How to Optimize LS2 Engine Air Intake for Max Horsepower

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Air Intake Technology Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family, featuring a 6.0L displacement and aluminum block construction. This powerplant became renowned for its robust performance characteristics and substantial aftermarket support, making it a popular choice among performance enthusiasts and racing professionals. The air intake system serves as the respiratory system of this engine, directly influencing combustion efficiency, power output, and overall engine performance.

The development of air intake technology for internal combustion engines has progressed substantially over the past decades, transitioning from simple mechanical designs to sophisticated systems that optimize airflow dynamics. Early LS-series engines utilized relatively restrictive factory intake systems designed primarily for reliability and emissions compliance rather than maximum performance. The evolution of aftermarket solutions has demonstrated that significant power gains can be achieved through optimized intake design.

Current industry trends indicate a growing focus on computational fluid dynamics (CFD) analysis to perfect intake geometry, advanced materials to reduce weight and heat absorption, and integration with electronic engine management systems for adaptive performance. The convergence of these technologies has created new opportunities for substantial horsepower improvements without sacrificing reliability or emissions compliance.

The primary technical objective in LS2 air intake optimization is to maximize volumetric efficiency—the measure of how effectively an engine can breathe. This involves reducing restriction points, optimizing air velocity, ensuring proper air density, and minimizing turbulence that can disrupt airflow. Secondary objectives include maintaining or improving filtration efficiency to protect engine components and ensuring compatibility with existing engine management systems.

Quantifiable goals for LS2 intake optimization typically target 15-25 horsepower gains at peak RPM ranges, improved throttle response across the powerband, and enhanced torque characteristics particularly in mid-range RPM where street-driven vehicles operate most frequently. These improvements must be achieved while maintaining acceptable air filtration standards and without creating detrimental effects on other engine systems.

The technological trajectory suggests that future intake systems will increasingly incorporate active geometry components that can adapt to different driving conditions, integrated sensors for real-time airflow optimization, and composite materials that offer superior thermal and weight characteristics compared to traditional plastics or metals. Understanding this evolution is crucial for developing intake solutions that not only deliver immediate performance benefits but also align with broader industry directions.

The development of air intake technology for internal combustion engines has progressed substantially over the past decades, transitioning from simple mechanical designs to sophisticated systems that optimize airflow dynamics. Early LS-series engines utilized relatively restrictive factory intake systems designed primarily for reliability and emissions compliance rather than maximum performance. The evolution of aftermarket solutions has demonstrated that significant power gains can be achieved through optimized intake design.

Current industry trends indicate a growing focus on computational fluid dynamics (CFD) analysis to perfect intake geometry, advanced materials to reduce weight and heat absorption, and integration with electronic engine management systems for adaptive performance. The convergence of these technologies has created new opportunities for substantial horsepower improvements without sacrificing reliability or emissions compliance.

The primary technical objective in LS2 air intake optimization is to maximize volumetric efficiency—the measure of how effectively an engine can breathe. This involves reducing restriction points, optimizing air velocity, ensuring proper air density, and minimizing turbulence that can disrupt airflow. Secondary objectives include maintaining or improving filtration efficiency to protect engine components and ensuring compatibility with existing engine management systems.

Quantifiable goals for LS2 intake optimization typically target 15-25 horsepower gains at peak RPM ranges, improved throttle response across the powerband, and enhanced torque characteristics particularly in mid-range RPM where street-driven vehicles operate most frequently. These improvements must be achieved while maintaining acceptable air filtration standards and without creating detrimental effects on other engine systems.

The technological trajectory suggests that future intake systems will increasingly incorporate active geometry components that can adapt to different driving conditions, integrated sensors for real-time airflow optimization, and composite materials that offer superior thermal and weight characteristics compared to traditional plastics or metals. Understanding this evolution is crucial for developing intake solutions that not only deliver immediate performance benefits but also align with broader industry directions.

Market Analysis for High-Performance LS2 Engine Components

The high-performance aftermarket for LS2 engine components represents a significant segment within the automotive industry, with the air intake system being one of the most frequently modified components. The global automotive aftermarket was valued at approximately $390 billion in 2022, with performance parts accounting for roughly $45 billion of this total. Within this market, LS-series engine components constitute a robust niche, driven by the platform's popularity among performance enthusiasts and professional racers alike.

