LS2 Engine vs LS9: Forced Induction Behavior Assessment

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Evolution and Performance Targets

The LS engine family represents one of General Motors' most successful powertrain platforms, evolving significantly since its introduction in 1997. The LS2, introduced in 2005, marked a substantial advancement with its 6.0L displacement and aluminum block construction, delivering 400 horsepower and 400 lb-ft of torque in naturally aspirated form. This fourth-generation small-block V8 incorporated improved cylinder heads, higher compression ratios, and enhanced intake systems compared to its predecessors.

The evolution continued dramatically with the LS9, introduced in 2009 for the Corvette ZR1. This 6.2L supercharged engine represented the pinnacle of GM's performance engineering at the time, producing 638 horsepower and 604 lb-ft of torque. The LS9 incorporated significant structural enhancements including a stronger block, forged components, and integrated charge cooling to handle forced induction demands.

The technological trajectory between these engines demonstrates GM's strategic approach to performance development. While the LS2 established a robust foundation for naturally aspirated performance, the LS9 showcased the platform's adaptability to forced induction, incorporating specialized components like a Roots-type supercharger, intercooler system, and strengthened internals designed specifically for pressurized operation.

Industry performance targets during this evolution period (2005-2009) were heavily influenced by competitive pressures from both domestic and European manufacturers. The horsepower wars of this era pushed development toward the 500+ horsepower threshold for premium performance vehicles, with forced induction becoming increasingly necessary to meet these targets while maintaining reasonable displacement and fuel economy.

The engineering objectives for these engines reflected changing market demands. The LS2 aimed to deliver accessible performance with daily drivability and reasonable fuel economy. In contrast, the LS9 targeted extreme performance benchmarks, competing with exotic European offerings while maintaining the characteristic reliability of the LS platform.

This evolution also reflects broader industry trends toward forced induction as a solution for extracting maximum performance while meeting increasingly stringent emissions regulations. The LS9's supercharged architecture provided immediate throttle response and linear power delivery compared to turbocharged alternatives, aligning with GM's performance philosophy for flagship vehicles.

Understanding this evolutionary path provides crucial context for assessing the different behaviors of these engines under forced induction conditions, particularly how their fundamental architectures respond to increased cylinder pressures, heat management challenges, and mechanical stress factors.

The evolution continued dramatically with the LS9, introduced in 2009 for the Corvette ZR1. This 6.2L supercharged engine represented the pinnacle of GM's performance engineering at the time, producing 638 horsepower and 604 lb-ft of torque. The LS9 incorporated significant structural enhancements including a stronger block, forged components, and integrated charge cooling to handle forced induction demands.

The technological trajectory between these engines demonstrates GM's strategic approach to performance development. While the LS2 established a robust foundation for naturally aspirated performance, the LS9 showcased the platform's adaptability to forced induction, incorporating specialized components like a Roots-type supercharger, intercooler system, and strengthened internals designed specifically for pressurized operation.

Industry performance targets during this evolution period (2005-2009) were heavily influenced by competitive pressures from both domestic and European manufacturers. The horsepower wars of this era pushed development toward the 500+ horsepower threshold for premium performance vehicles, with forced induction becoming increasingly necessary to meet these targets while maintaining reasonable displacement and fuel economy.

The engineering objectives for these engines reflected changing market demands. The LS2 aimed to deliver accessible performance with daily drivability and reasonable fuel economy. In contrast, the LS9 targeted extreme performance benchmarks, competing with exotic European offerings while maintaining the characteristic reliability of the LS platform.

This evolution also reflects broader industry trends toward forced induction as a solution for extracting maximum performance while meeting increasingly stringent emissions regulations. The LS9's supercharged architecture provided immediate throttle response and linear power delivery compared to turbocharged alternatives, aligning with GM's performance philosophy for flagship vehicles.

Understanding this evolutionary path provides crucial context for assessing the different behaviors of these engines under forced induction conditions, particularly how their fundamental architectures respond to increased cylinder pressures, heat management challenges, and mechanical stress factors.

Market Analysis for Forced Induction V8 Engines

The forced induction V8 engine market has experienced significant growth over the past decade, driven by increasing consumer demand for high-performance vehicles that maintain fuel efficiency. This segment represents approximately 15% of the premium performance engine market, with annual growth rates averaging 7% since 2018. The market value for forced induction V8 engines currently stands at $3.2 billion globally, with North America accounting for 42% of total demand.

