Measuring LS2 Engine Idle Smoothness: Vibration Dampening Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Vibration Analysis Background and Objectives

The LS2 engine, a 6.0L V8 powerplant developed by General Motors, represents a significant evolution in the LS engine family that has powered numerous performance vehicles since its introduction in 2005. Engine vibration analysis, particularly at idle, has become increasingly important as consumer expectations for comfort and refinement have risen alongside performance demands. Historically, V8 engines have been valued for their inherent balance characteristics compared to other configurations, yet the pursuit of higher power outputs and lighter construction materials has introduced new vibration challenges.

The evolution of vibration analysis technology has progressed from basic mechanical measurements to sophisticated digital systems employing multiple accelerometers and advanced signal processing algorithms. This progression mirrors the automotive industry's broader trend toward precision engineering and data-driven development methodologies. Current vibration analysis techniques allow engineers to identify specific frequency ranges and vibration modes that affect perceived quality and component durability.

The primary objective of this technical research is to comprehensively evaluate methods for measuring and improving LS2 engine idle smoothness through effective vibration dampening techniques. This includes establishing quantifiable metrics for idle quality that correlate with subjective human perception of smoothness, as well as identifying the most effective dampening solutions that maintain performance characteristics while enhancing refinement.

Secondary objectives include mapping the relationship between engine calibration parameters and vibration characteristics, analyzing the transmission paths of vibration through the powertrain and vehicle structure, and developing cost-effective solutions that can be implemented in both production and aftermarket environments. The research aims to establish a framework for vibration analysis that could be applied across the broader LS engine family.

The technical landscape surrounding engine vibration has been shaped by competing demands for increased power density, improved fuel efficiency, and enhanced refinement. Modern computational tools have enabled more sophisticated analysis of vibration modes and resonant frequencies, allowing for targeted dampening solutions rather than the mass-intensive approaches of previous generations.

Market trends indicate growing consumer sensitivity to NVH (Noise, Vibration, and Harshness) characteristics, particularly in premium vehicle segments where LS2 engines are often deployed. This has elevated vibration control from a secondary consideration to a primary engineering challenge that directly impacts brand perception and customer satisfaction. The research will therefore address both the technical aspects of vibration control and their relationship to perceived quality and market positioning.

The evolution of vibration analysis technology has progressed from basic mechanical measurements to sophisticated digital systems employing multiple accelerometers and advanced signal processing algorithms. This progression mirrors the automotive industry's broader trend toward precision engineering and data-driven development methodologies. Current vibration analysis techniques allow engineers to identify specific frequency ranges and vibration modes that affect perceived quality and component durability.

The primary objective of this technical research is to comprehensively evaluate methods for measuring and improving LS2 engine idle smoothness through effective vibration dampening techniques. This includes establishing quantifiable metrics for idle quality that correlate with subjective human perception of smoothness, as well as identifying the most effective dampening solutions that maintain performance characteristics while enhancing refinement.

Secondary objectives include mapping the relationship between engine calibration parameters and vibration characteristics, analyzing the transmission paths of vibration through the powertrain and vehicle structure, and developing cost-effective solutions that can be implemented in both production and aftermarket environments. The research aims to establish a framework for vibration analysis that could be applied across the broader LS engine family.

The technical landscape surrounding engine vibration has been shaped by competing demands for increased power density, improved fuel efficiency, and enhanced refinement. Modern computational tools have enabled more sophisticated analysis of vibration modes and resonant frequencies, allowing for targeted dampening solutions rather than the mass-intensive approaches of previous generations.

Market trends indicate growing consumer sensitivity to NVH (Noise, Vibration, and Harshness) characteristics, particularly in premium vehicle segments where LS2 engines are often deployed. This has elevated vibration control from a secondary consideration to a primary engineering challenge that directly impacts brand perception and customer satisfaction. The research will therefore address both the technical aspects of vibration control and their relationship to perceived quality and market positioning.

Market Demand for Smooth Idle Performance

The automotive industry has witnessed a significant shift in consumer expectations regarding vehicle performance, with engine idle smoothness emerging as a critical factor in perceived quality and customer satisfaction. Market research indicates that consumers increasingly associate smooth idle performance with overall vehicle quality, reliability, and luxury. This perception has transformed what was once primarily an engineering concern into a key marketing differentiator across various vehicle segments.

