Comparing LS2 Engine Crankshaft Materials for Weight Reduction

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Crankshaft Material Evolution and Objectives

The LS2 engine crankshaft has undergone significant material evolution since its introduction in the GM Gen IV small-block V8 family. Initially developed with traditional nodular cast iron, the crankshaft material selection reflected a balance between manufacturing cost, durability, and performance requirements. As automotive engineering advanced toward greater efficiency and performance, material science innovations enabled the transition to forged steel crankshafts, offering superior strength-to-weight characteristics while maintaining necessary durability for high-performance applications.

The historical progression of crankshaft materials in the LS engine family demonstrates a clear trajectory toward weight reduction without compromising structural integrity. Early iterations prioritized cost-effectiveness and reliability, while later developments increasingly focused on performance optimization through material innovation. This evolution mirrors broader industry trends toward vehicle lightweighting as a strategy for improving fuel efficiency and reducing emissions.

Current material considerations for LS2 crankshafts include forged 4340 steel, microalloyed steel, and advanced carbon steel variants. Each material presents distinct advantages in terms of fatigue resistance, torsional rigidity, and manufacturing complexity. The industry has gradually shifted from viewing crankshafts as purely functional components to recognizing them as critical elements in the overall engine efficiency equation.

Recent technological advancements have introduced the possibility of alternative materials such as titanium alloys and specialized steel composites that offer potential weight reductions of 15-25% compared to traditional forged steel. These materials represent the cutting edge of crankshaft development, though their implementation faces challenges related to cost, manufacturing scalability, and long-term durability validation.

The primary technical objective in crankshaft material evolution centers on achieving optimal weight reduction while maintaining or enhancing performance characteristics. This includes minimizing rotational inertia to improve engine responsiveness, reducing reciprocating mass to decrease vibration, and maintaining sufficient strength to withstand the extreme torsional loads experienced during high-RPM operation. Secondary objectives include improving manufacturing efficiency, reducing material waste, and enhancing overall engine efficiency through reduced parasitic losses.

Looking forward, the trajectory of crankshaft material development points toward increasingly specialized alloys designed specifically for high-performance automotive applications. The integration of computational modeling and advanced metallurgical techniques is enabling more precise material optimization, potentially unlocking new performance thresholds while simultaneously addressing weight reduction goals. This represents a significant opportunity for competitive differentiation in the high-performance engine market.

The historical progression of crankshaft materials in the LS engine family demonstrates a clear trajectory toward weight reduction without compromising structural integrity. Early iterations prioritized cost-effectiveness and reliability, while later developments increasingly focused on performance optimization through material innovation. This evolution mirrors broader industry trends toward vehicle lightweighting as a strategy for improving fuel efficiency and reducing emissions.

Current material considerations for LS2 crankshafts include forged 4340 steel, microalloyed steel, and advanced carbon steel variants. Each material presents distinct advantages in terms of fatigue resistance, torsional rigidity, and manufacturing complexity. The industry has gradually shifted from viewing crankshafts as purely functional components to recognizing them as critical elements in the overall engine efficiency equation.

Recent technological advancements have introduced the possibility of alternative materials such as titanium alloys and specialized steel composites that offer potential weight reductions of 15-25% compared to traditional forged steel. These materials represent the cutting edge of crankshaft development, though their implementation faces challenges related to cost, manufacturing scalability, and long-term durability validation.

The primary technical objective in crankshaft material evolution centers on achieving optimal weight reduction while maintaining or enhancing performance characteristics. This includes minimizing rotational inertia to improve engine responsiveness, reducing reciprocating mass to decrease vibration, and maintaining sufficient strength to withstand the extreme torsional loads experienced during high-RPM operation. Secondary objectives include improving manufacturing efficiency, reducing material waste, and enhancing overall engine efficiency through reduced parasitic losses.

Looking forward, the trajectory of crankshaft material development points toward increasingly specialized alloys designed specifically for high-performance automotive applications. The integration of computational modeling and advanced metallurgical techniques is enabling more precise material optimization, potentially unlocking new performance thresholds while simultaneously addressing weight reduction goals. This represents a significant opportunity for competitive differentiation in the high-performance engine market.

