Looking ahead, market forecasts suggest that regions implementing new emission standards will see the most rapid growth. China's implementation of China VI standards is expected to create a market expansion of 11.2% annually in the region, while India's BS-VI standards are driving similar growth at 10.8% annually.

EGR System Challenges and Global Standards

Exhaust Gas Recirculation (EGR) systems face significant challenges across global markets due to increasingly stringent emission standards. The primary technical challenge involves accurate measurement and control of recirculated exhaust gases in LS2 engines, where precision directly impacts both pollution control effectiveness and engine performance. Current EGR systems struggle with carbon deposit accumulation on valves and passages, leading to restricted flow and reduced efficiency over time. This fouling issue is particularly problematic in LS2 engines due to their high-performance characteristics and operating temperatures.

Measurement accuracy presents another major challenge, as traditional flow sensors often fail to provide reliable data under varying engine conditions. The dynamic nature of exhaust gas composition—changing with engine load, temperature, and fuel quality—further complicates precise measurement. Engineers must balance the trade-off between NOx reduction and fuel economy, as higher EGR rates effectively reduce NOx but can negatively impact combustion efficiency and power output.

Global emission standards have evolved dramatically over the past decade, creating a complex regulatory landscape for automotive manufacturers. The European Union's Euro 6d standards impose strict NOx limits of 80 mg/km for passenger vehicles, while the United States EPA Tier 3 regulations require fleet-average NOx+NMOG emissions below 30 mg/mile. China's China 6b standards, implemented in 2023, align closely with Euro 6 requirements but include additional testing procedures specific to local driving conditions.

These divergent regional standards create significant challenges for global vehicle platforms, as manufacturers must design EGR systems that can be calibrated to meet different requirements without major hardware changes. The testing protocols also vary substantially—the EU's Real Driving Emissions (RDE) tests demand compliance across a wider range of operating conditions than traditional laboratory cycles, while the US focuses on long-term durability through extended useful life requirements.

The technical complexity is further increased by the need to integrate EGR systems with other emission control technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). This system integration challenge requires sophisticated control algorithms and sensor networks to optimize the overall emission reduction strategy while maintaining acceptable drivability and fuel economy.

Emerging markets present additional challenges, as fuel quality variations can significantly impact EGR system performance. Higher sulfur content in fuels accelerates component degradation, while inconsistent fuel properties complicate control strategy calibration. Manufacturers must design robust systems capable of functioning effectively despite these variables, often requiring additional protective measures and more frequent maintenance intervals.

Measurement accuracy presents another major challenge, as traditional flow sensors often fail to provide reliable data under varying engine conditions. The dynamic nature of exhaust gas composition—changing with engine load, temperature, and fuel quality—further complicates precise measurement. Engineers must balance the trade-off between NOx reduction and fuel economy, as higher EGR rates effectively reduce NOx but can negatively impact combustion efficiency and power output.

Global emission standards have evolved dramatically over the past decade, creating a complex regulatory landscape for automotive manufacturers. The European Union's Euro 6d standards impose strict NOx limits of 80 mg/km for passenger vehicles, while the United States EPA Tier 3 regulations require fleet-average NOx+NMOG emissions below 30 mg/mile. China's China 6b standards, implemented in 2023, align closely with Euro 6 requirements but include additional testing procedures specific to local driving conditions.

These divergent regional standards create significant challenges for global vehicle platforms, as manufacturers must design EGR systems that can be calibrated to meet different requirements without major hardware changes. The testing protocols also vary substantially—the EU's Real Driving Emissions (RDE) tests demand compliance across a wider range of operating conditions than traditional laboratory cycles, while the US focuses on long-term durability through extended useful life requirements.

The technical complexity is further increased by the need to integrate EGR systems with other emission control technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). This system integration challenge requires sophisticated control algorithms and sensor networks to optimize the overall emission reduction strategy while maintaining acceptable drivability and fuel economy.

Emerging markets present additional challenges, as fuel quality variations can significantly impact EGR system performance. Higher sulfur content in fuels accelerates component degradation, while inconsistent fuel properties complicate control strategy calibration. Manufacturers must design robust systems capable of functioning effectively despite these variables, often requiring additional protective measures and more frequent maintenance intervals.

