How to Compare LS2 Engine Rod Bolts for Tensile Strength

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Rod Bolt Technology Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family, featuring a 6.0L displacement and aluminum block construction. Rod bolts in these engines serve the critical function of securing connecting rods to crankshafts, withstanding extreme tensile forces during high-RPM operation. The historical development of engine rod bolts has seen a progression from basic fasteners to highly engineered components designed specifically for performance applications, with materials evolving from standard steel to aerospace-grade alloys.

Tensile strength comparison of LS2 rod bolts has become increasingly important as engine builders and performance enthusiasts push these powerplants beyond factory specifications. The primary objective of rod bolt tensile strength analysis is to identify fasteners capable of maintaining connecting rod assembly integrity under elevated horsepower, torque, and RPM conditions without experiencing catastrophic failure.

Current industry standards for LS2 rod bolt evaluation focus on several key metrics, including ultimate tensile strength (UTS), yield strength, fatigue resistance, and elongation characteristics. These parameters collectively determine a bolt's ability to maintain proper clamping force while resisting stretching and potential failure during operation. The technological evolution in this space has been driven by motorsport applications, where engine failure due to rod bolt issues can have both competitive and safety implications.

Material science advancements have significantly influenced rod bolt development, with manufacturers now utilizing proprietary alloys and heat treatment processes to enhance performance characteristics. The trend toward higher-strength materials with improved elasticity has enabled engines to operate at higher cylinder pressures without compromising reliability. This progression aligns with broader automotive industry trends toward higher-efficiency, higher-output engines in smaller packages.

The technical goals for modern LS2 rod bolt development include achieving tensile strength ratings exceeding 220,000 PSI, improving fatigue resistance through enhanced metallurgy, and maintaining dimensional stability under thermal cycling. Additionally, manufacturers aim to develop testing methodologies that accurately predict real-world performance beyond simple static load testing.

Understanding the relationship between bolt preload, stretch, and ultimate tensile strength represents a key area of focus, as proper installation techniques significantly impact performance outcomes. The industry continues to refine both the physical properties of these components and the analytical methods used to evaluate them, with digital modeling and simulation playing an increasingly important role in the development process.

As engine power capabilities continue to increase, the technological trajectory points toward further material innovations and design refinements to create rod bolts capable of supporting the next generation of high-performance LS2 applications, whether in racing, high-performance street, or specialized industrial environments.

Tensile strength comparison of LS2 rod bolts has become increasingly important as engine builders and performance enthusiasts push these powerplants beyond factory specifications. The primary objective of rod bolt tensile strength analysis is to identify fasteners capable of maintaining connecting rod assembly integrity under elevated horsepower, torque, and RPM conditions without experiencing catastrophic failure.

Current industry standards for LS2 rod bolt evaluation focus on several key metrics, including ultimate tensile strength (UTS), yield strength, fatigue resistance, and elongation characteristics. These parameters collectively determine a bolt's ability to maintain proper clamping force while resisting stretching and potential failure during operation. The technological evolution in this space has been driven by motorsport applications, where engine failure due to rod bolt issues can have both competitive and safety implications.

Material science advancements have significantly influenced rod bolt development, with manufacturers now utilizing proprietary alloys and heat treatment processes to enhance performance characteristics. The trend toward higher-strength materials with improved elasticity has enabled engines to operate at higher cylinder pressures without compromising reliability. This progression aligns with broader automotive industry trends toward higher-efficiency, higher-output engines in smaller packages.

The technical goals for modern LS2 rod bolt development include achieving tensile strength ratings exceeding 220,000 PSI, improving fatigue resistance through enhanced metallurgy, and maintaining dimensional stability under thermal cycling. Additionally, manufacturers aim to develop testing methodologies that accurately predict real-world performance beyond simple static load testing.

Understanding the relationship between bolt preload, stretch, and ultimate tensile strength represents a key area of focus, as proper installation techniques significantly impact performance outcomes. The industry continues to refine both the physical properties of these components and the analytical methods used to evaluate them, with digital modeling and simulation playing an increasingly important role in the development process.