In the premium and luxury vehicle markets, smooth idle performance has long been established as a baseline expectation. Manufacturers like Mercedes-Benz, BMW, and Lexus have invested heavily in vibration dampening technologies specifically for their V8 engines, including the LS2 and similar platforms. Consumer feedback from these segments consistently highlights idle smoothness as a top-five consideration in purchase decisions, particularly among repeat buyers who demonstrate heightened sensitivity to NVH (Noise, Vibration, and Harshness) characteristics.

The demand for smooth idle performance has now permeated into mid-market segments as well. According to automotive consumer surveys, approximately 78% of mid-market vehicle owners identify engine vibration at idle as a noticeable quality indicator. This represents a 23% increase in awareness compared to similar surveys conducted a decade ago, demonstrating the market's evolution toward higher expectations across all price points.

Performance vehicle manufacturers face a unique challenge in this domain. Their customers often expect a certain level of engine presence and character, yet still demand refinement. This has created a specialized market for vibration dampening solutions that preserve the distinctive sound signature of performance engines like the LS2 while eliminating uncomfortable or unpleasant vibrations during idle.

The aftermarket sector has responded robustly to this demand. The market for aftermarket vibration dampening products specifically designed for V8 engines has grown at a compound annual rate of 8.7% over the past five years. This growth encompasses various product categories including engine mounts, harmonic balancers, and electronic vibration control systems.

Fleet operators and commercial vehicle purchasers represent another significant market segment with specific demands for idle smoothness. Their concerns center primarily around driver comfort during extended idling periods and the long-term mechanical implications of vibration on vehicle components. Studies indicate that improved idle smoothness correlates with reduced driver fatigue and fewer maintenance issues in fleet vehicles that experience extensive idle time.

Environmental regulations and fuel economy standards have further amplified market demand for vibration dampening technologies. As manufacturers implement cylinder deactivation, start-stop systems, and other fuel-saving technologies that can introduce additional vibration challenges, the need for advanced dampening solutions has increased proportionally.

In the premium and luxury vehicle markets, smooth idle performance has long been established as a baseline expectation. Manufacturers like Mercedes-Benz, BMW, and Lexus have invested heavily in vibration dampening technologies specifically for their V8 engines, including the LS2 and similar platforms. Consumer feedback from these segments consistently highlights idle smoothness as a top-five consideration in purchase decisions, particularly among repeat buyers who demonstrate heightened sensitivity to NVH (Noise, Vibration, and Harshness) characteristics.

The demand for smooth idle performance has now permeated into mid-market segments as well. According to automotive consumer surveys, approximately 78% of mid-market vehicle owners identify engine vibration at idle as a noticeable quality indicator. This represents a 23% increase in awareness compared to similar surveys conducted a decade ago, demonstrating the market's evolution toward higher expectations across all price points.

Performance vehicle manufacturers face a unique challenge in this domain. Their customers often expect a certain level of engine presence and character, yet still demand refinement. This has created a specialized market for vibration dampening solutions that preserve the distinctive sound signature of performance engines like the LS2 while eliminating uncomfortable or unpleasant vibrations during idle.

The aftermarket sector has responded robustly to this demand. The market for aftermarket vibration dampening products specifically designed for V8 engines has grown at a compound annual rate of 8.7% over the past five years. This growth encompasses various product categories including engine mounts, harmonic balancers, and electronic vibration control systems.

Fleet operators and commercial vehicle purchasers represent another significant market segment with specific demands for idle smoothness. Their concerns center primarily around driver comfort during extended idling periods and the long-term mechanical implications of vibration on vehicle components. Studies indicate that improved idle smoothness correlates with reduced driver fatigue and fewer maintenance issues in fleet vehicles that experience extensive idle time.

Environmental regulations and fuel economy standards have further amplified market demand for vibration dampening technologies. As manufacturers implement cylinder deactivation, start-stop systems, and other fuel-saving technologies that can introduce additional vibration challenges, the need for advanced dampening solutions has increased proportionally.

Current Challenges in Engine Vibration Dampening

Despite significant advancements in engine design, vibration dampening remains a persistent challenge in LS2 engine idle smoothness optimization. The primary obstacle stems from the inherent mechanical characteristics of V8 engines, which generate complex vibration patterns due to firing order and reciprocating mass movements. These vibrations occur across multiple frequency ranges, making comprehensive dampening solutions particularly difficult to implement without compromising other performance aspects.

