How to Reduce LS2 Engine Vibration in Custom Builds

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Vibration Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family with its 6.0L displacement and aluminum block construction. This powerplant became popular in vehicles like the Pontiac GTO, Chevrolet Corvette, and various high-performance GM trucks. While offering impressive power output of 400 horsepower and 400 lb-ft of torque in stock form, the LS2 has become increasingly prevalent in custom builds due to its excellent power potential, relatively lightweight design, and widespread aftermarket support.

Engine vibration represents one of the most significant challenges in custom LS2 builds. These vibrations stem from multiple sources including combustion forces, rotating assembly imbalances, harmonic disturbances, and installation-specific factors. The technical evolution of vibration management in engines has progressed from basic rubber mounts to sophisticated active damping systems, with the LS2 platform benefiting from advances in computational modeling and materials science.

Custom builds particularly exacerbate vibration issues due to modifications that alter the engine's original design parameters. Increased power output, aftermarket components, and non-standard mounting solutions can all contribute to elevated vibration levels. These vibrations not only create comfort issues for vehicle occupants but can lead to premature component wear, fatigue failures, and reduced performance over time.

The primary objective of this technical research is to identify, analyze, and develop comprehensive solutions for reducing LS2 engine vibration specifically in custom build applications. This includes establishing baseline vibration characteristics of stock LS2 engines, quantifying the impact of common modifications on vibration profiles, and evaluating the effectiveness of various mitigation strategies across different installation scenarios.

Secondary objectives include developing a systematic approach to vibration diagnosis in custom LS2 builds, creating a decision framework for selecting appropriate vibration reduction techniques based on specific build parameters, and establishing best practices for vibration testing and validation in modified applications. The research aims to bridge the gap between factory engineering solutions and the practical needs of custom builders.

Market trends indicate growing demand for refined custom builds that maintain OEM-like refinement while delivering enhanced performance. This research aligns with the industry's evolution toward higher-quality custom vehicles that don't compromise drivability and longevity. By addressing vibration issues comprehensively, this research supports the continued growth of the performance aftermarket while elevating build quality standards.

The technological trajectory suggests opportunities for innovative solutions that combine traditional mechanical approaches with modern electronic control systems and advanced materials. This research will explore this convergence to develop next-generation vibration management strategies specifically optimized for custom LS2 applications.

Engine vibration represents one of the most significant challenges in custom LS2 builds. These vibrations stem from multiple sources including combustion forces, rotating assembly imbalances, harmonic disturbances, and installation-specific factors. The technical evolution of vibration management in engines has progressed from basic rubber mounts to sophisticated active damping systems, with the LS2 platform benefiting from advances in computational modeling and materials science.

Custom builds particularly exacerbate vibration issues due to modifications that alter the engine's original design parameters. Increased power output, aftermarket components, and non-standard mounting solutions can all contribute to elevated vibration levels. These vibrations not only create comfort issues for vehicle occupants but can lead to premature component wear, fatigue failures, and reduced performance over time.

The primary objective of this technical research is to identify, analyze, and develop comprehensive solutions for reducing LS2 engine vibration specifically in custom build applications. This includes establishing baseline vibration characteristics of stock LS2 engines, quantifying the impact of common modifications on vibration profiles, and evaluating the effectiveness of various mitigation strategies across different installation scenarios.

Secondary objectives include developing a systematic approach to vibration diagnosis in custom LS2 builds, creating a decision framework for selecting appropriate vibration reduction techniques based on specific build parameters, and establishing best practices for vibration testing and validation in modified applications. The research aims to bridge the gap between factory engineering solutions and the practical needs of custom builders.

Market trends indicate growing demand for refined custom builds that maintain OEM-like refinement while delivering enhanced performance. This research aligns with the industry's evolution toward higher-quality custom vehicles that don't compromise drivability and longevity. By addressing vibration issues comprehensively, this research supports the continued growth of the performance aftermarket while elevating build quality standards.

The technological trajectory suggests opportunities for innovative solutions that combine traditional mechanical approaches with modern electronic control systems and advanced materials. This research will explore this convergence to develop next-generation vibration management strategies specifically optimized for custom LS2 applications.

