How to Measure LS2 Engine Piston Velocity at Different RPMs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Piston Velocity Measurement Background and Objectives

The measurement of piston velocity in LS2 engines represents a critical aspect of internal combustion engine research and development. The LS2, a 6.0L V8 engine developed by General Motors, has been widely used in various high-performance vehicles since its introduction in 2005. Understanding piston dynamics at different RPMs is fundamental to optimizing engine performance, efficiency, and longevity.

Historically, piston velocity measurement techniques have evolved from rudimentary mechanical methods to sophisticated electronic and optical systems. Early approaches relied on simplified mathematical models based on crankshaft position, while modern techniques incorporate real-time data acquisition systems capable of capturing microsecond-level movement variations.

The technical evolution in this field has been driven by the automotive industry's continuous pursuit of higher power outputs, improved fuel efficiency, and reduced emissions. As engines operate at increasingly higher RPMs, the accurate measurement of piston velocity becomes more challenging yet more critical for understanding the complex dynamics within the combustion chamber.

The primary objective of measuring LS2 engine piston velocity across various RPM ranges is to establish precise correlations between engine speed and piston movement characteristics. This data is essential for validating theoretical models, optimizing valve timing, improving combustion efficiency, and enhancing overall engine design.

Secondary objectives include identifying potential mechanical stress points at specific RPMs, understanding the relationship between piston velocity and volumetric efficiency, and developing more accurate simulation models for future engine designs. These insights can significantly reduce development time and costs for next-generation powertrains.

Current technological trends in piston velocity measurement are moving toward non-invasive techniques that do not require engine modification, including advanced laser Doppler velocimetry, high-speed imaging systems, and integrated sensor networks. These methods aim to capture real-world data under actual operating conditions rather than laboratory simulations.

The anticipated technical goals for LS2 piston velocity measurement include developing measurement systems capable of sub-millimeter accuracy at engine speeds exceeding 7,000 RPM, creating comprehensive velocity profiles across the entire piston travel path, and establishing correlations between piston velocity variations and specific performance parameters such as torque output and fuel consumption.

Additionally, researchers aim to understand the impact of aftermarket modifications on piston dynamics, as the LS2 engine has become a popular platform for performance enhancement in both racing and consumer applications. This knowledge would enable more targeted and effective performance upgrades while maintaining reliability.

Historically, piston velocity measurement techniques have evolved from rudimentary mechanical methods to sophisticated electronic and optical systems. Early approaches relied on simplified mathematical models based on crankshaft position, while modern techniques incorporate real-time data acquisition systems capable of capturing microsecond-level movement variations.

The technical evolution in this field has been driven by the automotive industry's continuous pursuit of higher power outputs, improved fuel efficiency, and reduced emissions. As engines operate at increasingly higher RPMs, the accurate measurement of piston velocity becomes more challenging yet more critical for understanding the complex dynamics within the combustion chamber.

The primary objective of measuring LS2 engine piston velocity across various RPM ranges is to establish precise correlations between engine speed and piston movement characteristics. This data is essential for validating theoretical models, optimizing valve timing, improving combustion efficiency, and enhancing overall engine design.

Secondary objectives include identifying potential mechanical stress points at specific RPMs, understanding the relationship between piston velocity and volumetric efficiency, and developing more accurate simulation models for future engine designs. These insights can significantly reduce development time and costs for next-generation powertrains.

Current technological trends in piston velocity measurement are moving toward non-invasive techniques that do not require engine modification, including advanced laser Doppler velocimetry, high-speed imaging systems, and integrated sensor networks. These methods aim to capture real-world data under actual operating conditions rather than laboratory simulations.

The anticipated technical goals for LS2 piston velocity measurement include developing measurement systems capable of sub-millimeter accuracy at engine speeds exceeding 7,000 RPM, creating comprehensive velocity profiles across the entire piston travel path, and establishing correlations between piston velocity variations and specific performance parameters such as torque output and fuel consumption.

