LS2 Engine Emissions: Measuring NOx Levels Under Load

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Emissions Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the small-block V8 engine family. This 6.0L powerplant featured in various high-performance vehicles including the Pontiac GTO, Chevrolet Corvette, and several truck applications. As emissions regulations have progressively tightened globally, understanding and controlling NOx emissions from these performance engines has become increasingly critical for both regulatory compliance and environmental protection.

NOx (nitrogen oxides) emissions are particularly problematic as they contribute to smog formation, acid rain, and various respiratory health issues. The LS2 engine, while efficient for its era, faces challenges in NOx control particularly under load conditions when combustion temperatures rise significantly. These higher temperatures accelerate the formation of NOx compounds through the oxidation of atmospheric nitrogen.

Historical data indicates that performance engines like the LS2 typically produce elevated NOx levels during high-load operations such as acceleration, towing, or climbing. This presents a technical challenge as these are precisely the conditions where consumers expect optimal performance. The tension between performance expectations and emissions compliance represents a fundamental engineering challenge that continues to drive innovation in engine management systems.

The evolution of emissions control technology for the LS2 and similar engines has progressed through several generations, from early catalytic converters to more sophisticated systems incorporating exhaust gas recirculation (EGR), advanced fuel injection timing, and variable valve timing. Each iteration has aimed to better balance performance characteristics with increasingly stringent emissions requirements.

The primary objective of this technical research is to develop comprehensive methodologies for accurately measuring NOx emissions from LS2 engines specifically under varying load conditions. This includes establishing reliable testing protocols that can capture real-world emission profiles rather than just laboratory-controlled scenarios. Secondary objectives include identifying the correlation between specific engine operating parameters and NOx formation, and evaluating the effectiveness of various control strategies.

Additionally, this research aims to explore potential technological solutions that could be retrofitted to existing LS2 engines to improve their emissions profile without significantly compromising performance characteristics. This includes both hardware modifications and software-based engine management adjustments that could be implemented through calibration updates.

Understanding these emissions characteristics is not merely an academic exercise but has direct implications for regulatory compliance, vehicle certification, and the development of future performance engines that must meet increasingly strict environmental standards while still delivering the power and responsiveness that consumers demand.

NOx (nitrogen oxides) emissions are particularly problematic as they contribute to smog formation, acid rain, and various respiratory health issues. The LS2 engine, while efficient for its era, faces challenges in NOx control particularly under load conditions when combustion temperatures rise significantly. These higher temperatures accelerate the formation of NOx compounds through the oxidation of atmospheric nitrogen.

Historical data indicates that performance engines like the LS2 typically produce elevated NOx levels during high-load operations such as acceleration, towing, or climbing. This presents a technical challenge as these are precisely the conditions where consumers expect optimal performance. The tension between performance expectations and emissions compliance represents a fundamental engineering challenge that continues to drive innovation in engine management systems.

The evolution of emissions control technology for the LS2 and similar engines has progressed through several generations, from early catalytic converters to more sophisticated systems incorporating exhaust gas recirculation (EGR), advanced fuel injection timing, and variable valve timing. Each iteration has aimed to better balance performance characteristics with increasingly stringent emissions requirements.

The primary objective of this technical research is to develop comprehensive methodologies for accurately measuring NOx emissions from LS2 engines specifically under varying load conditions. This includes establishing reliable testing protocols that can capture real-world emission profiles rather than just laboratory-controlled scenarios. Secondary objectives include identifying the correlation between specific engine operating parameters and NOx formation, and evaluating the effectiveness of various control strategies.

Additionally, this research aims to explore potential technological solutions that could be retrofitted to existing LS2 engines to improve their emissions profile without significantly compromising performance characteristics. This includes both hardware modifications and software-based engine management adjustments that could be implemented through calibration updates.

Understanding these emissions characteristics is not merely an academic exercise but has direct implications for regulatory compliance, vehicle certification, and the development of future performance engines that must meet increasingly strict environmental standards while still delivering the power and responsiveness that consumers demand.