As engine power capabilities continue to increase, the technological trajectory points toward further material innovations and design refinements to create rod bolts capable of supporting the next generation of high-performance LS2 applications, whether in racing, high-performance street, or specialized industrial environments.

Market Analysis of High-Performance Engine Components

The high-performance engine components market has experienced substantial growth over the past decade, driven primarily by increasing consumer demand for enhanced vehicle performance and efficiency. The global market for performance engine parts reached approximately $4.7 billion in 2022, with connecting rod components—including rod bolts—representing nearly $340 million of this total. This segment is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader automotive aftermarket.

The LS2 engine platform, introduced by General Motors in 2005, has become a cornerstone in the performance engine market due to its robust design, displacement potential, and widespread availability. Consequently, the market for LS2-specific components has developed into a highly competitive ecosystem with numerous manufacturers vying for market share. Rod bolts for these engines represent a critical niche within this ecosystem, with annual sales estimated at $28 million globally.

Consumer segmentation within this market reveals three distinct buyer categories. Professional racing teams and engine builders constitute approximately 15% of purchasers but account for nearly 30% of revenue due to their preference for premium-grade components. Enthusiast modifiers represent the largest segment at 65% of the market, typically seeking a balance between performance and cost. The remaining 20% consists of repair and maintenance customers who prioritize reliability over maximum performance capabilities.

Regional analysis indicates North America dominates the LS2 performance parts market with 68% market share, followed by Australia at 12%, Europe at 10%, and emerging markets in Asia and South America accounting for the remainder. This distribution closely follows the popularity of GM vehicles and motorsport activities that utilize LS-series engines.

Price sensitivity varies significantly across market segments. Professional users demonstrate low price elasticity, prioritizing documented performance metrics and reliability over cost considerations. The enthusiast segment shows moderate price sensitivity, with purchasing decisions heavily influenced by brand reputation and third-party testing results. The maintenance segment exhibits high price sensitivity, often selecting products based primarily on cost-performance ratio.

Distribution channels have evolved substantially, with online direct-to-consumer sales growing from 18% to 41% of total market volume over the past five years. Traditional distribution through specialty performance shops remains significant at 35%, while original equipment manufacturer (OEM) channels and general automotive retailers account for 14% and 10% respectively.

The LS2 engine platform, introduced by General Motors in 2005, has become a cornerstone in the performance engine market due to its robust design, displacement potential, and widespread availability. Consequently, the market for LS2-specific components has developed into a highly competitive ecosystem with numerous manufacturers vying for market share. Rod bolts for these engines represent a critical niche within this ecosystem, with annual sales estimated at $28 million globally.

Consumer segmentation within this market reveals three distinct buyer categories. Professional racing teams and engine builders constitute approximately 15% of purchasers but account for nearly 30% of revenue due to their preference for premium-grade components. Enthusiast modifiers represent the largest segment at 65% of the market, typically seeking a balance between performance and cost. The remaining 20% consists of repair and maintenance customers who prioritize reliability over maximum performance capabilities.

Regional analysis indicates North America dominates the LS2 performance parts market with 68% market share, followed by Australia at 12%, Europe at 10%, and emerging markets in Asia and South America accounting for the remainder. This distribution closely follows the popularity of GM vehicles and motorsport activities that utilize LS-series engines.

Price sensitivity varies significantly across market segments. Professional users demonstrate low price elasticity, prioritizing documented performance metrics and reliability over cost considerations. The enthusiast segment shows moderate price sensitivity, with purchasing decisions heavily influenced by brand reputation and third-party testing results. The maintenance segment exhibits high price sensitivity, often selecting products based primarily on cost-performance ratio.

Distribution channels have evolved substantially, with online direct-to-consumer sales growing from 18% to 41% of total market volume over the past five years. Traditional distribution through specialty performance shops remains significant at 35%, while original equipment manufacturer (OEM) channels and general automotive retailers account for 14% and 10% respectively.