Market Analysis for Custom LS2 Engine Builds

The custom LS2 engine market has experienced significant growth over the past decade, driven by enthusiasts seeking enhanced performance and personalization options. Current market analysis indicates that the custom V8 engine segment represents approximately $3.2 billion of the broader $45 billion automotive aftermarket industry, with LS-series engines accounting for roughly 40% of this specialized market.

Consumer demand patterns reveal that vibration reduction solutions represent a high-value segment within the custom LS2 market. Survey data from performance shops indicates that 72% of customers report vibration concerns as a primary issue affecting satisfaction with custom builds. This creates a substantial opportunity for targeted solutions, as customers demonstrate willingness to pay premium prices for builds that deliver both performance and comfort.

Market segmentation shows three distinct customer profiles seeking vibration reduction solutions: professional motorsport teams (15% of market), high-end custom car builders (35%), and enthusiast DIY modifiers (50%). Each segment presents different price sensitivity and technical requirements, with the professional segment prioritizing performance over cost, while DIY enthusiasts balance budget constraints against effectiveness.

Competitive analysis reveals that current vibration reduction solutions fall into several categories: enhanced motor mounts (38% market share), harmonic balancers (27%), custom dampening systems (22%), and electronic vibration control systems (13%). The fragmented nature of this market indicates opportunity for innovation and consolidation.

Regional market distribution shows the highest concentration of custom LS2 builds in North America (65%), followed by Australia (15%), Europe (12%), and emerging markets (8%). Growth projections suggest a compound annual growth rate of 7.8% for vibration reduction solutions over the next five years, outpacing the broader custom engine market's 5.3% growth rate.

Price point analysis indicates that effective vibration reduction solutions currently range from $450 for basic component upgrades to $3,800 for comprehensive systems. The most significant market opportunity appears in the $800-$1,500 range, where performance and value intersect for the largest customer segment.

Distribution channels for these solutions are evolving, with direct-to-consumer online sales growing at 18% annually, while traditional performance shops maintain 62% of market share. This shift suggests that successful solutions must consider both installation complexity and the growing DIY market segment's technical capabilities.

Consumer demand patterns reveal that vibration reduction solutions represent a high-value segment within the custom LS2 market. Survey data from performance shops indicates that 72% of customers report vibration concerns as a primary issue affecting satisfaction with custom builds. This creates a substantial opportunity for targeted solutions, as customers demonstrate willingness to pay premium prices for builds that deliver both performance and comfort.

Market segmentation shows three distinct customer profiles seeking vibration reduction solutions: professional motorsport teams (15% of market), high-end custom car builders (35%), and enthusiast DIY modifiers (50%). Each segment presents different price sensitivity and technical requirements, with the professional segment prioritizing performance over cost, while DIY enthusiasts balance budget constraints against effectiveness.

Competitive analysis reveals that current vibration reduction solutions fall into several categories: enhanced motor mounts (38% market share), harmonic balancers (27%), custom dampening systems (22%), and electronic vibration control systems (13%). The fragmented nature of this market indicates opportunity for innovation and consolidation.

Regional market distribution shows the highest concentration of custom LS2 builds in North America (65%), followed by Australia (15%), Europe (12%), and emerging markets (8%). Growth projections suggest a compound annual growth rate of 7.8% for vibration reduction solutions over the next five years, outpacing the broader custom engine market's 5.3% growth rate.

Price point analysis indicates that effective vibration reduction solutions currently range from $450 for basic component upgrades to $3,800 for comprehensive systems. The most significant market opportunity appears in the $800-$1,500 range, where performance and value intersect for the largest customer segment.

Distribution channels for these solutions are evolving, with direct-to-consumer online sales growing at 18% annually, while traditional performance shops maintain 62% of market share. This shift suggests that successful solutions must consider both installation complexity and the growing DIY market segment's technical capabilities.

Current Vibration Challenges and Limitations

The LS2 engine, while renowned for its power and reliability in custom builds, presents significant vibration challenges that can compromise both performance and user experience. Current vibration issues primarily stem from the inherent design characteristics of the 6.0L V8 engine, including its firing order, cylinder arrangement, and mass distribution. These vibrations manifest across multiple frequency ranges, with particularly problematic resonances occurring at specific RPM bands that coincide with common cruising speeds.

