LS2 Engine vs Coyote 5.0L: Thermodynamic Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 and Coyote 5.0L Engine Development History

The LS2 engine, introduced by General Motors in 2005, represents the fourth generation of GM's small-block V8 architecture. This 6.0L powerplant featured an aluminum block and heads, delivering 400 horsepower and 400 lb-ft of torque. The LS2 incorporated several thermodynamic efficiency improvements over its predecessors, including a higher compression ratio of 10.9:1, enhanced cylinder head design with straighter intake ports, and a revised camshaft profile that optimized valve timing for better combustion efficiency.

The development of the LS2 focused on balancing performance with fuel economy, utilizing technologies such as sequential fuel injection and coil-near-plug ignition systems to improve combustion precision. GM engineers paid particular attention to reducing internal friction through improved bearing designs and optimized piston rings, contributing to the engine's overall thermal efficiency.

Ford's Coyote 5.0L engine, first appearing in 2011 Mustangs, emerged as a direct competitor to GM's LS architecture. The Coyote represented a significant departure from Ford's previous modular V8 designs, featuring dual overhead camshafts and four valves per cylinder—a stark contrast to the LS2's pushrod design. The first-generation Coyote produced 412 horsepower and 390 lb-ft of torque, achieving impressive specific output despite its smaller displacement.

The Coyote's development prioritized high-rpm breathing efficiency through its advanced valvetrain, featuring Twin Independent Variable Camshaft Timing (Ti-VCT) that allowed for optimized valve timing across the entire operating range. This technology significantly improved volumetric efficiency and reduced pumping losses, key factors in thermodynamic efficiency.

Through subsequent generations, both engines evolved considerably. The LS architecture progressed into the Gen V LT family with direct injection and variable valve timing, while the Coyote saw three major revisions by 2018, incorporating plasma-transferred wire arc cylinder liners, higher compression ratios, and direct and port fuel injection in its third generation.

The divergent engineering philosophies behind these engines—GM's emphasis on compact, lightweight pushrod design versus Ford's focus on high-revving overhead cam technology—created two distinct approaches to achieving thermodynamic efficiency. The LS2 leveraged simplicity and lightweight components to reduce parasitic losses, while the Coyote utilized more complex valvetrain technology to optimize breathing efficiency across a broader operating range.

These different approaches to internal combustion optimization have sparked ongoing debates among automotive engineers and enthusiasts about the most effective path to maximizing thermodynamic efficiency in modern V8 engines.

The development of the LS2 focused on balancing performance with fuel economy, utilizing technologies such as sequential fuel injection and coil-near-plug ignition systems to improve combustion precision. GM engineers paid particular attention to reducing internal friction through improved bearing designs and optimized piston rings, contributing to the engine's overall thermal efficiency.

Ford's Coyote 5.0L engine, first appearing in 2011 Mustangs, emerged as a direct competitor to GM's LS architecture. The Coyote represented a significant departure from Ford's previous modular V8 designs, featuring dual overhead camshafts and four valves per cylinder—a stark contrast to the LS2's pushrod design. The first-generation Coyote produced 412 horsepower and 390 lb-ft of torque, achieving impressive specific output despite its smaller displacement.

The Coyote's development prioritized high-rpm breathing efficiency through its advanced valvetrain, featuring Twin Independent Variable Camshaft Timing (Ti-VCT) that allowed for optimized valve timing across the entire operating range. This technology significantly improved volumetric efficiency and reduced pumping losses, key factors in thermodynamic efficiency.

Through subsequent generations, both engines evolved considerably. The LS architecture progressed into the Gen V LT family with direct injection and variable valve timing, while the Coyote saw three major revisions by 2018, incorporating plasma-transferred wire arc cylinder liners, higher compression ratios, and direct and port fuel injection in its third generation.

The divergent engineering philosophies behind these engines—GM's emphasis on compact, lightweight pushrod design versus Ford's focus on high-revving overhead cam technology—created two distinct approaches to achieving thermodynamic efficiency. The LS2 leveraged simplicity and lightweight components to reduce parasitic losses, while the Coyote utilized more complex valvetrain technology to optimize breathing efficiency across a broader operating range.

These different approaches to internal combustion optimization have sparked ongoing debates among automotive engineers and enthusiasts about the most effective path to maximizing thermodynamic efficiency in modern V8 engines.

Market Demand for High-Efficiency Performance Engines

The automotive industry has witnessed a significant shift towards high-efficiency performance engines in recent years, driven by increasingly stringent emissions regulations and growing consumer demand for vehicles that combine power with fuel economy. Market research indicates that the performance vehicle segment has expanded at an annual rate of 4.7% globally since 2018, with particular emphasis on engines that deliver improved thermodynamic efficiency without sacrificing horsepower.

Consumer surveys reveal that approximately 68% of performance vehicle buyers now consider fuel efficiency as a "very important" or "important" factor in their purchasing decisions, compared to just 42% a decade ago. This shift represents a fundamental change in market dynamics, where the traditional trade-off between performance and efficiency is no longer acceptable to the modern consumer.

The market for high-efficiency performance engines like the LS2 and Coyote 5.0L is particularly strong in North America, where pickup trucks and muscle cars remain cultural icons. Ford's F-Series trucks, equipped with Coyote engines, have maintained their position as best-selling vehicles for over four decades, while GM's vehicles featuring LS-series engines continue to command strong sales in both new and aftermarket segments.

