Optimizing LS2 Engine Camshaft Profile for Power Delivery

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Camshaft Evolution and Optimization Goals

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family, featuring a 6.0L displacement and aluminum block construction. The camshaft profile development for this engine has undergone substantial refinement since its inception, transitioning from conservative factory specifications to increasingly aggressive aftermarket designs that maximize power delivery across various RPM ranges.

Early LS2 camshafts featured relatively modest specifications with lift values typically around 0.500 inches and duration figures under 200 degrees at 0.050-inch lift. These conservative profiles prioritized reliability, emissions compliance, and daily drivability while providing adequate performance for stock applications. The evolution of camshaft technology for the LS2 platform has been driven by advancements in valvetrain components, including more robust valve springs, lightweight retainers, and improved rocker arm designs.

The technological progression of LS2 camshaft profiles has been marked by several key innovations. Computer-aided design and simulation tools have enabled engineers to model complex valve events and predict performance outcomes with increasing accuracy. Advanced manufacturing techniques, including precision grinding and improved heat treatment processes, have allowed for more aggressive lobe profiles while maintaining durability. Additionally, the development of variable valve timing systems has introduced new dimensions to camshaft optimization.

Current optimization goals for LS2 camshaft profiles focus on several critical parameters. Lobe separation angle (LSA) adjustment has become a primary tuning factor, with narrower angles typically favoring mid-range torque and wider angles supporting high-RPM power. Asymmetric lobe designs have gained popularity for their ability to optimize both the intake and exhaust events independently. Duration and lift values continue to increase as supporting components evolve to handle more aggressive valve motion.

The market has demonstrated clear trends toward application-specific camshaft profiles. Street performance applications typically target broader powerband delivery with emphasis on low-end torque and mid-range power. Competition-oriented profiles prioritize peak horsepower figures with more aggressive specifications, often sacrificing low-RPM drivability. The emerging segment of forced induction applications requires specialized camshaft profiles that accommodate the unique airflow characteristics of supercharged or turbocharged engines.

Looking forward, the technical objectives for LS2 camshaft development include achieving greater area under the lift curve without exceeding valvetrain component limitations, optimizing valve events for modern fuel quality and combustion chamber designs, and developing profiles that complement electronic control systems. The ultimate goal remains maximizing the engine's volumetric efficiency across the intended operating range while balancing considerations of durability, emissions, and drivability according to the specific application requirements.

Early LS2 camshafts featured relatively modest specifications with lift values typically around 0.500 inches and duration figures under 200 degrees at 0.050-inch lift. These conservative profiles prioritized reliability, emissions compliance, and daily drivability while providing adequate performance for stock applications. The evolution of camshaft technology for the LS2 platform has been driven by advancements in valvetrain components, including more robust valve springs, lightweight retainers, and improved rocker arm designs.

The technological progression of LS2 camshaft profiles has been marked by several key innovations. Computer-aided design and simulation tools have enabled engineers to model complex valve events and predict performance outcomes with increasing accuracy. Advanced manufacturing techniques, including precision grinding and improved heat treatment processes, have allowed for more aggressive lobe profiles while maintaining durability. Additionally, the development of variable valve timing systems has introduced new dimensions to camshaft optimization.

Current optimization goals for LS2 camshaft profiles focus on several critical parameters. Lobe separation angle (LSA) adjustment has become a primary tuning factor, with narrower angles typically favoring mid-range torque and wider angles supporting high-RPM power. Asymmetric lobe designs have gained popularity for their ability to optimize both the intake and exhaust events independently. Duration and lift values continue to increase as supporting components evolve to handle more aggressive valve motion.

The market has demonstrated clear trends toward application-specific camshaft profiles. Street performance applications typically target broader powerband delivery with emphasis on low-end torque and mid-range power. Competition-oriented profiles prioritize peak horsepower figures with more aggressive specifications, often sacrificing low-RPM drivability. The emerging segment of forced induction applications requires specialized camshaft profiles that accommodate the unique airflow characteristics of supercharged or turbocharged engines.

Looking forward, the technical objectives for LS2 camshaft development include achieving greater area under the lift curve without exceeding valvetrain component limitations, optimizing valve events for modern fuel quality and combustion chamber designs, and developing profiles that complement electronic control systems. The ultimate goal remains maximizing the engine's volumetric efficiency across the intended operating range while balancing considerations of durability, emissions, and drivability according to the specific application requirements.