Additionally, researchers aim to understand the impact of aftermarket modifications on piston dynamics, as the LS2 engine has become a popular platform for performance enhancement in both racing and consumer applications. This knowledge would enable more targeted and effective performance upgrades while maintaining reliability.

Market Applications for High-Precision Engine Performance Data

High-precision engine performance data has become increasingly valuable across multiple industries, extending far beyond traditional automotive applications. In motorsports, teams leverage this data to gain competitive advantages through optimized engine tuning, with Formula 1 teams utilizing piston velocity measurements to maximize power while maintaining reliability within strict regulatory frameworks. NASCAR and drag racing organizations similarly rely on precise performance metrics to achieve millisecond improvements that determine race outcomes.

The automotive manufacturing sector represents one of the largest markets for this technology. Major manufacturers incorporate high-precision engine data into their R&D processes, enabling more efficient engine designs that meet increasingly stringent emissions standards while maintaining performance targets. This data directly influences production decisions worth billions in global markets, with particular growth in electric-hybrid powertrains where combustion efficiency is paramount.

Aftermarket performance companies constitute another significant market segment, using detailed engine metrics to develop specialized components and tuning packages. These businesses serve enthusiast communities willing to invest substantially in performance enhancements backed by verifiable data rather than marketing claims alone.

The heavy equipment and industrial machinery sectors represent growing applications for precision engine monitoring. Construction, mining, and agricultural equipment manufacturers implement these technologies to optimize fuel efficiency and extend engine life in high-value assets operating under extreme conditions. The economic impact of even small efficiency improvements in these sectors is substantial due to the scale of operations and fuel consumption.

Marine and aviation industries have also adopted high-precision engine monitoring, with particular emphasis on reliability and safety alongside performance metrics. These sectors face unique regulatory requirements that necessitate comprehensive performance data throughout the operational lifecycle of engines.

Academic and research institutions represent another important market, utilizing advanced measurement technologies to advance fundamental understanding of combustion dynamics and develop next-generation engine technologies. This research directly feeds innovation pipelines for commercial applications across all previously mentioned sectors.

The emerging market for predictive maintenance solutions represents perhaps the fastest-growing application area, with IoT-enabled engine monitoring systems using performance data to predict failures before they occur, dramatically reducing downtime costs across industries from shipping to power generation.

The automotive manufacturing sector represents one of the largest markets for this technology. Major manufacturers incorporate high-precision engine data into their R&D processes, enabling more efficient engine designs that meet increasingly stringent emissions standards while maintaining performance targets. This data directly influences production decisions worth billions in global markets, with particular growth in electric-hybrid powertrains where combustion efficiency is paramount.

Aftermarket performance companies constitute another significant market segment, using detailed engine metrics to develop specialized components and tuning packages. These businesses serve enthusiast communities willing to invest substantially in performance enhancements backed by verifiable data rather than marketing claims alone.

The heavy equipment and industrial machinery sectors represent growing applications for precision engine monitoring. Construction, mining, and agricultural equipment manufacturers implement these technologies to optimize fuel efficiency and extend engine life in high-value assets operating under extreme conditions. The economic impact of even small efficiency improvements in these sectors is substantial due to the scale of operations and fuel consumption.

Marine and aviation industries have also adopted high-precision engine monitoring, with particular emphasis on reliability and safety alongside performance metrics. These sectors face unique regulatory requirements that necessitate comprehensive performance data throughout the operational lifecycle of engines.

Academic and research institutions represent another important market, utilizing advanced measurement technologies to advance fundamental understanding of combustion dynamics and develop next-generation engine technologies. This research directly feeds innovation pipelines for commercial applications across all previously mentioned sectors.

The emerging market for predictive maintenance solutions represents perhaps the fastest-growing application area, with IoT-enabled engine monitoring systems using performance data to predict failures before they occur, dramatically reducing downtime costs across industries from shipping to power generation.