Current Challenges in Rod Bolt Tensile Testing

The tensile testing of rod bolts for LS2 engines faces several significant technical challenges that impact both testing accuracy and practical application. Current testing methodologies often struggle with standardization issues, as different manufacturers employ varying protocols, making direct comparisons between bolt types problematic. This inconsistency creates difficulties in establishing reliable benchmarks for tensile strength across the industry.

Material composition variations present another substantial challenge. Rod bolts are manufactured using different alloy formulations, heat treatments, and manufacturing processes, all of which significantly affect tensile properties. Testing procedures must account for these variations to provide meaningful comparative data, yet many current methods fail to adequately control for these variables.

Environmental factors also complicate testing procedures. Temperature fluctuations during testing can dramatically alter results, as can humidity levels and exposure to engine fluids. Many current testing protocols do not sufficiently simulate real-world operating conditions, creating a disconnect between laboratory results and actual performance in high-stress engine environments.

The dynamic loading patterns experienced by rod bolts in operational engines represent another testing challenge. Most current tensile tests apply static loads, which fail to replicate the cyclic loading, vibration, and thermal cycling that bolts experience in functioning engines. This limitation means that static tensile strength measurements may not accurately predict bolt performance under actual operating conditions.

Measurement precision and repeatability issues further complicate testing efforts. Even small variations in testing equipment calibration, bolt positioning, or load application rates can produce significantly different results. The industry currently lacks universally accepted calibration standards for rod bolt tensile testing equipment.

Non-destructive testing limitations also present challenges. While destructive testing provides definitive tensile strength data, it eliminates the possibility of testing the same bolt under different conditions. Current non-destructive methods often lack the precision needed for high-performance applications where small differences in tensile strength can have significant consequences.

Cost and accessibility barriers further restrict comprehensive testing. High-precision tensile testing equipment requires significant investment, limiting access for smaller manufacturers and aftermarket parts producers. This creates information asymmetry in the market and potentially compromises quality control across the industry.

Material composition variations present another substantial challenge. Rod bolts are manufactured using different alloy formulations, heat treatments, and manufacturing processes, all of which significantly affect tensile properties. Testing procedures must account for these variations to provide meaningful comparative data, yet many current methods fail to adequately control for these variables.

Environmental factors also complicate testing procedures. Temperature fluctuations during testing can dramatically alter results, as can humidity levels and exposure to engine fluids. Many current testing protocols do not sufficiently simulate real-world operating conditions, creating a disconnect between laboratory results and actual performance in high-stress engine environments.

The dynamic loading patterns experienced by rod bolts in operational engines represent another testing challenge. Most current tensile tests apply static loads, which fail to replicate the cyclic loading, vibration, and thermal cycling that bolts experience in functioning engines. This limitation means that static tensile strength measurements may not accurately predict bolt performance under actual operating conditions.

Measurement precision and repeatability issues further complicate testing efforts. Even small variations in testing equipment calibration, bolt positioning, or load application rates can produce significantly different results. The industry currently lacks universally accepted calibration standards for rod bolt tensile testing equipment.

Non-destructive testing limitations also present challenges. While destructive testing provides definitive tensile strength data, it eliminates the possibility of testing the same bolt under different conditions. Current non-destructive methods often lack the precision needed for high-performance applications where small differences in tensile strength can have significant consequences.

Cost and accessibility barriers further restrict comprehensive testing. High-precision tensile testing equipment requires significant investment, limiting access for smaller manufacturers and aftermarket parts producers. This creates information asymmetry in the market and potentially compromises quality control across the industry.

Methodologies for Rod Bolt Tensile Strength Comparison

01 High-strength materials for engine rod bolts

Engine rod bolts, particularly for high-performance engines like the LS2, require materials with superior tensile strength to withstand extreme operating conditions. These bolts are typically manufactured using specialized alloy steels that undergo heat treatment processes to achieve optimal mechanical properties. The materials used often include chromium-molybdenum alloys or other high-strength steel compositions that can maintain their integrity under high temperatures and cyclic loading conditions.- High-strength materials for engine rod bolts: Various high-strength materials are used for manufacturing engine rod bolts to achieve the required tensile strength. These materials include specialized steel alloys, titanium alloys, and other composite materials that can withstand the extreme forces and temperatures in an engine environment. The material selection directly impacts the tensile strength properties of the rod bolts used in LS2 engines.