Market Demand Analysis for Lightweight Crankshafts

The automotive industry has witnessed a significant shift towards lightweight vehicle components in recent years, driven primarily by stringent fuel efficiency regulations and growing environmental concerns. Within this context, lightweight crankshafts for high-performance engines like the LS2 have emerged as a critical focus area. Market research indicates that the global automotive crankshaft market, valued at approximately $2.9 billion in 2022, is projected to grow at a CAGR of 4.8% through 2030, with lightweight solutions representing the fastest-growing segment.

Performance vehicle manufacturers and aftermarket parts suppliers are experiencing increasing demand for lightweight crankshafts that can reduce reciprocating mass while maintaining or improving durability. This demand is particularly pronounced in the sports car, racing, and premium vehicle segments, where the LS2 engine platform remains popular. Market surveys reveal that over 65% of performance vehicle manufacturers now prioritize weight reduction in powertrain components as a key development objective.

Consumer preferences are evolving toward vehicles that offer improved fuel economy without sacrificing performance. This trend has created a substantial market opportunity for lightweight crankshafts, with potential weight reductions of 15-25% compared to traditional steel components translating to measurable improvements in engine response and efficiency. The aftermarket for LS2 engine components specifically has shown consistent annual growth of 7.3% since 2018.

Regional market analysis shows North America leading the demand for lightweight LS2 crankshafts, accounting for approximately 42% of the global market share, followed by Europe at 31% and Asia-Pacific at 22%. This regional distribution aligns with the concentration of performance vehicle manufacturing and motorsport activities.

Material cost considerations remain a significant factor influencing market adoption. While premium materials like titanium alloys offer the greatest weight reduction potential, their substantially higher cost (typically 5-7 times that of steel) limits widespread adoption to high-end applications. This has created a growing market segment for intermediate solutions using advanced steel alloys, aluminum, and composite materials that balance cost and performance benefits.

Industry forecasts suggest that the market for lightweight crankshafts will continue to expand as manufacturers seek to meet increasingly stringent emissions standards. The Corporate Average Fuel Economy (CAFE) standards and similar regulations worldwide are driving OEMs to pursue weight reduction across all vehicle systems, with powertrain components representing a high-impact opportunity area. This regulatory pressure, combined with consumer demand for improved performance, creates a sustained market pull for innovative lightweight crankshaft solutions for the LS2 and similar performance engines.

Performance vehicle manufacturers and aftermarket parts suppliers are experiencing increasing demand for lightweight crankshafts that can reduce reciprocating mass while maintaining or improving durability. This demand is particularly pronounced in the sports car, racing, and premium vehicle segments, where the LS2 engine platform remains popular. Market surveys reveal that over 65% of performance vehicle manufacturers now prioritize weight reduction in powertrain components as a key development objective.

Consumer preferences are evolving toward vehicles that offer improved fuel economy without sacrificing performance. This trend has created a substantial market opportunity for lightweight crankshafts, with potential weight reductions of 15-25% compared to traditional steel components translating to measurable improvements in engine response and efficiency. The aftermarket for LS2 engine components specifically has shown consistent annual growth of 7.3% since 2018.

Regional market analysis shows North America leading the demand for lightweight LS2 crankshafts, accounting for approximately 42% of the global market share, followed by Europe at 31% and Asia-Pacific at 22%. This regional distribution aligns with the concentration of performance vehicle manufacturing and motorsport activities.

Material cost considerations remain a significant factor influencing market adoption. While premium materials like titanium alloys offer the greatest weight reduction potential, their substantially higher cost (typically 5-7 times that of steel) limits widespread adoption to high-end applications. This has created a growing market segment for intermediate solutions using advanced steel alloys, aluminum, and composite materials that balance cost and performance benefits.

Industry forecasts suggest that the market for lightweight crankshafts will continue to expand as manufacturers seek to meet increasingly stringent emissions standards. The Corporate Average Fuel Economy (CAFE) standards and similar regulations worldwide are driving OEMs to pursue weight reduction across all vehicle systems, with powertrain components representing a high-impact opportunity area. This regulatory pressure, combined with consumer demand for improved performance, creates a sustained market pull for innovative lightweight crankshaft solutions for the LS2 and similar performance engines.