Consumer demand for LS2 air intake systems has shown consistent growth at around 7% annually over the past five years, outpacing the broader automotive aftermarket. This growth is primarily fueled by the increasing popularity of track days, street performance upgrades, and competitive motorsports that utilize the LS2 platform. Market research indicates that approximately 65% of LS2 engine owners perform some form of intake modification within the first two years of ownership.

The market segmentation for high-performance LS2 air intake systems reveals three distinct consumer categories. The enthusiast segment, comprising roughly 60% of the market, seeks moderate performance gains with minimal technical complexity and moderate price points ($300-$700). The serious performance segment, representing about 30% of consumers, demands significant horsepower increases and is willing to invest in premium solutions ($700-$1,500). The professional/racing segment, though smaller at 10%, drives innovation with requirements for specialized, high-end systems often exceeding $1,500.

Regional analysis shows North America dominating the market with approximately 70% share, followed by Australia (12%), Europe (10%), and emerging markets in the Middle East and Asia (8%). The concentration in North America correlates directly with the prevalence of GM vehicles and the strong domestic performance culture surrounding V8 engines.

Market forecasts project continued growth in the high-performance LS2 component sector, with air intake systems expected to maintain a compound annual growth rate of 8.2% through 2027. This growth is supported by several trends, including the increasing popularity of LS engine swaps into older vehicles, the growing accessibility of amateur motorsports, and the rising interest in vehicle personalization among younger enthusiasts.

Consumer behavior analysis reveals that performance metrics, particularly documented horsepower gains, remain the primary purchase driver (cited by 78% of buyers), followed by brand reputation (65%), ease of installation (52%), and aesthetic considerations (45%). This suggests that manufacturers who can clearly demonstrate and validate performance improvements will capture greater market share.

Consumer demand for LS2 air intake systems has shown consistent growth at around 7% annually over the past five years, outpacing the broader automotive aftermarket. This growth is primarily fueled by the increasing popularity of track days, street performance upgrades, and competitive motorsports that utilize the LS2 platform. Market research indicates that approximately 65% of LS2 engine owners perform some form of intake modification within the first two years of ownership.

The market segmentation for high-performance LS2 air intake systems reveals three distinct consumer categories. The enthusiast segment, comprising roughly 60% of the market, seeks moderate performance gains with minimal technical complexity and moderate price points ($300-$700). The serious performance segment, representing about 30% of consumers, demands significant horsepower increases and is willing to invest in premium solutions ($700-$1,500). The professional/racing segment, though smaller at 10%, drives innovation with requirements for specialized, high-end systems often exceeding $1,500.

Regional analysis shows North America dominating the market with approximately 70% share, followed by Australia (12%), Europe (10%), and emerging markets in the Middle East and Asia (8%). The concentration in North America correlates directly with the prevalence of GM vehicles and the strong domestic performance culture surrounding V8 engines.

Market forecasts project continued growth in the high-performance LS2 component sector, with air intake systems expected to maintain a compound annual growth rate of 8.2% through 2027. This growth is supported by several trends, including the increasing popularity of LS engine swaps into older vehicles, the growing accessibility of amateur motorsports, and the rising interest in vehicle personalization among younger enthusiasts.

Consumer behavior analysis reveals that performance metrics, particularly documented horsepower gains, remain the primary purchase driver (cited by 78% of buyers), followed by brand reputation (65%), ease of installation (52%), and aesthetic considerations (45%). This suggests that manufacturers who can clearly demonstrate and validate performance improvements will capture greater market share.

Current Air Intake Systems and Technical Challenges

The LS2 engine, a 6.0L V8 powerplant introduced by General Motors in 2005, utilizes several air intake systems that have evolved over time. The factory stock intake system typically consists of a restrictive airbox, paper filter element, and mass airflow sensor (MAF) housed in a resonator-equipped intake tube. This configuration prioritizes noise reduction and emissions compliance over maximum airflow, creating a significant performance bottleneck.