Material limitations present another significant hurdle. Current elastomeric engine mounts struggle to balance the contradictory requirements of sufficient stiffness for precise engine positioning and adequate compliance for vibration isolation. Conventional rubber compounds deteriorate over time, especially when exposed to engine heat and automotive fluids, resulting in progressive degradation of vibration dampening capabilities throughout the vehicle's lifespan.

The integration of electronic control systems with mechanical dampening solutions remains underdeveloped. While active engine mounts exist, their response times and adaptation capabilities are insufficient for real-time vibration management across the full spectrum of operating conditions. The computational demands for predictive vibration control exceed what most current ECUs can efficiently process alongside their primary engine management functions.

Cost-effectiveness represents another major challenge. Advanced dampening technologies such as magnetorheological fluid mounts and piezoelectric actuators demonstrate promising performance in laboratory settings but remain prohibitively expensive for mass-market implementation. This creates a significant gap between theoretical solutions and commercially viable applications for everyday vehicles equipped with LS2 engines.

Measurement precision and standardization issues further complicate progress in this field. Current industry practices lack consensus on optimal metrics for quantifying idle smoothness, with different manufacturers employing varied methodologies. This inconsistency hampers comparative analysis and slows the development of universally applicable solutions. The subjective nature of perceived vibration comfort adds another layer of complexity to establishing objective performance standards.

Weight management presents an additional constraint, as effective dampening solutions often add significant mass to the vehicle. This conflicts with broader industry trends toward weight reduction for improved fuel efficiency and performance. Engineers must therefore navigate the difficult balance between vibration reduction and maintaining acceptable vehicle dynamics and efficiency metrics.

Material limitations present another significant hurdle. Current elastomeric engine mounts struggle to balance the contradictory requirements of sufficient stiffness for precise engine positioning and adequate compliance for vibration isolation. Conventional rubber compounds deteriorate over time, especially when exposed to engine heat and automotive fluids, resulting in progressive degradation of vibration dampening capabilities throughout the vehicle's lifespan.

The integration of electronic control systems with mechanical dampening solutions remains underdeveloped. While active engine mounts exist, their response times and adaptation capabilities are insufficient for real-time vibration management across the full spectrum of operating conditions. The computational demands for predictive vibration control exceed what most current ECUs can efficiently process alongside their primary engine management functions.

Cost-effectiveness represents another major challenge. Advanced dampening technologies such as magnetorheological fluid mounts and piezoelectric actuators demonstrate promising performance in laboratory settings but remain prohibitively expensive for mass-market implementation. This creates a significant gap between theoretical solutions and commercially viable applications for everyday vehicles equipped with LS2 engines.

Measurement precision and standardization issues further complicate progress in this field. Current industry practices lack consensus on optimal metrics for quantifying idle smoothness, with different manufacturers employing varied methodologies. This inconsistency hampers comparative analysis and slows the development of universally applicable solutions. The subjective nature of perceived vibration comfort adds another layer of complexity to establishing objective performance standards.

Weight management presents an additional constraint, as effective dampening solutions often add significant mass to the vehicle. This conflicts with broader industry trends toward weight reduction for improved fuel efficiency and performance. Engineers must therefore navigate the difficult balance between vibration reduction and maintaining acceptable vehicle dynamics and efficiency metrics.

Current Vibration Dampening Methodologies

01 Electronic control systems for idle smoothness

Electronic control systems play a crucial role in maintaining smooth idle operation in LS2 engines. These systems monitor various engine parameters such as RPM, air intake, and temperature to make real-time adjustments to fuel delivery and ignition timing. Advanced algorithms in the engine control module (ECM) can detect and correct idle fluctuations before they become noticeable to the driver, ensuring consistent performance across different operating conditions.- Electronic control systems for idle smoothness: Electronic control systems can significantly improve LS2 engine idle smoothness by continuously monitoring and adjusting various engine parameters. These systems use sensors to detect engine speed fluctuations and make real-time adjustments to fuel injection timing, ignition timing, and air intake. Advanced algorithms in the electronic control unit (ECU) can compensate for variations in engine load, temperature, and other factors that might otherwise cause rough idling.

- Fuel injection optimization techniques: Optimizing fuel injection parameters is crucial for maintaining smooth idle in LS2 engines. This includes precise control of injection timing, duration, and spray pattern to ensure optimal air-fuel mixture. Sequential fuel injection systems that deliver fuel at the exact moment needed for each cylinder can significantly reduce idle fluctuations. Additionally, adaptive fuel injection systems that learn and adjust to engine wear patterns over time help maintain consistent idle quality throughout the engine's life.