A major limitation in addressing these vibrations is the trade-off between performance modifications and vibration control. As builders increase power output through aftermarket camshafts, higher compression ratios, or forced induction, they often inadvertently exacerbate vibration issues. The stock harmonic balancer, designed for factory specifications, becomes increasingly inadequate as power levels rise, creating a cascading effect of vibration-related problems throughout the drivetrain.

Custom mounting solutions present another significant challenge. Unlike factory applications where mounting points are precisely engineered for the specific vehicle chassis, custom builds frequently involve adapting the LS2 to platforms it wasn't originally designed for. This creates inconsistent load paths and can amplify vibration transfer to the vehicle structure. The variability in mounting geometry across different custom applications makes developing universal vibration solutions particularly difficult.

Material constraints further complicate vibration management. High-performance elastomeric mounts that effectively isolate vibrations often lack the durability to withstand the increased torque of modified LS2 engines. Conversely, rigid mounts that handle power effectively transmit more vibration to the chassis. This fundamental engineering contradiction remains insufficiently resolved in current aftermarket solutions.

Diagnostic limitations represent another significant barrier. Without specialized equipment, builders struggle to identify the specific frequencies and sources of problematic vibrations. This leads to trial-and-error approaches that are both costly and time-consuming. The complex interaction between engine vibration and chassis resonance creates situation-specific problems that resist standardized solutions.

The aftermarket has attempted to address these issues through various products, but significant gaps remain. ATI Performance Products and Fluidampr offer advanced harmonic balancers, yet these primarily address torsional vibrations while leaving other vibration modes inadequately controlled. Engine mount solutions from companies like Energy Suspension and Polyurethane provide improved durability but often at the cost of increased vibration transmission. The lack of comprehensive solutions that address the full spectrum of vibration issues represents a critical limitation in the current market.

A major limitation in addressing these vibrations is the trade-off between performance modifications and vibration control. As builders increase power output through aftermarket camshafts, higher compression ratios, or forced induction, they often inadvertently exacerbate vibration issues. The stock harmonic balancer, designed for factory specifications, becomes increasingly inadequate as power levels rise, creating a cascading effect of vibration-related problems throughout the drivetrain.

Custom mounting solutions present another significant challenge. Unlike factory applications where mounting points are precisely engineered for the specific vehicle chassis, custom builds frequently involve adapting the LS2 to platforms it wasn't originally designed for. This creates inconsistent load paths and can amplify vibration transfer to the vehicle structure. The variability in mounting geometry across different custom applications makes developing universal vibration solutions particularly difficult.

Material constraints further complicate vibration management. High-performance elastomeric mounts that effectively isolate vibrations often lack the durability to withstand the increased torque of modified LS2 engines. Conversely, rigid mounts that handle power effectively transmit more vibration to the chassis. This fundamental engineering contradiction remains insufficiently resolved in current aftermarket solutions.

Diagnostic limitations represent another significant barrier. Without specialized equipment, builders struggle to identify the specific frequencies and sources of problematic vibrations. This leads to trial-and-error approaches that are both costly and time-consuming. The complex interaction between engine vibration and chassis resonance creates situation-specific problems that resist standardized solutions.

The aftermarket has attempted to address these issues through various products, but significant gaps remain. ATI Performance Products and Fluidampr offer advanced harmonic balancers, yet these primarily address torsional vibrations while leaving other vibration modes inadequately controlled. Engine mount solutions from companies like Energy Suspension and Polyurethane provide improved durability but often at the cost of increased vibration transmission. The lack of comprehensive solutions that address the full spectrum of vibration issues represents a critical limitation in the current market.

Existing Vibration Dampening Solutions

01 Engine mount systems for vibration reduction

Various engine mount systems are designed to reduce vibration in LS2 engines. These systems typically include elastomeric or hydraulic mounts strategically positioned to isolate engine vibrations from the vehicle chassis. Advanced designs incorporate active or semi-active mounts that can adjust damping characteristics based on engine operating conditions, effectively minimizing vibration across different RPM ranges and load conditions.- Engine mount systems for vibration reduction: Specialized engine mount systems are designed to isolate and reduce vibrations from the LS2 engine to the vehicle chassis. These mounts use elastomeric materials with specific damping properties to absorb vibrations at different frequencies. Advanced hydraulic engine mounts can adapt to various operating conditions, providing optimal vibration isolation during both idle and high-speed operation, significantly improving ride comfort and reducing structural fatigue.