Market Demand for Advanced NOx Monitoring Solutions

The global market for advanced NOx monitoring solutions is experiencing significant growth, driven primarily by increasingly stringent emissions regulations across major automotive markets. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards have all established progressively lower NOx emission limits, creating substantial demand for more precise and reliable monitoring technologies. This regulatory pressure has transformed what was once a niche market into a critical component of engine management systems.

Vehicle manufacturers are actively seeking advanced NOx monitoring solutions that can accurately measure emissions under various load conditions, particularly for the LS2 engine platform. The market size for automotive emission control systems reached approximately $92 billion in 2022 and is projected to grow at a CAGR of 8.3% through 2030, with NOx monitoring solutions representing a significant segment of this market.

Fleet operators constitute another major market segment, as they face increasing pressure to demonstrate compliance with emissions standards across their vehicle portfolios. This has created demand for retrofittable monitoring systems that can provide real-time data on NOx emissions under actual operating conditions, rather than just in laboratory testing environments.

The aftermarket sector has also emerged as a substantial revenue stream, with demand for diagnostic tools that can accurately assess NOx emissions during maintenance and repair procedures. This segment is particularly important for older LS2 engines that may require upgrades to meet current emissions standards.

From a geographical perspective, North America and Europe currently represent the largest markets for advanced NOx monitoring solutions, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China and India, is expected to show the highest growth rate over the next five years as these countries implement more stringent emissions regulations.

The market is also seeing increased demand for integrated systems that combine NOx monitoring with other emission control technologies, offering comprehensive solutions that address multiple pollutants simultaneously. This trend is particularly relevant for LS2 engines, which often require holistic approaches to emissions management due to their performance characteristics under varying load conditions.

Vehicle manufacturers are actively seeking advanced NOx monitoring solutions that can accurately measure emissions under various load conditions, particularly for the LS2 engine platform. The market size for automotive emission control systems reached approximately $92 billion in 2022 and is projected to grow at a CAGR of 8.3% through 2030, with NOx monitoring solutions representing a significant segment of this market.

Fleet operators constitute another major market segment, as they face increasing pressure to demonstrate compliance with emissions standards across their vehicle portfolios. This has created demand for retrofittable monitoring systems that can provide real-time data on NOx emissions under actual operating conditions, rather than just in laboratory testing environments.

The aftermarket sector has also emerged as a substantial revenue stream, with demand for diagnostic tools that can accurately assess NOx emissions during maintenance and repair procedures. This segment is particularly important for older LS2 engines that may require upgrades to meet current emissions standards.

From a geographical perspective, North America and Europe currently represent the largest markets for advanced NOx monitoring solutions, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China and India, is expected to show the highest growth rate over the next five years as these countries implement more stringent emissions regulations.

The market is also seeing increased demand for integrated systems that combine NOx monitoring with other emission control technologies, offering comprehensive solutions that address multiple pollutants simultaneously. This trend is particularly relevant for LS2 engines, which often require holistic approaches to emissions management due to their performance characteristics under varying load conditions.

Current NOx Measurement Technologies and Challenges

The measurement of NOx emissions from LS2 engines under load conditions presents significant technical challenges due to the complex nature of nitrogen oxide formation during combustion processes. Current technologies for NOx measurement can be broadly categorized into extractive and in-situ methods, each with distinct advantages and limitations when applied to engine testing environments.

Chemiluminescence Detection (CLD) remains the industry standard for extractive NOx measurement, offering high accuracy and reliability. This technology operates by detecting the light emitted when NO reacts with ozone, providing precise measurements in the parts-per-million range. However, CLD systems typically require sample conditioning and extraction, introducing potential measurement delays and sample alterations that can affect real-time analysis during variable load conditions.

Non-Dispersive Ultraviolet (NDUV) analyzers represent another extractive approach, utilizing the absorption characteristics of NO and NO2 in the ultraviolet spectrum. While these systems offer good stability and lower maintenance requirements compared to CLD, they may struggle with cross-interference from other exhaust components, particularly under the varying combustion conditions experienced during load changes.

For in-situ measurement, Tunable Diode Laser Absorption Spectroscopy (TDLAS) has emerged as a promising technology. TDLAS enables direct measurement within the exhaust stream without sample extraction, providing truly real-time data. However, implementation challenges include optical access requirements and potential signal degradation from particulate matter in the exhaust.