Market Demand for Enhanced LS2 Power Delivery

The LS2 engine, a 6.0L V8 powerplant introduced by General Motors in 2005, has established a significant presence in the performance automotive market. Market research indicates a growing demand for enhanced power delivery solutions specifically targeting this engine platform, driven by several key factors in the automotive aftermarket sector.

Performance enthusiasts represent the primary market segment seeking LS2 camshaft profile optimizations. This demographic consistently demonstrates willingness to invest in modifications that deliver tangible performance improvements, with average spending on engine modifications ranging between $2,000 and $5,000 per vehicle. The camshaft upgrade market for LS2 engines has shown steady annual growth of approximately 7% over the past five years.

Racing applications constitute another substantial market segment. Professional and semi-professional racers in drag racing, circuit racing, and time attack competitions require specialized camshaft profiles that maximize power delivery characteristics specific to their racing discipline. This segment values data-driven performance gains and demonstrates less price sensitivity when measurable improvements can be documented.

The restomod market has emerged as a particularly lucrative segment, with builders incorporating LS2 engines into classic vehicles while seeking modern performance characteristics. These customers typically pursue camshaft profiles that balance aggressive power delivery with streetable drivability, representing a premium market willing to pay for optimized solutions.

Market analysis reveals geographic concentrations of demand, with particularly strong markets in the Southern United States, California, and Australia - regions with robust car cultures and favorable regulatory environments for performance modifications. Online communities and forums dedicated to LS-platform engines show consistently high engagement metrics around camshaft-related discussions.

Consumer behavior research indicates that buyers in this market segment are highly influenced by dyno-verified performance data, with particular emphasis on mid-range torque improvements and top-end horsepower gains. The market increasingly demands application-specific optimization rather than generic "performance" camshafts.

Industry forecasts project continued growth in this market segment, driven by the large existing vehicle population equipped with LS2 engines and their continued popularity in engine swap projects. The aftermarket for LS2 performance parts is expected to maintain growth despite the automotive industry's broader shift toward electrification, as internal combustion enthusiasts become an increasingly dedicated niche market.

Competition in this space comes primarily from established performance camshaft manufacturers, with market leaders commanding premium pricing based on reputation and documented performance results. This creates opportunity for technically superior solutions that can demonstrate measurable advantages in specific performance metrics.

Performance enthusiasts represent the primary market segment seeking LS2 camshaft profile optimizations. This demographic consistently demonstrates willingness to invest in modifications that deliver tangible performance improvements, with average spending on engine modifications ranging between $2,000 and $5,000 per vehicle. The camshaft upgrade market for LS2 engines has shown steady annual growth of approximately 7% over the past five years.

Racing applications constitute another substantial market segment. Professional and semi-professional racers in drag racing, circuit racing, and time attack competitions require specialized camshaft profiles that maximize power delivery characteristics specific to their racing discipline. This segment values data-driven performance gains and demonstrates less price sensitivity when measurable improvements can be documented.

The restomod market has emerged as a particularly lucrative segment, with builders incorporating LS2 engines into classic vehicles while seeking modern performance characteristics. These customers typically pursue camshaft profiles that balance aggressive power delivery with streetable drivability, representing a premium market willing to pay for optimized solutions.

Market analysis reveals geographic concentrations of demand, with particularly strong markets in the Southern United States, California, and Australia - regions with robust car cultures and favorable regulatory environments for performance modifications. Online communities and forums dedicated to LS-platform engines show consistently high engagement metrics around camshaft-related discussions.

Consumer behavior research indicates that buyers in this market segment are highly influenced by dyno-verified performance data, with particular emphasis on mid-range torque improvements and top-end horsepower gains. The market increasingly demands application-specific optimization rather than generic "performance" camshafts.

Industry forecasts project continued growth in this market segment, driven by the large existing vehicle population equipped with LS2 engines and their continued popularity in engine swap projects. The aftermarket for LS2 performance parts is expected to maintain growth despite the automotive industry's broader shift toward electrification, as internal combustion enthusiasts become an increasingly dedicated niche market.

Competition in this space comes primarily from established performance camshaft manufacturers, with market leaders commanding premium pricing based on reputation and documented performance results. This creates opportunity for technically superior solutions that can demonstrate measurable advantages in specific performance metrics.