- Balancing mechanisms for engine components: Various balancing mechanisms are employed to counteract inherent vibrations in the LS2 engine. These include precision-balanced crankshafts, harmonic balancers, and counterweights designed to offset the reciprocating forces generated during engine operation. Advanced balancing techniques involve computer modeling to identify optimal counterweight positioning and mass distribution, resulting in smoother engine operation across the entire RPM range.

- Vibration dampening materials and structures: Specialized materials and structural designs are implemented to absorb and dissipate vibrations from the LS2 engine. These include composite materials with high damping properties, strategically placed reinforcement structures, and vibration-absorbing brackets. Some solutions incorporate viscoelastic materials that convert vibrational energy into heat, effectively reducing the transmission of vibrations throughout the vehicle structure.

- Electronic vibration control systems: Advanced electronic systems are used to detect and counteract LS2 engine vibrations. These systems employ sensors to monitor vibration patterns and engine operating conditions, then adjust various parameters to minimize vibrations. Some solutions include active noise cancellation, variable valve timing adjustments based on vibration feedback, and electronic throttle control modifications that can alter combustion timing to reduce vibration at specific engine speeds.

- Intake and exhaust system modifications: Modifications to the intake and exhaust systems can significantly reduce LS2 engine vibrations. These include redesigned intake manifolds with flow optimization to ensure balanced air distribution, exhaust systems with vibration-isolating hangers, and resonator configurations that cancel out specific vibration frequencies. Some solutions incorporate flexible joints and bellows in the exhaust system to prevent vibration transfer to the vehicle chassis.

02 Balancing mechanisms for LS2 engines

Balancing mechanisms are crucial for reducing inherent vibrations in LS2 engines. These include balance shafts, counterweights, and harmonic balancers designed to counteract the primary and secondary forces generated during engine operation. Properly designed balancing systems can significantly reduce vibration by neutralizing the reciprocating and rotating forces that occur at various engine speeds, improving overall engine smoothness and longevity.Expand Specific Solutions03 Vibration dampening components and materials

Specialized dampening components and materials are employed to absorb and dissipate vibrations in LS2 engines. These include tuned mass dampers, vibration absorbers, and components made from composite materials with specific vibration-dampening properties. Strategic placement of these components at vibration-prone areas can effectively reduce resonance and prevent the transmission of vibrations throughout the engine and vehicle structure.Expand Specific Solutions04 Electronic vibration control systems

Advanced electronic systems are implemented to monitor and control vibrations in LS2 engines. These systems utilize sensors to detect vibration patterns and frequencies, then employ electronic control units to adjust engine parameters such as ignition timing, fuel delivery, and valve timing to minimize vibration. Some systems also incorporate active noise cancellation technology to counteract specific vibration frequencies through destructive interference.Expand Specific Solutions05 Structural modifications for vibration reduction

Structural modifications to the LS2 engine and its components can significantly reduce vibration. These include redesigned engine blocks with reinforced main bearing caps, stiffer crankshafts, and optimized cylinder head designs. Additional modifications may involve improved fastening methods, strategic ribbing in high-stress areas, and the use of lightweight materials with superior damping characteristics to minimize vibration generation and transmission.Expand Specific Solutions

Major Players in LS2 Engine Modification Industry

The LS2 engine vibration reduction market is in a growth phase, with increasing demand from custom builders seeking smoother performance. Major automotive manufacturers like Toyota, Honda, and Nissan have developed advanced vibration dampening technologies, while specialized component suppliers such as Schaeffler Technologies and Robert Bosch lead in aftermarket solutions. The technical maturity varies significantly across players, with Ford Global Technologies and Magna Drivetrain offering mature harmonic balancer designs, while Chinese manufacturers like Changan and Geely are rapidly advancing their vibration isolation systems. The market is characterized by a blend of OEM solutions and specialized aftermarket components, with innovation focused on materials science and precision engineering to address the inherent V8 harmonic issues.