Current LS2 EGR Measurement Solutions

01 EGR system design for LS2 engines

Specific designs of Exhaust Gas Recirculation systems tailored for LS2 engines to reduce NOx emissions. These designs include specialized valve configurations, flow paths, and control mechanisms that optimize the recirculation of exhaust gases back into the combustion chamber. The systems are engineered to maintain engine performance while meeting stringent emission standards through precise control of exhaust gas flow rates.- EGR system design for LS2 engines: Specific design features of Exhaust Gas Recirculation systems for LS2 engines that help reduce emissions. These designs include specialized valve configurations, flow control mechanisms, and integration with the engine's electronic control unit to optimize the recirculation of exhaust gases based on operating conditions, thereby reducing NOx emissions and improving fuel efficiency.

- EGR cooling technologies: Technologies for cooling recirculated exhaust gases before reintroduction into the combustion chamber. Cooling the exhaust gases increases their density, which helps reduce combustion temperatures and NOx formation. These technologies include various heat exchanger designs, coolant circulation systems, and temperature control mechanisms specifically adapted for LS2 engine applications.

- EGR monitoring and control systems: Advanced monitoring and control systems for optimizing EGR operation in LS2 engines. These systems include sensors for measuring exhaust gas composition, flow rates, and temperatures, along with electronic control units that adjust EGR valve operation based on real-time engine parameters. These systems ensure optimal pollution control across various driving conditions while maintaining engine performance.

- Integration with other emission control technologies: Methods for integrating EGR systems with other emission control technologies in LS2 engines. These integration approaches combine EGR with catalytic converters, diesel particulate filters, selective catalytic reduction systems, or other aftertreatment devices to achieve comprehensive emission control. The integrated systems work synergistically to reduce multiple pollutants simultaneously while optimizing engine performance.

- Low-pressure and high-pressure EGR configurations: Different configurations of EGR systems for LS2 engines, including low-pressure and high-pressure designs. Low-pressure EGR systems extract exhaust gases after the turbine and reintroduce them before the compressor, while high-pressure systems extract gases before the turbine and reintroduce them after the compressor. Each configuration offers different advantages in terms of response time, cooling efficiency, and pollution control effectiveness under various operating conditions.

02 EGR cooling technologies

Technologies focused on cooling recirculated exhaust gases before reintroduction into the intake manifold. These cooling systems reduce the temperature of exhaust gases, which increases the density of the intake charge and lowers combustion temperatures, resulting in reduced NOx formation. Various heat exchanger designs and coolant routing strategies are employed to optimize the cooling efficiency while minimizing pressure losses in the EGR system.Expand Specific Solutions03 EGR control strategies and sensors

Advanced control strategies and sensor technologies for precise management of EGR flow rates based on engine operating conditions. These systems utilize various sensors to monitor parameters such as intake air temperature, exhaust gas temperature, and oxygen content to determine optimal EGR rates. Electronic control units process this data to adjust EGR valve positions, ensuring optimal emissions reduction across the engine's operating range while maintaining performance and fuel efficiency.Expand Specific Solutions04 Integration with other emission control systems

Methods for integrating EGR systems with other emission control technologies such as catalytic converters, diesel particulate filters, and selective catalytic reduction systems. These integrated approaches create comprehensive emission control strategies that address multiple pollutants simultaneously. The coordinated operation of these systems optimizes overall emission reduction while minimizing the negative impacts on engine performance and fuel economy.Expand Specific Solutions05 Low-pressure EGR systems

Low-pressure EGR systems that extract exhaust gases after the turbine in turbocharged engines and introduce them before the compressor. This configuration allows for better mixing of exhaust gases with fresh air and more uniform distribution across cylinders. Low-pressure EGR systems can achieve higher EGR rates at high loads compared to high-pressure systems, providing better NOx reduction under demanding operating conditions while minimizing particulate matter formation.Expand Specific Solutions