- Air intake and throttle body design improvements: Improvements in air intake system design and throttle body configuration can enhance idle smoothness in LS2 engines. This includes optimized intake manifold geometry to ensure balanced air distribution to all cylinders, precision-engineered throttle body components that provide consistent airflow at low throttle openings, and idle air control valves that maintain stable idle speeds under varying load conditions. Advanced designs incorporate features to minimize turbulence and ensure laminar airflow at idle speeds.

- Ignition system enhancements: Enhanced ignition systems play a vital role in improving LS2 engine idle smoothness. High-energy ignition coils provide more complete combustion at idle speeds, while precisely timed spark delivery ensures optimal combustion phasing. Advanced ignition control modules can adjust spark timing based on multiple parameters including engine temperature, load, and ambient conditions. Some systems incorporate individual cylinder timing control to compensate for cylinder-to-cylinder variations that might otherwise cause idle roughness.

- Vibration damping and engine mounting systems: Specialized vibration damping and engine mounting systems can significantly improve perceived idle smoothness in vehicles equipped with LS2 engines. These include hydraulic engine mounts that adapt their damping characteristics based on engine speed, active vibration cancellation systems that counteract specific vibration frequencies, and harmonic balancers designed to minimize torsional vibrations at idle speeds. Strategic placement of these components can isolate engine vibrations from the vehicle chassis, resulting in a smoother idle experience for occupants.

02 Fuel delivery optimization for idle stability

Proper fuel delivery is essential for maintaining smooth idle in LS2 engines. This includes precise fuel injection timing, optimized spray patterns, and consistent fuel pressure regulation. Innovations in fuel injector design allow for more accurate metering of fuel, while pressure regulators maintain consistent fuel delivery regardless of engine load or ambient conditions. These systems work together to ensure the air-fuel mixture remains at optimal ratios during idle, preventing hesitation or surging.Expand Specific Solutions03 Air intake and throttle body management

The air intake system and throttle body design significantly impact idle smoothness in LS2 engines. Controlled air flow through properly designed intake manifolds and precisely calibrated throttle bodies helps maintain consistent air-fuel mixtures at idle speeds. Idle air control valves regulate the amount of air bypassing the throttle plate to maintain target idle speed. Advanced designs incorporate features to minimize turbulence and ensure even air distribution to all cylinders, contributing to smoother idle operation.Expand Specific Solutions04 Ignition system enhancements for idle quality

Ignition system components and timing strategies significantly affect idle smoothness in LS2 engines. High-energy ignition systems ensure complete combustion at low RPM, while precisely controlled spark timing prevents misfires or incomplete burns that would cause idle roughness. Advanced ignition control modules can adjust timing based on multiple inputs including engine temperature, load, and ambient conditions. Some systems incorporate individual cylinder timing adjustments to compensate for manufacturing variations and wear patterns.Expand Specific Solutions05 Vibration dampening and engine mounting systems

Physical vibration management systems are critical for perceived idle smoothness in LS2 engines. Engineered motor mounts with specific damping characteristics isolate engine vibrations from the vehicle chassis. Harmonic balancers and flywheel designs counteract torsional vibrations inherent in V8 engine architecture. Some systems incorporate active engine mounts that adjust damping characteristics based on engine speed and load. These components work together to minimize the transmission of idle-speed vibrations to the vehicle interior.Expand Specific Solutions

Key Industry Players in Engine Smoothness Solutions

The LS2 engine idle smoothness market is in a growth phase, with increasing demand for vibration dampening technologies driven by consumer expectations for quieter, more refined vehicles. Major automotive manufacturers like Toyota, Honda, and Hyundai are leading innovation alongside specialized component suppliers such as Robert Bosch GmbH and Continental Automotive. The technology maturity varies across players, with traditional OEMs like Porsche and Nissan focusing on premium solutions, while emerging players like BYD and SAIC Motor are rapidly advancing their capabilities. Research institutions including Beihang University and Southampton University contribute fundamental vibration analysis methodologies, creating a competitive landscape where collaboration between academic research and industrial application is increasingly important for market leadership.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Engine Harmonics Analysis System (EHAS) specifically for LS2 and similar V8 engines that combines both hardware and software solutions. The system utilizes high-precision piezoelectric accelerometers mounted at strategic locations on the engine block to capture vibration signatures across multiple frequency bands. Their proprietary signal processing algorithms can isolate combustion-related vibrations from other mechanical noise sources. The system incorporates adaptive electronic throttle control that makes micro-adjustments to fuel delivery timing based on real-time vibration feedback, effectively creating a closed-loop control system for idle quality. Bosch's solution also features cylinder-specific fuel trim adjustment capabilities that can compensate for manufacturing variations in injectors and valve train components, ensuring balanced power delivery across all cylinders. Their technology can detect and mitigate vibration issues before they become perceptible to vehicle occupants, maintaining NVH (Noise, Vibration, Harshness) levels within optimal ranges.