Current Camshaft Technology Limitations and Challenges

The LS2 engine, a member of GM's Gen IV small-block family, faces several technological limitations in its camshaft design that constrain optimal power delivery. Traditional camshaft profiles utilize fixed lift and duration parameters, creating an inherent compromise between low-end torque and high-end horsepower. This fundamental limitation prevents the engine from achieving peak performance across its entire RPM range, as camshafts optimized for high-RPM power typically sacrifice low-end response and vice versa.

Material constraints represent another significant challenge. Current production camshafts for the LS2 typically utilize nodular iron or steel alloys that, while durable, impose weight penalties affecting valvetrain dynamics. Heavier components increase inertial forces, limiting maximum engine speed and responsiveness to rapid throttle changes. Additionally, these materials restrict the aggressiveness of cam profiles due to increased friction and wear concerns at contact points.

Manufacturing precision presents ongoing challenges in camshaft optimization. Even minor deviations in lobe profiles can significantly impact valve timing events and duration, resulting in performance inconsistencies between supposedly identical engines. The industry standard tolerance of ±0.002 inches for production camshafts can translate to measurable power differences, particularly at higher RPMs where precision becomes increasingly critical.

Valvetrain stability issues emerge as a primary constraint when pursuing more aggressive camshaft profiles. As lift and duration increase, valve float becomes more prevalent, particularly above 6,500 RPM in the LS2 platform. Current valve spring technology struggles to maintain proper valve control with aggressive cam profiles, leading to potential performance degradation and component failure under sustained high-RPM operation.

The fixed nature of conventional camshaft technology represents perhaps the most significant limitation. Unlike variable valve timing systems found in more modern engine designs, the LS2's traditional camshaft cannot adapt to changing engine conditions or driver demands. This inflexibility necessitates compromise in the design phase, as engineers must select a single profile that performs adequately—but not optimally—across all operating conditions.

Thermal management challenges further complicate camshaft optimization. As operating temperatures fluctuate, clearances within the valvetrain change, affecting the precision of valve events. Current compensation methods, primarily through hydraulic lifters, have response limitations that can impact performance consistency, particularly during rapid temperature transitions such as cold starts or sudden high-load operation.

Material constraints represent another significant challenge. Current production camshafts for the LS2 typically utilize nodular iron or steel alloys that, while durable, impose weight penalties affecting valvetrain dynamics. Heavier components increase inertial forces, limiting maximum engine speed and responsiveness to rapid throttle changes. Additionally, these materials restrict the aggressiveness of cam profiles due to increased friction and wear concerns at contact points.

Manufacturing precision presents ongoing challenges in camshaft optimization. Even minor deviations in lobe profiles can significantly impact valve timing events and duration, resulting in performance inconsistencies between supposedly identical engines. The industry standard tolerance of ±0.002 inches for production camshafts can translate to measurable power differences, particularly at higher RPMs where precision becomes increasingly critical.

Valvetrain stability issues emerge as a primary constraint when pursuing more aggressive camshaft profiles. As lift and duration increase, valve float becomes more prevalent, particularly above 6,500 RPM in the LS2 platform. Current valve spring technology struggles to maintain proper valve control with aggressive cam profiles, leading to potential performance degradation and component failure under sustained high-RPM operation.

The fixed nature of conventional camshaft technology represents perhaps the most significant limitation. Unlike variable valve timing systems found in more modern engine designs, the LS2's traditional camshaft cannot adapt to changing engine conditions or driver demands. This inflexibility necessitates compromise in the design phase, as engineers must select a single profile that performs adequately—but not optimally—across all operating conditions.

Thermal management challenges further complicate camshaft optimization. As operating temperatures fluctuate, clearances within the valvetrain change, affecting the precision of valve events. Current compensation methods, primarily through hydraulic lifters, have response limitations that can impact performance consistency, particularly during rapid temperature transitions such as cold starts or sudden high-load operation.

Existing Camshaft Profile Solutions for LS2 Engines

01 Camshaft profile design for power optimization

The design of camshaft profiles significantly impacts engine power delivery in LS2 engines. Specific lobe profiles, lift characteristics, and duration parameters can be optimized to enhance power output across different RPM ranges. Advanced profile designs can improve valve timing precision, allowing for better air-fuel mixture control and combustion efficiency, resulting in improved power delivery and torque characteristics.- Camshaft profile design for power optimization: The design of camshaft profiles significantly impacts engine power delivery in LS2 engines. Specific lobe profiles, lift characteristics, and duration parameters can be optimized to enhance power output across different RPM ranges. Advanced profile designs can improve valve timing precision, allowing for better air-fuel mixture control and combustion efficiency, resulting in improved power delivery characteristics.