Major Manufacturers in EGR Systems Industry

The LS2 Engine Exhaust Gas Recirculation (EGR) technology market is currently in a mature growth phase, with established players driving innovation in pollution control systems. The global automotive EGR market is estimated at approximately $12 billion, growing steadily due to stringent emission regulations worldwide. Leading companies like Robert Bosch GmbH, Continental Automotive, and DENSO Corp. have achieved high technical maturity in EGR systems, offering advanced solutions with precise measurement capabilities. OEMs including Toyota, Mercedes-Benz, and Ford are integrating sophisticated EGR technologies into their engine designs, while specialized suppliers such as Vitesco Technologies and Pierburg GmbH focus on component optimization. The competitive landscape shows a balance between established Tier-1 suppliers and automotive manufacturers developing proprietary EGR measurement systems to meet increasingly strict pollution standards.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced EGR (Exhaust Gas Recirculation) measurement systems for LS2 engines that combine high-precision sensors with integrated control algorithms. Their solution incorporates differential pressure sensors that can accurately measure EGR flow rates even under varying engine load conditions. The system utilizes a combination of cooled and uncooled EGR paths with electronically controlled valves to optimize recirculation based on real-time combustion parameters. Bosch's technology includes proprietary software that continuously adjusts EGR rates based on multiple inputs including oxygen sensors, mass airflow measurements, and engine temperature to maintain optimal NOx reduction while minimizing fuel economy penalties. Their latest systems incorporate predictive models that can anticipate required EGR adjustments based on driving patterns and environmental conditions, reducing response lag by up to 30% compared to reactive systems.

Strengths: Superior sensor integration with engine management systems provides comprehensive data for precise EGR control. Advanced algorithms enable dynamic adjustment across all operating conditions. Weaknesses: Higher system complexity increases initial cost and potential maintenance requirements compared to simpler solutions.

Ford Global Technologies LLC

Technical Solution: Ford has engineered a sophisticated LS2 engine EGR measurement system that employs dual-path EGR routing with independent cooling circuits. Their approach utilizes a combination of high and low-pressure EGR loops with dedicated mass flow sensors in each path to precisely quantify recirculation rates. Ford's system incorporates advanced thermal management that optimizes EGR temperature based on engine load conditions, significantly improving NOx reduction efficiency while minimizing particulate formation. The technology features adaptive control algorithms that continuously monitor and adjust EGR rates based on real-time combustion analysis and emissions feedback. Ford has implemented a patented sensor calibration method that compensates for deposit buildup on measurement components, maintaining accuracy over extended operating periods. Their system also includes fault detection capabilities that can identify EGR system degradation before emissions performance is compromised.

Strengths: Dual-path architecture provides exceptional flexibility across operating conditions, particularly during transient operations. Self-calibrating sensors maintain measurement accuracy over time. Weaknesses: Complex implementation requires sophisticated integration with powertrain control modules and may present challenges in aftermarket service environments.

Key Patents in EGR Sensing Technology

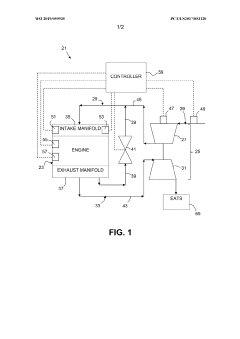

Method for measuring exhaust gas recirculation flow in an engine system, controlling emissions in an engine system, and an engine system

PatentWO2019059935A1

Innovation

- A method that calculates EGR flow by measuring turbo speed, inlet pressure, boost pressure, and engine intake temperature, using these parameters to determine air and exhaust mass flow, thereby subtracting air mass flow from exhaust mass flow to determine EGR flow without direct measurement equipment, utilizing existing sensors like turbo speed and pressure sensors.

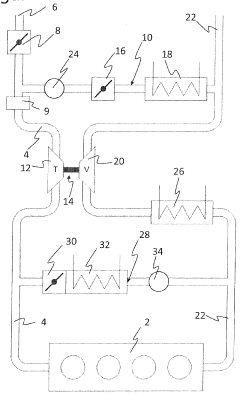

Exhaust gas recirculation system for internal combustion engine

PatentWO2010121852A1

Innovation

- The implementation of exhaust gas mass flow sensors in both the low-pressure and high-pressure exhaust gas recirculation ducts allows for direct measurement and precise control of exhaust gas flow, reducing the need for additional sensors and equipment, and incorporating air mass sensors and pressure sensors in the intake manifold for accurate determination of air flow.