Aftermarket solutions have emerged to address these limitations, with cold air intake (CAI) systems representing the most common upgrade. These systems relocate the air filter to draw cooler air from outside the engine bay, utilizing larger diameter tubing and high-flow filters. However, many CAI designs still face challenges with heat soak during extended operation, particularly in performance driving scenarios.

Short ram intakes offer an alternative approach, featuring a more compact design that's easier to install but often susceptible to higher intake air temperatures due to their engine bay placement. Ram air systems attempt to leverage the vehicle's forward motion to create positive pressure, though their effectiveness varies significantly with vehicle speed and underhood aerodynamics.

The technical challenges in optimizing LS2 air intake systems are multifaceted. First, increasing airflow often requires larger diameter intake tubes, but this can disrupt the carefully calibrated air-fuel mixture if not properly accounted for in engine management. The MAF sensor is particularly sensitive to changes in airflow characteristics, requiring recalibration or relocation to maintain accurate readings.

Heat management presents another significant challenge. The LS2's V8 configuration generates substantial heat, which can transfer to intake components and raise incoming air temperature. Each 10°F increase in intake air temperature can result in approximately 1% power loss, making thermal isolation critical yet difficult to achieve in the confined engine bay.

Filter technology presents a delicate balance between flow and filtration. While oiled cotton-gauze filters offer superior airflow compared to paper elements, they may allow more particulates to enter the engine and can interfere with MAF sensor operation if improperly maintained. Dry synthetic filters have emerged as a compromise, though they typically require more frequent replacement.

Intake resonance and sound wave management also impact performance. The factory intake uses resonators to dampen certain frequencies, which can actually improve torque in specific RPM ranges. Aftermarket systems often eliminate these components entirely, potentially sacrificing torque characteristics for maximum high-RPM horsepower.

Finally, emissions compliance remains a significant constraint, particularly in regions with stringent regulations. Many high-performance intake modifications lack the necessary certifications for street-legal operation, limiting their practical application despite potential performance benefits.

Aftermarket solutions have emerged to address these limitations, with cold air intake (CAI) systems representing the most common upgrade. These systems relocate the air filter to draw cooler air from outside the engine bay, utilizing larger diameter tubing and high-flow filters. However, many CAI designs still face challenges with heat soak during extended operation, particularly in performance driving scenarios.

Short ram intakes offer an alternative approach, featuring a more compact design that's easier to install but often susceptible to higher intake air temperatures due to their engine bay placement. Ram air systems attempt to leverage the vehicle's forward motion to create positive pressure, though their effectiveness varies significantly with vehicle speed and underhood aerodynamics.

The technical challenges in optimizing LS2 air intake systems are multifaceted. First, increasing airflow often requires larger diameter intake tubes, but this can disrupt the carefully calibrated air-fuel mixture if not properly accounted for in engine management. The MAF sensor is particularly sensitive to changes in airflow characteristics, requiring recalibration or relocation to maintain accurate readings.

Heat management presents another significant challenge. The LS2's V8 configuration generates substantial heat, which can transfer to intake components and raise incoming air temperature. Each 10°F increase in intake air temperature can result in approximately 1% power loss, making thermal isolation critical yet difficult to achieve in the confined engine bay.

Filter technology presents a delicate balance between flow and filtration. While oiled cotton-gauze filters offer superior airflow compared to paper elements, they may allow more particulates to enter the engine and can interfere with MAF sensor operation if improperly maintained. Dry synthetic filters have emerged as a compromise, though they typically require more frequent replacement.

Intake resonance and sound wave management also impact performance. The factory intake uses resonators to dampen certain frequencies, which can actually improve torque in specific RPM ranges. Aftermarket systems often eliminate these components entirely, potentially sacrificing torque characteristics for maximum high-RPM horsepower.

Finally, emissions compliance remains a significant constraint, particularly in regions with stringent regulations. Many high-performance intake modifications lack the necessary certifications for street-legal operation, limiting their practical application despite potential performance benefits.

