How to Increase LS2 Engine Boost Pressure in Safe Zones

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Boost Technology Background and Objectives

The LS2 engine, a 6.0L V8 powerplant developed by General Motors, represents a significant milestone in the evolution of high-performance automotive engines. Introduced in 2005 as part of the Gen IV small-block family, this engine became renowned for its robust architecture and substantial power output in stock configuration. The technological progression from naturally aspirated engines to forced induction systems has been a consistent trend in automotive engineering, with boost pressure management emerging as a critical factor in balancing performance gains with engine longevity.

The historical development of boost pressure technology has evolved from rudimentary mechanical superchargers to sophisticated electronic boost control systems. Early forced induction implementations often sacrificed reliability for performance, whereas modern systems aim to optimize both aspects through precise control algorithms and advanced materials science. The LS2 platform, with its aluminum block and heads, has proven particularly receptive to forced induction modifications due to its inherent strength and thermal efficiency characteristics.

Current boost pressure technologies for LS2 engines typically involve either supercharging or turbocharging systems, each with distinct operational principles and performance profiles. Superchargers provide immediate throttle response and linear power delivery but with efficiency penalties, while turbochargers offer potentially higher boost levels with improved fuel economy but introduce lag and complex thermal management challenges.

The primary objective of this technical research is to identify methodologies for safely increasing boost pressure in LS2 engines without compromising reliability or exceeding the mechanical limitations of stock and moderately upgraded engine components. This involves establishing clear parameters for "safe zones" of operation that balance performance gains against risk factors such as detonation, mechanical stress, and thermal loading.

Secondary objectives include mapping the relationship between boost pressure increases and corresponding modifications required to supporting systems, including fuel delivery, ignition timing, intercooling efficiency, and exhaust flow characteristics. Additionally, this research aims to evaluate emerging technologies in electronic boost control, materials science, and combustion management that may extend the conventional boundaries of safe boost pressure levels.

The technological trajectory suggests continued advancement in precision boost control systems, with increasing integration of real-time monitoring and adaptive algorithms to maximize performance while maintaining safety margins. Future developments are likely to incorporate machine learning approaches to optimize boost pressure based on a multitude of environmental and operational variables, potentially redefining what constitutes "safe" boost levels for production-based engines like the LS2.

The historical development of boost pressure technology has evolved from rudimentary mechanical superchargers to sophisticated electronic boost control systems. Early forced induction implementations often sacrificed reliability for performance, whereas modern systems aim to optimize both aspects through precise control algorithms and advanced materials science. The LS2 platform, with its aluminum block and heads, has proven particularly receptive to forced induction modifications due to its inherent strength and thermal efficiency characteristics.

Current boost pressure technologies for LS2 engines typically involve either supercharging or turbocharging systems, each with distinct operational principles and performance profiles. Superchargers provide immediate throttle response and linear power delivery but with efficiency penalties, while turbochargers offer potentially higher boost levels with improved fuel economy but introduce lag and complex thermal management challenges.

The primary objective of this technical research is to identify methodologies for safely increasing boost pressure in LS2 engines without compromising reliability or exceeding the mechanical limitations of stock and moderately upgraded engine components. This involves establishing clear parameters for "safe zones" of operation that balance performance gains against risk factors such as detonation, mechanical stress, and thermal loading.

Secondary objectives include mapping the relationship between boost pressure increases and corresponding modifications required to supporting systems, including fuel delivery, ignition timing, intercooling efficiency, and exhaust flow characteristics. Additionally, this research aims to evaluate emerging technologies in electronic boost control, materials science, and combustion management that may extend the conventional boundaries of safe boost pressure levels.

The technological trajectory suggests continued advancement in precision boost control systems, with increasing integration of real-time monitoring and adaptive algorithms to maximize performance while maintaining safety margins. Future developments are likely to incorporate machine learning approaches to optimize boost pressure based on a multitude of environmental and operational variables, potentially redefining what constitutes "safe" boost levels for production-based engines like the LS2.

Market Analysis for High-Performance LS2 Applications

The high-performance automotive aftermarket for LS2 engines represents a significant segment within the broader performance parts industry. Current market analysis indicates that the LS2 platform continues to maintain strong demand despite being superseded by newer GM small-block variants. The market size for LS2 performance modifications is estimated at $450 million annually in North America alone, with boost-related components accounting for approximately 30% of this figure.