Environmental Impact Assessment

The environmental impact of LS2 engine exhaust gas recirculation (EGR) systems extends far beyond the immediate vehicle performance considerations. These systems significantly reduce nitrogen oxide (NOx) emissions, which are primary contributors to smog formation and acid rain. By recirculating a portion of exhaust gases back into the combustion chamber, EGR systems lower combustion temperatures, thereby reducing NOx formation by up to 60% compared to non-EGR equipped engines.

However, the environmental benefits of EGR systems must be weighed against potential secondary effects. Improper EGR calibration can lead to increased particulate matter (PM) emissions, which pose serious respiratory health risks. Studies indicate that a 5% increase in EGR flow beyond optimal settings can result in a 15-20% increase in PM emissions, highlighting the critical importance of precise measurement and control systems.

Carbon dioxide (CO2) emissions, while not directly regulated by EGR systems, are indirectly affected through fuel economy impacts. Properly functioning EGR systems typically result in a 2-3% improvement in fuel efficiency under certain driving conditions, translating to proportional CO2 reductions. This represents approximately 20-30 grams of CO2 per kilometer driven for the average LS2-equipped vehicle.

The lifecycle environmental assessment of EGR technology reveals additional considerations. Manufacturing EGR components requires energy-intensive processes and specialized materials, including stainless steel and various alloys. The environmental footprint of these manufacturing processes must be factored into comprehensive impact evaluations. Furthermore, EGR system maintenance generates waste streams including contaminated valves and coolers that require proper disposal protocols.

Regional environmental impacts vary significantly based on implementation quality and regulatory enforcement. In regions with stringent emissions testing and maintenance requirements, LS2 EGR systems maintain their environmental benefits throughout the vehicle lifecycle. Conversely, in areas with limited enforcement, tampering and malfunction can negate intended environmental benefits, potentially resulting in emissions 3-5 times higher than design specifications.

Advanced measurement technologies for EGR systems, including digital mass flow sensors and real-time feedback controls, offer promising pathways to further environmental improvements. These technologies enable dynamic optimization of EGR rates based on driving conditions, potentially reducing overall emissions by an additional 10-15% compared to conventional systems while maintaining performance parameters.

However, the environmental benefits of EGR systems must be weighed against potential secondary effects. Improper EGR calibration can lead to increased particulate matter (PM) emissions, which pose serious respiratory health risks. Studies indicate that a 5% increase in EGR flow beyond optimal settings can result in a 15-20% increase in PM emissions, highlighting the critical importance of precise measurement and control systems.

Carbon dioxide (CO2) emissions, while not directly regulated by EGR systems, are indirectly affected through fuel economy impacts. Properly functioning EGR systems typically result in a 2-3% improvement in fuel efficiency under certain driving conditions, translating to proportional CO2 reductions. This represents approximately 20-30 grams of CO2 per kilometer driven for the average LS2-equipped vehicle.

The lifecycle environmental assessment of EGR technology reveals additional considerations. Manufacturing EGR components requires energy-intensive processes and specialized materials, including stainless steel and various alloys. The environmental footprint of these manufacturing processes must be factored into comprehensive impact evaluations. Furthermore, EGR system maintenance generates waste streams including contaminated valves and coolers that require proper disposal protocols.

Regional environmental impacts vary significantly based on implementation quality and regulatory enforcement. In regions with stringent emissions testing and maintenance requirements, LS2 EGR systems maintain their environmental benefits throughout the vehicle lifecycle. Conversely, in areas with limited enforcement, tampering and malfunction can negate intended environmental benefits, potentially resulting in emissions 3-5 times higher than design specifications.