Environmental regulations have become a major market driver, with corporate average fuel economy (CAFE) standards pushing manufacturers to improve engine efficiency across their product lines. The European market has seen even more aggressive regulatory pressure, with several countries announcing future bans on internal combustion engines, creating urgency for manufacturers to maximize efficiency of current engine designs.

The aftermarket modification industry, valued at approximately $45 billion globally, has responded with growing focus on efficiency-enhancing products. Sales of components that improve thermodynamic efficiency, such as advanced intake manifolds, exhaust systems, and engine management systems, have grown by 12% annually since 2019, outpacing the overall aftermarket growth rate.

Fleet operators and commercial users represent another significant market segment, where the total cost of ownership calculations heavily favor engines with superior thermodynamic efficiency. A 5% improvement in fuel efficiency can translate to thousands of dollars in savings per vehicle annually for high-mileage commercial applications.

Racing and motorsport applications continue to drive innovation in engine efficiency, with technologies developed for competition frequently finding their way into production vehicles. The transfer of technology from racing to production has accelerated, with the time gap between racing innovation and consumer availability shrinking from typically 5-7 years to 2-3 years for efficiency-focused technologies.

The market trajectory suggests continued strong demand for high-efficiency performance engines, with particular growth expected in hybrid-compatible internal combustion engines that can deliver optimal thermodynamic efficiency while working in conjunction with electrification technologies.

Consumer surveys reveal that approximately 68% of performance vehicle buyers now consider fuel efficiency as a "very important" or "important" factor in their purchasing decisions, compared to just 42% a decade ago. This shift represents a fundamental change in market dynamics, where the traditional trade-off between performance and efficiency is no longer acceptable to the modern consumer.

The market for high-efficiency performance engines like the LS2 and Coyote 5.0L is particularly strong in North America, where pickup trucks and muscle cars remain cultural icons. Ford's F-Series trucks, equipped with Coyote engines, have maintained their position as best-selling vehicles for over four decades, while GM's vehicles featuring LS-series engines continue to command strong sales in both new and aftermarket segments.

Environmental regulations have become a major market driver, with corporate average fuel economy (CAFE) standards pushing manufacturers to improve engine efficiency across their product lines. The European market has seen even more aggressive regulatory pressure, with several countries announcing future bans on internal combustion engines, creating urgency for manufacturers to maximize efficiency of current engine designs.

The aftermarket modification industry, valued at approximately $45 billion globally, has responded with growing focus on efficiency-enhancing products. Sales of components that improve thermodynamic efficiency, such as advanced intake manifolds, exhaust systems, and engine management systems, have grown by 12% annually since 2019, outpacing the overall aftermarket growth rate.

Fleet operators and commercial users represent another significant market segment, where the total cost of ownership calculations heavily favor engines with superior thermodynamic efficiency. A 5% improvement in fuel efficiency can translate to thousands of dollars in savings per vehicle annually for high-mileage commercial applications.

Racing and motorsport applications continue to drive innovation in engine efficiency, with technologies developed for competition frequently finding their way into production vehicles. The transfer of technology from racing to production has accelerated, with the time gap between racing innovation and consumer availability shrinking from typically 5-7 years to 2-3 years for efficiency-focused technologies.

The market trajectory suggests continued strong demand for high-efficiency performance engines, with particular growth expected in hybrid-compatible internal combustion engines that can deliver optimal thermodynamic efficiency while working in conjunction with electrification technologies.