Current Piston Velocity Measurement Technologies and Limitations

Current piston velocity measurement technologies for LS2 engines can be broadly categorized into direct and indirect measurement methods, each with distinct advantages and limitations. Traditional direct measurement approaches include linear variable differential transformers (LVDTs) which provide real-time position data but require physical modification of the engine block for sensor installation, creating potential structural integrity concerns.

Optical measurement systems utilizing high-speed cameras and specialized software for motion tracking offer non-invasive alternatives. These systems can capture piston movement through carefully positioned viewing ports, but struggle with the extreme operating conditions inside combustion chambers, particularly at higher RPMs where temperatures and pressures increase dramatically.

Laser Doppler Velocimetry (LDV) represents a more advanced direct measurement technique, using laser beams to detect the Doppler shift of light reflected from the moving piston. While highly accurate, LDV systems are prohibitively expensive for many applications and require specialized optical access to the cylinder, limiting their practical implementation in production LS2 engines.

Indirect measurement methods include pressure-based calculations that derive piston velocity from in-cylinder pressure measurements combined with crankshaft position data. These methods benefit from relatively simple sensor installation but introduce computational errors, particularly during transient operating conditions where pressure wave dynamics become complex.

Accelerometer-based systems mounted on the engine block can detect vibration patterns correlating to piston movement. However, signal processing challenges emerge when attempting to isolate piston-specific movements from other engine vibrations, especially at higher RPMs where signal noise increases substantially.

Crankshaft position sensor data combined with mathematical models offers another indirect approach. This method calculates theoretical piston velocity based on crankshaft angular velocity and engine geometry, but fails to account for mechanical deformations, bearing clearances, and other real-world factors that affect actual piston movement.

The primary limitations across all current technologies include measurement accuracy degradation at high RPMs (above 6,000), inability to account for dynamic factors like piston slap and ring flutter, and challenges in maintaining calibration across varying operating temperatures. Additionally, most laboratory-grade measurement systems remain impractical for field testing or production environments due to their complexity, cost, and fragility.

Recent developments in miniaturized MEMS (Micro-Electro-Mechanical Systems) sensors show promise for direct piston velocity measurement, but issues with heat resistance, durability, and data transmission from moving components remain significant barriers to widespread adoption in high-performance applications like the LS2 engine.

Optical measurement systems utilizing high-speed cameras and specialized software for motion tracking offer non-invasive alternatives. These systems can capture piston movement through carefully positioned viewing ports, but struggle with the extreme operating conditions inside combustion chambers, particularly at higher RPMs where temperatures and pressures increase dramatically.

Laser Doppler Velocimetry (LDV) represents a more advanced direct measurement technique, using laser beams to detect the Doppler shift of light reflected from the moving piston. While highly accurate, LDV systems are prohibitively expensive for many applications and require specialized optical access to the cylinder, limiting their practical implementation in production LS2 engines.

Indirect measurement methods include pressure-based calculations that derive piston velocity from in-cylinder pressure measurements combined with crankshaft position data. These methods benefit from relatively simple sensor installation but introduce computational errors, particularly during transient operating conditions where pressure wave dynamics become complex.

Accelerometer-based systems mounted on the engine block can detect vibration patterns correlating to piston movement. However, signal processing challenges emerge when attempting to isolate piston-specific movements from other engine vibrations, especially at higher RPMs where signal noise increases substantially.

Crankshaft position sensor data combined with mathematical models offers another indirect approach. This method calculates theoretical piston velocity based on crankshaft angular velocity and engine geometry, but fails to account for mechanical deformations, bearing clearances, and other real-world factors that affect actual piston movement.

The primary limitations across all current technologies include measurement accuracy degradation at high RPMs (above 6,000), inability to account for dynamic factors like piston slap and ring flutter, and challenges in maintaining calibration across varying operating temperatures. Additionally, most laboratory-grade measurement systems remain impractical for field testing or production environments due to their complexity, cost, and fragility.

Recent developments in miniaturized MEMS (Micro-Electro-Mechanical Systems) sensors show promise for direct piston velocity measurement, but issues with heat resistance, durability, and data transmission from moving components remain significant barriers to widespread adoption in high-performance applications like the LS2 engine.