Advanced measurement technologies for EGR systems, including digital mass flow sensors and real-time feedback controls, offer promising pathways to further environmental improvements. These technologies enable dynamic optimization of EGR rates based on driving conditions, potentially reducing overall emissions by an additional 10-15% compared to conventional systems while maintaining performance parameters.

Regulatory Compliance Framework

The regulatory landscape for vehicle emissions control has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. For LS2 engine exhaust gas recirculation (EGR) systems, compliance with these regulations represents both a technical challenge and a business imperative. The primary regulatory frameworks governing emissions include the U.S. Environmental Protection Agency's (EPA) Clean Air Act provisions, the California Air Resources Board (CARB) standards, and the European Union's Euro emissions standards.

The EPA's Tier 3 standards, phased in from 2017 to 2025, require substantial reductions in nitrogen oxides (NOx) and particulate matter (PM) emissions, directly impacting EGR system design and performance requirements. These standards establish fleet-average emission targets that manufacturers must meet across their vehicle lineup, with specific provisions for different vehicle classes and engine types. The LS2 engine, as a high-performance V8 platform, faces particularly challenging compliance hurdles.

CARB regulations, often more stringent than federal standards, have established the Low Emission Vehicle (LEV) III program, which includes specific requirements for EGR system monitoring and performance verification. These regulations mandate On-Board Diagnostic (OBD) systems capable of detecting EGR flow rate insufficiency and valve malfunctions, with specific thresholds for fault detection and reporting.

Internationally, the Euro 6d standards implemented in Europe impose strict NOx limits of 80 mg/km for diesel vehicles and 60 mg/km for gasoline vehicles, measured under both laboratory and real-world driving conditions. The Real Driving Emissions (RDE) test procedures have significantly impacted EGR system design, requiring robust performance across a wider range of operating conditions than previously necessary.

Compliance verification methodologies have also evolved, with regulatory bodies now requiring more sophisticated testing protocols. These include the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and various real-world driving cycles that better represent actual vehicle usage patterns. For LS2 engines, this necessitates precise EGR flow measurement capabilities across diverse operating conditions.

The regulatory framework also includes certification requirements, with manufacturers needing to demonstrate compliance through standardized testing procedures before vehicles can be sold. This includes specific protocols for measuring EGR flow rates, valve response times, and system durability over the vehicle's useful life. Non-compliance penalties have increased substantially, with potential fines reaching billions of dollars for systematic violations, as evidenced by recent industry enforcement actions.

The EPA's Tier 3 standards, phased in from 2017 to 2025, require substantial reductions in nitrogen oxides (NOx) and particulate matter (PM) emissions, directly impacting EGR system design and performance requirements. These standards establish fleet-average emission targets that manufacturers must meet across their vehicle lineup, with specific provisions for different vehicle classes and engine types. The LS2 engine, as a high-performance V8 platform, faces particularly challenging compliance hurdles.

CARB regulations, often more stringent than federal standards, have established the Low Emission Vehicle (LEV) III program, which includes specific requirements for EGR system monitoring and performance verification. These regulations mandate On-Board Diagnostic (OBD) systems capable of detecting EGR flow rate insufficiency and valve malfunctions, with specific thresholds for fault detection and reporting.

Internationally, the Euro 6d standards implemented in Europe impose strict NOx limits of 80 mg/km for diesel vehicles and 60 mg/km for gasoline vehicles, measured under both laboratory and real-world driving conditions. The Real Driving Emissions (RDE) test procedures have significantly impacted EGR system design, requiring robust performance across a wider range of operating conditions than previously necessary.

Compliance verification methodologies have also evolved, with regulatory bodies now requiring more sophisticated testing protocols. These include the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and various real-world driving cycles that better represent actual vehicle usage patterns. For LS2 engines, this necessitates precise EGR flow measurement capabilities across diverse operating conditions.

The regulatory framework also includes certification requirements, with manufacturers needing to demonstrate compliance through standardized testing procedures before vehicles can be sold. This includes specific protocols for measuring EGR flow rates, valve response times, and system durability over the vehicle's useful life. Non-compliance penalties have increased substantially, with potential fines reaching billions of dollars for systematic violations, as evidenced by recent industry enforcement actions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!