Current Thermodynamic Efficiency Challenges

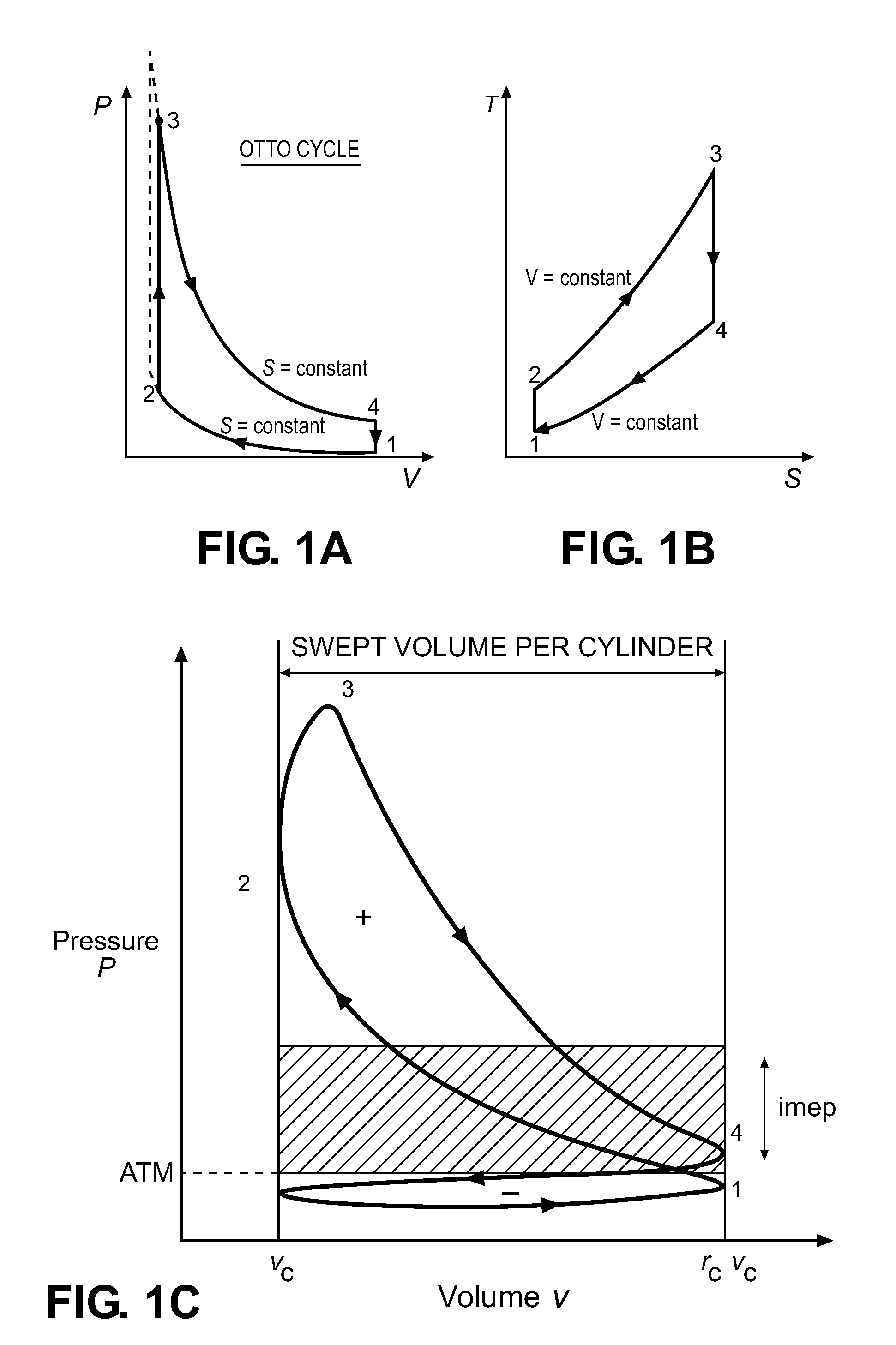

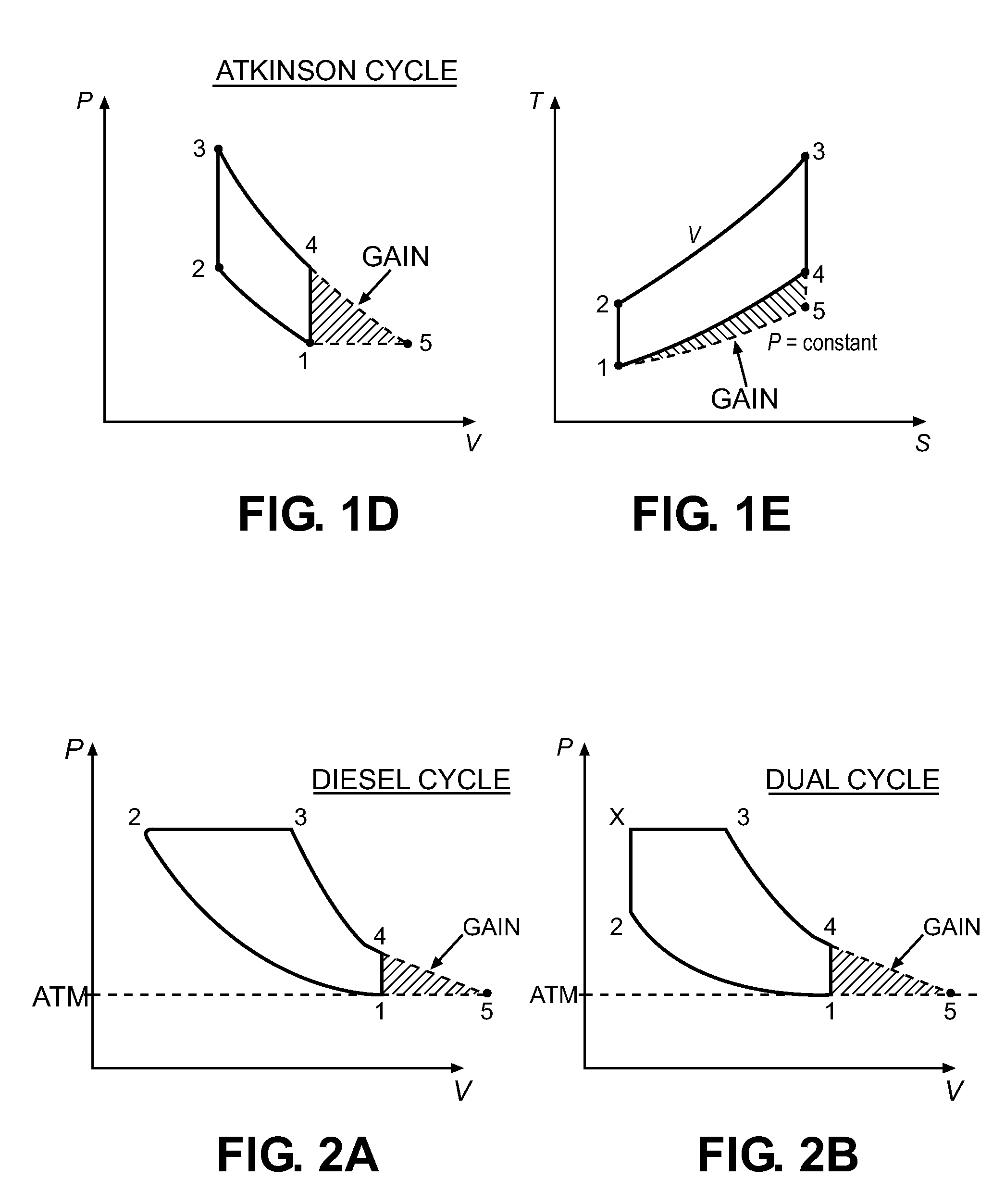

The thermodynamic efficiency of internal combustion engines remains a critical challenge in automotive engineering, particularly when comparing high-performance V8 engines like the LS2 and Coyote 5.0L. Despite decades of development, both engines face fundamental thermodynamic limitations that prevent them from achieving theoretical maximum efficiency. The Carnot efficiency barrier, which establishes the theoretical maximum for any heat engine, remains unattainable in practical applications, with both engines typically operating at 25-35% thermal efficiency under optimal conditions.