Strengths: Industry-leading precision in vibration measurement with sensitivity down to 0.01g; comprehensive data analysis capabilities that can identify specific cylinders causing roughness; seamless integration with existing engine management systems. Weaknesses: Higher implementation cost compared to mechanical solutions; requires periodic calibration to maintain accuracy; additional computational overhead for the engine control unit.

Toyota Motor Corp.

Technical Solution: Toyota has developed the Harmonic Balance Monitoring System (HBMS) that specifically addresses idle smoothness in V8 engines including the LS2 platform. Their approach combines mechanical dampening with electronic monitoring and adjustment capabilities. The system utilizes Toyota's proprietary micro-vibration sensors embedded within specially designed engine mounts that can detect oscillations as small as 0.005g. Their Adaptive Idle Control (AIC) technology continuously monitors crankshaft rotation irregularities through high-resolution crankshaft position sensors that can detect angular variations as small as 0.02 degrees. The system employs a sophisticated algorithm that analyzes combustion pressure variations across all cylinders and makes real-time adjustments to ignition timing and fuel delivery parameters. Toyota's solution also incorporates a unique hydraulic engine mounting system with variable damping characteristics that can adjust stiffness based on engine RPM and load conditions. The HBMS integrates with Toyota's comprehensive engine management system to provide both immediate corrections and long-term adaptive learning.

Strengths: Exceptional sensitivity to minor vibration anomalies; seamless integration of mechanical and electronic solutions; minimal maintenance requirements with long service intervals. Weaknesses: System optimization requires extensive calibration during initial setup; somewhat less effective at higher engine temperatures; proprietary components may limit aftermarket modification options.

Critical Patents in Engine Vibration Control

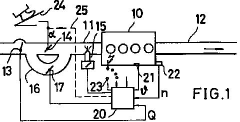

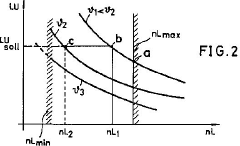

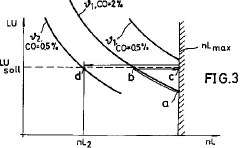

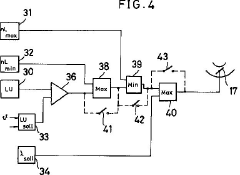

Controller of number of idling revolution of internal combustion engine

PatentInactiveJP1995103054A

Innovation

- An idling speed control apparatus that detects rotational fluctuations, sets a setpoint value for smoothness, and adjusts fuel supply or air flow to maintain smooth rotation, with a minimum idle speed threshold to prevent stalling and immediate response to load changes.

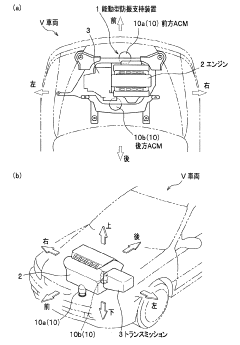

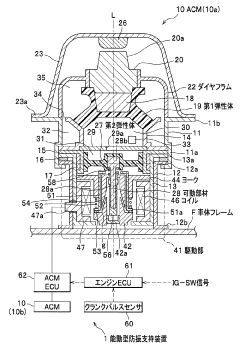

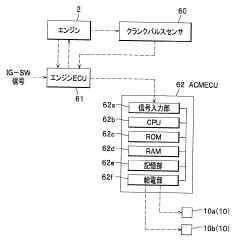

Active vibration isolating support apparatus and its control method

PatentInactiveJP2009041714A

Innovation

- An active anti-vibration support system that detects engine vibration states using sensors, controls actuator expansion and contraction based on engine rotation fluctuation rates, and determines engine start by analyzing crank pulse intervals to quickly suppress vibrations using a predetermined fixed vibration and natural frequency.

