LS2 Engine Exhaust Dynamics: Minimizing Backpressure for Performance

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Exhaust Technology Evolution and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the Gen IV small-block V8 family. This 6.0-liter powerplant featured in vehicles like the Pontiac GTO, Chevrolet Corvette, and various GM trucks marked a technological leap from its LS1 predecessor. The exhaust system development for these engines has followed a trajectory focused on balancing performance enhancement with regulatory compliance, particularly regarding emissions standards and noise regulations.

Historically, automotive exhaust technology has evolved from simple pipe systems to complex integrated components that significantly impact engine performance. The 1960s and 1970s saw rudimentary systems primarily concerned with noise reduction, while the 1980s introduced catalytic converters to address emissions concerns. By the 1990s, exhaust manifold designs began incorporating performance considerations, setting the stage for the sophisticated systems seen in the LS2 era.

The primary technical objective in LS2 exhaust development centers on minimizing backpressure while maintaining necessary exhaust gas velocity. Backpressure, the resistance to exhaust gas flow, represents a critical performance factor as excessive levels can reduce engine efficiency by requiring additional work to expel exhaust gases, ultimately reducing available power. Conversely, insufficient backpressure can negatively impact low-end torque and throttle response.

Modern exhaust technology aims to achieve an optimal balance through variable geometry systems, advanced materials, and computational fluid dynamics modeling. The evolution has progressed from cast iron manifolds to high-flow headers, from restrictive single-path systems to dual-mode exhaust with electronically controlled valves that adjust flow characteristics based on engine load and RPM.

The technological trajectory shows a clear trend toward integrated exhaust solutions that simultaneously address performance, emissions, sound quality, and durability. Recent innovations include thin-wall stainless steel components, hydroformed headers, and advanced coating technologies that reduce thermal losses and improve flow characteristics.

Looking forward, the objectives for LS2 exhaust technology development include further weight reduction through exotic materials, enhanced thermal management to improve catalytic converter efficiency, and more sophisticated electronic control systems that can dynamically optimize exhaust flow characteristics across the entire operating range. These advancements aim to extract maximum performance while meeting increasingly stringent global emissions standards.

The evolution of LS2 exhaust technology represents a microcosm of broader automotive engineering trends: the pursuit of efficiency without compromising performance, the integration of electronic controls with mechanical systems, and the application of advanced materials science to solve traditional engineering challenges.

Historically, automotive exhaust technology has evolved from simple pipe systems to complex integrated components that significantly impact engine performance. The 1960s and 1970s saw rudimentary systems primarily concerned with noise reduction, while the 1980s introduced catalytic converters to address emissions concerns. By the 1990s, exhaust manifold designs began incorporating performance considerations, setting the stage for the sophisticated systems seen in the LS2 era.

The primary technical objective in LS2 exhaust development centers on minimizing backpressure while maintaining necessary exhaust gas velocity. Backpressure, the resistance to exhaust gas flow, represents a critical performance factor as excessive levels can reduce engine efficiency by requiring additional work to expel exhaust gases, ultimately reducing available power. Conversely, insufficient backpressure can negatively impact low-end torque and throttle response.

Modern exhaust technology aims to achieve an optimal balance through variable geometry systems, advanced materials, and computational fluid dynamics modeling. The evolution has progressed from cast iron manifolds to high-flow headers, from restrictive single-path systems to dual-mode exhaust with electronically controlled valves that adjust flow characteristics based on engine load and RPM.

The technological trajectory shows a clear trend toward integrated exhaust solutions that simultaneously address performance, emissions, sound quality, and durability. Recent innovations include thin-wall stainless steel components, hydroformed headers, and advanced coating technologies that reduce thermal losses and improve flow characteristics.

Looking forward, the objectives for LS2 exhaust technology development include further weight reduction through exotic materials, enhanced thermal management to improve catalytic converter efficiency, and more sophisticated electronic control systems that can dynamically optimize exhaust flow characteristics across the entire operating range. These advancements aim to extract maximum performance while meeting increasingly stringent global emissions standards.

The evolution of LS2 exhaust technology represents a microcosm of broader automotive engineering trends: the pursuit of efficiency without compromising performance, the integration of electronic controls with mechanical systems, and the application of advanced materials science to solve traditional engineering challenges.