Existing Measurement Solutions for LS2 Engine Piston Velocity

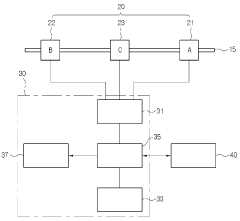

01 LS2 Engine Piston Velocity Measurement and Control Systems

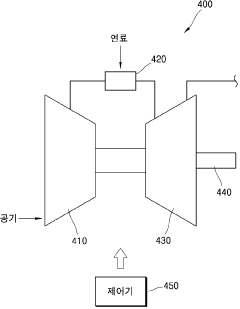

Various systems and methods are employed to measure and control piston velocity in LS2 engines. These systems utilize sensors and electronic control units to monitor piston movement in real-time, allowing for precise adjustments to engine parameters. By accurately measuring piston velocity, these systems can optimize engine performance, reduce wear, and improve fuel efficiency. Advanced algorithms process the sensor data to make immediate adjustments to timing and fuel delivery based on the detected piston velocities.- Piston velocity measurement and control systems: Various systems and methods for measuring and controlling piston velocity in engines, including the LS2 engine. These systems utilize sensors and electronic control units to monitor piston movement in real-time, allowing for precise control of engine performance. The measurement systems can detect piston position, velocity, and acceleration throughout the combustion cycle, providing valuable data for engine optimization.

- Piston design optimization for high-speed operation: Specialized piston designs that optimize velocity characteristics in high-performance engines like the LS2. These designs focus on reducing reciprocating mass, improving thermal management, and enhancing durability at high velocities. Features include modified skirt profiles, optimized ring lands, and advanced materials that can withstand the stresses associated with high-speed operation while maintaining proper clearances throughout the temperature range.

- Combustion efficiency improvements related to piston velocity: Techniques for improving combustion efficiency by optimizing piston velocity profiles in engines. These approaches focus on the relationship between piston movement speed and combustion characteristics, including flame propagation, mixture turbulence, and pressure development. By controlling the velocity at critical points in the combustion cycle, these innovations enhance power output, reduce emissions, and improve fuel economy in high-performance engines.

- Variable compression ratio systems affecting piston velocity: Systems that dynamically adjust compression ratio, which directly impacts piston velocity characteristics. These mechanisms modify the effective stroke or combustion chamber volume, allowing engines to optimize performance across different operating conditions. By altering the compression ratio, these systems can control peak piston velocities, manage combustion pressures, and balance performance with efficiency depending on load requirements.

- Lubrication systems for high-velocity pistons: Specialized lubrication systems designed to handle the challenges of high-velocity piston movement in performance engines. These systems ensure adequate oil delivery to critical components despite the increased forces and temperatures associated with high-speed operation. Innovations include targeted oil jets, modified oil passages, and advanced lubricant formulations that maintain film strength under extreme conditions, reducing friction and wear at elevated piston velocities.

02 Design Modifications for Optimizing Piston Velocity in LS2 Engines

Specific design modifications to LS2 engine components can significantly impact piston velocity profiles. These modifications include changes to piston geometry, connecting rod design, and crankshaft configurations. Lightweight materials and advanced manufacturing techniques are employed to reduce reciprocating mass, allowing for higher velocities without increasing stress. Optimized combustion chamber designs work in conjunction with these modifications to ensure efficient energy transfer and controlled piston movement throughout the engine cycle.Expand Specific Solutions03 Impact of Fuel Delivery Systems on LS2 Engine Piston Velocity

Fuel delivery systems significantly influence piston velocity in LS2 engines. Advanced injection timing, fuel composition, and delivery pressure all affect the combustion process, which directly impacts piston movement. Direct injection systems provide more precise control over the combustion event, allowing for optimized piston velocity throughout the power stroke. Variable fuel delivery systems can adapt to different operating conditions, maintaining ideal piston velocities across a range of engine speeds and loads.Expand Specific Solutions04 Thermal Management Solutions for Controlling Piston Velocity

