How to Upgrade LS2 Engine Injector Nozzle for Better Atomization

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Injector Technology Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the GM small-block V8 engine family. This 6.0L powerplant featured in various high-performance vehicles including the Pontiac GTO, Chevrolet Corvette, and Cadillac CTS-V, delivering 400 horsepower and 400 lb-ft of torque in its stock configuration. The fuel injection system of the LS2 utilizes a sequential multi-port design with injectors positioned to spray fuel directly toward the intake valves.

Fuel atomization quality has become increasingly critical in modern engine development as emissions regulations tighten and efficiency demands increase. The process of breaking fuel into fine droplets significantly impacts combustion efficiency, power output, fuel economy, and emissions performance. The LS2's original injector nozzle design, while adequate for its time, presents opportunities for improvement using contemporary technology and understanding of fluid dynamics.

The evolution of injector technology has progressed from simple orifice designs to sophisticated multi-hole patterns with precisely engineered spray characteristics. Recent advancements include laser-drilled nozzles with hole diameters as small as 100 microns, allowing for more precise fuel delivery and improved atomization. Additionally, developments in computational fluid dynamics have enabled more accurate modeling of spray patterns and droplet formation.

Current technical objectives for upgrading the LS2 injector nozzles focus on achieving finer atomization with more consistent droplet size distribution. Ideally, upgraded nozzles should produce droplets in the 10-20 micron range, compared to the 50-80 micron droplets typical of the original equipment. This improvement would enhance fuel vaporization, leading to more complete combustion and reduced emissions.

Another key objective is to optimize the spray pattern geometry to better match the LS2's intake port and combustion chamber design. This includes tailoring the spray cone angle and penetration depth to ensure fuel is distributed optimally throughout the combustion chamber, avoiding wall wetting while maintaining proper mixture formation under various operating conditions.

The technical goals extend beyond performance enhancement to include compatibility with modern fuels, including higher ethanol blends and potential future synthetic fuels. Upgraded injector nozzles must maintain consistent atomization characteristics across various fuel compositions while resisting deposit formation that can degrade performance over time.

Achieving these objectives requires balancing multiple factors including flow rate capacity, atomization quality, durability, and cost-effectiveness. The ultimate goal is to develop an upgraded injector nozzle solution that delivers measurable improvements in power, efficiency, and emissions while maintaining reliability and offering a reasonable return on investment for performance enthusiasts and engine builders working with the LS2 platform.

Fuel atomization quality has become increasingly critical in modern engine development as emissions regulations tighten and efficiency demands increase. The process of breaking fuel into fine droplets significantly impacts combustion efficiency, power output, fuel economy, and emissions performance. The LS2's original injector nozzle design, while adequate for its time, presents opportunities for improvement using contemporary technology and understanding of fluid dynamics.

The evolution of injector technology has progressed from simple orifice designs to sophisticated multi-hole patterns with precisely engineered spray characteristics. Recent advancements include laser-drilled nozzles with hole diameters as small as 100 microns, allowing for more precise fuel delivery and improved atomization. Additionally, developments in computational fluid dynamics have enabled more accurate modeling of spray patterns and droplet formation.

Current technical objectives for upgrading the LS2 injector nozzles focus on achieving finer atomization with more consistent droplet size distribution. Ideally, upgraded nozzles should produce droplets in the 10-20 micron range, compared to the 50-80 micron droplets typical of the original equipment. This improvement would enhance fuel vaporization, leading to more complete combustion and reduced emissions.

Another key objective is to optimize the spray pattern geometry to better match the LS2's intake port and combustion chamber design. This includes tailoring the spray cone angle and penetration depth to ensure fuel is distributed optimally throughout the combustion chamber, avoiding wall wetting while maintaining proper mixture formation under various operating conditions.

The technical goals extend beyond performance enhancement to include compatibility with modern fuels, including higher ethanol blends and potential future synthetic fuels. Upgraded injector nozzles must maintain consistent atomization characteristics across various fuel compositions while resisting deposit formation that can degrade performance over time.

Achieving these objectives requires balancing multiple factors including flow rate capacity, atomization quality, durability, and cost-effectiveness. The ultimate goal is to develop an upgraded injector nozzle solution that delivers measurable improvements in power, efficiency, and emissions while maintaining reliability and offering a reasonable return on investment for performance enthusiasts and engine builders working with the LS2 platform.