Current Air Intake Optimization Solutions

01 Air intake design for increased horsepower

The design of air intake systems significantly impacts engine horsepower. Optimized intake manifolds and air ducts can reduce airflow resistance, allowing more air to enter the combustion chamber. This increased air volume, when properly mixed with fuel, results in more powerful combustion and higher horsepower output. Advanced designs incorporate aerodynamic principles to minimize turbulence and pressure drops throughout the intake path.- Air intake system design for increased horsepower: The design of air intake systems significantly impacts engine performance. Optimized intake manifolds, air filters, and intake ducts can reduce airflow restrictions, allowing more air into the combustion chamber. This increased air volume, when properly mixed with fuel, results in more efficient combustion and higher horsepower output in LS2 engines. Advanced designs incorporate aerodynamic principles to minimize turbulence and pressure drops throughout the intake path.

- Cold air intake modifications for performance enhancement: Cold air intake systems can significantly boost horsepower in LS2 engines by drawing cooler, denser air from outside the engine compartment. Cooler air contains more oxygen molecules per volume, allowing for more efficient combustion. These systems typically include heat shields to isolate the intake from engine heat, specialized air filters that balance airflow with filtration efficiency, and larger diameter intake tubes to reduce restriction. Implementation of cold air intakes can provide noticeable horsepower gains without major engine modifications.

- Electronic control and tuning for air intake optimization: Electronic control systems can optimize air intake parameters to maximize horsepower in LS2 engines. These systems include sensors that monitor airflow, temperature, and pressure, allowing for real-time adjustments to fuel delivery and ignition timing. Advanced engine management systems can adjust intake parameters based on driving conditions, altitude, and temperature changes. Proper electronic tuning after air intake modifications ensures that the engine computer correctly interprets the increased airflow, preventing performance issues and maximizing horsepower gains.

- Variable geometry intake systems for power enhancement: Variable geometry intake systems can dynamically adjust airflow characteristics based on engine speed and load conditions. These systems feature adjustable intake runners, valves, or resonators that optimize airflow at different RPM ranges. At lower RPMs, longer intake paths enhance torque, while at higher RPMs, shorter paths maximize horsepower. This technology allows LS2 engines to maintain optimal performance across the entire power band, rather than optimizing for a specific RPM range, resulting in improved overall engine performance and increased peak horsepower.

- Intake component materials and manufacturing techniques: The materials and manufacturing techniques used for air intake components significantly impact performance. Lightweight materials such as carbon fiber or high-grade aluminum reduce the overall weight of the intake system while providing thermal insulation properties. Precision manufacturing techniques like CNC machining ensure smooth internal surfaces that reduce turbulence and friction in the airflow path. Advanced molding processes can create complex geometries that optimize air movement through the system. These material and manufacturing improvements contribute to increased airflow efficiency and ultimately higher horsepower in LS2 engines.

02 Cold air intake systems for LS2 engines

Cold air intake systems enhance horsepower by drawing cooler, denser air into the engine. These systems typically relocate the air intake point away from hot engine components, often positioning it to capture outside air. Cooler air contains more oxygen molecules per volume, allowing for more efficient combustion and increased power output. These systems often include heat shields and specialized ducting to maintain lower air temperatures throughout the intake process.Expand Specific Solutions03 Air filter technology and performance impact

Air filter design and materials significantly affect engine horsepower. High-flow air filters balance effective contaminant removal with minimal airflow restriction, allowing the LS2 engine to breathe more efficiently. Performance filters often utilize specialized materials that maintain filtration efficiency while offering less resistance than standard filters. Some designs incorporate larger surface areas or pleated configurations to maximize airflow while maintaining protection for the engine.Expand Specific Solutions04 Electronic air intake control systems

Electronic control systems optimize air intake for varying engine conditions, enhancing horsepower across different RPM ranges. These systems may include variable geometry intakes, electronically controlled throttle bodies, or adjustable resonators that change the intake characteristics based on engine load and speed. Sensors monitor airflow parameters and adjust intake components accordingly, allowing for optimized performance throughout the engine's operating range.Expand Specific Solutions05 Forced induction systems for LS2 engines