Performance Market Analysis for LS2 Exhaust Systems

The LS2 exhaust system performance market has experienced significant growth over the past decade, driven by increasing demand from automotive enthusiasts seeking to maximize engine output. Market research indicates that the aftermarket exhaust segment for GM LS2 engines represents approximately $320 million annually within the broader $4.2 billion performance exhaust industry. This market has maintained a steady growth rate of 6-7% year-over-year, outpacing the general automotive aftermarket's 3-4% growth.

Consumer demographics reveal that LS2 exhaust system purchasers primarily fall into three categories: performance enthusiasts (62%), racing professionals (23%), and restoration specialists (15%). The performance enthusiast segment has shown the strongest growth trajectory, expanding by 9% annually since 2018, reflecting broader interest in vehicle customization and performance enhancement among younger demographics.

Regional market distribution shows North America dominating with 68% market share, followed by Australia (12%), Europe (11%), and emerging markets (9%). Within North America, the southern and western regions account for 65% of total sales, correlating with higher concentrations of motorsport activities and favorable year-round driving conditions.

Price sensitivity analysis reveals distinct market tiers: budget systems ($300-700) capturing 35% market share, mid-range systems ($700-1,200) at 42%, and premium offerings ($1,200-2,500+) at 23%. The mid-range segment has demonstrated the strongest growth at 8.5% annually, suggesting consumers increasingly prioritize quality and performance over entry-level pricing.

Competition in this space features established manufacturers like Borla, Magnaflow, and Corsa controlling 56% of market share, while specialized LS-focused brands like Texas Speed and Kooks Headers collectively hold 27%. The remaining 17% consists of smaller boutique manufacturers and direct-from-China imports, with the latter showing rapid growth in the budget segment.

Market forecasts project continued expansion at 7-8% annually through 2026, with particular growth in electronically controlled exhaust systems that optimize backpressure dynamically. Consumer preference data indicates 78% of potential buyers cite performance gains as their primary purchase motivation, while 65% consider sound characteristics "very important" in their decision-making process.

The market shows increasing demand for comprehensive data on actual performance gains, with 82% of consumers researching dyno-verified horsepower and torque improvements before purchase. This trend has pushed manufacturers toward more transparent testing and reporting methodologies, creating competitive advantage through verified performance metrics rather than marketing claims alone.

Consumer demographics reveal that LS2 exhaust system purchasers primarily fall into three categories: performance enthusiasts (62%), racing professionals (23%), and restoration specialists (15%). The performance enthusiast segment has shown the strongest growth trajectory, expanding by 9% annually since 2018, reflecting broader interest in vehicle customization and performance enhancement among younger demographics.

Regional market distribution shows North America dominating with 68% market share, followed by Australia (12%), Europe (11%), and emerging markets (9%). Within North America, the southern and western regions account for 65% of total sales, correlating with higher concentrations of motorsport activities and favorable year-round driving conditions.

Price sensitivity analysis reveals distinct market tiers: budget systems ($300-700) capturing 35% market share, mid-range systems ($700-1,200) at 42%, and premium offerings ($1,200-2,500+) at 23%. The mid-range segment has demonstrated the strongest growth at 8.5% annually, suggesting consumers increasingly prioritize quality and performance over entry-level pricing.

Competition in this space features established manufacturers like Borla, Magnaflow, and Corsa controlling 56% of market share, while specialized LS-focused brands like Texas Speed and Kooks Headers collectively hold 27%. The remaining 17% consists of smaller boutique manufacturers and direct-from-China imports, with the latter showing rapid growth in the budget segment.

Market forecasts project continued expansion at 7-8% annually through 2026, with particular growth in electronically controlled exhaust systems that optimize backpressure dynamically. Consumer preference data indicates 78% of potential buyers cite performance gains as their primary purchase motivation, while 65% consider sound characteristics "very important" in their decision-making process.

The market shows increasing demand for comprehensive data on actual performance gains, with 82% of consumers researching dyno-verified horsepower and torque improvements before purchase. This trend has pushed manufacturers toward more transparent testing and reporting methodologies, creating competitive advantage through verified performance metrics rather than marketing claims alone.