- Manufacturing processes for enhancing tensile strength: Specific manufacturing processes are employed to enhance the tensile strength of engine rod bolts. These processes include heat treatment, forging, cold working, and specialized surface treatments. The manufacturing methodology significantly affects the mechanical properties of the rod bolts, particularly their tensile strength and durability under high-stress conditions in LS2 engines.

- Testing and measurement methods for rod bolt tensile strength: Various testing and measurement methods are used to evaluate the tensile strength of engine rod bolts. These include tensile testing machines, stress analysis, fatigue testing, and non-destructive testing methods. These testing procedures ensure that the rod bolts meet the required specifications for use in high-performance engines like the LS2, where reliability under extreme conditions is crucial.

- Design innovations for improved tensile performance: Design innovations in rod bolts focus on improving tensile performance through geometric optimizations, thread design, and stress distribution considerations. These innovations include specialized head designs, thread profiles, and material distribution patterns that enhance the overall tensile strength and fatigue resistance of the bolts used in LS2 engines.

- Fastening systems and torque specifications: Fastening systems and torque specifications are critical for achieving optimal tensile strength in engine rod bolts. These include precise torque values, bolt stretching methods, and assembly procedures that ensure proper preload and clamping force. The correct installation and torque application significantly impact the effective tensile strength and performance of rod bolts in LS2 engines under operating conditions.

02 Fastening systems and torque specifications for engine connecting rods

The fastening systems used in engine connecting rods, including those in LS2 engines, are designed with specific torque specifications to achieve the required tensile strength. These systems often incorporate precise bolt stretching methods rather than simple torque measurements to ensure optimal clamping force. The design of the fastening system considers factors such as bolt diameter, thread pitch, and head design to distribute stress evenly and prevent failure under high-load conditions.Expand Specific Solutions03 Manufacturing processes affecting rod bolt tensile strength

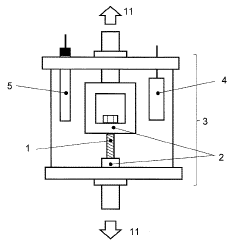

The manufacturing processes used for engine rod bolts significantly impact their tensile strength. These processes include precision forging, rolling of threads rather than cutting to preserve grain structure, and specialized heat treatment protocols. Surface treatments such as shot peening may be applied to increase fatigue resistance, while coatings can be used to reduce friction and improve torque consistency. Quality control measures during manufacturing ensure consistent tensile strength properties across production batches.Expand Specific Solutions04 Testing methods for rod bolt tensile strength verification

Various testing methods are employed to verify the tensile strength of engine rod bolts. These include direct tensile testing, fatigue cycle testing, and ultrasonic measurement techniques to detect internal flaws. Specialized equipment is used to apply controlled loads to the bolts until failure, allowing for precise measurement of yield strength, ultimate tensile strength, and elongation properties. These tests ensure that the bolts meet the stringent requirements for high-performance engines like the LS2.Expand Specific Solutions05 Innovative designs for improved rod bolt performance

Innovative designs have been developed to improve the performance of engine rod bolts. These include asymmetrical thread profiles that distribute stress more effectively, tapered shanks that optimize load distribution, and specialized head designs that improve seating and reduce stress concentration. Some designs incorporate unique material combinations or composite structures to achieve higher tensile strength while maintaining necessary elasticity. These innovations help to increase the reliability and durability of rod bolts in high-performance applications.Expand Specific Solutions