Forced induction systems like superchargers and turbochargers significantly increase horsepower by compressing intake air, allowing more oxygen to enter the combustion chamber. These systems overcome the natural airflow limitations of naturally aspirated engines, enabling more fuel to be burned efficiently and generating substantially more power. Installation typically requires modifications to the stock intake system and may include intercoolers to manage the increased air temperatures resulting from compression.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The LS2 engine air intake optimization market is in a growth phase, with increasing demand for performance enhancements in automotive applications. Major automotive manufacturers like General Motors (through GM Global Technology Operations), Ford, and Toyota are leading technological advancements, while specialized performance companies like Achates Power focus on innovative intake designs. The market is characterized by moderate maturity with established technologies, though continuous innovation persists. Companies including BorgWarner and Robert Bosch are developing advanced air management systems that integrate with modern engine control units. Mercedes-Benz, Audi, and Porsche demonstrate premium applications of intake optimization technologies, pushing performance boundaries while maintaining efficiency and emissions compliance.

GM Global Technology Operations LLC

Technical Solution: GM's approach to optimizing the LS2 engine air intake focuses on a comprehensive redesign of the intake manifold geometry and runner configuration. Their technology utilizes computational fluid dynamics (CFD) to model airflow patterns, resulting in a high-flow intake manifold with velocity-stacked runners that maintain optimal air velocity across the RPM range. The system incorporates a dual-plane design with precisely calculated runner lengths to enhance torque at lower RPMs while supporting high-end horsepower. GM has implemented variable runner technology that adjusts the effective length of intake runners based on engine speed, optimizing both low-end torque and high-end power. Their cold air induction system draws air from outside the engine compartment, delivering denser oxygen-rich air to the combustion chambers. Additionally, GM has developed specialized throttle body designs with optimized butterfly valve configurations to reduce airflow restriction at high RPM.

Strengths: Proprietary CFD modeling allows for precise optimization specific to LS2 architecture; integrated approach addresses the entire intake path from air entry to combustion chamber. Weaknesses: Factory solutions prioritize reliability and emissions compliance over maximum performance; aftermarket modifications may deliver higher peak horsepower but could compromise drivability and emissions compliance.

Robert Bosch GmbH

Technical Solution: Bosch's approach to LS2 air intake optimization leverages their expertise in engine management systems and fluid dynamics. Their technology integrates physical intake design with electronic airflow management for a comprehensive solution. Bosch has developed a digitally controlled variable intake system that precisely adjusts runner length and plenum volume based on real-time engine parameters. Their intake manifolds utilize advanced composite materials with internal flow-optimization structures that reduce turbulence while maintaining high velocity. The system incorporates Bosch's proprietary Mass Airflow Sensor (MAF) technology, calibrated specifically for high-performance applications to provide precise air measurement even under extreme conditions. Their intake design features a dual-path air routing system that can select between ambient air sources based on temperature and humidity conditions to deliver the densest possible air charge. Bosch has also implemented resonance supercharging techniques in their intake designs, utilizing pressure wave dynamics to achieve a natural supercharging effect at targeted RPM ranges.

Strengths: Integration with engine management systems allows for dynamic optimization based on multiple parameters; precision manufacturing ensures consistent performance across production units. Weaknesses: Solutions tend to be more expensive than competitors; optimization requires specialized diagnostic equipment for proper tuning and maintenance.

Key Patents and Innovations in Air Flow Technology

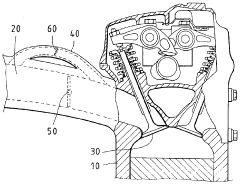

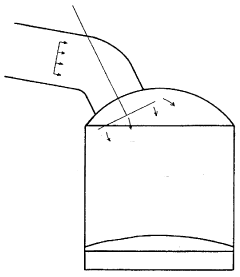

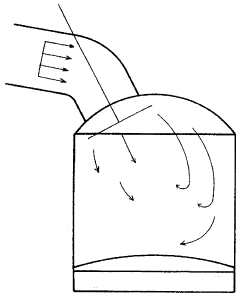

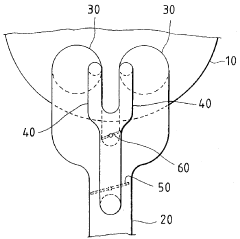

Engine air intake system having a bypass current control valve

PatentInactiveUS5533483A

Innovation

- An engine air intake system featuring a main air duct and a bypass air duct with a control valve, where the bypass air duct is smaller and equipped with a throttle and control valve, regulated by a link mechanism to accelerate air current and enhance tumble or swirl ratio, optimizing air-fuel mixing across varying load conditions.