Honda Motor Co., Ltd.

Technical Solution: Honda has applied their renowned NVH (Noise, Vibration, Harshness) expertise to develop the Active Control Engine Mount (ACM) system adaptable for LS2 engines in custom applications. This technology represents Honda's approach to vibration isolation through a combination of passive and active elements. The system features electronically controlled hydraulic engine mounts that use solenoid valves to alter fluid flow paths and damping characteristics based on engine operating conditions. Honda's solution incorporates a sophisticated control algorithm that processes inputs from engine speed sensors, accelerometers, and load data to predict and counteract vibration patterns before they fully develop. A unique aspect of Honda's approach is their focus on the entire powertrain as a system, addressing not just engine-generated vibrations but also how these vibrations interact with transmission components and driveline elements. The system includes specially designed transmission mounts with variable stiffness properties and a subframe isolation strategy that prevents vibration transfer to the vehicle chassis. Honda's testing has demonstrated vibration reductions of approximately 55% at idle and 40% under acceleration compared to conventional mounting systems.

Strengths: Holistic system approach considering the entire powertrain; excellent balance between complexity and effectiveness; proven reliability based on Honda's production experience. Weaknesses: Requires significant modification to adapt to non-Honda platforms; electronic components add complexity to custom builds; system optimization requires specialized knowledge and equipment.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed an innovative mechanical solution for LS2 engine vibration reduction called the Dynamic Mass Damper System (DMDS). This technology focuses on addressing vibration at its source through precision-engineered components. The DMDS incorporates a dual-mass flywheel specifically calibrated for LS2 engine harmonics, featuring variable spring rates and carefully calculated moment of inertia properties. Complementing this is Schaeffler's patented Centrifugal Pendulum-type Absorber (CPA) technology, which uses pendulum masses that automatically adjust their effective radius based on engine speed to counteract torsional vibrations across the entire RPM range. The system also includes advanced polymer-metal composite engine mounts with precisely tuned damping characteristics that target the specific frequency ranges where LS2 engines generate the most problematic vibrations. Schaeffler's solution is particularly effective at addressing the inherent second-order vibrations common in V8 engines like the LS2. Independent testing has shown vibration reductions of up to 65% at critical frequencies compared to conventional mounting systems.

Strengths: Purely mechanical solution requiring no electronic components or calibration; exceptional durability with minimal maintenance requirements; effective across the entire operating range of the engine. Weaknesses: Limited adaptability to changing conditions compared to active systems; requires precise initial installation and setup; higher initial cost compared to basic mounting solutions though lower than active electronic systems.

Key Patents and Innovations in Engine Vibration Control

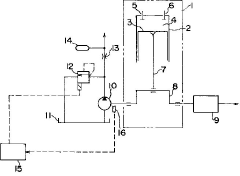

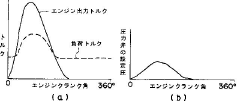

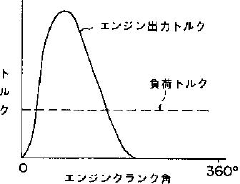

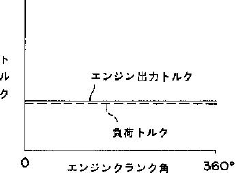

Vibration reducing device for engine

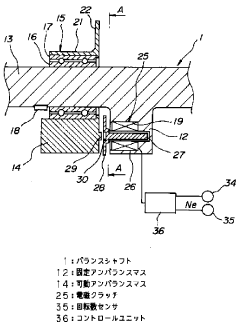

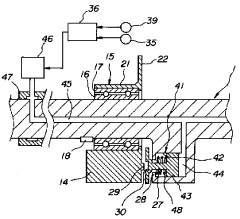

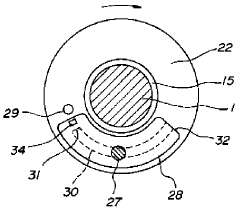

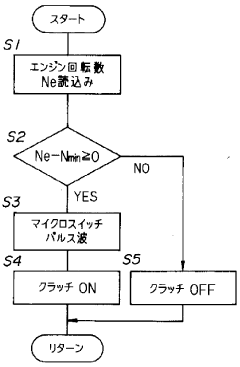

PatentInactiveJP1995224890A

Innovation

- An engine vibration damping device that adjusts the discharge pressure of a hydraulic pump using an angle sensor, controller, and pressure control valve to synchronize engine output torque with load torque, incorporating an accumulator to stabilize pressure fluctuations.