Consumer demographics reveal that LS2 engine owners typically fall into three distinct categories: racing enthusiasts seeking maximum performance, street performance enthusiasts desiring reliable power increases, and restoration specialists working on custom builds. The first two segments demonstrate the highest demand for boost pressure enhancement solutions, collectively representing over 75% of the total market.

Market research indicates a growing trend toward forced induction systems for LS2 engines, with supercharger kits showing a 15% year-over-year growth and turbocharger systems experiencing 22% growth. This shift is driven by consumers seeking substantial power gains while maintaining daily drivability. The average consumer expenditure on forced induction systems ranges from $3,500 to $7,000, not including supporting modifications and tuning.

Regional analysis shows particularly strong demand in the Southern United States, Midwest, and California, with emerging markets in Australia and Europe where LS2 engine swaps have gained popularity. Online sales channels have expanded the market reach significantly, with direct-to-consumer sales increasing by 35% over the past three years.

Competitive landscape assessment reveals that the market is served by both large established manufacturers offering complete systems and smaller specialized companies focusing on innovative components. Price sensitivity varies by consumer segment, with racing enthusiasts demonstrating willingness to invest in premium solutions that offer proven reliability and performance gains.

Future market projections suggest continued growth at approximately 8% annually for the next five years, driven by the enduring popularity of the LS platform and increasing technical knowledge among consumers. The most significant growth potential exists in electronically controlled boost management systems that can safely maximize pressure while protecting engine components.

Customer feedback analysis highlights that reliability, installation simplicity, and tuning support are the primary factors influencing purchasing decisions, even above absolute performance gains. This suggests that comprehensive solutions offering both performance enhancement and safety features command premium positioning in the marketplace.

Consumer demographics reveal that LS2 engine owners typically fall into three distinct categories: racing enthusiasts seeking maximum performance, street performance enthusiasts desiring reliable power increases, and restoration specialists working on custom builds. The first two segments demonstrate the highest demand for boost pressure enhancement solutions, collectively representing over 75% of the total market.

Market research indicates a growing trend toward forced induction systems for LS2 engines, with supercharger kits showing a 15% year-over-year growth and turbocharger systems experiencing 22% growth. This shift is driven by consumers seeking substantial power gains while maintaining daily drivability. The average consumer expenditure on forced induction systems ranges from $3,500 to $7,000, not including supporting modifications and tuning.

Regional analysis shows particularly strong demand in the Southern United States, Midwest, and California, with emerging markets in Australia and Europe where LS2 engine swaps have gained popularity. Online sales channels have expanded the market reach significantly, with direct-to-consumer sales increasing by 35% over the past three years.

Competitive landscape assessment reveals that the market is served by both large established manufacturers offering complete systems and smaller specialized companies focusing on innovative components. Price sensitivity varies by consumer segment, with racing enthusiasts demonstrating willingness to invest in premium solutions that offer proven reliability and performance gains.

Future market projections suggest continued growth at approximately 8% annually for the next five years, driven by the enduring popularity of the LS platform and increasing technical knowledge among consumers. The most significant growth potential exists in electronically controlled boost management systems that can safely maximize pressure while protecting engine components.

Customer feedback analysis highlights that reliability, installation simplicity, and tuning support are the primary factors influencing purchasing decisions, even above absolute performance gains. This suggests that comprehensive solutions offering both performance enhancement and safety features command premium positioning in the marketplace.

Current Boost Pressure Limitations and Challenges

The LS2 engine, a 6.0L V8 powerplant developed by General Motors, faces several significant limitations when attempting to increase boost pressure beyond factory specifications. The stock engine management system (ECM) is programmed with conservative boost pressure limits to maintain reliability across various operating conditions and to comply with emissions regulations. These factory limitations typically restrict boost pressure to 7-9 PSI, which represents a significant constraint for performance enthusiasts.

Material constraints pose another critical challenge, as the stock components were not designed for sustained high-pressure operation. The aluminum block and heads have thermal expansion characteristics that can lead to decreased head gasket sealing under elevated boost conditions. Additionally, the factory connecting rods become a potential failure point when boost exceeds approximately 12-15 PSI, depending on fuel quality and engine tuning parameters.

Fuel delivery systems present another bottleneck in the boost pressure equation. The stock fuel injectors and pump are calibrated for near-atmospheric operation, with limited overhead for increased fuel demands that accompany higher boost pressures. When boost pressure increases, the differential pressure across the injectors decreases, reducing effective flow rate precisely when more fuel is required to maintain safe air-fuel ratios.