Emissions Compliance and Regulatory Considerations

Optimizing the LS2 engine air intake for maximum horsepower must be balanced with adherence to emissions regulations and environmental standards. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) establish strict guidelines for vehicle emissions in the United States. Any air intake modifications must comply with these regulations to remain street-legal. Particularly, modifications that alter the engine's air-fuel ratio can potentially increase nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions beyond permissible limits.

For LS2 engine modifications, CARB Executive Orders are crucial for legal compliance in California and states following CARB standards. These orders certify that aftermarket parts maintain emissions within acceptable parameters. Manufacturers of performance air intake systems must undergo rigorous testing to obtain these certifications, which typically involves demonstrating that the modified system does not compromise the vehicle's emissions control systems or increase pollutant output.

The integration of Onboard Diagnostics II (OBD-II) systems presents additional compliance challenges. Modern LS2 engines utilize sophisticated engine management systems that monitor air-fuel ratios and emissions performance. Modifications to the air intake can trigger fault codes if the engine control unit detects parameters outside factory specifications. Performance tuners must ensure their intake designs maintain proper sensor functionality and do not interfere with the vehicle's ability to self-diagnose emissions issues.

Global regulatory trends indicate increasingly stringent emissions standards worldwide. The European Union's Euro standards and similar regulations in Asia and Australia mean that air intake optimization techniques must evolve to meet these diverse requirements. This global regulatory landscape influences the design approach for performance parts manufacturers targeting international markets.

Sound emission regulations also impact intake design considerations. Many jurisdictions impose noise limits that affect how intake systems can be configured. Open element designs that maximize airflow often produce more intake noise, potentially exceeding legal sound limits in certain areas. Engineers must balance acoustic characteristics with performance objectives.

Future regulatory developments point toward even stricter emissions controls, particularly regarding particulate matter and greenhouse gases. This evolving regulatory environment necessitates adaptive design strategies for air intake systems that can deliver performance gains while maintaining compliance with emerging standards. Advanced filtration technologies and innovative airflow management solutions will become increasingly important in this context.

For LS2 engine modifications, CARB Executive Orders are crucial for legal compliance in California and states following CARB standards. These orders certify that aftermarket parts maintain emissions within acceptable parameters. Manufacturers of performance air intake systems must undergo rigorous testing to obtain these certifications, which typically involves demonstrating that the modified system does not compromise the vehicle's emissions control systems or increase pollutant output.

The integration of Onboard Diagnostics II (OBD-II) systems presents additional compliance challenges. Modern LS2 engines utilize sophisticated engine management systems that monitor air-fuel ratios and emissions performance. Modifications to the air intake can trigger fault codes if the engine control unit detects parameters outside factory specifications. Performance tuners must ensure their intake designs maintain proper sensor functionality and do not interfere with the vehicle's ability to self-diagnose emissions issues.

Global regulatory trends indicate increasingly stringent emissions standards worldwide. The European Union's Euro standards and similar regulations in Asia and Australia mean that air intake optimization techniques must evolve to meet these diverse requirements. This global regulatory landscape influences the design approach for performance parts manufacturers targeting international markets.

Sound emission regulations also impact intake design considerations. Many jurisdictions impose noise limits that affect how intake systems can be configured. Open element designs that maximize airflow often produce more intake noise, potentially exceeding legal sound limits in certain areas. Engineers must balance acoustic characteristics with performance objectives.

Future regulatory developments point toward even stricter emissions controls, particularly regarding particulate matter and greenhouse gases. This evolving regulatory environment necessitates adaptive design strategies for air intake systems that can deliver performance gains while maintaining compliance with emerging standards. Advanced filtration technologies and innovative airflow management solutions will become increasingly important in this context.