Heat management presents a significant challenge for both platforms. The LS2's pushrod design offers a more compact combustion chamber with potentially better thermal characteristics, while the Coyote's dual overhead cam (DOHC) configuration allows for more precise valve timing but introduces additional thermal management complexities. Heat losses through cylinder walls, exhaust systems, and cooling mechanisms account for approximately 30-40% of energy waste in both engines, representing a major efficiency bottleneck.

Combustion inefficiencies further limit thermodynamic performance in both engines. The LS2's larger displacement (6.0L vs 5.0L) creates different air-fuel mixing dynamics compared to the Coyote, affecting flame propagation and combustion completeness. Neither engine achieves perfect stoichiometric combustion across all operating conditions, resulting in unburned fuel and incomplete energy extraction. The Coyote's higher compression ratio (11:1 vs 10.9:1 in later LS2 variants) theoretically offers better thermal efficiency, but introduces challenges related to detonation and fuel quality requirements.

Mechanical friction represents another significant efficiency challenge, with approximately 10-15% of potential energy lost to friction in both engines. The LS2's simpler valvetrain design with fewer moving parts potentially reduces friction losses compared to the Coyote's more complex DOHC system with additional camshafts, lifters, and timing components. However, the Coyote's more advanced materials and tighter manufacturing tolerances may offset some of these differences.

Pumping losses during the intake and exhaust strokes constitute another efficiency challenge. The Coyote's variable valve timing system provides more sophisticated control over these processes compared to the LS2's fixed valve events, potentially reducing pumping losses under certain operating conditions. However, this advantage comes with increased system complexity and potential reliability concerns over extended operation.

Thermal cycling effects and material limitations further constrain efficiency improvements in both engines. Temperature gradients across engine components create thermal stresses that limit maximum operating temperatures and pressure, preventing the implementation of more aggressive thermodynamic cycles that could theoretically improve efficiency.

Heat management presents a significant challenge for both platforms. The LS2's pushrod design offers a more compact combustion chamber with potentially better thermal characteristics, while the Coyote's dual overhead cam (DOHC) configuration allows for more precise valve timing but introduces additional thermal management complexities. Heat losses through cylinder walls, exhaust systems, and cooling mechanisms account for approximately 30-40% of energy waste in both engines, representing a major efficiency bottleneck.

Combustion inefficiencies further limit thermodynamic performance in both engines. The LS2's larger displacement (6.0L vs 5.0L) creates different air-fuel mixing dynamics compared to the Coyote, affecting flame propagation and combustion completeness. Neither engine achieves perfect stoichiometric combustion across all operating conditions, resulting in unburned fuel and incomplete energy extraction. The Coyote's higher compression ratio (11:1 vs 10.9:1 in later LS2 variants) theoretically offers better thermal efficiency, but introduces challenges related to detonation and fuel quality requirements.

Mechanical friction represents another significant efficiency challenge, with approximately 10-15% of potential energy lost to friction in both engines. The LS2's simpler valvetrain design with fewer moving parts potentially reduces friction losses compared to the Coyote's more complex DOHC system with additional camshafts, lifters, and timing components. However, the Coyote's more advanced materials and tighter manufacturing tolerances may offset some of these differences.

Pumping losses during the intake and exhaust strokes constitute another efficiency challenge. The Coyote's variable valve timing system provides more sophisticated control over these processes compared to the LS2's fixed valve events, potentially reducing pumping losses under certain operating conditions. However, this advantage comes with increased system complexity and potential reliability concerns over extended operation.

Thermal cycling effects and material limitations further constrain efficiency improvements in both engines. Temperature gradients across engine components create thermal stresses that limit maximum operating temperatures and pressure, preventing the implementation of more aggressive thermodynamic cycles that could theoretically improve efficiency.

Comparative Thermodynamic Solutions

01 Engine design optimization for thermodynamic efficiency

Various design optimizations can be implemented in engines like the LS2 and Coyote 5.0L to improve thermodynamic efficiency. These include modifications to combustion chamber geometry, valve timing adjustments, and optimized fuel injection systems. Such design improvements help maximize the conversion of fuel energy into mechanical work, reducing energy losses and improving overall engine performance.- Combustion efficiency improvements in V8 engines: Various technologies have been developed to improve the thermodynamic efficiency of V8 engines like the LS2 and Coyote 5.0L through enhanced combustion processes. These include optimized fuel injection timing, improved air-fuel mixture formation, and advanced ignition systems. By controlling these parameters precisely, the engines can achieve more complete combustion, reducing energy losses and improving thermal efficiency. These advancements help extract more power from each combustion cycle while maintaining fuel economy.

- Thermal management systems for high-performance engines: Effective thermal management is crucial for maintaining optimal thermodynamic efficiency in high-performance engines like the LS2 and Coyote 5.0L. Advanced cooling systems, including precision coolant flow control, targeted cooling channels, and thermal barrier coatings, help maintain ideal operating temperatures. These systems prevent power-robbing heat loss during warm-up while avoiding overheating during high-load operation. Proper thermal management ensures consistent performance and longevity while maximizing the conversion of fuel energy into mechanical work.