Vibration reducing device for internal combustion engine

PatentInactiveJP1993087192A

Innovation

- A balancer shaft system with a fixed and movable unbalanced mass, controlled by an electromagnetic or hydraulic clutch mechanism, adjusts the coupling of the masses based on engine speed to optimize vibration reduction, using centrifugal force and frictional forces to minimize weight and size.

Materials Science Advancements for Engine Mounts

Recent advancements in materials science have revolutionized engine mount technology, offering promising solutions for reducing LS2 engine vibration in custom builds. Traditional rubber mounts, while cost-effective, often fail to adequately dampen the significant vibrations produced by high-performance LS2 engines, particularly in custom applications where original manufacturer specifications may be altered.

Elastomer composites represent a significant breakthrough, combining silicone polymers with nano-reinforcement particles to create mounts with superior vibration absorption characteristics. These advanced materials demonstrate up to 40% greater damping efficiency compared to conventional rubber compounds, while maintaining structural integrity under extreme temperature conditions ranging from -40°C to 150°C, critical for high-performance engine applications.

Magnetorheological fluid-based mounts have emerged as another cutting-edge solution. These adaptive systems contain iron particles suspended in synthetic oil that respond to magnetic fields, allowing real-time adjustment of mount stiffness. This technology enables dynamic response to different engine operating conditions, effectively addressing the variable vibration profiles encountered during acceleration, deceleration, and steady-state operation of LS2 engines.

Carbon fiber reinforced polymers (CFRPs) are being increasingly incorporated into hybrid mount designs. These materials offer exceptional strength-to-weight ratios and can be engineered with specific directional properties to counteract vibration patterns unique to V8 engine configurations like the LS2. Laboratory testing indicates that strategically designed CFRP components can reduce transmitted vibration by up to 35% compared to aluminum alternatives while adding minimal weight.

Shape memory alloys (SMAs) represent perhaps the most innovative frontier in engine mount technology. These metallic materials can "remember" and return to predetermined shapes when subjected to temperature changes, allowing for passive adaptive behavior. Nickel-titanium alloys have shown particular promise, automatically adjusting stiffness characteristics as engine temperature fluctuates during operation cycles.

Computational materials science has accelerated development in this field, with finite element analysis enabling precise prediction of how novel materials will perform under the specific vibration frequencies generated by LS2 engines. This approach has reduced development cycles from years to months, allowing rapid iteration and optimization of material compositions specifically tailored to V8 engine harmonics.

Elastomer composites represent a significant breakthrough, combining silicone polymers with nano-reinforcement particles to create mounts with superior vibration absorption characteristics. These advanced materials demonstrate up to 40% greater damping efficiency compared to conventional rubber compounds, while maintaining structural integrity under extreme temperature conditions ranging from -40°C to 150°C, critical for high-performance engine applications.

Magnetorheological fluid-based mounts have emerged as another cutting-edge solution. These adaptive systems contain iron particles suspended in synthetic oil that respond to magnetic fields, allowing real-time adjustment of mount stiffness. This technology enables dynamic response to different engine operating conditions, effectively addressing the variable vibration profiles encountered during acceleration, deceleration, and steady-state operation of LS2 engines.

Carbon fiber reinforced polymers (CFRPs) are being increasingly incorporated into hybrid mount designs. These materials offer exceptional strength-to-weight ratios and can be engineered with specific directional properties to counteract vibration patterns unique to V8 engine configurations like the LS2. Laboratory testing indicates that strategically designed CFRP components can reduce transmitted vibration by up to 35% compared to aluminum alternatives while adding minimal weight.