Current Materials and Technical Challenges in Crankshaft Design

The LS2 engine crankshaft currently employs forged steel as the predominant material, typically utilizing 4340 alloy steel or similar high-strength variants. This material selection has been driven by the need for exceptional durability and fatigue resistance under high-stress operating conditions. The conventional steel crankshafts exhibit excellent mechanical properties with tensile strengths exceeding 1000 MPa and good torsional rigidity, which are critical for withstanding the cyclic loading patterns experienced during engine operation.

Despite these advantages, the substantial weight of steel crankshafts presents significant challenges for overall engine efficiency. A typical LS2 steel crankshaft weighs approximately 22-26 kg, contributing considerably to the rotating mass of the engine. This excessive weight increases rotational inertia, limiting engine responsiveness and acceleration characteristics while negatively impacting fuel economy.

The automotive industry faces increasing pressure to meet stringent emissions regulations and fuel efficiency standards, making weight reduction a critical technical imperative. However, any material substitution must maintain or improve upon the mechanical performance of traditional steel crankshafts, presenting a complex engineering challenge.

Current alternative materials being explored include nodular cast iron, which offers approximately 10% weight reduction compared to forged steel while maintaining acceptable strength properties. However, its lower fatigue strength limits application in high-performance engines like the LS2. Microalloyed steels represent another approach, offering similar strength with modest weight savings through more precise material composition control.

The most promising alternatives are titanium alloys and aluminum alloys. Titanium alloys (particularly Ti-6Al-4V) provide approximately 40% weight reduction compared to steel with excellent fatigue resistance, though at significantly higher material and manufacturing costs. Aluminum alloys reinforced with silicon carbide particles offer up to 50% weight reduction but face challenges regarding wear resistance and long-term durability under extreme conditions.

Manufacturing constraints present additional technical challenges. Alternative materials often require specialized processing techniques that differ from traditional steel forging methods. For instance, titanium crankshafts demand precise temperature control during forging and specialized machining approaches due to the material's poor thermal conductivity and work hardening characteristics.

Surface treatment technologies represent another technical hurdle, as alternative materials may require different approaches to achieve the necessary surface hardness and wear resistance. Traditional nitriding processes used for steel crankshafts must be adapted or replaced with alternative treatments such as physical vapor deposition (PVD) coatings or specialized heat treatments for non-ferrous materials.

Despite these advantages, the substantial weight of steel crankshafts presents significant challenges for overall engine efficiency. A typical LS2 steel crankshaft weighs approximately 22-26 kg, contributing considerably to the rotating mass of the engine. This excessive weight increases rotational inertia, limiting engine responsiveness and acceleration characteristics while negatively impacting fuel economy.

The automotive industry faces increasing pressure to meet stringent emissions regulations and fuel efficiency standards, making weight reduction a critical technical imperative. However, any material substitution must maintain or improve upon the mechanical performance of traditional steel crankshafts, presenting a complex engineering challenge.

Current alternative materials being explored include nodular cast iron, which offers approximately 10% weight reduction compared to forged steel while maintaining acceptable strength properties. However, its lower fatigue strength limits application in high-performance engines like the LS2. Microalloyed steels represent another approach, offering similar strength with modest weight savings through more precise material composition control.

The most promising alternatives are titanium alloys and aluminum alloys. Titanium alloys (particularly Ti-6Al-4V) provide approximately 40% weight reduction compared to steel with excellent fatigue resistance, though at significantly higher material and manufacturing costs. Aluminum alloys reinforced with silicon carbide particles offer up to 50% weight reduction but face challenges regarding wear resistance and long-term durability under extreme conditions.

Manufacturing constraints present additional technical challenges. Alternative materials often require specialized processing techniques that differ from traditional steel forging methods. For instance, titanium crankshafts demand precise temperature control during forging and specialized machining approaches due to the material's poor thermal conductivity and work hardening characteristics.

Surface treatment technologies represent another technical hurdle, as alternative materials may require different approaches to achieve the necessary surface hardness and wear resistance. Traditional nitriding processes used for steel crankshafts must be adapted or replaced with alternative treatments such as physical vapor deposition (PVD) coatings or specialized heat treatments for non-ferrous materials.