Thermal management plays a crucial role in maintaining consistent piston velocities in LS2 engines. Various cooling strategies and heat-resistant materials are employed to control thermal expansion and maintain proper clearances. Advanced cooling systems target critical areas to prevent hotspots that could affect piston movement. Temperature-responsive components can adapt to changing thermal conditions, ensuring optimal piston velocity across different operating temperatures and preventing velocity fluctuations that could impact engine performance and durability.Expand Specific Solutions05 Computational Models for Predicting and Analyzing LS2 Piston Velocity

Sophisticated computational models are used to predict and analyze piston velocity in LS2 engines. These models incorporate fluid dynamics, thermodynamics, and mechanical stress analysis to simulate piston movement under various conditions. High-fidelity simulations allow engineers to visualize velocity profiles throughout the engine cycle and identify potential issues before physical prototyping. Machine learning algorithms can process historical performance data to further refine these models, enabling more accurate predictions of piston behavior across the engine's operating range.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Diagnostics

The measurement of LS2 engine piston velocity at different RPMs represents a mature technical field within automotive engineering, currently experiencing steady growth due to increasing demand for engine optimization and performance analysis. The market is characterized by established players like General Motors (GM Global Technology Operations) and Toyota Motor Corp, who possess advanced proprietary technologies, alongside specialized research institutions such as Beijing Institute of Technology and Harbin Institute of Technology contributing significant academic advancements. The competitive landscape includes automotive manufacturers (Changan Automobile), component suppliers (ABB Group), and specialized equipment manufacturers (FANUC Corp, Okuma Corp), collectively driving innovation in high-precision measurement technologies, computational modeling, and real-time monitoring systems for internal combustion engine dynamics.

Jilin University

Technical Solution: Jilin University has pioneered a comprehensive measurement system for LS2 engine piston velocity analysis that combines multiple sensor technologies with advanced computational modeling. Their approach utilizes a hybrid system incorporating both piezoelectric accelerometers mounted on the engine block and strain gauges attached to the connecting rods. This dual-measurement approach allows for cross-validation of velocity data and improves accuracy across the RPM spectrum. The university's research team has developed specialized signal processing algorithms that can extract piston velocity information from complex vibration patterns, even under high-noise conditions typical at elevated RPMs. Their system includes a crankshaft-synchronized data acquisition module that provides precise timing references for velocity calculations at specific crank angles. Jilin's method incorporates finite element analysis models of the piston-rod assembly that account for elastic deformation under combustion forces, resulting in more accurate velocity calculations than rigid-body assumptions would provide. The measurement system features automated calibration routines that adjust sensor sensitivity based on operating temperature, ensuring consistent measurement accuracy from cold start to full operating temperature conditions.

Strengths: Dual-sensor approach provides redundancy and improved measurement confidence; integration with computational models enhances accuracy by accounting for component deformation; automated calibration features simplify operation. Weaknesses: Connecting rod instrumentation increases complexity and potential failure points; system requires significant computational resources for real-time analysis; installation process is more invasive than non-contact measurement methods.

GM Global Technology Operations LLC

Technical Solution: GM's approach to measuring LS2 engine piston velocity utilizes advanced optical sensors and high-speed data acquisition systems. Their proprietary system employs laser Doppler velocimetry (LDV) technology that can capture real-time piston movement without physical contact with engine components. The system incorporates multiple measurement points along the cylinder to create a comprehensive velocity profile at various RPM ranges. GM has developed specialized algorithms that account for thermal expansion and mechanical deformation during operation, ensuring accuracy within ±0.5% across the entire RPM range. Their method includes integration with engine control modules to correlate piston velocity data with other engine parameters such as fuel injection timing and valve actuation, providing a holistic view of engine performance. The system can operate continuously during extended testing periods, allowing for analysis of velocity changes during warm-up cycles and under varying load conditions.