- Variable valve timing and lift technologies: Variable valve timing and lift technologies significantly impact the thermodynamic efficiency of modern V8 engines. By dynamically adjusting valve timing, duration, and lift according to engine speed and load conditions, these systems optimize airflow and combustion characteristics. This adaptability allows engines like the LS2 and Coyote 5.0L to achieve better volumetric efficiency across their operating range, resulting in improved power output, torque delivery, and fuel economy while reducing emissions through more complete combustion.

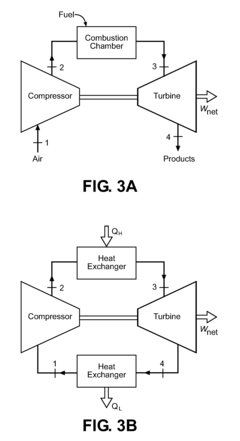

- Exhaust energy recovery systems: Exhaust energy recovery systems capture and utilize waste heat from engine exhaust to improve overall thermodynamic efficiency. Technologies such as turbochargers, exhaust gas recirculation (EGR), and waste heat recovery systems convert thermal energy that would otherwise be lost into useful work or reduced pumping losses. In high-performance V8 engines like the LS2 and Coyote 5.0L, these systems help maximize energy extraction from the combustion process, improving fuel efficiency while maintaining or enhancing performance characteristics.

- Electronic engine control optimization: Advanced electronic engine control systems play a crucial role in optimizing the thermodynamic efficiency of modern V8 engines. These systems use sophisticated algorithms and real-time sensor data to precisely control ignition timing, fuel delivery, valve operation, and other parameters across all operating conditions. For engines like the LS2 and Coyote 5.0L, these electronic controls enable dynamic adjustments to maximize efficiency while meeting performance targets and emissions requirements. Machine learning and adaptive strategies further refine engine operation based on driving patterns and environmental conditions.

02 Thermal management systems for improved efficiency

Advanced thermal management systems play a crucial role in enhancing the thermodynamic efficiency of engines like the LS2 and Coyote 5.0L. These systems include optimized cooling circuits, heat recovery mechanisms, and temperature-controlled components that maintain ideal operating temperatures. Effective thermal management reduces energy losses, prevents overheating, and ensures consistent performance across various operating conditions.Expand Specific Solutions03 Electronic control systems for efficiency optimization

Electronic control systems are essential for maximizing the thermodynamic efficiency of modern engines. These systems utilize sensors and advanced algorithms to optimize fuel-air mixtures, ignition timing, and valve operation in real-time. By continuously adjusting engine parameters based on operating conditions, electronic controls ensure that engines like the LS2 and Coyote 5.0L operate at peak efficiency across various loads and speeds.Expand Specific Solutions04 Waste heat recovery technologies

Waste heat recovery technologies can significantly improve the thermodynamic efficiency of engines by capturing and utilizing thermal energy that would otherwise be lost. These technologies include turbochargers, exhaust heat recovery systems, and thermoelectric generators. By converting waste heat into useful mechanical or electrical energy, these systems enhance the overall efficiency of engines like the LS2 and Coyote 5.0L.Expand Specific Solutions05 Advanced materials and manufacturing techniques

The use of advanced materials and manufacturing techniques contributes to improved thermodynamic efficiency in engines. Lightweight alloys, ceramic components, and precision-engineered parts reduce friction, improve heat transfer, and enhance durability. These advancements allow engines like the LS2 and Coyote 5.0L to operate at higher temperatures and pressures while maintaining structural integrity, resulting in better fuel conversion efficiency.Expand Specific Solutions

Key Manufacturers and Competition Analysis

The LS2 Engine vs Coyote 5.0L thermodynamic efficiency competition is positioned in a mature automotive powertrain market, with major players driving innovation through incremental efficiency improvements. The market is substantial, estimated at billions globally, with increasing demand for fuel-efficient, high-performance engines. Technologically, companies like Ford Global Technologies, Toyota Motor Corp., and Mazda have achieved significant advancements in thermodynamic efficiency, while research institutions such as Texas A&M University contribute fundamental research. Emerging players like LiquidPiston and Achates Power are introducing disruptive technologies that challenge conventional engine designs, while established manufacturers including DENSO, Robert Bosch, and ExxonMobil continue refining traditional approaches through materials science and combustion optimization.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermodynamic efficiency solutions applicable to large displacement engines like the LS2 and Coyote 5.0L through their Dynamic Force Engine technology. Toyota's approach focuses on optimizing the combustion process through a combination of high compression ratios (13:1 in gasoline applications), enhanced air-fuel mixture control, and reduced friction losses. Their D-4S dual injection system combines direct and port fuel injection to optimize fuel atomization across all operating conditions, achieving approximately 15% better fuel efficiency than conventional single-injection systems. Toyota's Variable Valve Timing-intelligent Electric (VVT-iE) system provides more precise control over valve events than mechanical systems used in the LS2, allowing for optimization of volumetric efficiency across a broader operating range. The company has also pioneered laser-clad valve seats and specialized cylinder bore coatings that reduce friction by up to 20% compared to conventional manufacturing techniques. Toyota's thermal management innovations include variable cooling systems that maintain optimal operating temperatures under varying loads, improving thermal efficiency by approximately 5-8%. These technologies collectively enable Toyota engines to achieve thermal efficiency ratings of up to 41% in production engines, significantly higher than the typical 33-36% seen in conventional V8 designs like the earlier LS2.