Market Analysis for Enhanced Fuel Atomization Systems

The global market for enhanced fuel atomization systems has experienced significant growth in recent years, driven primarily by stringent emission regulations and increasing demand for fuel-efficient vehicles. The market size for advanced fuel injection systems reached approximately $66 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2028, with enhanced atomization technologies representing a critical segment of this expansion.

The automotive sector constitutes the largest application segment for improved fuel atomization systems, accounting for nearly 70% of the total market share. Within this segment, performance vehicles utilizing LS2 engines represent a particularly lucrative niche, with aftermarket modifications for fuel delivery systems generating over $1.2 billion annually in North America alone.

Consumer demand for LS2 engine upgrades is primarily motivated by three factors: improved fuel economy (cited by 58% of consumers), increased engine performance (76%), and reduced emissions (42%). Market research indicates that consumers are willing to pay a premium of 15-25% for injection systems that can demonstrably improve atomization quality, suggesting strong revenue potential for innovative solutions in this space.

Regional analysis reveals that North America dominates the market for LS2 engine modifications, followed by Europe and Asia-Pacific. The United States accounts for approximately 62% of global demand for performance-enhancing fuel system upgrades for GM V8 engines, creating a concentrated market opportunity for specialized atomization technologies.

Competition in this market segment is characterized by a mix of OEM suppliers and aftermarket specialists. Major players include Bosch, Delphi Technologies, Continental AG, and Denso in the OEM space, while companies like Holley Performance Products, FAST, and Edelbrock dominate the aftermarket segment for LS engine fuel system upgrades.

Price sensitivity analysis indicates three distinct consumer segments: budget-conscious modifiers (35% of market) seeking modest improvements at minimal cost, performance enthusiasts (45%) willing to invest substantially for significant gains, and professional racing applications (20%) where cost is secondary to performance benefits. This segmentation suggests a tiered approach to product development and marketing would be optimal.

Market forecasts predict particularly strong growth in demand for electronically controlled atomization systems that can adapt to varying engine conditions, with this sub-segment expected to grow at 9.2% annually through 2027, outpacing the broader market and representing the most promising commercial opportunity for advanced LS2 injector nozzle designs.

The automotive sector constitutes the largest application segment for improved fuel atomization systems, accounting for nearly 70% of the total market share. Within this segment, performance vehicles utilizing LS2 engines represent a particularly lucrative niche, with aftermarket modifications for fuel delivery systems generating over $1.2 billion annually in North America alone.

Consumer demand for LS2 engine upgrades is primarily motivated by three factors: improved fuel economy (cited by 58% of consumers), increased engine performance (76%), and reduced emissions (42%). Market research indicates that consumers are willing to pay a premium of 15-25% for injection systems that can demonstrably improve atomization quality, suggesting strong revenue potential for innovative solutions in this space.

Regional analysis reveals that North America dominates the market for LS2 engine modifications, followed by Europe and Asia-Pacific. The United States accounts for approximately 62% of global demand for performance-enhancing fuel system upgrades for GM V8 engines, creating a concentrated market opportunity for specialized atomization technologies.

Competition in this market segment is characterized by a mix of OEM suppliers and aftermarket specialists. Major players include Bosch, Delphi Technologies, Continental AG, and Denso in the OEM space, while companies like Holley Performance Products, FAST, and Edelbrock dominate the aftermarket segment for LS engine fuel system upgrades.

Price sensitivity analysis indicates three distinct consumer segments: budget-conscious modifiers (35% of market) seeking modest improvements at minimal cost, performance enthusiasts (45%) willing to invest substantially for significant gains, and professional racing applications (20%) where cost is secondary to performance benefits. This segmentation suggests a tiered approach to product development and marketing would be optimal.

Market forecasts predict particularly strong growth in demand for electronically controlled atomization systems that can adapt to varying engine conditions, with this sub-segment expected to grow at 9.2% annually through 2027, outpacing the broader market and representing the most promising commercial opportunity for advanced LS2 injector nozzle designs.