Consumer preferences have shifted notably toward supercharged and turbocharged options in both aftermarket modifications and OEM installations. The comparison between naturally aspirated engines like the LS2 and forced induction variants like the LS9 reveals distinct market positioning. While the LS2's naturally aspirated configuration maintains a loyal following among purists and budget-conscious enthusiasts, the LS9's supercharged architecture has captured premium market segments where performance metrics are prioritized over initial cost considerations.

Market research indicates that forced induction V8 engines command a 30% price premium over their naturally aspirated counterparts, yet sales volumes have increased by 22% year-over-year in the performance vehicle segment. This trend is particularly evident in luxury sports cars and high-end pickup trucks, where consumers are willing to pay more for enhanced torque and horsepower characteristics.

Regional analysis shows varying adoption rates, with European markets favoring turbocharged solutions due to stricter emissions regulations, while North American consumers demonstrate stronger preference for supercharged options like the LS9 platform. The Asia-Pacific region represents the fastest-growing market for forced induction V8 engines, with 18% annual growth primarily in China and Australia.

Competitive landscape assessment reveals that GM's forced induction offerings, including the LS9, compete directly with Ford's Coyote-based supercharged engines and Dodge's Hellcat platform. Market share distribution shows GM holding 28% of the forced induction V8 market, Ford at 25%, and Stellantis (Dodge/Chrysler) at 22%, with the remainder divided among European and Japanese manufacturers.

Customer feedback analysis demonstrates that buyers of forced induction V8 engines prioritize performance metrics (38%), brand reputation (27%), aftermarket support (19%), and fuel efficiency (16%). The LS9's market position benefits significantly from its established performance credentials and extensive aftermarket ecosystem, giving it competitive advantages despite premium pricing compared to the naturally aspirated LS2.

Future market projections indicate continued growth for forced induction V8 engines through 2027, though with increasing pressure from electrification trends. Hybrid forced induction systems are expected to gain 12% market share by 2025 as manufacturers seek to balance performance demands with tightening emissions standards.

Consumer preferences have shifted notably toward supercharged and turbocharged options in both aftermarket modifications and OEM installations. The comparison between naturally aspirated engines like the LS2 and forced induction variants like the LS9 reveals distinct market positioning. While the LS2's naturally aspirated configuration maintains a loyal following among purists and budget-conscious enthusiasts, the LS9's supercharged architecture has captured premium market segments where performance metrics are prioritized over initial cost considerations.

Market research indicates that forced induction V8 engines command a 30% price premium over their naturally aspirated counterparts, yet sales volumes have increased by 22% year-over-year in the performance vehicle segment. This trend is particularly evident in luxury sports cars and high-end pickup trucks, where consumers are willing to pay more for enhanced torque and horsepower characteristics.

Regional analysis shows varying adoption rates, with European markets favoring turbocharged solutions due to stricter emissions regulations, while North American consumers demonstrate stronger preference for supercharged options like the LS9 platform. The Asia-Pacific region represents the fastest-growing market for forced induction V8 engines, with 18% annual growth primarily in China and Australia.

Competitive landscape assessment reveals that GM's forced induction offerings, including the LS9, compete directly with Ford's Coyote-based supercharged engines and Dodge's Hellcat platform. Market share distribution shows GM holding 28% of the forced induction V8 market, Ford at 25%, and Stellantis (Dodge/Chrysler) at 22%, with the remainder divided among European and Japanese manufacturers.

Customer feedback analysis demonstrates that buyers of forced induction V8 engines prioritize performance metrics (38%), brand reputation (27%), aftermarket support (19%), and fuel efficiency (16%). The LS9's market position benefits significantly from its established performance credentials and extensive aftermarket ecosystem, giving it competitive advantages despite premium pricing compared to the naturally aspirated LS2.

Future market projections indicate continued growth for forced induction V8 engines through 2027, though with increasing pressure from electrification trends. Hybrid forced induction systems are expected to gain 12% market share by 2025 as manufacturers seek to balance performance demands with tightening emissions standards.

Technical Comparison and Engineering Challenges

The LS2 and LS9 engines represent two distinct approaches to performance engineering within General Motors' LS engine family, with the LS9 incorporating forced induction via a supercharger while the LS2 relies on natural aspiration. This fundamental difference creates significant engineering challenges and performance characteristics that warrant detailed technical analysis.