Leading Manufacturers in Performance Engine Fasteners

The LS2 engine rod bolt tensile strength comparison market is in a growth phase, with increasing demand driven by automotive performance and racing sectors. The market size is expanding as more vehicle owners seek high-performance upgrades, though it remains a specialized segment within the broader automotive components industry. Technologically, this field shows moderate maturity with established testing methodologies, but continuous innovation from key players. Companies like Nissan, Honda, and Renault bring significant automotive engineering expertise, while specialized materials firms such as BASF, Arconic Technologies, and JFE Steel contribute advanced metallurgical knowledge. Academic institutions including Chongqing University and Harbin Institute of Technology provide research support, creating a competitive landscape balanced between established manufacturers and innovative materials science companies.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a comprehensive testing methodology for LS2 engine rod bolts that combines digital strain analysis with physical testing protocols. Their approach utilizes high-precision torque-to-yield measurement systems that can detect microscopic elongation during the tightening process. Nissan's engineers have implemented a multi-stage validation process that includes ultrasonic measurement of bolt stretch, clamp load verification using specialized load cells, and cyclic fatigue testing under simulated engine operating conditions. Their testing protocol specifically addresses the unique metallurgical properties of LS2 connecting rod bolts, with particular attention to the effects of heat cycling on tensile strength retention. Nissan's research has established correlations between bolt preload, thread engagement percentage, and ultimate failure points.

Strengths: Superior data acquisition systems that can detect minute changes in bolt elongation during testing; extensive experience with various alloy compositions used in high-performance engine applications. Weaknesses: Their testing methodology requires specialized equipment that may not be accessible to smaller facilities; some of their proprietary testing protocols are not publicly available.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered an advanced comparative analysis system for LS2 engine rod bolts that integrates digital imaging with material science principles. Their methodology employs high-resolution strain mapping during tensile testing, allowing for precise identification of stress concentration points along the bolt shaft and thread roots. Honda's engineers utilize specialized fixtures that replicate exact engine block mounting conditions, ensuring test results accurately reflect real-world performance. Their protocol includes thermal cycling between tests to evaluate how repeated heating and cooling affects bolt integrity and clamping force retention. Honda has developed proprietary algorithms that correlate torque values with actual achieved preload, accounting for variables such as lubricant type, surface finish, and thread quality. Their comprehensive approach includes metallurgical analysis of failed specimens to identify failure modes and material limitations.

Strengths: Exceptional repeatability in test results through rigorous control of testing variables; sophisticated data analysis capabilities that can predict long-term performance based on short-term test results. Weaknesses: Their testing methodology is optimized for Honda's specific manufacturing tolerances and may require adaptation for aftermarket components; relatively high implementation cost for their complete testing protocol.

Critical Patents in High-Strength Fastener Technology

Steel bolt and method of manufacturing the same

PatentActiveJP2012233244A

Innovation

- A steel bolt with optimized chemical composition and controlled residual stress distribution, combined with specific quenching and tempering processes, ensures a tensile strength of 1200 MPa or more while maintaining a favorable ratio of compressive to tensile residual stress and suppressing surface hardness below 450 Vickers hardness.

Steel for bolts, and manufacturing method therefor

PatentPendingUS20240209469A1

Innovation

- A steel composition for bolts with specific chemical elements (C: 0.37-0.45%, Si: 0.01-0.08%, Mn: 0.45-0.80%, Cr: 0.90-1.30%, Mo: 0.20-0.45%, Ni: 0.10-0.30%, V: 0.15-0.30%, Al: 0.015-0.035%) and a manufacturing method involving smelting, casting, rough rolling, high-speed wire rolling, Stelmor controlled cooling, and heat treatment to achieve a uniform structure and high strength with improved delayed fracture resistance.

Quality Control Standards for Critical Engine Components

Quality control standards for critical engine components, particularly connecting rod bolts in LS2 engines, require rigorous testing and validation protocols to ensure operational safety and performance. These standards typically encompass material specifications, manufacturing tolerances, and testing methodologies that collectively guarantee the integrity of components under extreme mechanical stress conditions.

For connecting rod bolts specifically, tensile strength represents a critical quality parameter that directly impacts engine reliability and longevity. Industry standards such as SAE J429, ASTM A574, and ISO 898-1 provide baseline requirements for mechanical fasteners, though automotive manufacturers often implement more stringent proprietary specifications tailored to their specific engine designs and performance targets.