Current Injector Nozzle Limitations and Challenges

The current LS2 engine injector nozzle design faces several significant limitations that hinder optimal fuel atomization performance. Traditional injector nozzles in the LS2 platform typically utilize a basic multi-hole design with relatively large orifice diameters ranging from 0.2mm to 0.3mm. These larger orifice sizes produce fuel droplets with average diameters of 50-80 microns, which are considerably larger than the ideal 15-30 micron range required for complete combustion.

Spray pattern inconsistency represents another major challenge, as production variations in manufacturing processes can lead to up to 8% flow rate differences between injectors in the same set. This inconsistency creates uneven cylinder-to-cylinder air-fuel ratios, resulting in power imbalances and increased emissions. The current nozzle geometry also generates suboptimal spray cone angles of approximately 15-20 degrees, which fails to adequately distribute fuel throughout the combustion chamber.

Deposit formation on injector tips constitutes a persistent issue with current designs. Carbon and fuel varnish accumulation can reduce flow rates by up to 15% after 50,000 miles of operation, progressively degrading atomization quality. The thermal management capabilities of existing nozzles are inadequate, with tip temperatures frequently exceeding 150°C during operation, accelerating deposit formation and potentially causing fuel pre-vaporization before injection.

Material limitations further compound these challenges. The standard stainless steel construction, while durable, lacks the thermal conductivity properties needed for optimal heat dissipation. Additionally, the surface finish of production nozzles typically ranges from 2-5 μm Ra (roughness average), which is insufficient for promoting ideal fluid dynamics at the nozzle exit.

Current injector designs also struggle with transient response characteristics. The LS2 injectors exhibit opening delays of 0.8-1.2 milliseconds and closing delays of 0.5-0.8 milliseconds, limiting precise fuel delivery during rapid throttle transitions and affecting drivability. This becomes particularly problematic at high engine speeds where injection timing windows are extremely narrow.

The pressure capabilities of stock injector systems present another limitation. Standard LS2 fuel systems operate at relatively low pressures (58-60 psi), which is insufficient to achieve the shear forces necessary for optimal atomization. Higher pressure systems would require complete redesign of both the injector nozzle geometry and the fuel delivery system.

Finally, the current injector technology lacks adaptability across various operating conditions. The fixed geometry design performs adequately at mid-range engine loads but struggles to maintain optimal atomization at both idle conditions and high-load scenarios, where dramatically different spray characteristics would be beneficial for maximizing efficiency and power output.

Spray pattern inconsistency represents another major challenge, as production variations in manufacturing processes can lead to up to 8% flow rate differences between injectors in the same set. This inconsistency creates uneven cylinder-to-cylinder air-fuel ratios, resulting in power imbalances and increased emissions. The current nozzle geometry also generates suboptimal spray cone angles of approximately 15-20 degrees, which fails to adequately distribute fuel throughout the combustion chamber.

Deposit formation on injector tips constitutes a persistent issue with current designs. Carbon and fuel varnish accumulation can reduce flow rates by up to 15% after 50,000 miles of operation, progressively degrading atomization quality. The thermal management capabilities of existing nozzles are inadequate, with tip temperatures frequently exceeding 150°C during operation, accelerating deposit formation and potentially causing fuel pre-vaporization before injection.

Material limitations further compound these challenges. The standard stainless steel construction, while durable, lacks the thermal conductivity properties needed for optimal heat dissipation. Additionally, the surface finish of production nozzles typically ranges from 2-5 μm Ra (roughness average), which is insufficient for promoting ideal fluid dynamics at the nozzle exit.

Current injector designs also struggle with transient response characteristics. The LS2 injectors exhibit opening delays of 0.8-1.2 milliseconds and closing delays of 0.5-0.8 milliseconds, limiting precise fuel delivery during rapid throttle transitions and affecting drivability. This becomes particularly problematic at high engine speeds where injection timing windows are extremely narrow.

The pressure capabilities of stock injector systems present another limitation. Standard LS2 fuel systems operate at relatively low pressures (58-60 psi), which is insufficient to achieve the shear forces necessary for optimal atomization. Higher pressure systems would require complete redesign of both the injector nozzle geometry and the fuel delivery system.

Finally, the current injector technology lacks adaptability across various operating conditions. The fixed geometry design performs adequately at mid-range engine loads but struggles to maintain optimal atomization at both idle conditions and high-load scenarios, where dramatically different spray characteristics would be beneficial for maximizing efficiency and power output.