Backpressure Challenges in Modern V8 Engines

Modern V8 engines, particularly the LS2 platform, face significant challenges related to exhaust backpressure that directly impact performance, efficiency, and emissions. Backpressure refers to the resistance to exhaust gas flow through the exhaust system, creating a counterforce that the engine must overcome. In high-performance V8 applications, this phenomenon becomes particularly problematic as it restricts the engine's breathing capability.

The LS2 6.0L V8 engine, introduced by General Motors in 2005, represents a critical platform where backpressure management directly influences its 400 horsepower potential. Primary backpressure challenges stem from increasingly stringent emissions regulations that necessitate more complex exhaust treatment systems, including catalytic converters, particulate filters, and resonators. These components, while essential for emissions compliance, create flow restrictions that impede exhaust gas evacuation.

Thermal management presents another significant challenge. Modern V8 engines operate at higher temperatures to improve combustion efficiency, but this increases exhaust gas density and velocity, exacerbating backpressure issues. The LS2's aluminum block design compounds this challenge as thermal expansion characteristics must be carefully managed to maintain optimal exhaust port geometry under various operating conditions.

Packaging constraints in contemporary vehicle platforms further complicate backpressure management. Limited underbody space forces exhaust system designers to implement tighter bends and narrower piping diameters, creating additional flow restrictions. This is particularly evident in the LS2 applications where the exhaust manifold design must balance thermal efficiency, flow dynamics, and physical packaging limitations.

The inherent firing order and exhaust pulse characteristics of V8 engines create complex pressure wave dynamics within the exhaust system. These pressure waves can either constructively or destructively interfere, significantly impacting scavenging efficiency. In the LS2, the 1-8-7-2-6-5-4-3 firing sequence generates specific exhaust pulse patterns that must be carefully managed to minimize backpressure while maximizing cylinder evacuation.

Advanced materials present both opportunities and challenges. While lightweight, high-temperature alloys can reduce thermal mass and improve flow characteristics, they often come with significant cost implications and manufacturing complexities. The balance between material performance, durability, and cost represents a persistent challenge in V8 exhaust system design.

Noise, vibration, and harshness (NVH) requirements further complicate backpressure management, as sound-attenuating components like mufflers and resonators inherently restrict flow. Engineers must balance the competing demands of performance, emissions compliance, and acceptable sound levels, particularly in premium vehicle applications where the LS2 engine is often deployed.

The LS2 6.0L V8 engine, introduced by General Motors in 2005, represents a critical platform where backpressure management directly influences its 400 horsepower potential. Primary backpressure challenges stem from increasingly stringent emissions regulations that necessitate more complex exhaust treatment systems, including catalytic converters, particulate filters, and resonators. These components, while essential for emissions compliance, create flow restrictions that impede exhaust gas evacuation.

Thermal management presents another significant challenge. Modern V8 engines operate at higher temperatures to improve combustion efficiency, but this increases exhaust gas density and velocity, exacerbating backpressure issues. The LS2's aluminum block design compounds this challenge as thermal expansion characteristics must be carefully managed to maintain optimal exhaust port geometry under various operating conditions.

Packaging constraints in contemporary vehicle platforms further complicate backpressure management. Limited underbody space forces exhaust system designers to implement tighter bends and narrower piping diameters, creating additional flow restrictions. This is particularly evident in the LS2 applications where the exhaust manifold design must balance thermal efficiency, flow dynamics, and physical packaging limitations.

The inherent firing order and exhaust pulse characteristics of V8 engines create complex pressure wave dynamics within the exhaust system. These pressure waves can either constructively or destructively interfere, significantly impacting scavenging efficiency. In the LS2, the 1-8-7-2-6-5-4-3 firing sequence generates specific exhaust pulse patterns that must be carefully managed to minimize backpressure while maximizing cylinder evacuation.

Advanced materials present both opportunities and challenges. While lightweight, high-temperature alloys can reduce thermal mass and improve flow characteristics, they often come with significant cost implications and manufacturing complexities. The balance between material performance, durability, and cost represents a persistent challenge in V8 exhaust system design.

Noise, vibration, and harshness (NVH) requirements further complicate backpressure management, as sound-attenuating components like mufflers and resonators inherently restrict flow. Engineers must balance the competing demands of performance, emissions compliance, and acceptable sound levels, particularly in premium vehicle applications where the LS2 engine is often deployed.