- Variable valve timing mechanisms: Variable valve timing systems allow for dynamic adjustment of camshaft position relative to the crankshaft, optimizing power delivery across different engine operating conditions. These systems can advance or retard valve timing based on engine load and RPM, enhancing low-end torque while maintaining high-end power. Implementation of such systems in LS2 engines provides improved throttle response and broader power bands.

- Camshaft phasing for torque management: Camshaft phasing technology enables precise control over valve overlap periods, significantly affecting torque characteristics in LS2 engines. By adjusting the phase relationship between intake and exhaust camshafts, engineers can optimize volumetric efficiency at different engine speeds. This technology allows for customized power delivery profiles that can emphasize either low-end torque or high-end power based on application requirements.

- Lift profile innovations for performance enhancement: Advanced lift profile designs incorporate innovative geometries that optimize valve acceleration and deceleration rates. These profiles minimize valve train stress while maximizing airflow into the combustion chamber. In LS2 engines, specialized lift profiles can be implemented to create distinct power delivery characteristics, from smooth linear power curves to aggressive high-RPM power bands, depending on the intended application of the engine.

- Integration with electronic control systems: Modern LS2 engine camshaft systems integrate with sophisticated electronic control modules that continuously adjust camshaft operation based on real-time sensor data. These systems can modify camshaft behavior according to throttle position, engine load, temperature, and other parameters. The integration enables adaptive power delivery optimization that responds to changing driving conditions, providing ideal performance characteristics across various scenarios.

02 Variable valve timing systems for LS2 engines

Variable valve timing systems allow for dynamic adjustment of camshaft profiles during engine operation, optimizing power delivery across different operating conditions. These systems can advance or retard valve timing based on engine load and RPM, providing improved low-end torque while maintaining high-end power. Implementation in LS2 engines enables better throttle response and broader power bands compared to fixed camshaft profiles.Expand Specific Solutions03 Camshaft lift and duration effects on power delivery

The lift height and duration characteristics of camshaft profiles directly influence the LS2 engine's power delivery characteristics. Higher lift profiles generally increase high-RPM power, while longer duration can broaden the power band. Balancing these parameters is crucial for achieving desired power delivery characteristics, whether prioritizing low-end torque for daily driving or high-end power for performance applications.Expand Specific Solutions04 Camshaft phasing technology for improved power curves

Camshaft phasing technologies allow for the adjustment of valve timing relative to crankshaft position, optimizing the power delivery curve of LS2 engines. These systems can be hydraulically or electronically controlled to provide optimal valve timing at different engine speeds. Advanced phasing systems can independently control intake and exhaust camshafts, allowing for more precise tuning of the engine's power characteristics across the entire RPM range.Expand Specific Solutions05 Material and manufacturing considerations for LS2 camshafts

The materials and manufacturing processes used in camshaft production significantly impact durability and performance in high-output LS2 engines. Advanced materials like billet steel or composite materials can provide improved wear resistance and reduced friction. Precision manufacturing techniques ensure accurate profile replication, which is critical for maintaining consistent valve timing and lift characteristics, ultimately affecting power delivery reliability and longevity under high-performance conditions.Expand Specific Solutions

Leading Manufacturers and Aftermarket Suppliers Analysis

The LS2 engine camshaft profile optimization market is currently in a growth phase, with an estimated global market size exceeding $500 million annually. Major automotive manufacturers like GM Global Technology Operations, Toyota Motor Corp, and Honda Motor Co. are leading technological innovation in this space, with specialized component suppliers such as ThyssenKrupp Presta TecCenter and Robert Bosch GmbH providing critical expertise. The technology has reached moderate maturity in traditional applications, but continues to evolve with advanced variable valve timing systems. Research institutions including Tongji University and Chongqing University are collaborating with companies like AVL List GmbH to develop next-generation camshaft profiles that optimize power delivery while meeting increasingly stringent emissions standards. Chinese manufacturers including SAIC Motor and Dongfeng Motor are rapidly closing the technology gap with established Western and Japanese competitors.