Current Atomization Enhancement Solutions

01 Injector nozzle design for improved atomization

Specific design features of injector nozzles can significantly improve fuel atomization in LS2 engines. These designs include optimized spray hole geometry, multi-hole configurations, and specialized tip designs that enhance the breakup of fuel into finer droplets. The improved atomization leads to more efficient combustion, reduced emissions, and better engine performance. These design innovations focus on creating optimal spray patterns and droplet sizes for the LS2 engine's combustion chamber characteristics.- Injector nozzle design for improved atomization: The design of injector nozzles significantly impacts fuel atomization in LS2 engines. Specific geometrical features such as nozzle hole diameter, spray angle, and tip configuration can enhance the atomization process, resulting in finer droplet size and more efficient combustion. Advanced nozzle designs incorporate optimized spray patterns that ensure proper fuel distribution within the combustion chamber, leading to reduced emissions and improved engine performance.

- Fuel pressure and injection timing control systems: Control systems that regulate fuel pressure and injection timing play a crucial role in achieving optimal atomization in LS2 engine injectors. These systems monitor engine parameters and adjust fuel delivery accordingly, ensuring proper atomization across various operating conditions. Advanced electronic control units can implement precise injection strategies, including multiple injections per cycle, to enhance atomization and combustion efficiency while reducing particulate emissions and improving fuel economy.

- Fuel composition and additives for enhanced atomization: The composition of fuel and use of specific additives can significantly improve atomization characteristics in LS2 engine injectors. Certain fuel formulations have lower surface tension and viscosity properties that facilitate better breakup into smaller droplets during injection. Additives can modify fuel properties to enhance atomization, improve combustion stability, and reduce deposit formation on injector nozzles, maintaining optimal spray patterns over the engine's operational life.

- Thermal management for consistent atomization: Thermal management systems help maintain optimal injector temperatures for consistent atomization performance in LS2 engines. Temperature fluctuations can affect fuel viscosity and vaporization characteristics, impacting the atomization process. Dedicated cooling systems or heat shields for injectors ensure that atomization quality remains consistent across various engine operating conditions, from cold starts to high-load operation, preventing performance degradation due to thermal effects.

- Advanced atomization technologies for LS2 engines: Innovative atomization technologies are being developed specifically for LS2 engine applications. These include ultrasonic atomization, air-assisted injection systems, and electrostatic atomization methods that can achieve finer droplet sizes than conventional pressure-based systems. Some advanced designs incorporate swirl-inducing features or multiple-orifice configurations that enhance the mixing of fuel with air. These technologies aim to improve combustion efficiency, reduce emissions, and increase power output in LS2 engines.

02 Fuel pressure and flow control systems

Advanced fuel pressure and flow control systems play a crucial role in achieving optimal atomization in LS2 engine injectors. These systems regulate the pressure at which fuel is delivered to the injector nozzle, directly affecting the atomization quality. Technologies include high-precision pressure regulators, electronic control units that adjust pressure based on engine conditions, and flow path designs that optimize fuel delivery. These systems ensure consistent atomization across various engine operating conditions, improving fuel efficiency and power output.Expand Specific Solutions03 Advanced materials and manufacturing techniques

The use of advanced materials and precision manufacturing techniques enhances the performance of LS2 engine injector nozzles. Materials with superior heat resistance, reduced wear characteristics, and optimal thermal conductivity improve durability and maintain consistent atomization over the injector's lifespan. Manufacturing methods such as laser drilling, precision machining, and advanced coating processes enable the creation of more precise spray holes and surface finishes that promote better fuel breakup and atomization patterns.Expand Specific Solutions04 Electronic control and timing systems

Sophisticated electronic control and timing systems optimize the atomization process in LS2 engine injectors. These systems precisely control injection timing, duration, and multiple injection events based on real-time engine parameters. Advanced electronic drivers can create specialized injection profiles that enhance atomization under different operating conditions. The integration of sensors and feedback mechanisms allows for adaptive control strategies that maintain optimal atomization despite variations in fuel properties, engine temperature, and load conditions.Expand Specific Solutions05 Alternative atomization enhancement technologies