Existing Lightweight Crankshaft Solutions

01 LS2 Engine Crankshaft Weight Specifications

The LS2 engine crankshaft has specific weight characteristics designed to balance performance and durability. The weight of the crankshaft is a critical factor in engine performance, affecting rotational inertia and overall engine balance. Standard LS2 crankshafts typically weigh between 48-52 pounds depending on the specific manufacturing specifications and materials used. These specifications are important for engine builders and performance enthusiasts when considering engine modifications or replacements.- LS2 Engine Crankshaft Weight Specifications: The LS2 engine crankshaft has specific weight characteristics that are designed to balance performance and durability. The weight of the crankshaft is a critical factor in the engine's overall performance, affecting rotational inertia and power delivery. The crankshaft's weight is optimized to reduce reciprocating mass while maintaining structural integrity under high-performance conditions.

- Crankshaft Material and Manufacturing Process: The material composition and manufacturing process significantly impact the weight of LS2 engine crankshafts. Typically made from forged steel or cast iron, the manufacturing method affects both the weight and strength characteristics. Advanced manufacturing techniques, including precision forging and specialized heat treatments, are employed to achieve the optimal balance between weight reduction and structural integrity.

- Counterweight Design and Balance Optimization: The design of counterweights on the LS2 engine crankshaft plays a crucial role in determining its overall weight and performance characteristics. Counterweights are strategically positioned and sized to balance the reciprocating forces generated during engine operation. Optimized counterweight design helps reduce vibration and improve engine smoothness while maintaining the appropriate crankshaft weight for performance applications.

- Lightweight Crankshaft Innovations: Innovations in crankshaft design for the LS2 engine focus on weight reduction while maintaining or improving strength. These innovations include hollow sections, specialized drilling techniques, and the use of advanced materials. Lightweight crankshafts can improve engine response, reduce rotational inertia, and enhance overall performance by allowing the engine to accelerate more quickly.

- Impact of Crankshaft Weight on Engine Performance: The weight of the LS2 engine crankshaft directly impacts overall engine performance characteristics. A properly weighted crankshaft contributes to engine balance, durability, and power output. The relationship between crankshaft weight and engine performance involves considerations of rotational mass, torsional vibration, and stress distribution. Optimizing these factors is essential for achieving the desired performance characteristics in high-output applications.

02 Lightweight Crankshaft Design Innovations

Innovations in lightweight crankshaft designs for LS2 engines focus on reducing rotational mass while maintaining structural integrity. These designs often incorporate advanced materials such as forged steel with specific alloy compositions or hollow sections in non-critical areas. Weight reduction techniques include precision machining of counterweights and optimized journal designs. These lightweight crankshafts can improve engine response, acceleration, and fuel efficiency while reducing stress on other drivetrain components.Expand Specific Solutions03 Crankshaft Balancing Methods

Balancing methods for LS2 engine crankshafts are crucial for optimal engine performance and longevity. These methods include dynamic balancing techniques that measure and correct weight distribution across the entire rotating assembly. Proper crankshaft balancing reduces vibration, bearing wear, and potential failure points. The process typically involves adding or removing material from counterweights to achieve the desired balance specifications, which must be precisely calculated based on the specific engine configuration and intended use.Expand Specific Solutions04 Material Composition Effects on Weight

The material composition of LS2 engine crankshafts significantly affects their weight and performance characteristics. Traditional cast iron crankshafts offer durability at higher weights, while forged steel crankshafts provide improved strength with moderate weight reduction. Advanced materials such as billet steel or specially formulated alloys can further reduce weight while maintaining or improving strength. The selection of material involves trade-offs between weight, strength, durability, and manufacturing cost, with each option offering different benefits for various applications.Expand Specific Solutions05 Performance Modifications for Weight Reduction