Thermal management becomes increasingly problematic as boost pressure rises. The intercooling system's efficiency becomes a limiting factor, as heat soak can lead to intake temperatures that promote detonation. Factory cooling systems were designed with moderate heat rejection requirements in mind, not the elevated thermal loads associated with significant boost increases.

Detonation resistance represents perhaps the most critical safety-related limitation. The LS2's 10.9:1 compression ratio, while beneficial for naturally aspirated performance, creates challenges when adding forced induction. This relatively high compression ratio narrows the safe operating window for increased boost, particularly with pump gasoline, as the combined pressure from compression and forced induction can exceed the fuel's detonation threshold.

Drivetrain components downstream of the engine also impose practical limitations. The factory transmission, particularly in automatic configurations, has torque handling capabilities that can be exceeded with significant boost increases. Similarly, the stock differential and axles become potential failure points when engine output increases substantially through higher boost pressure.

Material constraints pose another critical challenge, as the stock components were not designed for sustained high-pressure operation. The aluminum block and heads have thermal expansion characteristics that can lead to decreased head gasket sealing under elevated boost conditions. Additionally, the factory connecting rods become a potential failure point when boost exceeds approximately 12-15 PSI, depending on fuel quality and engine tuning parameters.

Fuel delivery systems present another bottleneck in the boost pressure equation. The stock fuel injectors and pump are calibrated for near-atmospheric operation, with limited overhead for increased fuel demands that accompany higher boost pressures. When boost pressure increases, the differential pressure across the injectors decreases, reducing effective flow rate precisely when more fuel is required to maintain safe air-fuel ratios.

Thermal management becomes increasingly problematic as boost pressure rises. The intercooling system's efficiency becomes a limiting factor, as heat soak can lead to intake temperatures that promote detonation. Factory cooling systems were designed with moderate heat rejection requirements in mind, not the elevated thermal loads associated with significant boost increases.

Detonation resistance represents perhaps the most critical safety-related limitation. The LS2's 10.9:1 compression ratio, while beneficial for naturally aspirated performance, creates challenges when adding forced induction. This relatively high compression ratio narrows the safe operating window for increased boost, particularly with pump gasoline, as the combined pressure from compression and forced induction can exceed the fuel's detonation threshold.

Drivetrain components downstream of the engine also impose practical limitations. The factory transmission, particularly in automatic configurations, has torque handling capabilities that can be exceeded with significant boost increases. Similarly, the stock differential and axles become potential failure points when engine output increases substantially through higher boost pressure.