The quality control process for LS2 engine rod bolts typically begins with material certification, ensuring that the alloy composition meets specified requirements—typically chrome-molybdenum or similar high-strength steels. Heat treatment processes must be carefully controlled and validated to achieve the desired metallurgical properties without introducing structural weaknesses or hydrogen embrittlement.

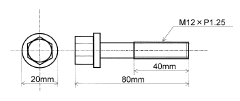

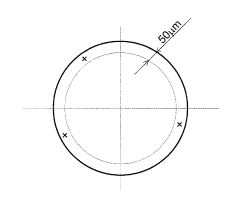

Dimensional inspection represents another crucial aspect of quality control, with critical dimensions such as thread pitch, minor diameter, and bolt length requiring verification against engineering specifications. Surface finish quality must also be assessed, as microscopic imperfections can serve as stress concentration points that potentially lead to premature failure under cyclic loading conditions.

Non-destructive testing methods including magnetic particle inspection, ultrasonic testing, and eddy current analysis are commonly employed to detect internal flaws or surface discontinuities that might compromise structural integrity. These techniques allow manufacturers to identify defects without sacrificing the components being tested.

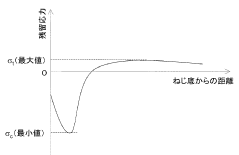

Destructive testing on statistical samples from production batches provides definitive validation of tensile strength properties. Such testing typically involves applying increasing axial loads until failure occurs, with data collected on yield strength, ultimate tensile strength, and elongation characteristics. The resulting stress-strain curves offer valuable insights into material behavior under load.

Fatigue testing represents perhaps the most critical quality control measure for rod bolts, as it simulates the cyclic loading conditions experienced during actual engine operation. Components must withstand specified numbers of load cycles without failure to meet qualification requirements, with test parameters designed to exceed normal operating conditions by substantial safety margins.

For connecting rod bolts specifically, tensile strength represents a critical quality parameter that directly impacts engine reliability and longevity. Industry standards such as SAE J429, ASTM A574, and ISO 898-1 provide baseline requirements for mechanical fasteners, though automotive manufacturers often implement more stringent proprietary specifications tailored to their specific engine designs and performance targets.

The quality control process for LS2 engine rod bolts typically begins with material certification, ensuring that the alloy composition meets specified requirements—typically chrome-molybdenum or similar high-strength steels. Heat treatment processes must be carefully controlled and validated to achieve the desired metallurgical properties without introducing structural weaknesses or hydrogen embrittlement.

Dimensional inspection represents another crucial aspect of quality control, with critical dimensions such as thread pitch, minor diameter, and bolt length requiring verification against engineering specifications. Surface finish quality must also be assessed, as microscopic imperfections can serve as stress concentration points that potentially lead to premature failure under cyclic loading conditions.

Non-destructive testing methods including magnetic particle inspection, ultrasonic testing, and eddy current analysis are commonly employed to detect internal flaws or surface discontinuities that might compromise structural integrity. These techniques allow manufacturers to identify defects without sacrificing the components being tested.

Destructive testing on statistical samples from production batches provides definitive validation of tensile strength properties. Such testing typically involves applying increasing axial loads until failure occurs, with data collected on yield strength, ultimate tensile strength, and elongation characteristics. The resulting stress-strain curves offer valuable insights into material behavior under load.

Fatigue testing represents perhaps the most critical quality control measure for rod bolts, as it simulates the cyclic loading conditions experienced during actual engine operation. Components must withstand specified numbers of load cycles without failure to meet qualification requirements, with test parameters designed to exceed normal operating conditions by substantial safety margins.

Failure Analysis Techniques for Rod Bolt Assessment

Failure analysis of rod bolts is a critical component in evaluating tensile strength comparisons for LS2 engine components. The methodologies employed must be systematic and comprehensive to ensure accurate assessment of failure modes and prevention strategies. These techniques can be broadly categorized into non-destructive and destructive testing approaches, each offering unique insights into bolt integrity.