Fourier Transform Infrared (FTIR) spectroscopy offers comprehensive multi-component analysis capabilities, measuring NOx alongside other emissions simultaneously. This advantage comes with increased complexity and cost, limiting widespread adoption in production testing environments despite its analytical power.

A significant challenge across all measurement technologies is maintaining accuracy during transient load conditions. The LS2 engine's emission profile changes dramatically between steady-state and dynamic load scenarios, with thermal effects and changing exhaust flow rates affecting measurement precision. Current systems often struggle to capture these rapid fluctuations without introducing measurement lag or dilution effects.

Miniaturization represents another frontier in NOx measurement technology. While laboratory-grade instruments provide excellent accuracy, their size and complexity make them impractical for certain applications. Recent developments in solid-state sensors and micro-electromechanical systems (MEMS) show promise for compact, cost-effective NOx monitoring, though they currently lack the precision of traditional analyzers.

Calibration and drift compensation remain persistent challenges, particularly in extended testing scenarios. Environmental factors such as temperature and humidity can influence measurement accuracy, requiring sophisticated compensation algorithms and regular recalibration procedures to maintain data integrity throughout testing cycles.

Chemiluminescence Detection (CLD) remains the industry standard for extractive NOx measurement, offering high accuracy and reliability. This technology operates by detecting the light emitted when NO reacts with ozone, providing precise measurements in the parts-per-million range. However, CLD systems typically require sample conditioning and extraction, introducing potential measurement delays and sample alterations that can affect real-time analysis during variable load conditions.

Non-Dispersive Ultraviolet (NDUV) analyzers represent another extractive approach, utilizing the absorption characteristics of NO and NO2 in the ultraviolet spectrum. While these systems offer good stability and lower maintenance requirements compared to CLD, they may struggle with cross-interference from other exhaust components, particularly under the varying combustion conditions experienced during load changes.

For in-situ measurement, Tunable Diode Laser Absorption Spectroscopy (TDLAS) has emerged as a promising technology. TDLAS enables direct measurement within the exhaust stream without sample extraction, providing truly real-time data. However, implementation challenges include optical access requirements and potential signal degradation from particulate matter in the exhaust.

Fourier Transform Infrared (FTIR) spectroscopy offers comprehensive multi-component analysis capabilities, measuring NOx alongside other emissions simultaneously. This advantage comes with increased complexity and cost, limiting widespread adoption in production testing environments despite its analytical power.

A significant challenge across all measurement technologies is maintaining accuracy during transient load conditions. The LS2 engine's emission profile changes dramatically between steady-state and dynamic load scenarios, with thermal effects and changing exhaust flow rates affecting measurement precision. Current systems often struggle to capture these rapid fluctuations without introducing measurement lag or dilution effects.

Miniaturization represents another frontier in NOx measurement technology. While laboratory-grade instruments provide excellent accuracy, their size and complexity make them impractical for certain applications. Recent developments in solid-state sensors and micro-electromechanical systems (MEMS) show promise for compact, cost-effective NOx monitoring, though they currently lack the precision of traditional analyzers.

Calibration and drift compensation remain persistent challenges, particularly in extended testing scenarios. Environmental factors such as temperature and humidity can influence measurement accuracy, requiring sophisticated compensation algorithms and regular recalibration procedures to maintain data integrity throughout testing cycles.

Current NOx Measurement Methods Under Load Conditions

01 NOx reduction systems for LS2 engines

Various systems have been developed to reduce NOx emissions in LS2 engines. These systems include selective catalytic reduction (SCR), exhaust gas recirculation (EGR), and advanced catalytic converters. These technologies work by either converting NOx into less harmful substances or reducing the formation of NOx during combustion. Implementation of these systems has shown significant reduction in NOx levels while maintaining engine performance.- NOx reduction systems for LS2 engines: Various systems and methods are employed to reduce NOx emissions in LS2 engines. These include selective catalytic reduction (SCR) systems, exhaust gas recirculation (EGR) systems, and advanced catalytic converters. These technologies work by either converting NOx into less harmful substances or by reducing the formation of NOx during combustion through temperature control and oxygen management.