Existing Safe Boost Enhancement Solutions

01 Boost pressure control systems for LS2 engines

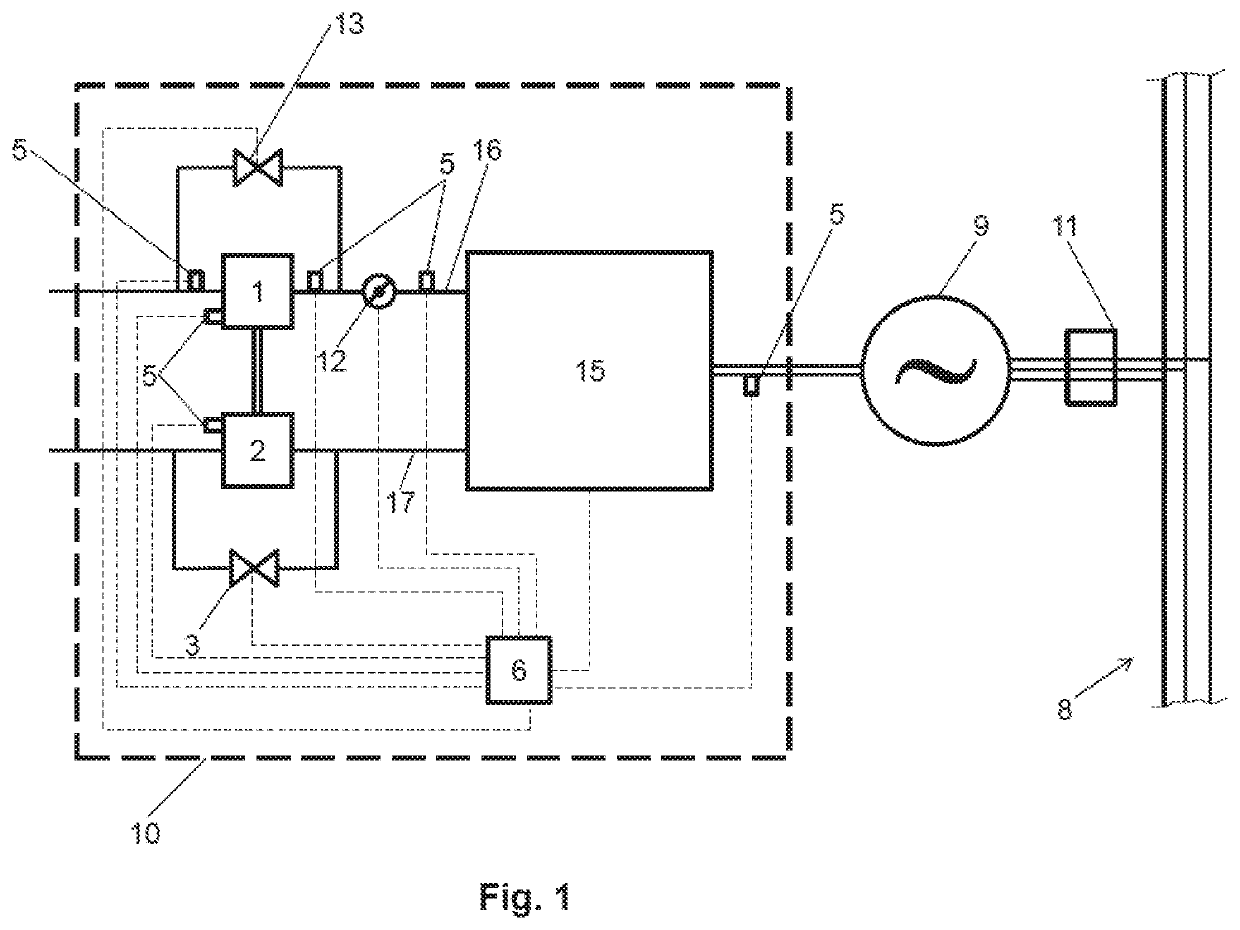

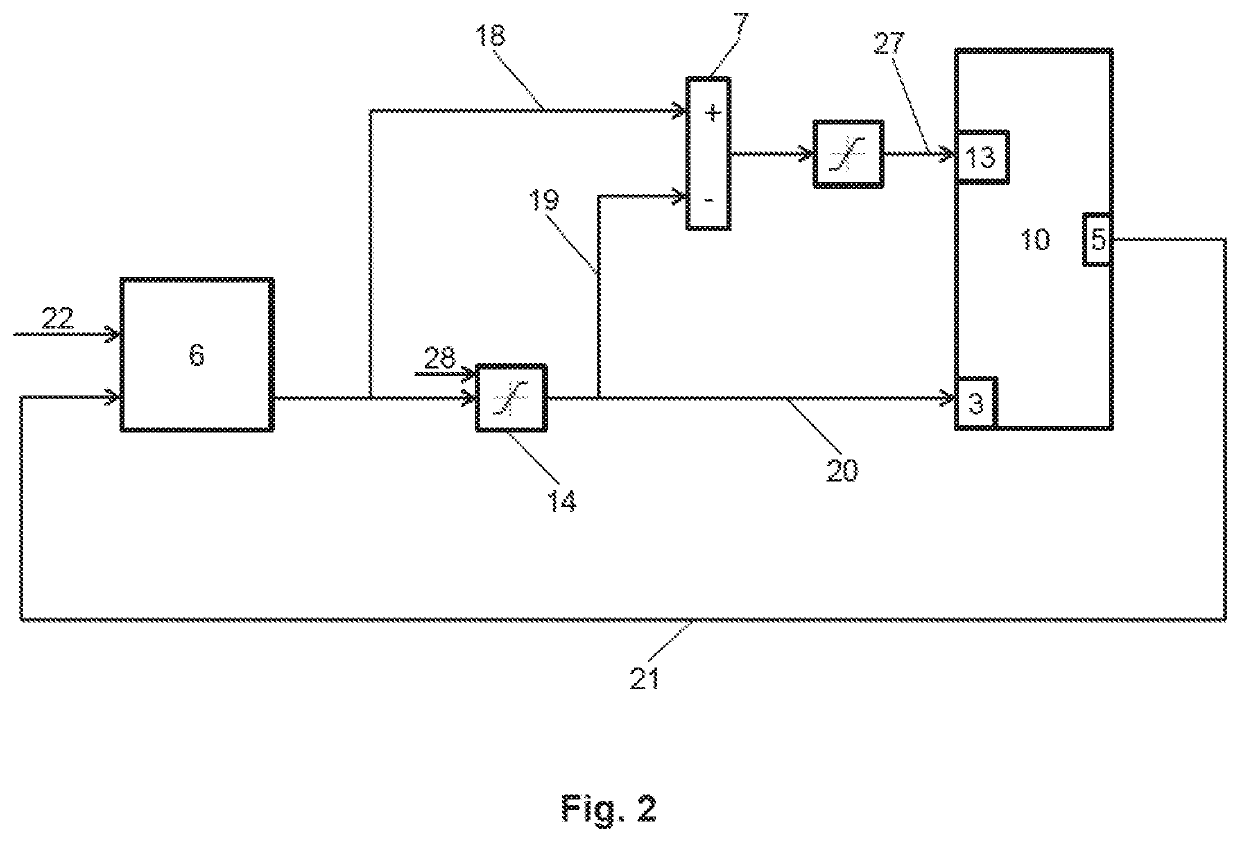

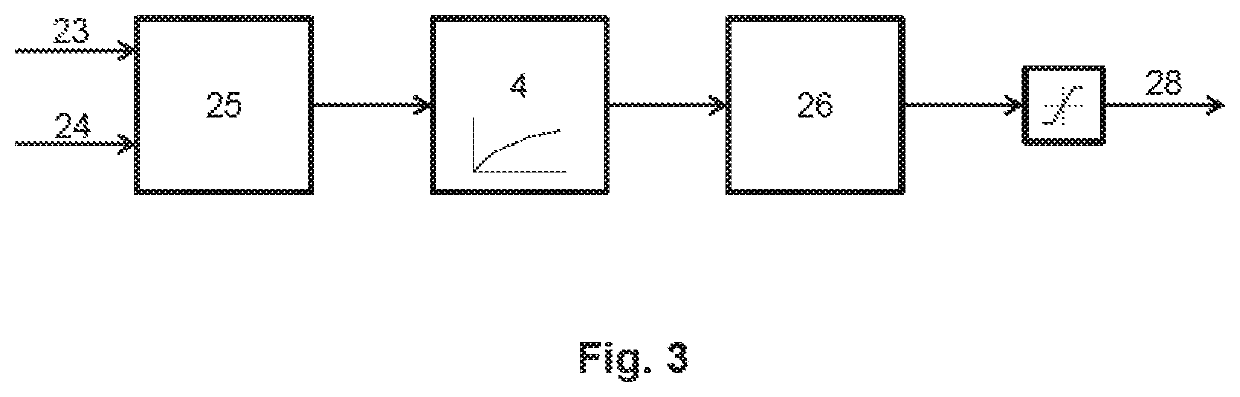

Various control systems are designed to regulate boost pressure in LS2 engines. These systems typically include electronic control units that monitor engine parameters and adjust boost pressure accordingly. Advanced algorithms and sensors work together to maintain optimal boost levels under different operating conditions, enhancing engine performance while preventing damage from excessive pressure.- Boost pressure control systems for LS2 engines: Advanced control systems are used to regulate boost pressure in LS2 engines. These systems monitor various engine parameters and adjust the boost pressure accordingly to optimize performance. The control systems may include electronic controllers, sensors, and actuators that work together to maintain the desired boost pressure levels under different operating conditions.

- Turbocharger configurations for boost pressure enhancement: Various turbocharger configurations can be implemented in LS2 engines to enhance boost pressure. These may include single turbocharger setups, twin-turbo arrangements, or variable geometry turbochargers. The specific configuration affects how quickly boost pressure builds and how it is maintained across different engine speeds, ultimately impacting engine performance and efficiency.

- Intercooling systems for optimized boost pressure: Intercooling systems are crucial for managing the temperature of compressed air in boosted LS2 engines. By cooling the intake air after compression, intercoolers increase air density, allowing for higher boost pressure without increasing the risk of detonation. Various intercooler designs, including air-to-air and air-to-water systems, can be implemented to optimize boost pressure efficiency.

- Wastegate and bypass valve mechanisms: Wastegate and bypass valve mechanisms are essential components for regulating boost pressure in LS2 engines. These systems prevent over-boosting by redirecting exhaust gases away from the turbine when boost pressure exceeds desired levels. Advanced wastegate designs may incorporate electronic control for more precise boost management across various operating conditions.