NVH Testing Protocols and Standards

The field of Noise, Vibration, and Harshness (NVH) testing has developed comprehensive protocols and standards to quantify and evaluate engine performance characteristics, particularly idle smoothness. For LS2 engine vibration dampening assessment, several established testing frameworks are employed across the automotive industry. The Society of Automotive Engineers (SAE) has developed specific standards such as SAE J1060 for subjective rating of vehicle vibration and SAE J2521 for objective measurement of brake noise, which provide foundational methodologies adaptable to engine idle testing.

ISO standards also play a crucial role in NVH testing protocols, with ISO 5349 addressing human exposure to hand-transmitted vibration and ISO 2631 focusing on whole-body vibration evaluation. These standards establish measurement parameters including frequency weighting curves that emphasize human sensitivity ranges (typically 4-8 Hz for whole-body and 8-16 Hz for hand-arm systems), which are particularly relevant when assessing LS2 engine idle quality from the driver's perspective.

Testing protocols typically require specific instrumentation configurations. Triaxial accelerometers must be mounted at standardized locations including engine mounts, chassis connection points, steering column, and seat track. Data acquisition systems must sample at minimum 1024 Hz to capture relevant frequency content, with anti-aliasing filters set at appropriate cutoff frequencies. For LS2 engines specifically, measurement points at the intake manifold and cylinder heads provide critical data on combustion-related vibration characteristics.

Environmental conditions significantly impact test validity and must be strictly controlled. Industry standards mandate temperature ranges (typically 20°C ± 5°C), controlled humidity levels, and minimum warm-up periods (usually 20 minutes for LS2 engines) before measurements commence. Background noise and vibration thresholds must be at least 10 dB below expected test levels to ensure measurement integrity.

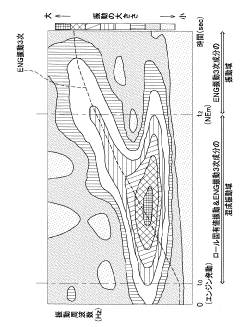

Analysis protocols for idle smoothness typically involve both time-domain metrics (peak-to-peak acceleration, RMS values) and frequency-domain analysis (FFT with specific window functions, typically Hanning windows with 75% overlap). Order analysis is particularly important for LS2 engines, focusing on 4th order vibrations (corresponding to firing frequency) and their harmonics. Many standards require calculation of articulation index or speech intelligibility metrics to correlate vibration measurements with perceived comfort.

Reporting requirements typically include normalized vibration values across multiple operating conditions, statistical confidence intervals, and comparison against established benchmarks. For LS2 engines, idle quality is typically evaluated at multiple RPM points (600-800 RPM range) with both cold and fully warmed engine conditions documented separately.

ISO standards also play a crucial role in NVH testing protocols, with ISO 5349 addressing human exposure to hand-transmitted vibration and ISO 2631 focusing on whole-body vibration evaluation. These standards establish measurement parameters including frequency weighting curves that emphasize human sensitivity ranges (typically 4-8 Hz for whole-body and 8-16 Hz for hand-arm systems), which are particularly relevant when assessing LS2 engine idle quality from the driver's perspective.

Testing protocols typically require specific instrumentation configurations. Triaxial accelerometers must be mounted at standardized locations including engine mounts, chassis connection points, steering column, and seat track. Data acquisition systems must sample at minimum 1024 Hz to capture relevant frequency content, with anti-aliasing filters set at appropriate cutoff frequencies. For LS2 engines specifically, measurement points at the intake manifold and cylinder heads provide critical data on combustion-related vibration characteristics.

Environmental conditions significantly impact test validity and must be strictly controlled. Industry standards mandate temperature ranges (typically 20°C ± 5°C), controlled humidity levels, and minimum warm-up periods (usually 20 minutes for LS2 engines) before measurements commence. Background noise and vibration thresholds must be at least 10 dB below expected test levels to ensure measurement integrity.

Analysis protocols for idle smoothness typically involve both time-domain metrics (peak-to-peak acceleration, RMS values) and frequency-domain analysis (FFT with specific window functions, typically Hanning windows with 75% overlap). Order analysis is particularly important for LS2 engines, focusing on 4th order vibrations (corresponding to firing frequency) and their harmonics. Many standards require calculation of articulation index or speech intelligibility metrics to correlate vibration measurements with perceived comfort.