- Monitoring and measurement of NOx levels: Advanced sensors and diagnostic systems are used to monitor and measure NOx emissions from LS2 engines. These systems provide real-time data on emission levels, allowing for adjustments to engine parameters to maintain compliance with emission standards. The monitoring systems include NOx sensors, oxygen sensors, and comprehensive engine management systems that analyze exhaust composition.

- Engine control strategies for NOx reduction: Specific engine control strategies are implemented to reduce NOx emissions in LS2 engines. These include optimized fuel injection timing, air-fuel ratio management, and combustion temperature control. Advanced engine control units (ECUs) use algorithms to balance performance requirements with emission control, adjusting parameters in real-time based on operating conditions.

- Aftertreatment technologies for NOx control: Aftertreatment technologies are crucial for controlling NOx emissions in LS2 engines. These include lean NOx traps (LNT), diesel particulate filters (DPF) with NOx reduction capabilities, and urea-based systems that inject diesel exhaust fluid (DEF) into the exhaust stream. These technologies work downstream of the engine to capture or convert NOx before it exits the exhaust system.

- Compliance with emission standards and regulations: LS2 engines are designed and modified to comply with increasingly stringent emission standards and regulations worldwide. This involves comprehensive testing procedures, certification processes, and ongoing monitoring to ensure NOx levels remain within legal limits throughout the engine's operational life. Manufacturers implement various technologies and strategies to meet these requirements while maintaining engine performance and efficiency.

02 Monitoring and measurement of NOx levels

Advanced sensors and diagnostic systems have been developed to monitor and measure NOx emissions from LS2 engines. These systems provide real-time data on emission levels, allowing for better control and optimization of engine parameters. The monitoring technologies include NOx sensors, exhaust gas analyzers, and onboard diagnostic systems that can detect abnormal emission patterns and alert operators to potential issues.Expand Specific Solutions03 Engine control strategies for NOx reduction

Various engine control strategies have been implemented to reduce NOx emissions in LS2 engines. These include optimized fuel injection timing, air-fuel ratio management, and combustion temperature control. Advanced engine control units (ECUs) use complex algorithms to balance performance requirements with emission targets. These strategies can significantly reduce NOx formation during the combustion process without compromising engine efficiency.Expand Specific Solutions04 Aftertreatment technologies for NOx control

Aftertreatment technologies specifically designed for LS2 engines help control NOx emissions after combustion. These include lean NOx traps (LNT), selective catalytic reduction (SCR) systems using urea or ammonia, and advanced catalytic converters. These systems are designed to capture and convert NOx into nitrogen and other harmless compounds before they are released into the atmosphere, significantly reducing the environmental impact of LS2 engines.Expand Specific Solutions05 Compliance with emission standards

Technologies and methods have been developed to ensure LS2 engines comply with increasingly stringent NOx emission standards worldwide. These include integrated emission control systems, certification testing procedures, and calibration methods. Manufacturers have implemented various strategies to meet regulatory requirements while maintaining engine performance and fuel efficiency. These compliance solutions often involve a combination of engine design modifications, control strategies, and aftertreatment systems.Expand Specific Solutions

Key Players in Automotive Emissions Testing Industry

The NOx emissions measurement landscape for LS2 engines is currently in a growth phase, with market size expanding due to stringent global emissions regulations. The technology is approaching maturity with key players demonstrating varied capabilities. Weichai Power and Cummins lead in heavy-duty engine emissions control, while Robert Bosch, NGK Insulators, and Johnson Matthey offer advanced sensing and catalyst technologies. Automotive OEMs including Mercedes-Benz, Hyundai, GM, and Ford are investing significantly in compliance solutions. Specialized testing equipment providers like Horiba are developing more precise load-based NOx measurement systems. Research institutions such as China Automotive Technology & Research Center and UT-Battelle are advancing measurement methodologies to meet increasingly complex regulatory requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced NOx sensing technology specifically designed for measuring emissions in high-performance engines like the LS2. Their system combines electrochemical sensors with integrated heating elements that maintain optimal operating temperature regardless of engine load conditions. The technology utilizes amperometric measurement principles with dual chambers that allow for precise differentiation between NOx and other exhaust gases. Bosch's solution incorporates real-time data processing algorithms that compensate for temperature variations during different load conditions, ensuring measurement accuracy within ±5ppm even under high-load scenarios where traditional sensors often fail. Their system integrates with engine control units to provide continuous monitoring capabilities that meet Euro 6d and EPA Tier 3 standards.