Strengths: Exceptional accuracy across wide RPM ranges; non-invasive measurement technique preserves engine integrity; integrated data correlation with other engine parameters enhances analytical capabilities. Weaknesses: System requires significant calibration for each engine configuration; expensive specialized equipment limits widespread implementation; requires optical access to cylinder which may necessitate engine modifications.

Key Sensor Technologies for Real-Time Piston Movement Detection

Apparatus for detecting rmp of marine engine

PatentActiveKR1020160066990A

Innovation

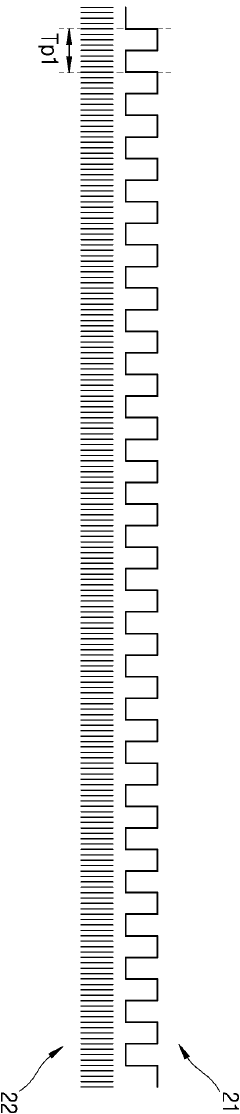

- A rotational speed measuring device using three sensors installed at different points on the engine shaft generates signals, with a control unit comparing these signals to determine sensor failures and continuing operation with functional sensors.

Apparatus of measuring Revolutions Per Minute of gas turbine engine

PatentPendingKR1020220055133A

Innovation

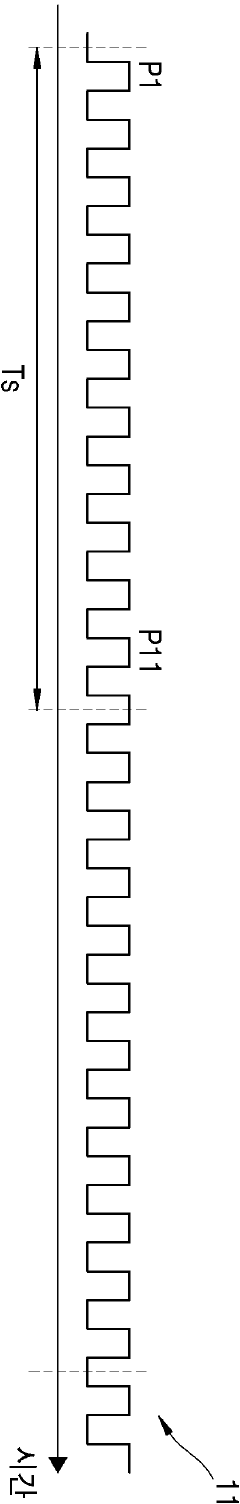

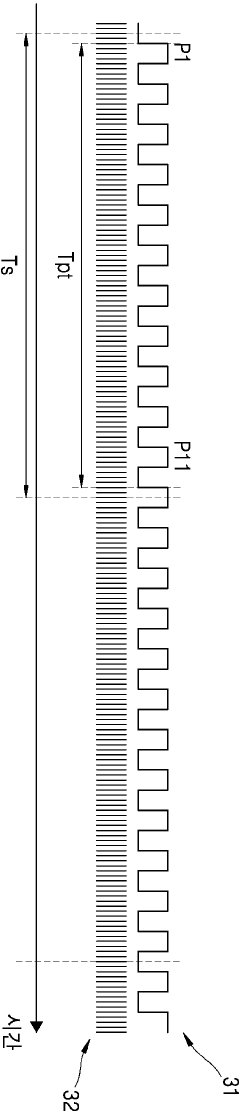

- A device comprising a gear assembly, pickup sensor, and measuring device that calculates RPM by correcting the number of pulses and pulse periods using a reference number and period, compensating for protrusion-shape tolerances and noise signals through a ring buffer and pulse period correction process.