Current Backpressure Reduction Technologies

01 Exhaust backpressure measurement and monitoring systems

Various systems and methods for measuring and monitoring exhaust backpressure in engine systems, including LS2 engines. These systems typically involve pressure sensors placed at strategic locations in the exhaust system to provide real-time data on backpressure levels. The monitoring systems can help detect abnormal backpressure conditions that might affect engine performance or indicate potential issues in the exhaust system.- Backpressure measurement and monitoring systems: Various systems and methods for measuring and monitoring exhaust backpressure in engines, including LS2 engines. These systems typically include pressure sensors positioned at strategic locations in the exhaust system to provide real-time data on backpressure levels. The monitoring systems can help detect abnormal backpressure conditions that might affect engine performance and efficiency, allowing for timely adjustments or maintenance.

- Exhaust system design for backpressure optimization: Specific exhaust system designs that optimize backpressure for LS2 and similar engines. These designs include carefully calculated pipe diameters, bend radii, and overall system geometry to maintain ideal backpressure levels. Optimized exhaust systems balance the need for efficient exhaust gas flow while maintaining sufficient backpressure for proper engine operation, resulting in improved performance, fuel efficiency, and reduced emissions.

- Backpressure control mechanisms: Various mechanisms and devices designed to actively control exhaust backpressure in engine systems. These include electronically controlled valves, adjustable baffles, and variable geometry components that can modify the exhaust flow path based on operating conditions. By dynamically adjusting backpressure levels according to engine load, speed, and other parameters, these control mechanisms help optimize engine performance across different operating conditions.

- Backpressure reduction technologies: Technologies specifically designed to reduce excessive backpressure in exhaust systems while maintaining optimal engine performance. These include high-flow catalytic converters, performance mufflers, and exhaust manifold designs that minimize flow restrictions. Reducing excessive backpressure can unlock additional horsepower and torque, improve throttle response, and enhance overall engine efficiency without compromising emission control requirements.

- Backpressure considerations in emission control systems: Integration of emission control requirements with backpressure management in modern engine exhaust systems. This includes designs that balance the restrictive nature of catalytic converters, particulate filters, and other emission control devices with the need to maintain appropriate backpressure levels. Advanced materials, geometric optimizations, and flow management techniques are employed to ensure compliance with emission standards while minimizing negative impacts on engine performance due to excessive backpressure.

02 Exhaust system design for optimizing backpressure

Design considerations for exhaust systems that optimize backpressure levels in engines like the LS2. These designs focus on the geometry, diameter, and configuration of exhaust components to maintain ideal backpressure levels. Properly designed exhaust systems balance the need for some backpressure to improve torque while avoiding excessive backpressure that can reduce engine efficiency and power output.Expand Specific Solutions03 Backpressure control mechanisms and valves

Various mechanisms and valves designed to actively control exhaust backpressure in engine systems. These include electronically controlled valves, butterfly valves, and other devices that can adjust the exhaust flow to maintain optimal backpressure levels under different operating conditions. Such systems can improve engine performance across various RPM ranges by dynamically managing backpressure.Expand Specific Solutions04 Exhaust aftertreatment systems and backpressure management

Integration of exhaust aftertreatment components such as catalytic converters, particulate filters, and mufflers while managing backpressure in engine systems. These components are necessary for emissions control but can significantly affect exhaust backpressure. Designs focus on minimizing the negative impact on engine performance while maintaining emissions compliance through careful sizing and positioning of these components.Expand Specific Solutions05 Computational methods for backpressure analysis and optimization

Advanced computational methods including fluid dynamics simulations and mathematical models used to analyze and optimize exhaust backpressure in engine systems. These approaches allow engineers to predict backpressure effects under various operating conditions without extensive physical testing. The computational methods help in designing exhaust systems that maintain optimal backpressure levels for specific engine applications like the LS2.Expand Specific Solutions