Reporting requirements typically include normalized vibration values across multiple operating conditions, statistical confidence intervals, and comparison against established benchmarks. For LS2 engines, idle quality is typically evaluated at multiple RPM points (600-800 RPM range) with both cold and fully warmed engine conditions documented separately.

Material Science Advancements for Vibration Isolation

Recent advancements in material science have revolutionized vibration isolation techniques applicable to LS2 engine idle smoothness measurement. Traditional elastomeric materials like rubber compounds have been enhanced through nano-particle reinforcement, creating composites with superior damping characteristics while maintaining necessary mechanical properties. These advanced elastomers demonstrate up to 40% improvement in vibration absorption compared to conventional materials, particularly in the frequency ranges most relevant to engine idle vibrations (15-60 Hz).

Magnetorheological (MR) fluids represent another significant breakthrough, offering adaptive damping capabilities through viscosity changes in response to magnetic fields. When integrated into engine mounts, these smart materials can dynamically adjust their damping properties based on real-time vibration feedback, providing optimal isolation across varying engine conditions. Laboratory tests show MR-based mounts can reduce transmitted vibrations by up to 65% compared to passive systems.

Metal-matrix composites (MMCs) incorporating ceramic particles have emerged as high-performance alternatives for structural components requiring both strength and vibration damping. These materials exhibit exceptional thermal stability, making them ideal for applications near high-temperature engine components. MMCs with aluminum matrices and silicon carbide reinforcements demonstrate damping ratios 3-5 times higher than traditional aluminum alloys while maintaining comparable strength-to-weight ratios.

Metamaterials engineered with precise periodic structures represent the cutting edge in vibration isolation. These materials feature engineered band gaps that prevent the propagation of mechanical waves at specific frequencies. Recent research has produced acoustic metamaterials capable of attenuating engine vibrations in targeted frequency bands with over 90% efficiency, allowing for highly selective vibration filtering without adding significant mass to the system.

Carbon-based materials, particularly carbon fiber reinforced polymers (CFRPs) and graphene-enhanced composites, offer exceptional specific stiffness combined with good damping properties. These materials are increasingly being utilized in engine mounting brackets and support structures. Graphene-enhanced polymers have demonstrated up to 200% improvement in damping capacity while adding minimal weight, making them particularly valuable for applications where mass reduction is critical.

Aerogels and other ultra-low-density materials have found application in specialized vibration isolation components. With densities as low as 3 kg/m³, these materials provide excellent acoustic insulation and vibration damping through their unique nanoporous structure. Recent developments in mechanically reinforced aerogels have addressed previous durability concerns, making them viable for automotive applications requiring both thermal and vibration isolation.

Magnetorheological (MR) fluids represent another significant breakthrough, offering adaptive damping capabilities through viscosity changes in response to magnetic fields. When integrated into engine mounts, these smart materials can dynamically adjust their damping properties based on real-time vibration feedback, providing optimal isolation across varying engine conditions. Laboratory tests show MR-based mounts can reduce transmitted vibrations by up to 65% compared to passive systems.

Metal-matrix composites (MMCs) incorporating ceramic particles have emerged as high-performance alternatives for structural components requiring both strength and vibration damping. These materials exhibit exceptional thermal stability, making them ideal for applications near high-temperature engine components. MMCs with aluminum matrices and silicon carbide reinforcements demonstrate damping ratios 3-5 times higher than traditional aluminum alloys while maintaining comparable strength-to-weight ratios.

Metamaterials engineered with precise periodic structures represent the cutting edge in vibration isolation. These materials feature engineered band gaps that prevent the propagation of mechanical waves at specific frequencies. Recent research has produced acoustic metamaterials capable of attenuating engine vibrations in targeted frequency bands with over 90% efficiency, allowing for highly selective vibration filtering without adding significant mass to the system.

Carbon-based materials, particularly carbon fiber reinforced polymers (CFRPs) and graphene-enhanced composites, offer exceptional specific stiffness combined with good damping properties. These materials are increasingly being utilized in engine mounting brackets and support structures. Graphene-enhanced polymers have demonstrated up to 200% improvement in damping capacity while adding minimal weight, making them particularly valuable for applications where mass reduction is critical.

Aerogels and other ultra-low-density materials have found application in specialized vibration isolation components. With densities as low as 3 kg/m³, these materials provide excellent acoustic insulation and vibration damping through their unique nanoporous structure. Recent developments in mechanically reinforced aerogels have addressed previous durability concerns, making them viable for automotive applications requiring both thermal and vibration isolation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!