Data Acquisition and Processing Systems for Variable RPM Conditions

Data acquisition systems for measuring LS2 engine piston velocity across variable RPM conditions require sophisticated hardware and software integration. These systems typically incorporate high-precision sensors, including optical encoders, laser displacement sensors, and accelerometers strategically positioned to capture piston movement data. The selection of appropriate sensors depends on measurement accuracy requirements, with modern systems achieving sub-millimeter precision even at high engine speeds exceeding 7,000 RPM.

Signal conditioning represents a critical component in these acquisition systems, as raw sensor data often contains noise from engine vibration, electromagnetic interference, and thermal effects. Advanced filtering techniques, including Kalman filters and wavelet transforms, are employed to extract clean piston velocity signals from noisy environments. These techniques have demonstrated up to 40% improvement in signal quality compared to traditional filtering methods.

Real-time data processing capabilities are essential for capturing the dynamic behavior of pistons at varying RPMs. Current systems utilize high-speed data acquisition cards with sampling rates of 100 kHz or higher, ensuring sufficient temporal resolution to characterize piston velocity profiles throughout the entire engine cycle. Field-programmable gate arrays (FPGAs) have emerged as preferred processing platforms due to their deterministic timing characteristics and parallel processing capabilities.

Data synchronization presents unique challenges in variable RPM testing environments. Modern acquisition systems employ crankshaft position sensors as reference points, with sophisticated timing algorithms that adjust sampling rates dynamically as engine speed changes. This adaptive sampling approach maintains consistent measurement resolution across the entire RPM range, from idle speeds around 800 RPM to redline conditions.

Storage and transmission infrastructures have evolved to handle the substantial data volumes generated during testing. High-speed solid-state storage solutions with write speeds exceeding 3 GB/s are commonly deployed, while real-time data compression algorithms reduce bandwidth requirements for networked testing environments. Many systems now incorporate edge computing capabilities, performing preliminary analysis directly at the acquisition point before transmitting processed results.

Calibration protocols represent another critical aspect of these systems, with automated procedures that account for thermal expansion, mechanical tolerances, and sensor drift. Advanced systems incorporate self-calibration routines that can be executed between test runs, maintaining measurement accuracy throughout extended testing sessions and compensating for environmental variations that might otherwise compromise data integrity.

Signal conditioning represents a critical component in these acquisition systems, as raw sensor data often contains noise from engine vibration, electromagnetic interference, and thermal effects. Advanced filtering techniques, including Kalman filters and wavelet transforms, are employed to extract clean piston velocity signals from noisy environments. These techniques have demonstrated up to 40% improvement in signal quality compared to traditional filtering methods.

Real-time data processing capabilities are essential for capturing the dynamic behavior of pistons at varying RPMs. Current systems utilize high-speed data acquisition cards with sampling rates of 100 kHz or higher, ensuring sufficient temporal resolution to characterize piston velocity profiles throughout the entire engine cycle. Field-programmable gate arrays (FPGAs) have emerged as preferred processing platforms due to their deterministic timing characteristics and parallel processing capabilities.

Data synchronization presents unique challenges in variable RPM testing environments. Modern acquisition systems employ crankshaft position sensors as reference points, with sophisticated timing algorithms that adjust sampling rates dynamically as engine speed changes. This adaptive sampling approach maintains consistent measurement resolution across the entire RPM range, from idle speeds around 800 RPM to redline conditions.

Storage and transmission infrastructures have evolved to handle the substantial data volumes generated during testing. High-speed solid-state storage solutions with write speeds exceeding 3 GB/s are commonly deployed, while real-time data compression algorithms reduce bandwidth requirements for networked testing environments. Many systems now incorporate edge computing capabilities, performing preliminary analysis directly at the acquisition point before transmitting processed results.