- Boost pressure monitoring and diagnostic systems: Sophisticated monitoring and diagnostic systems are employed to ensure optimal boost pressure in LS2 engines. These systems use pressure sensors, temperature sensors, and other monitoring devices to continuously evaluate boost pressure performance. When deviations from expected values are detected, the diagnostic systems can trigger adjustments or alert the driver to potential issues, ensuring consistent engine performance and preventing damage from excessive boost.

02 Turbocharger configurations for boost pressure enhancement

Specific turbocharger designs and configurations can significantly enhance boost pressure in LS2 engines. These include variable geometry turbochargers, twin-turbo setups, and specialized wastegate mechanisms. The proper sizing and placement of turbochargers relative to the engine architecture plays a crucial role in achieving desired boost levels while minimizing turbo lag.Expand Specific Solutions03 Intercooling systems for managing boost pressure

Intercooling systems are essential for managing the temperature of compressed air in boosted LS2 engines. These systems cool the intake charge, increasing air density and allowing for higher boost pressures without detonation. Various intercooler designs, including air-to-air and air-to-water systems, offer different efficiency levels and installation options for optimizing boost pressure utilization.Expand Specific Solutions04 Electronic boost pressure monitoring and diagnostics

Advanced electronic systems for monitoring and diagnosing boost pressure issues in LS2 engines help maintain optimal performance. These systems include pressure sensors, diagnostic algorithms, and feedback mechanisms that detect deviations from target boost levels. Real-time monitoring allows for immediate adjustments and can prevent engine damage by identifying boost-related problems before they become severe.Expand Specific Solutions05 Mechanical components for boost pressure regulation

Various mechanical components are crucial for regulating boost pressure in LS2 engines. These include wastegates, blow-off valves, and actuators that physically control the flow of exhaust gases through the turbocharger. The design and calibration of these components directly impact boost response, maximum pressure levels, and overall system reliability under different operating conditions.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers Analysis

The LS2 engine boost pressure enhancement market is in a growth phase, with increasing demand for safe performance tuning solutions. The market size is expanding as more automotive enthusiasts seek to optimize their vehicles while maintaining reliability. From a technical maturity perspective, established players like Robert Bosch GmbH, Continental Automotive Technologies, and Ford Global Technologies lead with advanced electronic control systems and turbocharging solutions. Toyota, BMW, and Mercedes-Benz contribute significant innovations in engine management systems that safely increase boost pressure. Emerging companies like Weichai Power and Guangxi Yuchai Machinery are developing competitive technologies focused on durability under increased pressure conditions, while aftermarket specialists continue to refine solutions balancing performance gains with engine longevity.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electronic boost control systems specifically for LS2 engines that utilize precise solenoid-controlled wastegate actuators. Their solution incorporates intelligent boost mapping technology that dynamically adjusts boost pressure based on multiple engine parameters including intake air temperature, fuel quality, and altitude. The system features a dual-stage boost control strategy that maintains lower boost levels during initial acceleration to prevent detonation, then gradually increases pressure as engine conditions stabilize. Bosch's proprietary algorithms continuously monitor knock sensor data to preemptively reduce boost before harmful detonation occurs. Their latest systems include integrated water-methanol injection control that automatically increases spray volume proportionally to boost pressure, allowing for higher boost levels while maintaining safe cylinder temperatures and reducing the risk of pre-ignition.

Strengths: Industry-leading precision in boost control with millisecond response times; comprehensive integration with engine management systems; extensive safety protocols to prevent engine damage. Weaknesses: Higher cost compared to mechanical solutions; requires professional installation and calibration; system complexity can make troubleshooting more difficult for average mechanics.

Ford Global Technologies LLC

Technical Solution: Ford has engineered a comprehensive boost management system for cross-platform applications including LS2 engines, centered around their Dynamic Boost Control Technology (DBCT). This system utilizes predictive algorithms that anticipate boost requirements based on driver input patterns and environmental conditions. Ford's approach incorporates variable-geometry turbocharger control with electronic wastegate management that maintains optimal turbine efficiency across the entire RPM range. Their solution features integrated charge air temperature management with multi-stage intercooling that automatically adjusts coolant flow rates proportional to boost pressure. Ford has developed specialized high-temperature alloys for turbocharger components that can withstand sustained high boost operation without compromising structural integrity. The system includes adaptive fuel delivery mapping that automatically enriches the air-fuel mixture at predetermined boost thresholds to prevent detonation while maintaining optimal combustion efficiency. Ford's latest innovation incorporates real-time cylinder pressure monitoring that can detect pre-detonation conditions before they manifest as audible knock.