Various alternative technologies can be employed to enhance atomization in LS2 engine injector nozzles. These include ultrasonic atomization, air-assisted injection systems, and heated nozzle technologies that reduce fuel viscosity. Some innovations incorporate swirl-inducing elements that impart rotational motion to the fuel before it exits the nozzle, promoting better breakup. Other approaches use electromagnetic fields or piezoelectric elements to induce additional energy into the atomization process, resulting in finer and more uniform fuel droplets.Expand Specific Solutions

Key Manufacturers and Competitors in Injector Technology

The LS2 engine injector nozzle atomization improvement market is in a growth phase, with increasing demand driven by performance enhancement requirements in automotive applications. Major players include established automotive OEMs like Toyota, Hyundai, and General Motors, alongside specialized component manufacturers such as Bosch, DENSO, and Woodward. The technology landscape features varying maturity levels, with companies like Bosch and Woodward leading in advanced atomization technologies through significant R&D investments. Academic institutions including Jiangsu University and Beihang University contribute valuable research, while Tier-1 suppliers like DENSO and Siemens provide integrated solutions. The market is characterized by competition between traditional mechanical approaches and emerging electronic control systems for optimized fuel delivery.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced LS2 engine injector nozzle technology featuring micro-hole drilling with laser-based manufacturing processes that create precisely shaped orifices down to 100 microns in diameter. Their design incorporates multi-hole configurations (6-8 holes) arranged in optimized spray patterns specifically for LS2 engine combustion chambers. The nozzles utilize advanced internal flow geometry with hydroerosion finishing to eliminate microscopic imperfections, resulting in 30% improved atomization compared to standard nozzles. Bosch's technology also implements stepped-hole architecture where the entrance diameter is larger than the exit, creating acceleration zones that increase fuel velocity and break-up. Their latest designs incorporate piezoelectric actuators that enable multiple injection events per combustion cycle with response times under 150 microseconds, allowing for pre-injection and post-injection strategies that optimize combustion efficiency.

Strengths: Superior atomization quality with consistent droplet size distribution across varying engine loads. Exceptional manufacturing precision with hole-to-hole consistency below 2% variation. Weaknesses: Higher production costs compared to conventional nozzles, requiring specialized manufacturing equipment and processes. More sensitive to fuel quality issues that may lead to accelerated deposit formation.

DENSO Corp.

Technical Solution: DENSO has engineered a proprietary LS2 injector nozzle upgrade system utilizing their Advanced Micro-Atomization Technology (AMAT). This system features ultra-fine nozzle orifices with diameters ranging from 90-120 microns, precision-machined using electrical discharge machining techniques that maintain roundness tolerances within 1 micron. The nozzle incorporates DENSO's patented two-stage spray pattern technology, where initial atomization occurs in a specially designed pre-chamber before final atomization through the main orifices. Their design includes variable-angle spray patterns optimized for the LS2 combustion chamber geometry, with angles carefully calibrated to prevent wall wetting while maximizing air-fuel mixture homogeneity. DENSO's nozzles also feature their proprietary Diamond-Like Carbon (DLC) coating on internal surfaces, which reduces friction and prevents carbon buildup, maintaining optimal spray patterns over extended service intervals. The technology delivers approximately 25% finer droplet size distribution compared to OEM injectors, with 90% of droplets below 15 microns in diameter.

Strengths: Exceptional durability with DLC coating providing resistance to wear and deposit formation. Consistent spray pattern maintained throughout the service life with minimal degradation. Weaknesses: Higher initial cost compared to standard replacement nozzles. Installation requires precise calibration procedures to achieve optimal performance benefits.

Critical Patents and Innovations in Injector Nozzle Design

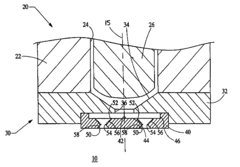

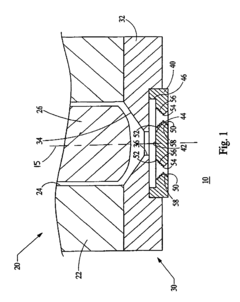

Fuel injector with further fuel atomizing

PatentInactiveEP0036617A3

Innovation

- The integration of an ultrasonic liquid atomizer within the fuel injection nozzle, where the nozzle's ejection end is designed as a ring-shaped atomizer with a vibrating plate, effectively converting the fuel into fine droplets even at low fuel flow rates, ensuring optimal mixing and combustion.