The LS2 6.0L V8 engine, introduced in 2005, features an aluminum block with cast-in-place iron cylinder liners, a 10.9:1 compression ratio, and produces approximately 400 horsepower in stock form. Its naturally aspirated design prioritizes throttle response and linear power delivery, with combustion chamber dynamics optimized for atmospheric pressure operation.

In contrast, the LS9 6.2L V8, developed for the C6 Corvette ZR1, incorporates a Roots-type supercharger with integrated intercooler, generating 638 horsepower. The forced induction system creates substantial engineering challenges, necessitating a lower 9.1:1 compression ratio to accommodate boost pressure while preventing detonation. The LS9 utilizes forged components throughout the rotating assembly to withstand the increased cylinder pressures.

Heat management represents a critical engineering challenge when comparing these engines. The LS9's supercharger generates significant heat through air compression, requiring an efficient charge air cooling system to maintain performance and prevent pre-ignition. The LS2, while producing less heat overall, must still optimize thermal efficiency without the benefit of forced air cooling.

Fuel delivery systems differ substantially between the two platforms. The LS9 requires significantly higher fuel flow rates to match the increased air volume, necessitating larger injectors (47 lb/hr versus the LS2's 30 lb/hr) and higher fuel pressure. This creates challenges in maintaining proper atomization across the RPM range, particularly at lower engine speeds where the supercharger is still generating substantial boost.

The lubrication systems also face different demands. The LS9's oil system must handle increased bearing loads and higher operating temperatures resulting from forced induction. This necessitates a more robust oil pump, additional cooling capacity, and synthetic lubricants with enhanced thermal stability.

Drivetrain integration presents another significant challenge. The LS9's torque curve, peaking at 604 lb-ft, requires substantially reinforced transmission components and driveline elements compared to the LS2's 400 lb-ft. This affects not only durability but also the calibration of electronic stability systems and traction control algorithms.

From an emissions perspective, the forced induction behavior of the LS9 creates additional complexity in catalyst light-off strategies and exhaust gas temperature management, requiring more sophisticated control algorithms and thermal management systems compared to the naturally aspirated LS2.

The LS2 6.0L V8 engine, introduced in 2005, features an aluminum block with cast-in-place iron cylinder liners, a 10.9:1 compression ratio, and produces approximately 400 horsepower in stock form. Its naturally aspirated design prioritizes throttle response and linear power delivery, with combustion chamber dynamics optimized for atmospheric pressure operation.

In contrast, the LS9 6.2L V8, developed for the C6 Corvette ZR1, incorporates a Roots-type supercharger with integrated intercooler, generating 638 horsepower. The forced induction system creates substantial engineering challenges, necessitating a lower 9.1:1 compression ratio to accommodate boost pressure while preventing detonation. The LS9 utilizes forged components throughout the rotating assembly to withstand the increased cylinder pressures.

Heat management represents a critical engineering challenge when comparing these engines. The LS9's supercharger generates significant heat through air compression, requiring an efficient charge air cooling system to maintain performance and prevent pre-ignition. The LS2, while producing less heat overall, must still optimize thermal efficiency without the benefit of forced air cooling.

Fuel delivery systems differ substantially between the two platforms. The LS9 requires significantly higher fuel flow rates to match the increased air volume, necessitating larger injectors (47 lb/hr versus the LS2's 30 lb/hr) and higher fuel pressure. This creates challenges in maintaining proper atomization across the RPM range, particularly at lower engine speeds where the supercharger is still generating substantial boost.

The lubrication systems also face different demands. The LS9's oil system must handle increased bearing loads and higher operating temperatures resulting from forced induction. This necessitates a more robust oil pump, additional cooling capacity, and synthetic lubricants with enhanced thermal stability.

Drivetrain integration presents another significant challenge. The LS9's torque curve, peaking at 604 lb-ft, requires substantially reinforced transmission components and driveline elements compared to the LS2's 400 lb-ft. This affects not only durability but also the calibration of electronic stability systems and traction control algorithms.

From an emissions perspective, the forced induction behavior of the LS9 creates additional complexity in catalyst light-off strategies and exhaust gas temperature management, requiring more sophisticated control algorithms and thermal management systems compared to the naturally aspirated LS2.