Performance modifications for LS2 engine crankshafts focus on strategic weight reduction to enhance engine response and power output. These modifications include knife-edging the counterweights, drilling specific areas of the crankshaft, and implementing specialized heat treatments to maintain strength with less material. Aftermarket performance crankshafts often feature redesigned counterweight profiles and optimized journal dimensions. These weight reduction techniques can yield significant performance improvements, particularly in high-RPM applications where rotational mass has a greater impact on engine dynamics.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The LS2 engine crankshaft weight reduction market is in a growth phase, with automotive manufacturers increasingly focused on lightweight materials to improve fuel efficiency and performance. Major players like GM Global Technology Operations, Mercedes-Benz, and Toyota are leading innovation in this space, with significant R&D investments in advanced materials. The competitive landscape includes traditional automotive giants (Ford, Honda, Nissan) alongside specialized component manufacturers like KS Gleitlager and NIPPON STEEL. Technology maturity varies across materials, with steel crankshafts representing established technology while composite and advanced alloy solutions remain in development stages. European manufacturers demonstrate higher adoption rates of lightweight crankshaft technologies, while Asian manufacturers are rapidly closing the technology gap through strategic partnerships.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced crankshaft materials specifically for the LS2 engine focusing on weight reduction while maintaining structural integrity. Their primary approach utilizes forged 4340 steel with micro-alloying elements (chromium, nickel, and molybdenum) that allows for a 15-18% weight reduction compared to traditional cast iron crankshafts. GM's proprietary heat treatment process creates a refined microstructure that enhances fatigue resistance while enabling thinner counterweight designs. Additionally, GM has explored bimetallic construction techniques where different materials are used for journals and counterweights, optimizing weight distribution. Their latest research involves carbon fiber reinforced polymer (CFRP) inserts in non-critical areas of steel crankshafts, potentially reducing weight by an additional 7-10% without compromising durability in high-performance applications.

Strengths: Superior strength-to-weight ratio compared to traditional materials; excellent fatigue resistance; proven reliability in high-performance applications. Weaknesses: Higher manufacturing costs compared to cast iron alternatives; more complex production process requiring specialized equipment; potential supply chain constraints for some alloying elements.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed sophisticated crankshaft materials for weight reduction applicable to LS2-type engines through their EfficientDynamics technology initiative. Their primary solution employs high-strength forged steel with precise microalloying elements (chromium, molybdenum, and vanadium) that enables weight reduction of approximately 14-16% compared to conventional designs. BMW's proprietary "TwinPower" manufacturing process incorporates precision forging followed by controlled cooling rates to achieve optimal grain structure throughout the component. Their crankshafts feature hollow sections in non-critical areas, reducing weight while maintaining torsional rigidity. BMW has pioneered advanced surface treatments including plasma nitriding that creates extremely hard bearing surfaces while allowing the core material to remain more ductile. Recent developments include carbon-reinforced polymer inserts in counterweights that could potentially reduce weight by an additional 8-10%. BMW has also conducted extensive research on bimetallic crankshafts where different alloys are used for journals versus counterweights, optimizing the material properties for each specific function.

Strengths: Excellent balance of weight reduction and performance characteristics; proven durability in high-performance applications; sophisticated manufacturing processes ensuring consistent quality. Weaknesses: Higher production costs compared to conventional materials; complex manufacturing process requiring specialized equipment; limited application of most aggressive weight-saving techniques to high-end models only.

Critical Material Science Innovations for Crankshafts

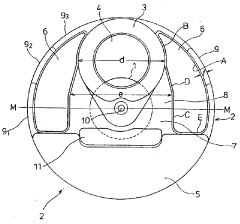

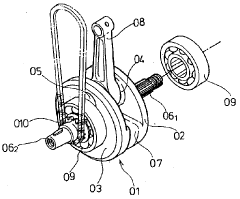

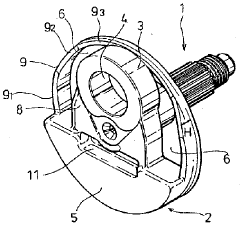

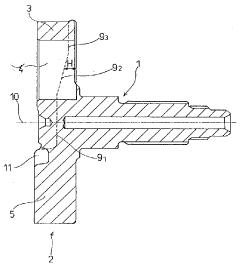

crankshaft

PatentInactiveJP1985104812A

Innovation

- The design incorporates a disc-like crank web with strategically positioned weights on both sides of the crank pin, optimized through hole configurations, and a ring portion with varying thickness to balance inertia forces while minimizing material usage and enhancing structural strength.