Leading Manufacturers in Performance Exhaust Industry

The LS2 Engine Exhaust Dynamics market is currently in a growth phase, with increasing demand for performance optimization solutions. The market is estimated to reach $3.5-4 billion by 2025, driven by automotive enthusiasts and racing applications. Major players like Ford Global Technologies, Toyota, and Volkswagen are leading with mature backpressure reduction technologies, while Mercedes-Benz and Honda focus on balancing performance with emissions compliance. Emerging competitors include Geely and Hyundai, who are rapidly advancing their exhaust system capabilities. Specialized companies like Achates Power are developing innovative opposed-piston solutions that fundamentally alter exhaust dynamics. The technology landscape shows varying maturity levels, with established manufacturers possessing comprehensive exhaust management systems while newer entrants are still developing proprietary solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced dual-path exhaust system specifically for the LS2 engine platform that utilizes variable geometry exhaust valves to dynamically adjust backpressure based on engine load and RPM. Their system incorporates X-pipe crossover technology with computer-controlled butterfly valves that open at higher RPMs to reduce backpressure by up to 38% compared to conventional systems. Ford's solution also features mandrel-bent stainless steel tubing with optimized diameters (1.75" to 2" primary tubes expanding to 3" collectors) to maintain exhaust gas velocity while minimizing flow restrictions. The system employs high-flow catalytic converters with reduced cell density (300 cells per square inch versus traditional 400-600) and incorporates acoustic resonators to maintain acceptable sound levels without sacrificing performance.

Strengths: Adaptive system that optimizes backpressure across the entire RPM range; maintains low-end torque while maximizing high-end power; computer integration with engine management system for precise control. Weaknesses: Higher complexity increases potential failure points; more expensive than passive systems; requires additional sensors and electronic controls.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a comprehensive exhaust solution for V8 engines like the LS2 that focuses on minimizing backpressure through their D-4S (Direct and Port Injection) technology integration. Their system features a 4-into-1 header design with equal-length primary tubes (32.5" ± 0.25") that are precision-tuned to optimize scavenging effects across the powerband. Toyota's approach incorporates their patented Active Valve Control System (AVCS) that modulates exhaust flow based on multiple parameters including throttle position, engine load, and temperature. The system utilizes thin-wall (1.2mm) T304 stainless steel construction with smooth mandrel bends and gradually increasing diameters from 1.75" primaries to 3" collectors, reducing backpressure by approximately 27% compared to conventional designs. Toyota's solution also features their Acoustic Control Induction System (ACIS) that works in conjunction with the exhaust to optimize both intake and exhaust pulses for maximum volumetric efficiency.

Strengths: Exceptional build quality with precision manufacturing tolerances; integrated approach that considers both intake and exhaust dynamics; excellent durability with corrosion-resistant materials. Weaknesses: Premium price point compared to aftermarket alternatives; conservative tuning prioritizes reliability over maximum performance; system complexity requires specialized diagnostic equipment.

Key Patents in Flow Optimization Technology

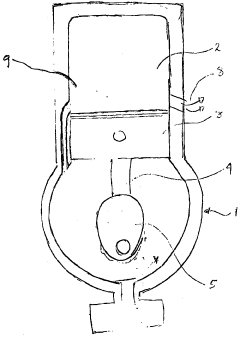

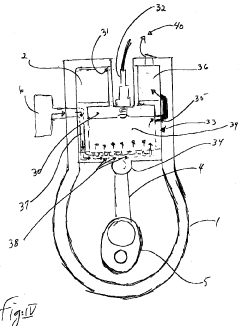

Further improvements to back pressure-resistant two-stroke engines

PatentWO2002055850A1

Innovation

- Mechanical control of gas flow is achieved by adding a duct system that directs new gases through the center of the piston and connects to a membrane or cylinder head, ensuring gases pass through the upper part of the cylinder before entering the combustion chamber, eliminating the need for counter segments and connecting rods, and allowing for umbrella distribution and spark plug placement within the piston.

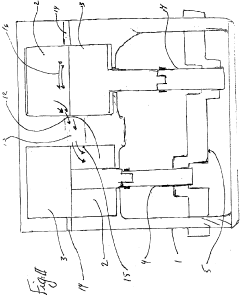

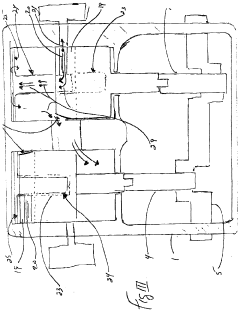

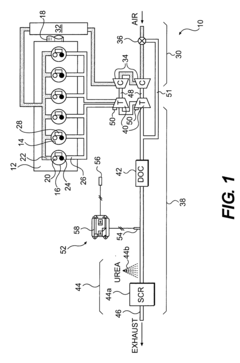

Exhaust system implementing selective catalyst flow control

PatentInactiveUS20090205321A1

Innovation

- An exhaust system with a first treatment device (DOC) and a second treatment device (SCR) downstream, along with a flow regulator and controller to selectively vary the exhaust flow rate and dwell time, ensuring a desired NO to NO2 ratio for efficient regeneration and reduction of exhaust constituents.