Strengths: Industry-leading accuracy across wide temperature ranges; fast response time (<150ms) allowing for real-time engine management adjustments; robust design with extended sensor life even under high-temperature conditions. Weaknesses: Higher initial cost compared to basic oxygen sensors; requires periodic calibration to maintain accuracy; complex integration with some older engine management systems.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered proprietary technology specifically for LS2 engine emissions monitoring, leveraging their extensive experience as the original manufacturer of this powertrain. Their approach combines in-cylinder pressure sensors with advanced exhaust gas recirculation (EGR) control algorithms to predict and measure NOx formation in real-time. GM's system utilizes a network of strategically positioned temperature and pressure sensors throughout the exhaust system that work in conjunction with their proprietary "Dynamic NOx Prediction Model" to accurately measure emissions under varying load conditions. The technology incorporates adaptive learning algorithms that continuously refine measurement accuracy based on driving patterns and engine wear characteristics. GM has also developed specialized calibration procedures for their LS2 platforms that optimize the balance between performance and emissions control.

Strengths: Purpose-built for LS2 architecture with deep integration into engine management systems; comprehensive historical data on LS2 performance characteristics; ability to simultaneously optimize for performance and emissions. Weaknesses: Solutions are primarily designed for GM vehicles and may require significant adaptation for other applications; higher computational requirements for real-time processing compared to standalone sensor systems.

Critical Technologies for Real-time NOx Detection

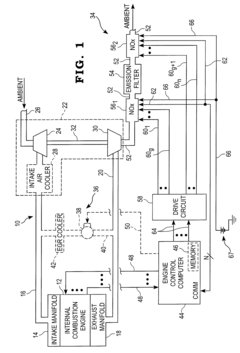

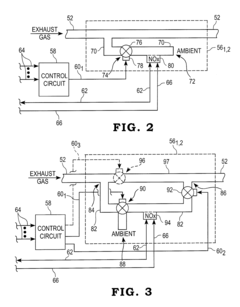

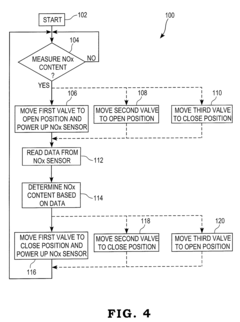

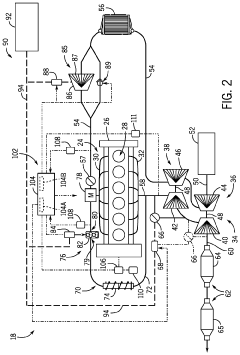

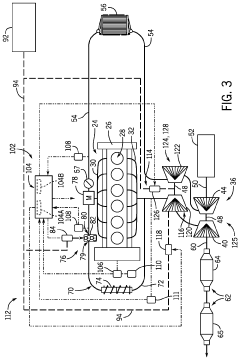

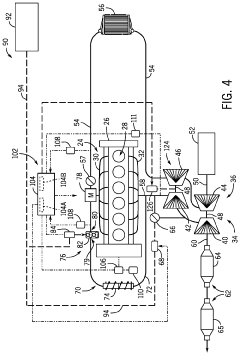

System for measuring NOx content of exhaust gas

PatentInactiveUS7263823B2

Innovation

- A system with a bypass conduit and a controllable valve that directs exhaust gas past the NOx sensor only when measurement is desired, and vents it to ambient air when not in use, minimizing exposure and extending sensor life.

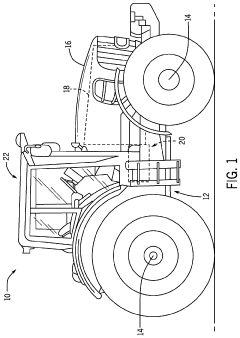

Engine system with electrified air system components for managing emissions of nitrogen oxides in a work vehicle

PatentActiveUS11536213B2

Innovation

- The engine system incorporates electrified air system components, including a turbocharger with a regulator and a controller that monitors engine load and exhaust gas temperature to modify the flow of exhaust gas through the turbine, reducing energy extraction and intake air flow, and utilizes an electrified wastegate or variable geometry turbocharger to optimize NOx emissions control.