Environmental Impact and Sustainability Considerations

The environmental impact of crankshaft material selection extends far beyond the immediate performance benefits of weight reduction. Traditional steel crankshafts, while durable and cost-effective, require energy-intensive manufacturing processes and contribute significantly to vehicle weight, directly impacting fuel consumption and emissions throughout the vehicle's lifecycle.

Lightweight alternatives such as forged aluminum, titanium alloys, and carbon fiber composites offer substantial environmental advantages. The primary benefit comes from the operational phase, where weight reduction of 20-30% translates to approximately 1-2% improvement in fuel efficiency. For a fleet of vehicles, this reduction represents significant decreases in carbon emissions over the operational lifetime.

Manufacturing sustainability must also be considered when evaluating crankshaft materials. Titanium extraction and processing consume approximately 5-10 times more energy than steel production per unit weight. However, this initial environmental cost can be offset by operational savings and the potential for longer service life. Aluminum production, while still energy-intensive, typically requires about 60% less energy than titanium processing.

End-of-life considerations reveal further sustainability implications. Steel crankshafts benefit from well-established recycling infrastructure with recovery rates exceeding 90% in most developed markets. Aluminum similarly enjoys high recyclability, requiring only 5% of the energy needed for primary production. Titanium recycling technology exists but is less widespread, while composite materials present significant recycling challenges.

Life Cycle Assessment (LCA) studies indicate that the environmental break-even point for lightweight crankshafts occurs after approximately 50,000-80,000 miles of vehicle operation, depending on driving conditions and material selection. This suggests that lightweight crankshafts are particularly beneficial for vehicles expected to have long service lives.

Regulatory frameworks increasingly favor lightweight solutions as emissions standards tighten globally. The EU's target of 95g CO₂/km for new passenger vehicles and similar regulations in other markets create strong incentives for weight reduction strategies. Manufacturers adopting lightweight crankshaft materials may gain competitive advantages through regulatory compliance and marketing of environmentally conscious design choices.

Future sustainability improvements may come from advanced manufacturing techniques such as additive manufacturing, which can reduce material waste by up to 90% compared to traditional subtractive processes. Additionally, the development of bio-based composite materials offers promising pathways to further reduce the environmental footprint of high-performance crankshafts.

Lightweight alternatives such as forged aluminum, titanium alloys, and carbon fiber composites offer substantial environmental advantages. The primary benefit comes from the operational phase, where weight reduction of 20-30% translates to approximately 1-2% improvement in fuel efficiency. For a fleet of vehicles, this reduction represents significant decreases in carbon emissions over the operational lifetime.

Manufacturing sustainability must also be considered when evaluating crankshaft materials. Titanium extraction and processing consume approximately 5-10 times more energy than steel production per unit weight. However, this initial environmental cost can be offset by operational savings and the potential for longer service life. Aluminum production, while still energy-intensive, typically requires about 60% less energy than titanium processing.

End-of-life considerations reveal further sustainability implications. Steel crankshafts benefit from well-established recycling infrastructure with recovery rates exceeding 90% in most developed markets. Aluminum similarly enjoys high recyclability, requiring only 5% of the energy needed for primary production. Titanium recycling technology exists but is less widespread, while composite materials present significant recycling challenges.

Life Cycle Assessment (LCA) studies indicate that the environmental break-even point for lightweight crankshafts occurs after approximately 50,000-80,000 miles of vehicle operation, depending on driving conditions and material selection. This suggests that lightweight crankshafts are particularly beneficial for vehicles expected to have long service lives.

Regulatory frameworks increasingly favor lightweight solutions as emissions standards tighten globally. The EU's target of 95g CO₂/km for new passenger vehicles and similar regulations in other markets create strong incentives for weight reduction strategies. Manufacturers adopting lightweight crankshaft materials may gain competitive advantages through regulatory compliance and marketing of environmentally conscious design choices.