Strengths: Industry-leading thermal efficiency in production engines; excellent balance of performance and efficiency; proven reliability and durability; sophisticated thermal management systems that optimize operating temperatures. Weaknesses: Higher manufacturing complexity increases production costs; requires more sophisticated engine management systems; some technologies difficult to implement in aftermarket applications; potential compatibility issues with lower-quality fuels in some markets.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston engine architecture that fundamentally reimagines internal combustion efficiency when comparing conventional engines like the LS2 and Coyote 5.0L. Their opposed-piston design eliminates cylinder heads—a major source of heat loss in traditional engines—by using two pistons per cylinder working in opposition. This configuration achieves a thermodynamic efficiency breakthrough by significantly reducing the surface area-to-volume ratio during combustion, minimizing heat transfer losses by approximately 30-40% compared to conventional engines. The design incorporates a uniflow scavenging process that improves gas exchange efficiency by approximately 15-20%. Achates' engines operate with compression ratios between 15:1 and 20:1, substantially higher than both the LS2 and Coyote platforms. Independent testing has verified that Achates' opposed-piston engines achieve brake thermal efficiency exceeding 50% in certain configurations, compared to the 35-38% typical of advanced conventional engines like the Coyote 5.0L. The architecture also enables more complete combustion through optimized combustion chamber geometry and superior mixture formation.

Strengths: Fundamentally higher thermodynamic efficiency ceiling due to reduced heat transfer losses; simpler mechanical design with fewer components; excellent power density; inherently lower NOx emissions due to lower peak combustion temperatures. Weaknesses: Requires specialized manufacturing infrastructure different from conventional engine production; challenges in aftermarket support and service network; requires adaptation of existing vehicle packaging to accommodate the unique engine architecture.