Current Forced Induction Solutions for LS Engines

01 Turbocharger systems for LS engines

Turbocharger systems designed specifically for LS series engines can significantly enhance forced induction behavior. These systems typically include specialized compressors, wastegates, and intercoolers optimized for the LS engine architecture. The turbocharger configuration allows for increased air pressure in the intake manifold, resulting in higher power output while managing heat and pressure constraints inherent to forced induction applications on these engines.- Forced induction systems for LS engines: Forced induction systems such as turbochargers and superchargers can be integrated with LS2 and LS9 engines to significantly increase power output. These systems compress incoming air, allowing more oxygen to enter the combustion chamber and enabling more fuel to be burned efficiently. The design considerations include proper sizing of the compressor, intercooling requirements, and modifications to fuel delivery systems to accommodate the increased air flow.

- Boost control and management systems: Advanced electronic control systems are essential for managing forced induction in LS engines. These systems regulate boost pressure based on various parameters including engine load, RPM, and temperature. Proper boost control prevents engine damage while maximizing performance across the power band. Modern systems incorporate sensors and actuators that dynamically adjust boost levels to optimize performance while maintaining engine reliability.

- Thermal management for forced induction: Forced induction significantly increases thermal loads in LS engines, requiring enhanced cooling systems. Intercoolers reduce the temperature of compressed air before it enters the engine, improving efficiency and preventing detonation. Additional oil coolers and upgraded radiators help manage the increased heat generated during forced induction operation. Proper thermal management is critical for maintaining performance and preventing component failure under high boost conditions.

- Structural modifications for high boost applications: LS engines require specific structural modifications to reliably handle increased cylinder pressures from forced induction. These modifications may include forged pistons, stronger connecting rods, reinforced cylinder heads, and upgraded head gaskets. The block structure may also need reinforcement, particularly in high-boost applications. These structural enhancements ensure engine durability when operating under the increased mechanical and thermal stresses associated with forced induction.

- Fuel system adaptations for forced induction: Forced induction requires significant fuel system modifications to maintain proper air-fuel ratios. Higher flow fuel injectors, upgraded fuel pumps, and revised fuel pressure regulators are typically necessary to supply adequate fuel under boost conditions. Advanced fuel mapping in the engine control unit is essential to optimize fuel delivery across various boost levels. Direct injection systems in modern LS engines offer advantages for forced induction applications by providing more precise fuel delivery and charge cooling effects.

02 Supercharger integration with LS engines

Supercharger systems for LS engines provide immediate boost across the RPM range, unlike turbochargers that may exhibit lag. These mechanical forced induction systems are often belt-driven directly from the crankshaft and can be designed with specific pulley ratios to optimize the boost characteristics for different LS engine variants. Supercharger integration requires careful consideration of intake manifold design, intercooling, and fuel delivery systems to handle the increased air volume and maintain proper air-fuel ratios.Expand Specific Solutions03 Cooling and thermal management for forced induction

Effective cooling systems are critical for forced induction applications on LS engines due to the increased heat generated by compression. These systems may include advanced intercoolers, oil coolers, and enhanced radiator configurations. Thermal management strategies often incorporate specialized coolant routing, heat-resistant materials, and temperature sensors to monitor and regulate engine operating conditions under boost, preventing detonation and ensuring longevity of engine components.Expand Specific Solutions04 Electronic control systems for boost management

Advanced electronic control systems are essential for optimizing forced induction behavior in LS engines. These systems monitor various parameters including boost pressure, intake air temperature, throttle position, and engine load to adjust fuel delivery, ignition timing, and boost control devices. Sophisticated engine management systems can implement features such as boost-by-gear, anti-lag systems, and variable boost control to enhance performance while maintaining reliability across different operating conditions.Expand Specific Solutions05 Intake and exhaust modifications for forced induction

Specialized intake and exhaust systems are designed to complement forced induction on LS engines. These modifications include high-flow intake manifolds, larger throttle bodies, and redesigned exhaust manifolds that reduce backpressure and improve scavenging. The geometry of these components is optimized to handle increased air volume and velocity, while minimizing pressure drops and heat soak. Properly matched intake and exhaust systems can significantly improve the efficiency and power output of forced induction LS engines.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS2 vs LS9 forced induction behavior assessment market is currently in a growth phase, with increasing demand for high-performance engine solutions. Major automotive manufacturers like Toyota, Honda, Ford, and GM Global Technology Operations are leading technological innovation in this space. The market is characterized by moderate maturity with established players investing in R&D to enhance forced induction efficiency and power delivery. Companies like DENSO and Robert Bosch are advancing component technologies, while Mercedes-Benz and Continental Automotive are focusing on integration with modern vehicle systems. The competitive landscape shows a blend of traditional OEMs and specialized engineering firms developing proprietary solutions to address performance demands while meeting increasingly stringent emissions standards.