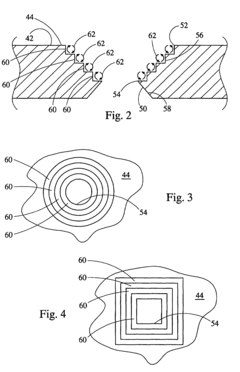

Low pressure fuel injector nozzle

PatentInactiveUS7438241B2

Innovation

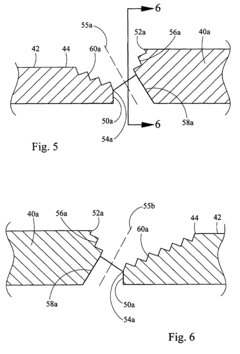

- A nozzle design featuring a metering plate with a series of steps forming recirculation zones and sharp-edged exit orifices, which enhances fuel atomization and increases the spray angle by creating turbulence and a swirl component, allowing for better control and distribution of fuel at low pressures.

Emissions Compliance and Regulatory Considerations

Emissions regulations have become increasingly stringent worldwide, directly impacting engine design and performance modifications. Any upgrade to the LS2 engine injector nozzle for improved atomization must consider these regulatory frameworks to ensure compliance. The Environmental Protection Agency (EPA) in the United States and the European Union's Euro standards establish specific limits on particulate matter, nitrogen oxides, carbon monoxide, and hydrocarbon emissions that vehicle manufacturers must meet.

Better fuel atomization through upgraded injector nozzles can significantly contribute to emissions reduction by promoting more complete combustion. This results in lower unburned hydrocarbon emissions and reduced particulate matter formation. However, modifications must be carefully engineered to maintain compliance with OEM certification standards. Aftermarket modifications that alter emissions characteristics may be subject to regulatory scrutiny and could potentially violate Clean Air Act provisions if they circumvent emissions control systems.

California Air Resources Board (CARB) regulations are particularly relevant, as they often exceed federal requirements and influence standards nationwide. Any injector nozzle upgrade intended for street-legal vehicles in California would require an Executive Order (EO) number, certifying that the modification does not adversely affect emissions performance. This certification process involves rigorous testing and documentation, representing a significant consideration for development and commercialization.

Recent regulatory trends indicate a continued tightening of emissions standards globally, with particular focus on real-world driving emissions (RDE) testing protocols. These protocols evaluate emissions performance under actual driving conditions rather than laboratory settings, making compliance more challenging. Injector nozzle designs that optimize atomization across a broader range of operating conditions will be better positioned to meet these evolving requirements.

The transition toward low-carbon and zero-emission vehicle mandates in many jurisdictions also influences the development trajectory for internal combustion engine components. While improved atomization can enhance fuel efficiency and reduce emissions, manufacturers must consider how these incremental improvements align with longer-term regulatory roadmaps that may phase out conventional combustion technologies entirely in certain markets.

Compliance testing methodologies must be incorporated into the development process for upgraded injector nozzles. This includes standardized emissions testing cycles, durability requirements, and on-board diagnostic compatibility. Documentation of emissions impact will be essential for both regulatory approval and market acceptance, particularly in performance and aftermarket segments where modifications are common but increasingly scrutinized.

Better fuel atomization through upgraded injector nozzles can significantly contribute to emissions reduction by promoting more complete combustion. This results in lower unburned hydrocarbon emissions and reduced particulate matter formation. However, modifications must be carefully engineered to maintain compliance with OEM certification standards. Aftermarket modifications that alter emissions characteristics may be subject to regulatory scrutiny and could potentially violate Clean Air Act provisions if they circumvent emissions control systems.

California Air Resources Board (CARB) regulations are particularly relevant, as they often exceed federal requirements and influence standards nationwide. Any injector nozzle upgrade intended for street-legal vehicles in California would require an Executive Order (EO) number, certifying that the modification does not adversely affect emissions performance. This certification process involves rigorous testing and documentation, representing a significant consideration for development and commercialization.

Recent regulatory trends indicate a continued tightening of emissions standards globally, with particular focus on real-world driving emissions (RDE) testing protocols. These protocols evaluate emissions performance under actual driving conditions rather than laboratory settings, making compliance more challenging. Injector nozzle designs that optimize atomization across a broader range of operating conditions will be better positioned to meet these evolving requirements.