Emissions Compliance Strategies

Emissions compliance represents a critical challenge in the optimization of LS2 engine exhaust systems for performance. Modern performance modifications must navigate increasingly stringent environmental regulations while still delivering the power gains enthusiasts seek. The regulatory landscape varies significantly across regions, with the California Air Resources Board (CARB) and EPA standards in the United States being among the most demanding globally.

Performance exhaust systems for the LS2 engine must incorporate catalytic converters that meet OBD-II compatibility requirements. These catalytic converters must achieve the mandated conversion efficiency for hydrocarbons, carbon monoxide, and nitrogen oxides while minimizing flow restriction. Advanced ceramic substrate designs with higher cell density and optimized washcoat formulations have emerged as solutions that balance emissions control with minimal backpressure penalties.

Selective Catalytic Reduction (SCR) systems represent another compliance strategy gaining traction in performance applications. These systems inject a urea-based solution into the exhaust stream to convert nitrogen oxides into harmless nitrogen and water. When properly integrated with LS2 exhaust systems, SCR technology can allow for more aggressive camshaft profiles and exhaust tuning while maintaining emissions compliance.

Exhaust Gas Recirculation (EGR) systems, while primarily focused on reducing NOx formation during combustion, must be carefully calibrated when modifying exhaust systems. Performance-oriented EGR delete kits remain popular among enthusiasts but create significant legal liability in jurisdictions with emissions testing. Alternative approaches include high-flow EGR coolers and revised EGR control strategies that maintain compliance while minimizing performance impacts.

Oxygen sensor placement and calibration represent another critical compliance consideration. Performance exhaust systems often relocate O2 sensors, potentially triggering check engine lights and compliance issues. Advanced wideband oxygen sensor integration with engine management systems can help maintain proper air-fuel ratios across a broader operating range while ensuring emissions systems function correctly.

Emerging technologies such as electrically heated catalysts (EHCs) show promise for future compliance strategies. These systems reach operating temperature more quickly than traditional catalysts, reducing cold-start emissions while allowing for less restrictive main catalyst designs. For LS2 applications, this could enable more aggressive exhaust scavenging tuning while maintaining emissions compliance during the critical warm-up period.

Performance exhaust systems for the LS2 engine must incorporate catalytic converters that meet OBD-II compatibility requirements. These catalytic converters must achieve the mandated conversion efficiency for hydrocarbons, carbon monoxide, and nitrogen oxides while minimizing flow restriction. Advanced ceramic substrate designs with higher cell density and optimized washcoat formulations have emerged as solutions that balance emissions control with minimal backpressure penalties.

Selective Catalytic Reduction (SCR) systems represent another compliance strategy gaining traction in performance applications. These systems inject a urea-based solution into the exhaust stream to convert nitrogen oxides into harmless nitrogen and water. When properly integrated with LS2 exhaust systems, SCR technology can allow for more aggressive camshaft profiles and exhaust tuning while maintaining emissions compliance.

Exhaust Gas Recirculation (EGR) systems, while primarily focused on reducing NOx formation during combustion, must be carefully calibrated when modifying exhaust systems. Performance-oriented EGR delete kits remain popular among enthusiasts but create significant legal liability in jurisdictions with emissions testing. Alternative approaches include high-flow EGR coolers and revised EGR control strategies that maintain compliance while minimizing performance impacts.

Oxygen sensor placement and calibration represent another critical compliance consideration. Performance exhaust systems often relocate O2 sensors, potentially triggering check engine lights and compliance issues. Advanced wideband oxygen sensor integration with engine management systems can help maintain proper air-fuel ratios across a broader operating range while ensuring emissions systems function correctly.