Non-destructive testing (NDT) methods provide valuable preliminary data without compromising the bolt structure. Ultrasonic testing can detect internal flaws by measuring sound wave reflections through the bolt material. Magnetic particle inspection is particularly effective for ferromagnetic rod bolts, revealing surface and near-surface discontinuities that may lead to failure under tension. X-ray and computed tomography scanning offer detailed internal visualization of potential defects, while dye penetrant testing highlights surface cracks invisible to the naked eye.

Destructive testing techniques, while sacrificing the test specimen, deliver definitive tensile strength data. Tensile testing to failure provides direct measurement of ultimate tensile strength, yield strength, and elongation properties. Metallographic examination of fractured surfaces reveals microstructural characteristics and failure mechanisms. Hardness testing correlates with tensile properties and can identify inconsistencies in heat treatment or material composition across different bolt manufacturers.

Chemical composition analysis using spectrometry identifies material deviations that may compromise performance. This is particularly relevant when comparing OEM versus aftermarket rod bolts for LS2 engines, where material substitutions might occur. Scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) provides high-resolution imaging of fracture surfaces and elemental analysis at failure points.

Fatigue testing simulates real-world cyclic loading conditions, critical for engine components subjected to repeated stress cycles. Specialized equipment applies alternating loads at frequencies representative of engine operation, generating S-N curves (stress vs. number of cycles) that predict service life under various loading conditions. This data is invaluable when comparing different rod bolt designs or materials.

Finite element analysis (FEA) complements physical testing by modeling stress distributions under various loading scenarios. This computational approach can identify stress concentration points before physical testing begins, guiding test protocols and design improvements. When combined with actual test data, FEA creates powerful predictive models for bolt performance under diverse operating conditions.

Implementation of these failure analysis techniques must follow standardized protocols such as ASTM E8 for tensile testing and ASTM E606 for fatigue testing to ensure reproducibility and valid comparisons between different LS2 rod bolt options.

Non-destructive testing (NDT) methods provide valuable preliminary data without compromising the bolt structure. Ultrasonic testing can detect internal flaws by measuring sound wave reflections through the bolt material. Magnetic particle inspection is particularly effective for ferromagnetic rod bolts, revealing surface and near-surface discontinuities that may lead to failure under tension. X-ray and computed tomography scanning offer detailed internal visualization of potential defects, while dye penetrant testing highlights surface cracks invisible to the naked eye.

Destructive testing techniques, while sacrificing the test specimen, deliver definitive tensile strength data. Tensile testing to failure provides direct measurement of ultimate tensile strength, yield strength, and elongation properties. Metallographic examination of fractured surfaces reveals microstructural characteristics and failure mechanisms. Hardness testing correlates with tensile properties and can identify inconsistencies in heat treatment or material composition across different bolt manufacturers.

Chemical composition analysis using spectrometry identifies material deviations that may compromise performance. This is particularly relevant when comparing OEM versus aftermarket rod bolts for LS2 engines, where material substitutions might occur. Scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) provides high-resolution imaging of fracture surfaces and elemental analysis at failure points.

Fatigue testing simulates real-world cyclic loading conditions, critical for engine components subjected to repeated stress cycles. Specialized equipment applies alternating loads at frequencies representative of engine operation, generating S-N curves (stress vs. number of cycles) that predict service life under various loading conditions. This data is invaluable when comparing different rod bolt designs or materials.

Finite element analysis (FEA) complements physical testing by modeling stress distributions under various loading scenarios. This computational approach can identify stress concentration points before physical testing begins, guiding test protocols and design improvements. When combined with actual test data, FEA creates powerful predictive models for bolt performance under diverse operating conditions.

Implementation of these failure analysis techniques must follow standardized protocols such as ASTM E8 for tensile testing and ASTM E606 for fatigue testing to ensure reproducibility and valid comparisons between different LS2 rod bolt options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!