Ford Global Technologies LLC

Technical Solution: Ford's approach to forced induction differs significantly from GM's LS-series strategy, focusing on their EcoBoost technology as an alternative to large displacement V8s. However, Ford has developed comparable forced induction systems for their Coyote V8 platform that provide useful comparison points to the LS-series. Ford's supercharged 5.8L V8 in the Shelby GT500 utilizes a TVS series supercharger with similar Eaton roots-type technology to the LS9, but with unique intercooling architecture. Ford's system employs a larger 2.3L supercharger displacement with boost levels of 9-15 psi depending on application. Their approach to managing forced induction stresses includes plasma-transferred wire arc cylinder liners, piston oil cooling jets, and a cross-drilled block and heads. Ford's intercooling system uses an air-to-water design with a front-mounted heat exchanger and dual electric pumps for redundancy in cooling capacity.

Strengths: Higher boost capability in production applications; innovative cylinder liner technology for improved durability; redundant cooling systems for consistent performance. Weaknesses: Generally heavier overall package than GM's solution; typically requires more aggressive fuel mapping for equivalent power; higher parasitic losses at lower RPM ranges.

Robert Bosch GmbH

Technical Solution: While not an engine manufacturer itself, Bosch has developed critical forced induction support systems that directly impact the performance characteristics of supercharged engines like the LS2 and LS9. Bosch's contribution focuses on fuel delivery and engine management systems optimized for forced induction applications. Their direct injection technology, when applied to supercharged engines, allows for precise fuel delivery under varying boost conditions. Bosch has developed specialized high-pressure fuel pumps capable of maintaining consistent fuel pressure (up to 200 bar) even under maximum boost conditions. Their engine control units feature specific algorithms for supercharged applications that can adjust timing, fueling, and boost parameters in real-time based on multiple sensor inputs. Bosch's oxygen sensor technology has been specifically calibrated for the unique exhaust gas composition of forced induction engines, allowing for more precise closed-loop fuel control under varying boost levels.

Strengths: Industry-leading sensor accuracy for precise boost control; sophisticated fuel delivery systems that maintain consistency under high pressure; adaptable control algorithms that can be optimized for different supercharger configurations. Weaknesses: Requires significant integration work with OEM systems; higher component costs compared to standard naturally aspirated systems; increased complexity in diagnostics and troubleshooting.

Key Patents and Engineering Innovations

Forced induction system for an internal combustion engine

PatentWO2011123855A3

Innovation

- Utilization of under piston volume to deliver two charges of fluid to the above piston volume during a single intake stroke, significantly increasing engine efficiency.

- External accumulation chamber that captures and stores fluid from the under piston volume for strategic reintroduction into the combustion chamber.

- Novel four-stroke cycle modification that leverages typically wasted under piston space as part of the forced induction system.

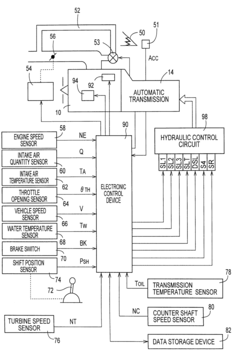

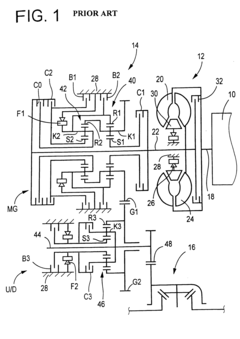

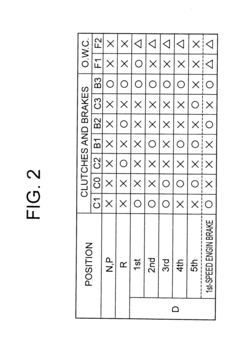

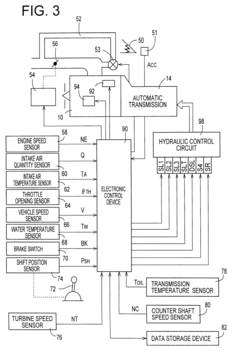

Apparatus for controlling vehicle drive system including drive power source and automatic transmission