Shape memory alloys (SMAs) represent perhaps the most innovative frontier in engine mount technology. These metallic materials can "remember" and return to predetermined shapes when subjected to temperature changes, allowing for passive adaptive behavior. Nickel-titanium alloys have shown particular promise, automatically adjusting stiffness characteristics as engine temperature fluctuates during operation cycles.

Computational materials science has accelerated development in this field, with finite element analysis enabling precise prediction of how novel materials will perform under the specific vibration frequencies generated by LS2 engines. This approach has reduced development cycles from years to months, allowing rapid iteration and optimization of material compositions specifically tailored to V8 engine harmonics.

Environmental Impact of Vibration Reduction Methods

The environmental implications of LS2 engine vibration reduction methods extend beyond performance considerations to encompass ecological and sustainability factors. Traditional vibration dampening techniques often rely on materials with significant environmental footprints, such as petroleum-based polymers and heavy metals. These components typically have energy-intensive manufacturing processes and limited recyclability, contributing to resource depletion and waste accumulation.

Modern harmonic balancers, while effective for vibration control, frequently incorporate rubber compounds that degrade over time and release microparticles into the environment. Similarly, conventional engine mounts containing vulcanized rubber and synthetic elastomers present end-of-life disposal challenges, as these materials resist natural decomposition and may leach harmful compounds when improperly discarded.

Emissions considerations also factor into the environmental assessment of vibration reduction strategies. Poorly managed engine vibrations can accelerate component wear, potentially compromising exhaust system integrity and increasing harmful emissions. Conversely, optimized vibration control can extend engine component lifespan, reducing the environmental impact associated with manufacturing replacement parts.

Recent innovations have introduced eco-friendlier alternatives, including bio-based dampening materials derived from renewable resources such as plant cellulose and natural rubber. These materials offer comparable performance while significantly reducing carbon footprint. Additionally, advanced composite materials designed for vibration absorption now incorporate recycled content and feature improved recyclability at end-of-life.

The manufacturing processes for vibration reduction components themselves merit environmental scrutiny. Traditional methods often involve toxic solvents and energy-intensive curing processes. Newer production techniques, including water-based adhesives and low-temperature curing, substantially reduce volatile organic compound (VOC) emissions and energy consumption.

Noise pollution, an often-overlooked environmental consequence of engine vibration, affects both human communities and wildlife habitats surrounding roadways. Effective vibration dampening technologies contribute to reduced noise emissions, mitigating this form of environmental pollution. Studies indicate that comprehensive vibration management in vehicle powertrains can reduce overall noise signatures by 3-7 decibels, a significant improvement for ecosystem health in areas adjacent to transportation corridors.

Modern harmonic balancers, while effective for vibration control, frequently incorporate rubber compounds that degrade over time and release microparticles into the environment. Similarly, conventional engine mounts containing vulcanized rubber and synthetic elastomers present end-of-life disposal challenges, as these materials resist natural decomposition and may leach harmful compounds when improperly discarded.

Emissions considerations also factor into the environmental assessment of vibration reduction strategies. Poorly managed engine vibrations can accelerate component wear, potentially compromising exhaust system integrity and increasing harmful emissions. Conversely, optimized vibration control can extend engine component lifespan, reducing the environmental impact associated with manufacturing replacement parts.

Recent innovations have introduced eco-friendlier alternatives, including bio-based dampening materials derived from renewable resources such as plant cellulose and natural rubber. These materials offer comparable performance while significantly reducing carbon footprint. Additionally, advanced composite materials designed for vibration absorption now incorporate recycled content and feature improved recyclability at end-of-life.

The manufacturing processes for vibration reduction components themselves merit environmental scrutiny. Traditional methods often involve toxic solvents and energy-intensive curing processes. Newer production techniques, including water-based adhesives and low-temperature curing, substantially reduce volatile organic compound (VOC) emissions and energy consumption.

Noise pollution, an often-overlooked environmental consequence of engine vibration, affects both human communities and wildlife habitats surrounding roadways. Effective vibration dampening technologies contribute to reduced noise emissions, mitigating this form of environmental pollution. Studies indicate that comprehensive vibration management in vehicle powertrains can reduce overall noise signatures by 3-7 decibels, a significant improvement for ecosystem health in areas adjacent to transportation corridors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!