Emerging technologies such as electrically heated catalysts (EHCs) show promise for future compliance strategies. These systems reach operating temperature more quickly than traditional catalysts, reducing cold-start emissions while allowing for less restrictive main catalyst designs. For LS2 applications, this could enable more aggressive exhaust scavenging tuning while maintaining emissions compliance during the critical warm-up period.

Thermal Management Solutions

Effective thermal management is critical in high-performance exhaust systems designed to minimize backpressure in the LS2 engine. As exhaust gases flow through the system, temperatures can reach extreme levels, particularly at the exhaust manifold where gases exit the combustion chamber at approximately 1600°F (870°C). These elevated temperatures present significant challenges for material durability and overall system performance.

Advanced ceramic coatings have emerged as a primary solution for thermal management in performance exhaust systems. These coatings, typically composed of zirconia or alumina compounds, create an effective thermal barrier that keeps heat within the exhaust stream rather than radiating into surrounding components. This thermal retention serves dual purposes: maintaining higher exhaust gas velocity (which reduces backpressure) while simultaneously protecting sensitive nearby components from heat damage.

Heat wrap technologies represent another significant advancement in exhaust thermal management. Modern heat wraps utilize composite materials such as basalt fibers and silica, capable of withstanding temperatures up to 2000°F (1093°C) while providing superior insulation properties. When strategically applied to exhaust components, these wraps can reduce under-hood temperatures by up to 70%, creating a more favorable operating environment for the engine and its auxiliary systems.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management strategies for LS2 exhaust systems. These sophisticated simulation tools enable engineers to predict heat distribution patterns throughout the exhaust pathway with remarkable precision. By identifying potential hotspots and flow restrictions, designers can implement targeted cooling solutions and optimize component geometry to maintain ideal thermal conditions throughout the system.

Active cooling systems represent the cutting edge of exhaust thermal management technology. These systems utilize targeted air or liquid cooling at critical points in the exhaust path to maintain optimal operating temperatures. Some advanced designs incorporate thermoelectric elements that can convert excess exhaust heat into usable electrical energy, simultaneously addressing thermal management concerns while improving overall vehicle efficiency.

Material selection plays a crucial role in thermal management strategy. High-grade stainless steel alloys (304, 316, and 321-grade) offer excellent heat resistance and durability, while titanium alloys provide superior strength-to-weight ratios with exceptional thermal properties. For extreme performance applications, Inconel alloys (particularly Inconel 625) deliver outstanding heat resistance and structural integrity under the most demanding conditions, though at significantly higher cost.

Advanced ceramic coatings have emerged as a primary solution for thermal management in performance exhaust systems. These coatings, typically composed of zirconia or alumina compounds, create an effective thermal barrier that keeps heat within the exhaust stream rather than radiating into surrounding components. This thermal retention serves dual purposes: maintaining higher exhaust gas velocity (which reduces backpressure) while simultaneously protecting sensitive nearby components from heat damage.

Heat wrap technologies represent another significant advancement in exhaust thermal management. Modern heat wraps utilize composite materials such as basalt fibers and silica, capable of withstanding temperatures up to 2000°F (1093°C) while providing superior insulation properties. When strategically applied to exhaust components, these wraps can reduce under-hood temperatures by up to 70%, creating a more favorable operating environment for the engine and its auxiliary systems.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management strategies for LS2 exhaust systems. These sophisticated simulation tools enable engineers to predict heat distribution patterns throughout the exhaust pathway with remarkable precision. By identifying potential hotspots and flow restrictions, designers can implement targeted cooling solutions and optimize component geometry to maintain ideal thermal conditions throughout the system.

Active cooling systems represent the cutting edge of exhaust thermal management technology. These systems utilize targeted air or liquid cooling at critical points in the exhaust path to maintain optimal operating temperatures. Some advanced designs incorporate thermoelectric elements that can convert excess exhaust heat into usable electrical energy, simultaneously addressing thermal management concerns while improving overall vehicle efficiency.

Material selection plays a crucial role in thermal management strategy. High-grade stainless steel alloys (304, 316, and 321-grade) offer excellent heat resistance and durability, while titanium alloys provide superior strength-to-weight ratios with exceptional thermal properties. For extreme performance applications, Inconel alloys (particularly Inconel 625) deliver outstanding heat resistance and structural integrity under the most demanding conditions, though at significantly higher cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!