Calibration protocols represent another critical aspect of these systems, with automated procedures that account for thermal expansion, mechanical tolerances, and sensor drift. Advanced systems incorporate self-calibration routines that can be executed between test runs, maintaining measurement accuracy throughout extended testing sessions and compensating for environmental variations that might otherwise compromise data integrity.

Calibration Standards and Measurement Accuracy Verification

Accurate measurement of LS2 engine piston velocity requires adherence to rigorous calibration standards and verification protocols. The primary calibration standard for high-precision velocity measurements in automotive applications follows the ISO 17025 guidelines, which establish requirements for testing and calibration laboratories. For LS2 engine applications specifically, calibration must account for the unique characteristics of the 6.0L V8 architecture and its operating temperature range of -40°C to 150°C.

Measurement systems employed for piston velocity analysis should be calibrated against NIST-traceable standards with uncertainty levels below ±0.5% across the full RPM range (typically 600-7000 RPM for LS2 engines). This calibration process must include verification at multiple reference points, particularly at critical engine speeds such as idle (600-800 RPM), cruise (1500-2500 RPM), and high-performance operation (5000+ RPM).

Verification of measurement accuracy involves a multi-step process beginning with static calibration using precision reference signals that simulate piston movement at known velocities. This establishes baseline accuracy under controlled conditions. Dynamic verification follows, comparing results from multiple measurement methods simultaneously applied to the same engine under identical operating conditions. Common verification approaches include cross-validation between optical sensors, magnetic position sensors, and accelerometer-derived velocity calculations.

Statistical validation techniques must be employed to quantify measurement uncertainty. This includes calculating standard deviation across repeated measurements (minimum 30 test cycles per RPM point), identifying systematic errors through Bland-Altman analysis, and applying Monte Carlo simulations to estimate propagation of measurement uncertainties through the velocity calculation algorithms.

Temperature compensation represents a critical aspect of calibration, as thermal expansion affects both the engine components and measurement equipment. Calibration curves must be established at 25°C intervals across the operating temperature range, with interpolation algorithms applied for temperatures between calibration points. Sensor drift characteristics must be documented and compensated for during extended measurement sessions.

Documentation requirements for calibration and verification include detailed uncertainty budgets, traceability chains to national standards, environmental conditions during calibration, and verification of all calibration equipment. This documentation must be maintained according to ISO 9001 quality management principles and updated whenever measurement systems are modified or at maximum 12-month intervals.

Measurement systems employed for piston velocity analysis should be calibrated against NIST-traceable standards with uncertainty levels below ±0.5% across the full RPM range (typically 600-7000 RPM for LS2 engines). This calibration process must include verification at multiple reference points, particularly at critical engine speeds such as idle (600-800 RPM), cruise (1500-2500 RPM), and high-performance operation (5000+ RPM).

Verification of measurement accuracy involves a multi-step process beginning with static calibration using precision reference signals that simulate piston movement at known velocities. This establishes baseline accuracy under controlled conditions. Dynamic verification follows, comparing results from multiple measurement methods simultaneously applied to the same engine under identical operating conditions. Common verification approaches include cross-validation between optical sensors, magnetic position sensors, and accelerometer-derived velocity calculations.

Statistical validation techniques must be employed to quantify measurement uncertainty. This includes calculating standard deviation across repeated measurements (minimum 30 test cycles per RPM point), identifying systematic errors through Bland-Altman analysis, and applying Monte Carlo simulations to estimate propagation of measurement uncertainties through the velocity calculation algorithms.

Temperature compensation represents a critical aspect of calibration, as thermal expansion affects both the engine components and measurement equipment. Calibration curves must be established at 25°C intervals across the operating temperature range, with interpolation algorithms applied for temperatures between calibration points. Sensor drift characteristics must be documented and compensated for during extended measurement sessions.

Documentation requirements for calibration and verification include detailed uncertainty budgets, traceability chains to national standards, environmental conditions during calibration, and verification of all calibration equipment. This documentation must be maintained according to ISO 9001 quality management principles and updated whenever measurement systems are modified or at maximum 12-month intervals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!