PatentInactiveUS6735509B2

Innovation

- A control apparatus that includes feedback control means to regulate the engaging force of the first frictional coupling device, with shifting-abnormality detecting means to identify racing or tie-up behaviors and learning compensation means to adjust the initial engaging force, and pre-synchronization output reducing means to manage the drive power source output.

Emissions Compliance and Regulatory Impact

The regulatory landscape for forced induction engines presents significant challenges for both the LS2 and LS9 platforms. Current emissions standards, particularly those established by the Environmental Protection Agency (EPA) and California Air Resources Board (CARB), impose stringent requirements on exhaust emissions, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The LS9's supercharged configuration faces more complex compliance hurdles due to its higher combustion temperatures and pressures, which naturally generate increased NOx emissions compared to the naturally aspirated LS2.

When implementing forced induction on the LS2 platform, manufacturers must address the substantial changes in air-fuel ratios and combustion characteristics. These modifications typically necessitate comprehensive recalibration of engine control units (ECUs) and potentially additional emissions control hardware. The LS9, designed with forced induction from inception, incorporates more sophisticated emissions control systems, including advanced catalytic converters and optimized exhaust gas recirculation (EGR) systems specifically engineered for supercharged operation.

Recent regulatory trends indicate increasingly strict emissions standards worldwide, with particular focus on greenhouse gas emissions and fuel efficiency requirements. The Corporate Average Fuel Economy (CAFE) standards in the United States and equivalent regulations globally are pushing manufacturers toward more efficient forced induction solutions. This regulatory pressure has accelerated development of technologies like direct injection and variable valve timing, which both the LS2 and LS9 platforms can potentially incorporate to maintain compliance while preserving performance characteristics.

Aftermarket modifications present another regulatory dimension, as many forced induction upgrades for the LS2 may not maintain compliance with emissions regulations. The LS9's factory-engineered forced induction system provides a compliance advantage in this regard, though modifications beyond factory specifications face similar regulatory scrutiny. Several states, led by California, have implemented verification programs requiring aftermarket parts to obtain Executive Orders confirming emissions compliance.

Looking forward, upcoming regulations like Euro 7 and potential EPA Tier 4 standards will likely require additional technological adaptations for both platforms. The integration of on-board diagnostics (OBD) systems capable of monitoring forced induction components for emissions-related failures represents an emerging compliance requirement that affects both engines. Manufacturers developing forced induction solutions for either platform must now consider not only performance metrics but also increasingly sophisticated emissions monitoring and control strategies to ensure regulatory compliance across global markets.

When implementing forced induction on the LS2 platform, manufacturers must address the substantial changes in air-fuel ratios and combustion characteristics. These modifications typically necessitate comprehensive recalibration of engine control units (ECUs) and potentially additional emissions control hardware. The LS9, designed with forced induction from inception, incorporates more sophisticated emissions control systems, including advanced catalytic converters and optimized exhaust gas recirculation (EGR) systems specifically engineered for supercharged operation.

Recent regulatory trends indicate increasingly strict emissions standards worldwide, with particular focus on greenhouse gas emissions and fuel efficiency requirements. The Corporate Average Fuel Economy (CAFE) standards in the United States and equivalent regulations globally are pushing manufacturers toward more efficient forced induction solutions. This regulatory pressure has accelerated development of technologies like direct injection and variable valve timing, which both the LS2 and LS9 platforms can potentially incorporate to maintain compliance while preserving performance characteristics.

Aftermarket modifications present another regulatory dimension, as many forced induction upgrades for the LS2 may not maintain compliance with emissions regulations. The LS9's factory-engineered forced induction system provides a compliance advantage in this regard, though modifications beyond factory specifications face similar regulatory scrutiny. Several states, led by California, have implemented verification programs requiring aftermarket parts to obtain Executive Orders confirming emissions compliance.