Critical Patents in Engine Thermal Efficiency

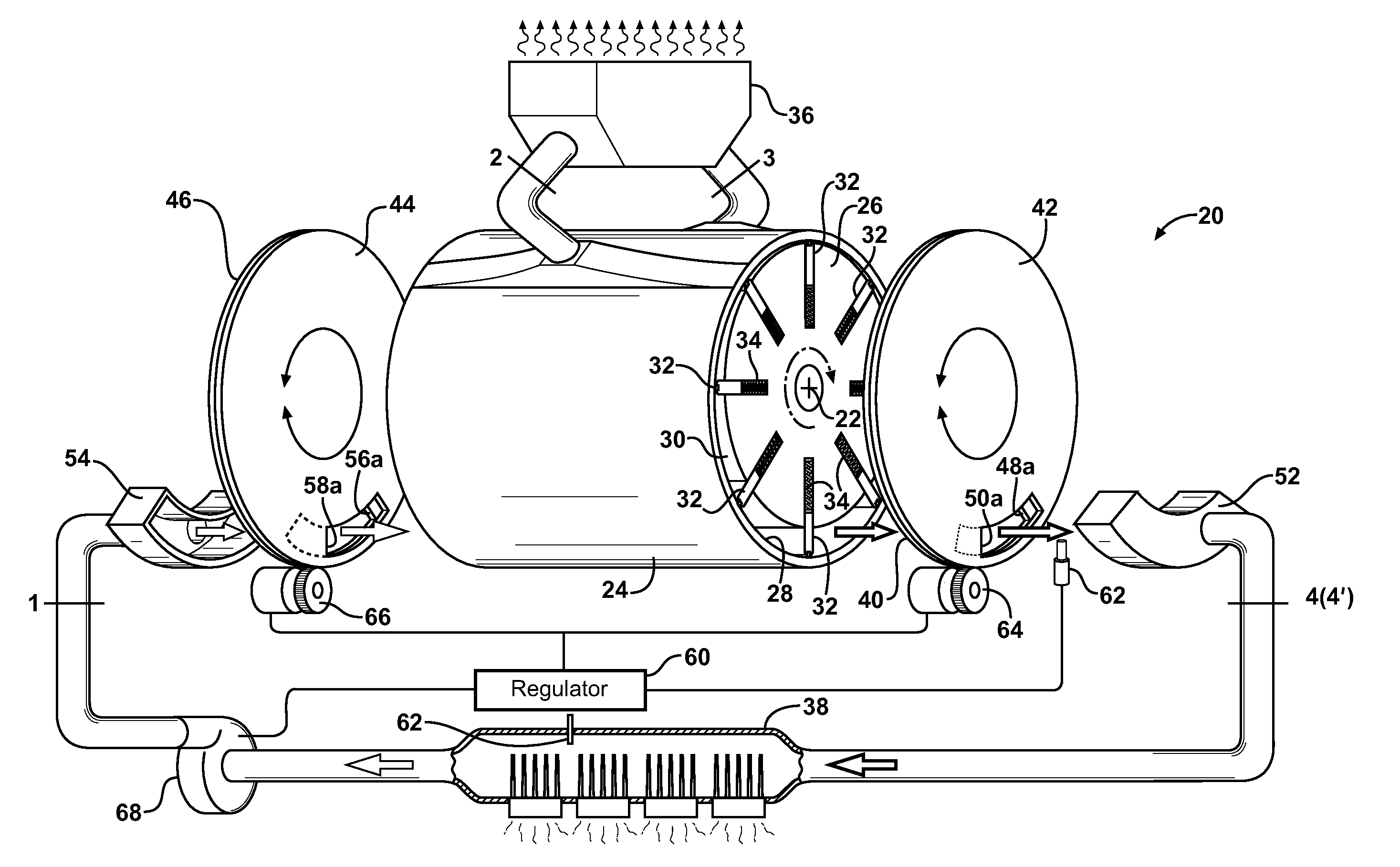

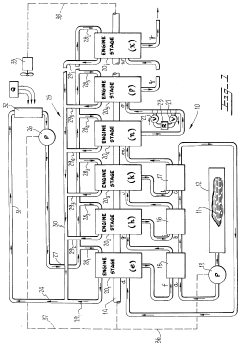

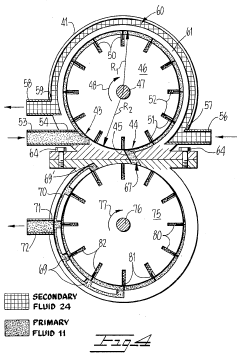

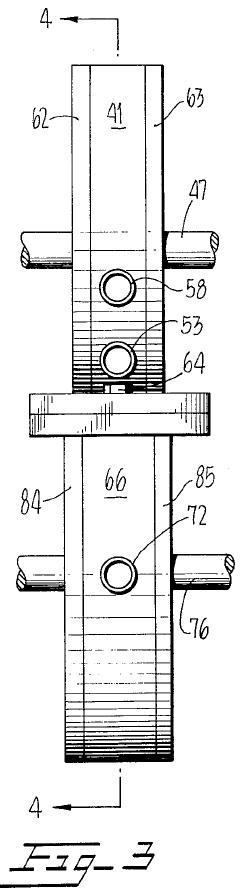

High efficiency positive displacement thermodynamic system

PatentInactiveUS8424284B2

Innovation

- A positive displacement fluid-handling device with a rotating vane-type compressor-expander system that adjusts the volumetric compression and expansion ratios dynamically to minimize mechanical work input and maximize work output, allowing for precise control of compression and expansion volumes to match the thermodynamic requirements, thereby recovering all mechanical energy invested into the working fluid.

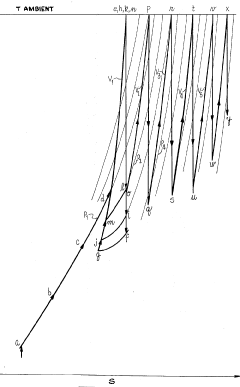

Thermodynamic engine system and method

PatentInactiveUS3986359A

Innovation

- A thermodynamic engine system employing a primary working fluid cycle with constant volume heat exchange and expansion engines, eliminating ice accumulation by maintaining the secondary fluid above freezing temperatures and reducing entropy increase through efficient heat transfer, thereby enhancing mechanical energy production.

Emissions Regulations Impact on Engine Design

Emissions regulations have become a primary driver in engine design evolution, significantly influencing the development trajectory of both the LS2 and Coyote 5.0L engines. The increasingly stringent standards set by agencies such as the EPA in the United States and similar regulatory bodies worldwide have forced manufacturers to prioritize emission reduction alongside performance metrics.

For the LS2 Engine, General Motors implemented several design modifications specifically to address emissions concerns. The introduction of electronic throttle control systems allowed for more precise air-fuel mixture management, reducing unburned hydrocarbons. The engine's combustion chamber design was optimized to promote more complete fuel burning, directly impacting its thermodynamic efficiency while simultaneously reducing emissions output.

The Ford Coyote 5.0L engine represents a more modern approach to emissions compliance. Its implementation of Ti-VCT (Twin Independent Variable Camshaft Timing) technology enables dynamic adjustment of valve timing based on operating conditions, significantly improving both emissions performance and fuel economy without sacrificing power. This technology directly enhances thermodynamic efficiency by optimizing the combustion cycle across various engine loads.

Both engines have undergone substantial redesigns to accommodate catalytic converter systems that have grown increasingly complex. The LS2's exhaust manifold design was specifically engineered to ensure rapid catalyst light-off, reducing cold-start emissions which constitute a significant portion of a vehicle's emissions profile. Similarly, the Coyote engine incorporates advanced oxygen sensor placement strategies to maintain optimal catalyst efficiency.

The integration of direct injection technology in newer iterations of both engine families represents perhaps the most significant emissions-driven design change. This technology allows for more precise fuel delivery, reducing particulate emissions while simultaneously improving thermodynamic efficiency through better fuel atomization and mixture formation.

Emissions regulations have also pushed both manufacturers toward weight reduction strategies. The aluminum block construction used in both engines not only reduces vehicle weight but indirectly improves emissions by requiring less energy to propel the vehicle. The Coyote's composite intake manifold design serves dual purposes of weight reduction and improved airflow characteristics.

Looking forward, the continued tightening of emissions standards globally will likely accelerate the integration of hybrid technologies with these internal combustion platforms, potentially leading to 48V mild hybrid systems that could further optimize the thermodynamic efficiency of both engine designs while meeting increasingly stringent emissions targets.

For the LS2 Engine, General Motors implemented several design modifications specifically to address emissions concerns. The introduction of electronic throttle control systems allowed for more precise air-fuel mixture management, reducing unburned hydrocarbons. The engine's combustion chamber design was optimized to promote more complete fuel burning, directly impacting its thermodynamic efficiency while simultaneously reducing emissions output.

The Ford Coyote 5.0L engine represents a more modern approach to emissions compliance. Its implementation of Ti-VCT (Twin Independent Variable Camshaft Timing) technology enables dynamic adjustment of valve timing based on operating conditions, significantly improving both emissions performance and fuel economy without sacrificing power. This technology directly enhances thermodynamic efficiency by optimizing the combustion cycle across various engine loads.