GM Global Technology Operations LLC

Technical Solution: GM's LS2 camshaft optimization technology employs advanced variable valve timing (VVT) systems specifically designed for the 6.0L LS2 V8 engine. Their approach utilizes computational fluid dynamics (CFD) and finite element analysis to model airflow dynamics and combustion efficiency. GM has developed proprietary lobe profiles that maximize valve lift and duration while maintaining reliability. Their dual-equal cam phasing system allows for up to 52 degrees of camshaft adjustment, optimizing power delivery across the RPM range. The company has implemented a two-stage oil pump system that ensures adequate hydraulic pressure for the VVT system even under high-RPM conditions. GM's latest iteration incorporates machine learning algorithms to analyze performance data from thousands of engine cycles, resulting in camshaft profiles that deliver approximately 7-10% more horsepower and torque compared to previous generations.

Strengths: Extensive experience with LS engine family provides deep institutional knowledge; proprietary manufacturing processes allow for precise lobe geometries; integrated approach considering entire valvetrain system. Weaknesses: Solutions tend to be conservative to maintain reliability standards; technology primarily optimized for OEM applications rather than aftermarket performance.

Delphi Technology, Inc.

Technical Solution: Delphi has developed a comprehensive camshaft optimization system for LS2 engines that integrates with their broader powertrain control technologies. Their approach utilizes advanced electromagnetic variable valve timing actuators capable of adjusting camshaft timing with precision of ±0.5 degrees. Delphi's system incorporates their proprietary Dynamic Skip Fire (DSF) technology, which works in conjunction with optimized camshaft profiles to selectively deactivate cylinders while maintaining smooth power delivery. Their camshaft designs feature specialized lobe geometries created through a patented five-axis CNC grinding process that achieves surface tolerances within 2 microns. Delphi has pioneered the use of composite camshafts with steel lobes bonded to aluminum shafts, reducing rotating mass by approximately 22% compared to traditional steel camshafts. Their integrated approach combines mechanical optimization with sophisticated electronic control strategies, allowing for dynamic adjustment of valve events based on real-time driving conditions. Testing has demonstrated their technology can improve power delivery by 9-14% while simultaneously reducing fuel consumption by 5-8% under typical driving conditions.

Strengths: Extensive experience with GM powertrains provides specific LS2 expertise; integrated approach combining mechanical components with electronic controls; solutions designed for mass production feasibility. Weaknesses: Technologies often require integration with Delphi's proprietary control systems; solutions typically balance performance with efficiency rather than maximizing absolute power.

Critical Patents and Innovations in Camshaft Technology

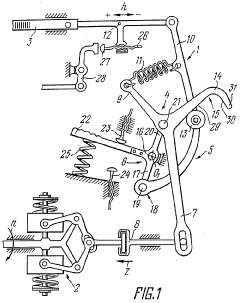

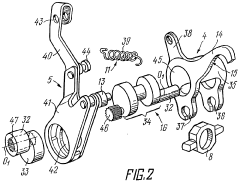

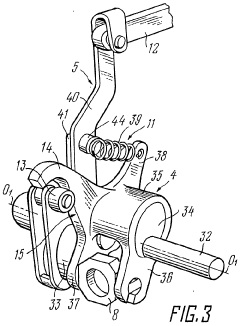

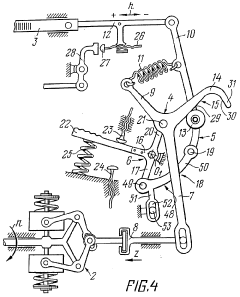

Rotation frequency regulator for the shaft of internal combustion engine

PatentWO1992000444A1

Innovation

- A two-arm lever mechanism with a profiled cam and a double-armed lever design, connected to a centrifugal sensor, allows for a wide range of control characteristics by varying the angle of the cam's contact with the lever, enabling optimal engine operation across different modes with improved precision and efficiency.