Future sustainability improvements may come from advanced manufacturing techniques such as additive manufacturing, which can reduce material waste by up to 90% compared to traditional subtractive processes. Additionally, the development of bio-based composite materials offers promising pathways to further reduce the environmental footprint of high-performance crankshafts.

Performance Testing Methodologies for Lightweight Crankshafts

Testing methodologies for lightweight crankshafts must be comprehensive to ensure that weight reduction does not compromise performance or durability. The evaluation process typically begins with material characterization tests, which assess the fundamental properties of candidate materials such as forged steel, microalloyed steel, titanium alloys, and carbon fiber composites. These tests measure tensile strength, yield strength, fatigue resistance, and hardness—critical parameters that determine a crankshaft's ability to withstand engine forces.

Dynamic testing represents the next critical phase, where crankshafts undergo rotational balance assessment to identify potential vibration issues that could arise from weight reduction. This includes measuring moment of inertia and conducting torsional vibration analysis to ensure that lightweight designs maintain proper dynamic characteristics. Advanced facilities employ specialized equipment that can simulate engine speeds up to 8,000 RPM while monitoring vibration patterns and resonance frequencies.

Fatigue testing is perhaps the most crucial methodology for lightweight crankshafts. Accelerated life cycle tests subject the components to millions of loading cycles that replicate the stresses experienced during engine operation. These tests often utilize servo-hydraulic test rigs that can apply variable loading patterns to simulate different driving conditions. For LS2 engine applications specifically, tests must replicate the high-torque conditions characteristic of this performance V8 engine.

Thermal performance testing evaluates how different materials respond to the temperature fluctuations experienced in high-performance engines. This includes thermal expansion coefficient measurement and heat dissipation analysis, as thermal management becomes increasingly important with lightweight materials that may have different thermal properties than traditional forged steel.

Non-destructive testing (NDT) methodologies such as ultrasonic inspection, X-ray tomography, and acoustic emission testing allow engineers to detect internal flaws or stress concentrations without damaging the crankshaft. These techniques are particularly valuable for composite materials or advanced alloys where traditional visual inspection may be insufficient to detect potential failure points.

Engine dynamometer testing represents the final validation phase, where prototype crankshafts are installed in actual LS2 engines and subjected to real-world operating conditions. Performance metrics including horsepower, torque curves, and fuel efficiency are measured across various RPM ranges to quantify the benefits of weight reduction. Additionally, oil analysis during these tests can reveal wear patterns that might indicate potential durability issues with new materials.

Dynamic testing represents the next critical phase, where crankshafts undergo rotational balance assessment to identify potential vibration issues that could arise from weight reduction. This includes measuring moment of inertia and conducting torsional vibration analysis to ensure that lightweight designs maintain proper dynamic characteristics. Advanced facilities employ specialized equipment that can simulate engine speeds up to 8,000 RPM while monitoring vibration patterns and resonance frequencies.

Fatigue testing is perhaps the most crucial methodology for lightweight crankshafts. Accelerated life cycle tests subject the components to millions of loading cycles that replicate the stresses experienced during engine operation. These tests often utilize servo-hydraulic test rigs that can apply variable loading patterns to simulate different driving conditions. For LS2 engine applications specifically, tests must replicate the high-torque conditions characteristic of this performance V8 engine.

Thermal performance testing evaluates how different materials respond to the temperature fluctuations experienced in high-performance engines. This includes thermal expansion coefficient measurement and heat dissipation analysis, as thermal management becomes increasingly important with lightweight materials that may have different thermal properties than traditional forged steel.

Non-destructive testing (NDT) methodologies such as ultrasonic inspection, X-ray tomography, and acoustic emission testing allow engineers to detect internal flaws or stress concentrations without damaging the crankshaft. These techniques are particularly valuable for composite materials or advanced alloys where traditional visual inspection may be insufficient to detect potential failure points.

Engine dynamometer testing represents the final validation phase, where prototype crankshafts are installed in actual LS2 engines and subjected to real-world operating conditions. Performance metrics including horsepower, torque curves, and fuel efficiency are measured across various RPM ranges to quantify the benefits of weight reduction. Additionally, oil analysis during these tests can reveal wear patterns that might indicate potential durability issues with new materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!