Both engines have undergone substantial redesigns to accommodate catalytic converter systems that have grown increasingly complex. The LS2's exhaust manifold design was specifically engineered to ensure rapid catalyst light-off, reducing cold-start emissions which constitute a significant portion of a vehicle's emissions profile. Similarly, the Coyote engine incorporates advanced oxygen sensor placement strategies to maintain optimal catalyst efficiency.

The integration of direct injection technology in newer iterations of both engine families represents perhaps the most significant emissions-driven design change. This technology allows for more precise fuel delivery, reducing particulate emissions while simultaneously improving thermodynamic efficiency through better fuel atomization and mixture formation.

Emissions regulations have also pushed both manufacturers toward weight reduction strategies. The aluminum block construction used in both engines not only reduces vehicle weight but indirectly improves emissions by requiring less energy to propel the vehicle. The Coyote's composite intake manifold design serves dual purposes of weight reduction and improved airflow characteristics.

Looking forward, the continued tightening of emissions standards globally will likely accelerate the integration of hybrid technologies with these internal combustion platforms, potentially leading to 48V mild hybrid systems that could further optimize the thermodynamic efficiency of both engine designs while meeting increasingly stringent emissions targets.

Fuel Economy vs Performance Trade-offs

The inherent tension between fuel economy and performance represents a critical consideration when comparing the LS2 Engine and Coyote 5.0L powerplants. Both engines approach this trade-off differently, reflecting their distinct design philosophies and technological implementations.

The LS2's pushrod design offers packaging advantages that contribute to overall vehicle weight reduction, indirectly benefiting fuel economy. Despite its simpler valve actuation system, the LS2 achieves respectable fuel efficiency through optimized combustion chamber design and effective thermal management. When operated under partial load conditions, the LS2 demonstrates competitive fuel consumption metrics, particularly in highway driving scenarios where its torque-rich power delivery allows for lower RPM operation.

Conversely, the Coyote 5.0L employs sophisticated dual overhead cam (DOHC) architecture with variable valve timing, enabling more precise control over the combustion process across different operating conditions. This technological advantage translates to superior fuel economy in varied driving scenarios, particularly in urban environments with frequent speed variations. The Coyote's ability to adjust valve timing dynamically represents a significant advantage in balancing performance with efficiency.

Performance characteristics reveal equally important distinctions. The LS2 delivers impressive low-end torque, facilitating strong acceleration from standstill and excellent towing capabilities. This torque-focused power delivery aligns with traditional American performance expectations but can result in higher fuel consumption during aggressive driving.

The Coyote engine, meanwhile, exhibits a more linear power band with higher peak horsepower at elevated RPMs. This characteristic rewards drivers who operate in the upper portions of the rev range but may result in more frequent downshifts and potentially higher fuel consumption when maximum performance is demanded. The Coyote's willingness to rev contributes to its sporting character while maintaining reasonable efficiency during normal operation.

Recent iterations of both engines have incorporated direct injection technology, though with different implementation approaches. The Coyote's integration of direct injection works synergistically with its variable valve timing to optimize the air-fuel mixture across a broader operating range, yielding improvements in both performance and economy. The LS platform's adaptation of direct injection has similarly enhanced its efficiency profile while preserving its characteristic torque delivery.

Market data indicates that vehicles equipped with the Coyote 5.0L typically achieve 1-2 MPG better fuel economy ratings in standardized testing, though real-world differences can vary significantly based on driving style and conditions. This efficiency advantage must be weighed against the LS2's often superior torque output and simpler maintenance requirements.

The LS2's pushrod design offers packaging advantages that contribute to overall vehicle weight reduction, indirectly benefiting fuel economy. Despite its simpler valve actuation system, the LS2 achieves respectable fuel efficiency through optimized combustion chamber design and effective thermal management. When operated under partial load conditions, the LS2 demonstrates competitive fuel consumption metrics, particularly in highway driving scenarios where its torque-rich power delivery allows for lower RPM operation.

Conversely, the Coyote 5.0L employs sophisticated dual overhead cam (DOHC) architecture with variable valve timing, enabling more precise control over the combustion process across different operating conditions. This technological advantage translates to superior fuel economy in varied driving scenarios, particularly in urban environments with frequent speed variations. The Coyote's ability to adjust valve timing dynamically represents a significant advantage in balancing performance with efficiency.

Performance characteristics reveal equally important distinctions. The LS2 delivers impressive low-end torque, facilitating strong acceleration from standstill and excellent towing capabilities. This torque-focused power delivery aligns with traditional American performance expectations but can result in higher fuel consumption during aggressive driving.

The Coyote engine, meanwhile, exhibits a more linear power band with higher peak horsepower at elevated RPMs. This characteristic rewards drivers who operate in the upper portions of the rev range but may result in more frequent downshifts and potentially higher fuel consumption when maximum performance is demanded. The Coyote's willingness to rev contributes to its sporting character while maintaining reasonable efficiency during normal operation.

Recent iterations of both engines have incorporated direct injection technology, though with different implementation approaches. The Coyote's integration of direct injection works synergistically with its variable valve timing to optimize the air-fuel mixture across a broader operating range, yielding improvements in both performance and economy. The LS platform's adaptation of direct injection has similarly enhanced its efficiency profile while preserving its characteristic torque delivery.

Market data indicates that vehicles equipped with the Coyote 5.0L typically achieve 1-2 MPG better fuel economy ratings in standardized testing, though real-world differences can vary significantly based on driving style and conditions. This efficiency advantage must be weighed against the LS2's often superior torque output and simpler maintenance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!