Regulatory Framework for Engine Emissions Standards

The regulatory landscape for engine emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide to combat air pollution and climate change. For LS2 engines, which are primarily used in General Motors vehicles, compliance with these regulations requires sophisticated measurement and control of NOx (nitrogen oxides) emissions, particularly under load conditions where emissions typically increase.

In the United States, the Environmental Protection Agency (EPA) establishes emissions standards through the Clean Air Act, with Tier 3 standards currently in effect for light-duty vehicles. These standards specifically limit NOx emissions to 0.030 grams per mile (g/mi) for passenger cars and light-duty trucks. The California Air Resources Board (CARB) maintains even stricter requirements through its Low Emission Vehicle (LEV) III program, which many other states have adopted.

European regulations follow the Euro standards framework, with Euro 6d being the current standard. This limits NOx emissions to 0.080 g/km for gasoline engines and 0.068 g/km for diesel engines under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). Additionally, Real Driving Emissions (RDE) testing has been implemented to ensure vehicles meet standards under actual driving conditions, not just in laboratory settings.

The testing protocols for measuring NOx emissions under load have become increasingly sophisticated. The Federal Test Procedure (FTP-75) in the US and the WLTP in Europe both include various driving cycles that simulate different load conditions. For LS2 engines specifically, dynamometer testing must accurately replicate the high-load conditions these performance engines often operate under, as NOx formation increases significantly with higher combustion temperatures.

Compliance verification involves both laboratory certification testing and in-use surveillance. Manufacturers must demonstrate that their engines meet emissions standards throughout their useful life, typically defined as 150,000 miles or 15 years in the US. This includes durability testing and deterioration factor calculations to account for emissions system degradation over time.

Penalties for non-compliance have increased substantially following high-profile emissions scandals. Manufacturers found violating emissions regulations face fines that can reach billions of dollars, mandatory recalls, and significant reputational damage. This regulatory pressure has driven substantial investment in emissions control technologies for engines like the LS2, including advanced catalytic converters, exhaust gas recirculation systems, and sophisticated engine control modules.

In the United States, the Environmental Protection Agency (EPA) establishes emissions standards through the Clean Air Act, with Tier 3 standards currently in effect for light-duty vehicles. These standards specifically limit NOx emissions to 0.030 grams per mile (g/mi) for passenger cars and light-duty trucks. The California Air Resources Board (CARB) maintains even stricter requirements through its Low Emission Vehicle (LEV) III program, which many other states have adopted.

European regulations follow the Euro standards framework, with Euro 6d being the current standard. This limits NOx emissions to 0.080 g/km for gasoline engines and 0.068 g/km for diesel engines under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). Additionally, Real Driving Emissions (RDE) testing has been implemented to ensure vehicles meet standards under actual driving conditions, not just in laboratory settings.

The testing protocols for measuring NOx emissions under load have become increasingly sophisticated. The Federal Test Procedure (FTP-75) in the US and the WLTP in Europe both include various driving cycles that simulate different load conditions. For LS2 engines specifically, dynamometer testing must accurately replicate the high-load conditions these performance engines often operate under, as NOx formation increases significantly with higher combustion temperatures.

Compliance verification involves both laboratory certification testing and in-use surveillance. Manufacturers must demonstrate that their engines meet emissions standards throughout their useful life, typically defined as 150,000 miles or 15 years in the US. This includes durability testing and deterioration factor calculations to account for emissions system degradation over time.

Penalties for non-compliance have increased substantially following high-profile emissions scandals. Manufacturers found violating emissions regulations face fines that can reach billions of dollars, mandatory recalls, and significant reputational damage. This regulatory pressure has driven substantial investment in emissions control technologies for engines like the LS2, including advanced catalytic converters, exhaust gas recirculation systems, and sophisticated engine control modules.