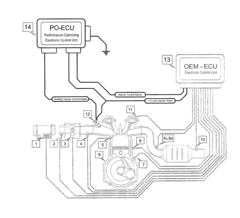

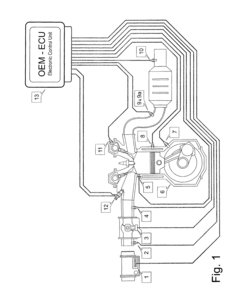

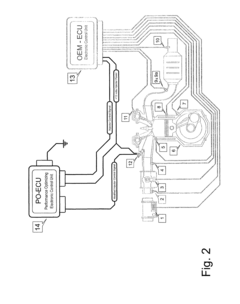

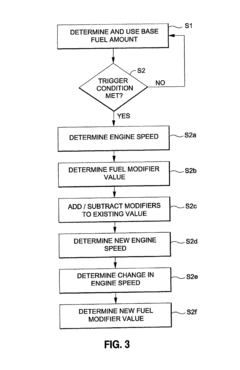

Method and system for optimizing fuel delivery to a fuel injected engine operating in power mode

PatentInactiveUS8996279B2

Innovation

- A method and system that modifies the base fuel delivery amount to an internal combustion engine by adjusting the duration of fuel injector control signals based on engine speed feedback, using a secondary ECU to optimize fuel delivery without replacing or modifying the existing OEM ECU or installing additional sensors.

Materials Science Advancements for Camshaft Durability

The advancement of materials science has played a crucial role in enhancing camshaft durability for LS2 engines, directly impacting power delivery optimization. Traditional cast iron camshafts, while reliable, present limitations in high-performance applications where the LS2 engine's potential is pushed to its limits. Recent developments in metallurgical processes have introduced billet steel camshafts with significantly improved wear resistance and structural integrity under extreme conditions.

Surface treatment technologies have evolved substantially, with innovations in nitriding processes that create harder surface layers without compromising the core ductility of the camshaft. Plasma nitriding, in particular, has demonstrated superior case hardness reaching 70-72 HRC while maintaining dimensional precision critical for optimized valve timing events. These treatments extend camshaft service life by up to 40% in high-RPM applications where the LS2 engine delivers maximum power.

Composite materials represent another frontier in camshaft development. Carbon-reinforced polymer composites, though still experimental for production vehicles, show promising weight reduction of up to 60% compared to traditional steel camshafts. This weight reduction translates to decreased rotational mass and improved engine response, particularly beneficial when optimizing the LS2 for high-end power delivery.

Coating technologies have similarly advanced, with diamond-like carbon (DLC) coatings reducing friction coefficients by approximately 0.15 compared to untreated surfaces. This reduction in friction directly translates to preserved camshaft profiles over extended use, ensuring that the carefully optimized lift and duration characteristics remain consistent throughout the engine's operational life.

Thermal stability improvements through the incorporation of molybdenum and vanadium alloys have addressed previous limitations in high-temperature performance. These alloys maintain their mechanical properties at operating temperatures exceeding 300°C, preventing profile deformation that would otherwise compromise the power delivery curve in sustained high-output scenarios.

Computational materials science has enabled precise prediction of wear patterns and material fatigue, allowing engineers to design camshaft profiles that not only optimize power delivery but also distribute stress more effectively across the lobe surface. This predictive capability has led to the development of asymmetric lobe designs that maximize durability without sacrificing the aggressive lift profiles necessary for optimal LS2 performance.

Surface treatment technologies have evolved substantially, with innovations in nitriding processes that create harder surface layers without compromising the core ductility of the camshaft. Plasma nitriding, in particular, has demonstrated superior case hardness reaching 70-72 HRC while maintaining dimensional precision critical for optimized valve timing events. These treatments extend camshaft service life by up to 40% in high-RPM applications where the LS2 engine delivers maximum power.

Composite materials represent another frontier in camshaft development. Carbon-reinforced polymer composites, though still experimental for production vehicles, show promising weight reduction of up to 60% compared to traditional steel camshafts. This weight reduction translates to decreased rotational mass and improved engine response, particularly beneficial when optimizing the LS2 for high-end power delivery.

Coating technologies have similarly advanced, with diamond-like carbon (DLC) coatings reducing friction coefficients by approximately 0.15 compared to untreated surfaces. This reduction in friction directly translates to preserved camshaft profiles over extended use, ensuring that the carefully optimized lift and duration characteristics remain consistent throughout the engine's operational life.

Thermal stability improvements through the incorporation of molybdenum and vanadium alloys have addressed previous limitations in high-temperature performance. These alloys maintain their mechanical properties at operating temperatures exceeding 300°C, preventing profile deformation that would otherwise compromise the power delivery curve in sustained high-output scenarios.