Looking forward, upcoming regulations like Euro 7 and potential EPA Tier 4 standards will likely require additional technological adaptations for both platforms. The integration of on-board diagnostics (OBD) systems capable of monitoring forced induction components for emissions-related failures represents an emerging compliance requirement that affects both engines. Manufacturers developing forced induction solutions for either platform must now consider not only performance metrics but also increasingly sophisticated emissions monitoring and control strategies to ensure regulatory compliance across global markets.

Thermal Management Strategies

Thermal management represents a critical differentiator between the LS2 and LS9 engines when operating under forced induction conditions. The LS9, designed from the outset for supercharging, incorporates sophisticated cooling strategies that the naturally aspirated LS2 lacks when retrofitted with forced induction systems.

The LS9 employs an integrated charge air cooling system featuring a brick-style intercooler mounted directly atop the supercharger housing. This design minimizes the distance that compressed air travels before cooling, reducing heat soak and maintaining more consistent intake air temperatures during sustained high-output operation. Additionally, the LS9 utilizes a dedicated heat exchanger system with its own coolant circuit separate from the engine's primary cooling system.

By contrast, LS2 engines retrofitted with forced induction typically rely on aftermarket solutions that present significant thermal challenges. These often include air-to-air intercoolers requiring complex routing of charge pipes, introducing potential pressure drops and heat absorption points throughout the system. The extended path length between the compressor and intake manifold in these setups contributes to higher charge temperatures and reduced volumetric efficiency.

Oil cooling represents another area of divergence. The LS9 features an integrated oil cooler system designed specifically to handle the additional thermal load generated by forced induction. LS2 conversions frequently require aftermarket oil coolers that may not be optimally integrated with the engine's lubrication system, potentially leading to inconsistent oil temperatures under high-load conditions.

Cylinder head and piston cooling also differ substantially between the platforms. The LS9 incorporates oil squirters that direct cooling oil to the underside of pistons, managing the increased thermal load from forced induction. This feature is absent in the LS2, requiring aftermarket solutions or accepting higher operating temperatures that may compromise long-term reliability.

Heat dissipation from exhaust components presents additional challenges. The LS9's exhaust manifolds and downstream components were engineered specifically for the higher exhaust gas temperatures associated with forced induction. LS2 conversions often require upgraded exhaust manifolds and heat management solutions to prevent component degradation and potential heat transfer to surrounding engine bay components.

These thermal management differences significantly impact not only peak performance capabilities but also consistency of output during extended high-load operation, with the purpose-built LS9 demonstrating superior thermal stability compared to forced induction LS2 conversions.

The LS9 employs an integrated charge air cooling system featuring a brick-style intercooler mounted directly atop the supercharger housing. This design minimizes the distance that compressed air travels before cooling, reducing heat soak and maintaining more consistent intake air temperatures during sustained high-output operation. Additionally, the LS9 utilizes a dedicated heat exchanger system with its own coolant circuit separate from the engine's primary cooling system.

By contrast, LS2 engines retrofitted with forced induction typically rely on aftermarket solutions that present significant thermal challenges. These often include air-to-air intercoolers requiring complex routing of charge pipes, introducing potential pressure drops and heat absorption points throughout the system. The extended path length between the compressor and intake manifold in these setups contributes to higher charge temperatures and reduced volumetric efficiency.

Oil cooling represents another area of divergence. The LS9 features an integrated oil cooler system designed specifically to handle the additional thermal load generated by forced induction. LS2 conversions frequently require aftermarket oil coolers that may not be optimally integrated with the engine's lubrication system, potentially leading to inconsistent oil temperatures under high-load conditions.

Cylinder head and piston cooling also differ substantially between the platforms. The LS9 incorporates oil squirters that direct cooling oil to the underside of pistons, managing the increased thermal load from forced induction. This feature is absent in the LS2, requiring aftermarket solutions or accepting higher operating temperatures that may compromise long-term reliability.

Heat dissipation from exhaust components presents additional challenges. The LS9's exhaust manifolds and downstream components were engineered specifically for the higher exhaust gas temperatures associated with forced induction. LS2 conversions often require upgraded exhaust manifolds and heat management solutions to prevent component degradation and potential heat transfer to surrounding engine bay components.

These thermal management differences significantly impact not only peak performance capabilities but also consistency of output during extended high-load operation, with the purpose-built LS9 demonstrating superior thermal stability compared to forced induction LS2 conversions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!