Environmental Impact Assessment of LS2 Engine Emissions

The environmental impact of LS2 engine emissions, particularly NOx levels under load conditions, represents a significant concern for both regulatory compliance and ecological sustainability. NOx emissions from LS2 engines contribute substantially to air pollution, forming ground-level ozone and particulate matter that adversely affect respiratory health in urban populations. Studies indicate that under high-load conditions, LS2 engines can produce up to 3-5 times more NOx than during standard operating parameters, exacerbating environmental degradation in high-traffic areas.

When examining the atmospheric chemistry implications, NOx emissions from LS2 engines interact with volatile organic compounds (VOCs) in the presence of sunlight, creating photochemical smog that reduces visibility and damages vegetation. Research from the Environmental Protection Agency suggests that these reactions can persist for days, extending the geographical impact well beyond the emission source. The resulting acid deposition affects water bodies, soil composition, and forest ecosystems, with documented pH changes in affected watersheds.

Climate change considerations must also factor into the assessment, as NOx indirectly influences global warming potential. While carbon dioxide remains the primary greenhouse gas concern for combustion engines, NOx has a warming potential approximately 298 times greater than CO2 over a 100-year period. LS2 engines operating under load conditions can significantly contribute to this effect, particularly in commercial and industrial applications where sustained high-output operation is common.

Biodiversity impacts present another critical dimension of environmental assessment. Elevated NOx levels from LS2 engines contribute to nitrogen saturation in sensitive ecosystems, altering competitive dynamics among plant species and reducing overall biodiversity. Field studies in proximity to major transportation corridors show up to 30% reduction in sensitive lichen species, serving as early bioindicators of ecosystem stress.

The cumulative environmental burden must be evaluated through comprehensive lifecycle assessment methodologies. From raw material extraction for engine components to operational emissions and eventual disposal, the LS2 engine's environmental footprint extends beyond tailpipe emissions. Accurate measurement of NOx levels under various load conditions provides essential data for calculating this lifecycle impact, enabling more precise environmental cost-benefit analyses for different technological interventions.

Regulatory frameworks worldwide increasingly recognize these multifaceted environmental impacts, with evolving standards specifically targeting NOx emissions under real-world driving conditions rather than laboratory testing alone. This shift acknowledges the significant discrepancy between certified and actual environmental performance, particularly under variable load conditions characteristic of LS2 engine applications.

When examining the atmospheric chemistry implications, NOx emissions from LS2 engines interact with volatile organic compounds (VOCs) in the presence of sunlight, creating photochemical smog that reduces visibility and damages vegetation. Research from the Environmental Protection Agency suggests that these reactions can persist for days, extending the geographical impact well beyond the emission source. The resulting acid deposition affects water bodies, soil composition, and forest ecosystems, with documented pH changes in affected watersheds.

Climate change considerations must also factor into the assessment, as NOx indirectly influences global warming potential. While carbon dioxide remains the primary greenhouse gas concern for combustion engines, NOx has a warming potential approximately 298 times greater than CO2 over a 100-year period. LS2 engines operating under load conditions can significantly contribute to this effect, particularly in commercial and industrial applications where sustained high-output operation is common.

Biodiversity impacts present another critical dimension of environmental assessment. Elevated NOx levels from LS2 engines contribute to nitrogen saturation in sensitive ecosystems, altering competitive dynamics among plant species and reducing overall biodiversity. Field studies in proximity to major transportation corridors show up to 30% reduction in sensitive lichen species, serving as early bioindicators of ecosystem stress.

The cumulative environmental burden must be evaluated through comprehensive lifecycle assessment methodologies. From raw material extraction for engine components to operational emissions and eventual disposal, the LS2 engine's environmental footprint extends beyond tailpipe emissions. Accurate measurement of NOx levels under various load conditions provides essential data for calculating this lifecycle impact, enabling more precise environmental cost-benefit analyses for different technological interventions.

Regulatory frameworks worldwide increasingly recognize these multifaceted environmental impacts, with evolving standards specifically targeting NOx emissions under real-world driving conditions rather than laboratory testing alone. This shift acknowledges the significant discrepancy between certified and actual environmental performance, particularly under variable load conditions characteristic of LS2 engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!