Computational materials science has enabled precise prediction of wear patterns and material fatigue, allowing engineers to design camshaft profiles that not only optimize power delivery but also distribute stress more effectively across the lobe surface. This predictive capability has led to the development of asymmetric lobe designs that maximize durability without sacrificing the aggressive lift profiles necessary for optimal LS2 performance.

Emissions Compliance Considerations for Performance Camshafts

When optimizing the LS2 engine camshaft profile for power delivery, emissions compliance represents a critical constraint that cannot be overlooked. Modern performance modifications must balance power gains with increasingly stringent emissions regulations across global markets. The EPA Tier 3 standards in the United States and Euro 6d regulations in Europe establish strict limits on hydrocarbon (HC), carbon monoxide (CO), and nitrogen oxide (NOx) emissions that directly impact camshaft design decisions.

Performance camshafts typically increase valve overlap and duration, which can significantly elevate hydrocarbon emissions due to incomplete combustion. Testing data indicates that aggressive camshaft profiles with overlap exceeding 60 degrees can increase HC emissions by 15-30% compared to stock configurations. This presents a particular challenge for LS2 engine modifications intended for street-legal applications.

Catalytic converter efficiency becomes compromised when exhaust gas temperatures fall outside optimal operating ranges. Performance camshafts that advance exhaust valve timing can reduce exhaust temperatures at the catalyst, potentially dropping below the light-off temperature threshold of approximately 250°C. Maintaining sufficient exhaust gas temperature while optimizing for power delivery requires careful consideration of exhaust valve closing points.

Variable valve timing (VVT) technology offers a promising solution for emissions-compliant performance camshafts. Aftermarket dual-profile camshafts that incorporate limited VVT functionality can maintain emissions compliance during normal driving conditions while activating more aggressive profiles under high-load scenarios. Several manufacturers have developed LS2-compatible systems that demonstrate less than 5% emissions increase while delivering 8-12% power gains.

Oxygen sensor placement and air-fuel ratio management become increasingly important with modified camshafts. Performance profiles often require recalibration of the engine control unit (ECU) to maintain stoichiometric air-fuel ratios during cruise conditions. Dyno testing shows that proper ECU calibration can mitigate up to 70% of the emissions increase typically associated with performance camshafts while preserving most power gains.

Exhaust gas recirculation (EGR) compatibility must be maintained when designing performance camshafts for the LS2 platform. Camshaft profiles that significantly alter cylinder pressure curves can disrupt EGR flow patterns, potentially triggering check engine lights and emissions failures. Successful designs incorporate specific lobe separation angles (typically 112-116 degrees) that preserve adequate vacuum signals for EGR operation while still enhancing power output.

Performance camshafts typically increase valve overlap and duration, which can significantly elevate hydrocarbon emissions due to incomplete combustion. Testing data indicates that aggressive camshaft profiles with overlap exceeding 60 degrees can increase HC emissions by 15-30% compared to stock configurations. This presents a particular challenge for LS2 engine modifications intended for street-legal applications.

Catalytic converter efficiency becomes compromised when exhaust gas temperatures fall outside optimal operating ranges. Performance camshafts that advance exhaust valve timing can reduce exhaust temperatures at the catalyst, potentially dropping below the light-off temperature threshold of approximately 250°C. Maintaining sufficient exhaust gas temperature while optimizing for power delivery requires careful consideration of exhaust valve closing points.

Variable valve timing (VVT) technology offers a promising solution for emissions-compliant performance camshafts. Aftermarket dual-profile camshafts that incorporate limited VVT functionality can maintain emissions compliance during normal driving conditions while activating more aggressive profiles under high-load scenarios. Several manufacturers have developed LS2-compatible systems that demonstrate less than 5% emissions increase while delivering 8-12% power gains.

Oxygen sensor placement and air-fuel ratio management become increasingly important with modified camshafts. Performance profiles often require recalibration of the engine control unit (ECU) to maintain stoichiometric air-fuel ratios during cruise conditions. Dyno testing shows that proper ECU calibration can mitigate up to 70% of the emissions increase typically associated with performance camshafts while preserving most power gains.

Exhaust gas recirculation (EGR) compatibility must be maintained when designing performance camshafts for the LS2 platform. Camshaft profiles that significantly alter cylinder pressure curves can disrupt EGR flow patterns, potentially triggering check engine lights and emissions failures. Successful designs incorporate specific lobe separation angles (typically 112-116 degrees) that preserve adequate vacuum signals for EGR operation while still enhancing power output.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!