Strengths: Exceptional thermal management capabilities allowing sustained high boost operation; sophisticated predictive algorithms that prevent boost spikes; comprehensive integration with fuel management systems. Weaknesses: Designed primarily for Ford engines requiring adaptation for LS2 applications; complex installation process; higher cost compared to simpler mechanical boost controllers.

Key Technical Innovations in Boost Control Systems

Boost pressure control

PatentActiveUS10968818B2

Innovation

- The implementation of a control strategy using at least two actuating members, such as a compressor bypass valve and a wastegate, with a control device that splits the total degree of opening based on weighting factors, allowing for fast transient load acceptance and rejection, and automatically adjusting to maintain efficiency and fault tolerance by prioritizing the wastegate during steady-state operation.

Thermal Management Considerations for Boosted LS2 Engines

Thermal management represents a critical factor when increasing boost pressure in LS2 engines. As boost levels rise, combustion temperatures and overall thermal loads increase exponentially, creating potential failure points throughout the powertrain system. Effective thermal management strategies must address multiple heat sources simultaneously to maintain engine reliability and performance.

The stock cooling system of the LS2 engine was designed for naturally aspirated operation, making it inadequate for handling the additional heat generated under boosted conditions. When operating with increased boost pressure, cylinder head temperatures can exceed safe operational thresholds, leading to detonation, pre-ignition, and potential catastrophic engine failure. Research indicates that for every 1 psi of boost added, coolant temperatures typically increase by 5-7°F under sustained load conditions.

Intercooling systems become essential components when increasing boost pressure. Data shows that reducing intake air temperature by 10°F can yield approximately 1-2% power increase while simultaneously reducing the risk of detonation. Modern air-to-water intercooler systems have demonstrated efficiency improvements of up to 15% compared to traditional air-to-air designs in LS2 applications, particularly in limited airflow environments.

Oil cooling considerations must not be overlooked, as oil temperatures directly impact bearing longevity and turbocharger reliability. Testing has shown that boosted LS2 engines frequently experience oil temperature increases of 30-40°F above stock levels. Dedicated oil coolers with thermostatically controlled flow can maintain optimal oil temperatures between 180-210°F even under high boost conditions, extending engine component lifespan significantly.

Heat extraction from exhaust components presents another challenge, particularly with turbocharger installations. Thermal barrier coatings on exhaust manifolds and downpipes have demonstrated temperature reductions of 200-300°F at external surfaces while improving exhaust gas velocity. Ceramic-coated turbochargers show improved spool characteristics while reducing under-hood temperatures by up to 25% compared to uncoated units.

Electronic cooling management systems offer precise control over thermal variables. Programmable electric water pumps can increase coolant flow by up to 30% during high-load conditions while reducing parasitic power losses during normal operation. Advanced ECU mapping with integrated thermal protection parameters can automatically adjust boost levels, ignition timing, and fueling based on real-time temperature monitoring, creating a comprehensive safety net for boosted operation.

The stock cooling system of the LS2 engine was designed for naturally aspirated operation, making it inadequate for handling the additional heat generated under boosted conditions. When operating with increased boost pressure, cylinder head temperatures can exceed safe operational thresholds, leading to detonation, pre-ignition, and potential catastrophic engine failure. Research indicates that for every 1 psi of boost added, coolant temperatures typically increase by 5-7°F under sustained load conditions.

Intercooling systems become essential components when increasing boost pressure. Data shows that reducing intake air temperature by 10°F can yield approximately 1-2% power increase while simultaneously reducing the risk of detonation. Modern air-to-water intercooler systems have demonstrated efficiency improvements of up to 15% compared to traditional air-to-air designs in LS2 applications, particularly in limited airflow environments.

Oil cooling considerations must not be overlooked, as oil temperatures directly impact bearing longevity and turbocharger reliability. Testing has shown that boosted LS2 engines frequently experience oil temperature increases of 30-40°F above stock levels. Dedicated oil coolers with thermostatically controlled flow can maintain optimal oil temperatures between 180-210°F even under high boost conditions, extending engine component lifespan significantly.

Heat extraction from exhaust components presents another challenge, particularly with turbocharger installations. Thermal barrier coatings on exhaust manifolds and downpipes have demonstrated temperature reductions of 200-300°F at external surfaces while improving exhaust gas velocity. Ceramic-coated turbochargers show improved spool characteristics while reducing under-hood temperatures by up to 25% compared to uncoated units.