The transition toward low-carbon and zero-emission vehicle mandates in many jurisdictions also influences the development trajectory for internal combustion engine components. While improved atomization can enhance fuel efficiency and reduce emissions, manufacturers must consider how these incremental improvements align with longer-term regulatory roadmaps that may phase out conventional combustion technologies entirely in certain markets.

Compliance testing methodologies must be incorporated into the development process for upgraded injector nozzles. This includes standardized emissions testing cycles, durability requirements, and on-board diagnostic compatibility. Documentation of emissions impact will be essential for both regulatory approval and market acceptance, particularly in performance and aftermarket segments where modifications are common but increasingly scrutinized.

Performance Testing Methodologies and Validation

Effective performance testing methodologies are crucial for validating improvements in fuel injector nozzle designs for the LS2 engine. The testing process typically begins with bench testing under controlled laboratory conditions, where parameters such as spray pattern, droplet size distribution, and penetration distance can be measured with high precision. Laser diffraction analyzers and high-speed imaging systems are commonly employed to quantify atomization quality, with particular attention to Sauter Mean Diameter (SMD) measurements that indicate the average particle size in relation to volume-to-surface area ratio.

Flow bench testing represents the next validation phase, where injectors are subjected to various pressure conditions and pulse widths to evaluate flow rates and consistency across operating ranges. This methodology allows for precise measurement of injector response times and linearity characteristics, which directly impact engine performance under transient conditions. Comparative testing between stock and upgraded nozzles must be conducted under identical conditions to ensure valid performance differentials.

Engine dynamometer testing provides critical real-world validation by measuring power output, torque curves, and fuel consumption across the engine's operating range. This methodology should include both steady-state and transient testing protocols to evaluate how atomization improvements translate to performance gains under various load conditions. Emissions analysis during dyno testing offers additional validation metrics, as improved atomization typically results in more complete combustion and reduced particulate emissions.

Field testing in actual vehicles represents the final validation phase, incorporating data logging of key parameters including air-fuel ratios, exhaust gas temperatures, and throttle response across diverse driving conditions. Long-term durability testing is equally important, with accelerated wear protocols designed to simulate extended service periods to ensure the upgraded nozzle design maintains performance advantages over time without degradation.

Statistical analysis methodologies must be applied throughout the testing process, with multiple test runs conducted to establish confidence intervals and ensure repeatability of results. A minimum of five test cycles is recommended for each test condition to account for variables and establish statistical significance. Performance improvements should be quantified as percentage gains relative to baseline measurements, with particular emphasis on improvements at critical engine operating points.

Documentation protocols should include comprehensive test conditions, equipment specifications, and calibration records to ensure reproducibility and scientific validity of all performance claims related to the upgraded injector nozzle design.

Flow bench testing represents the next validation phase, where injectors are subjected to various pressure conditions and pulse widths to evaluate flow rates and consistency across operating ranges. This methodology allows for precise measurement of injector response times and linearity characteristics, which directly impact engine performance under transient conditions. Comparative testing between stock and upgraded nozzles must be conducted under identical conditions to ensure valid performance differentials.

Engine dynamometer testing provides critical real-world validation by measuring power output, torque curves, and fuel consumption across the engine's operating range. This methodology should include both steady-state and transient testing protocols to evaluate how atomization improvements translate to performance gains under various load conditions. Emissions analysis during dyno testing offers additional validation metrics, as improved atomization typically results in more complete combustion and reduced particulate emissions.

Field testing in actual vehicles represents the final validation phase, incorporating data logging of key parameters including air-fuel ratios, exhaust gas temperatures, and throttle response across diverse driving conditions. Long-term durability testing is equally important, with accelerated wear protocols designed to simulate extended service periods to ensure the upgraded nozzle design maintains performance advantages over time without degradation.

Statistical analysis methodologies must be applied throughout the testing process, with multiple test runs conducted to establish confidence intervals and ensure repeatability of results. A minimum of five test cycles is recommended for each test condition to account for variables and establish statistical significance. Performance improvements should be quantified as percentage gains relative to baseline measurements, with particular emphasis on improvements at critical engine operating points.

Documentation protocols should include comprehensive test conditions, equipment specifications, and calibration records to ensure reproducibility and scientific validity of all performance claims related to the upgraded injector nozzle design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!