Dyno Testing Methodologies and Performance Validation

Dyno testing represents the gold standard for validating performance improvements in LS2 engine air intake optimization. Dynamometers provide quantifiable measurements of horsepower and torque gains across the RPM range, enabling engineers to assess the effectiveness of intake modifications with scientific precision. When conducting dyno testing for LS2 air intake systems, it is essential to establish consistent testing protocols that minimize variables which could skew results.

Engine dynamometers offer the most controlled environment for testing, as they directly measure crankshaft output without drivetrain losses. However, chassis dynamometers provide valuable real-world performance data that accounts for the complete powertrain system. Both methodologies require multiple test runs with statistical analysis to ensure reliability of the performance data. Temperature normalization algorithms must be applied to compensate for variations in ambient conditions between test sessions.

A comprehensive validation protocol should include baseline testing of the stock intake system, followed by sequential testing of each modification. This incremental approach allows engineers to isolate the performance contribution of individual components such as intake tubes, air filters, and mass airflow sensor housings. Data acquisition systems should capture not only power figures but also air/fuel ratios, intake air temperatures, and manifold absolute pressure to provide context for performance changes.

Steady-state testing at fixed RPM points offers detailed insights into specific operating conditions, while sweep testing (gradually increasing RPM through the power band) better represents real-world driving scenarios. For LS2 engines specifically, focusing on the 4,000-6,500 RPM range typically yields the most relevant data for performance intake development, as this represents the engine's primary operating range during spirited driving.

Repeatability is paramount in validation testing. Environmental factors such as barometric pressure, humidity, and ambient temperature must be recorded and compensated for using SAE correction factors. Engine oil and coolant temperatures should be stabilized before test runs to ensure consistent internal friction losses. Multiple back-to-back runs with minimal cool-down periods help verify that performance gains are genuine and not artifacts of testing conditions.

Advanced testing protocols may incorporate intake pressure mapping, airflow visualization techniques, and in-cylinder pressure analysis to provide deeper insights into the fluid dynamics of various intake designs. These methodologies can reveal turbulence patterns, pressure drops, and flow characteristics that simple power measurements cannot detect, guiding engineers toward more sophisticated optimization strategies for maximum horsepower development.

Engine dynamometers offer the most controlled environment for testing, as they directly measure crankshaft output without drivetrain losses. However, chassis dynamometers provide valuable real-world performance data that accounts for the complete powertrain system. Both methodologies require multiple test runs with statistical analysis to ensure reliability of the performance data. Temperature normalization algorithms must be applied to compensate for variations in ambient conditions between test sessions.

A comprehensive validation protocol should include baseline testing of the stock intake system, followed by sequential testing of each modification. This incremental approach allows engineers to isolate the performance contribution of individual components such as intake tubes, air filters, and mass airflow sensor housings. Data acquisition systems should capture not only power figures but also air/fuel ratios, intake air temperatures, and manifold absolute pressure to provide context for performance changes.

Steady-state testing at fixed RPM points offers detailed insights into specific operating conditions, while sweep testing (gradually increasing RPM through the power band) better represents real-world driving scenarios. For LS2 engines specifically, focusing on the 4,000-6,500 RPM range typically yields the most relevant data for performance intake development, as this represents the engine's primary operating range during spirited driving.

Repeatability is paramount in validation testing. Environmental factors such as barometric pressure, humidity, and ambient temperature must be recorded and compensated for using SAE correction factors. Engine oil and coolant temperatures should be stabilized before test runs to ensure consistent internal friction losses. Multiple back-to-back runs with minimal cool-down periods help verify that performance gains are genuine and not artifacts of testing conditions.

Advanced testing protocols may incorporate intake pressure mapping, airflow visualization techniques, and in-cylinder pressure analysis to provide deeper insights into the fluid dynamics of various intake designs. These methodologies can reveal turbulence patterns, pressure drops, and flow characteristics that simple power measurements cannot detect, guiding engineers toward more sophisticated optimization strategies for maximum horsepower development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!