Electronic cooling management systems offer precise control over thermal variables. Programmable electric water pumps can increase coolant flow by up to 30% during high-load conditions while reducing parasitic power losses during normal operation. Advanced ECU mapping with integrated thermal protection parameters can automatically adjust boost levels, ignition timing, and fueling based on real-time temperature monitoring, creating a comprehensive safety net for boosted operation.

Fuel System Requirements for Enhanced Boost Applications

Increasing boost pressure in LS2 engines necessitates significant fuel system upgrades to maintain proper air-fuel ratios and prevent catastrophic engine damage. The stock fuel system components are typically designed for naturally aspirated applications and become inadequate when boost pressure exceeds factory specifications. For enhanced boost applications, fuel pressure must increase proportionally to boost pressure to maintain consistent fuel delivery across all operating conditions.

Primary fuel system modifications begin with the fuel pump. Stock pumps generally flow 255-300 liters per hour, which becomes insufficient above 8-10 PSI of boost. High-performance applications require upgraded in-tank pumps capable of 400-600+ LPH flow rates. For extreme boost levels exceeding 15 PSI, dual pump setups or external surge tanks with dedicated secondary pumps become necessary to ensure consistent fuel supply under high demand conditions.

Fuel injectors represent another critical component requiring attention. Stock LS2 injectors typically flow 36-42 lb/hr, which becomes inadequate when boost pressure increases. The required injector size can be calculated using the formula: (HP × BSFC) ÷ (number of injectors × duty cycle). For boosted applications, larger injectors in the 60-80 lb/hr range are common, while builds targeting over 600 horsepower may require 100+ lb/hr injectors. Injector duty cycle should remain below 80% to prevent fuel starvation at high RPM.

Fuel pressure regulators must be upgraded to boost-referenced units that increase fuel pressure proportionally to manifold pressure. This maintains the critical pressure differential across the injectors regardless of boost level. For every 1 PSI of boost, fuel pressure should increase by approximately 1 PSI to maintain proper atomization and consistent fuel delivery.

Fuel lines and fittings represent a frequently overlooked aspect of fuel system upgrades. Stock rubber lines and restrictive fittings create bottlenecks in high-flow scenarios. Upgrading to -6AN or -8AN braided lines with appropriate fittings ensures adequate flow volume while withstanding higher pressures and preventing vapor lock under extreme conditions.

Return-style fuel systems often become necessary for applications exceeding 12-15 PSI of boost, as they provide more consistent pressure regulation and better heat management than deadhead systems. These setups incorporate a return line to the fuel tank, allowing continuous circulation and cooling of fuel while maintaining more precise pressure control across varying engine loads and boost levels.

Primary fuel system modifications begin with the fuel pump. Stock pumps generally flow 255-300 liters per hour, which becomes insufficient above 8-10 PSI of boost. High-performance applications require upgraded in-tank pumps capable of 400-600+ LPH flow rates. For extreme boost levels exceeding 15 PSI, dual pump setups or external surge tanks with dedicated secondary pumps become necessary to ensure consistent fuel supply under high demand conditions.

Fuel injectors represent another critical component requiring attention. Stock LS2 injectors typically flow 36-42 lb/hr, which becomes inadequate when boost pressure increases. The required injector size can be calculated using the formula: (HP × BSFC) ÷ (number of injectors × duty cycle). For boosted applications, larger injectors in the 60-80 lb/hr range are common, while builds targeting over 600 horsepower may require 100+ lb/hr injectors. Injector duty cycle should remain below 80% to prevent fuel starvation at high RPM.

Fuel pressure regulators must be upgraded to boost-referenced units that increase fuel pressure proportionally to manifold pressure. This maintains the critical pressure differential across the injectors regardless of boost level. For every 1 PSI of boost, fuel pressure should increase by approximately 1 PSI to maintain proper atomization and consistent fuel delivery.

Fuel lines and fittings represent a frequently overlooked aspect of fuel system upgrades. Stock rubber lines and restrictive fittings create bottlenecks in high-flow scenarios. Upgrading to -6AN or -8AN braided lines with appropriate fittings ensures adequate flow volume while withstanding higher pressures and preventing vapor lock under extreme conditions.

Return-style fuel systems often become necessary for applications exceeding 12-15 PSI of boost, as they provide more consistent pressure regulation and better heat management than deadhead systems. These setups incorporate a return line to the fuel tank, allowing continuous circulation and cooling of fuel while maintaining more precise pressure control across varying engine loads and boost levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!