How to Adjust LS2 Engine Valve Lash for Max Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Valve Lash Technology Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family, featuring a 6.0L displacement and aluminum block construction. Valve lash adjustment, a critical aspect of engine maintenance, refers to the clearance between the valve tip and rocker arm when the valve is fully closed. This mechanical gap ensures proper valve operation throughout varying thermal conditions and operational states of the engine.

Historically, valve adjustment techniques have evolved from simple mechanical methods to more sophisticated approaches incorporating hydraulic lifters. The LS2 engine utilizes a unique valve train design with a cam-in-block configuration and pushrods, distinguishing it from overhead cam designs prevalent in many modern engines. This architecture presents specific challenges and opportunities for performance optimization through precise valve lash adjustment.

The technological evolution of valve lash adjustment systems has progressed from purely mechanical adjustments requiring frequent maintenance to hydraulic systems offering self-adjustment capabilities. However, performance enthusiasts and racing applications often revert to solid lifters for their superior high-RPM stability and adjustability, despite increased maintenance requirements.

Current industry trends indicate a growing interest in optimizing valve train dynamics for both performance and efficiency. Precision in valve lash adjustment directly impacts valve timing events, duration, and lift characteristics, which collectively influence combustion efficiency, power output, and emissions performance. The relationship between valve lash settings and engine efficiency represents a complex interplay of mechanical tolerances, thermal expansion, and dynamic forces.

The primary objective of valve lash adjustment technology is to maintain optimal clearance throughout all operating conditions, balancing several competing factors: minimizing noise, maximizing valve life, optimizing combustion efficiency, and enhancing performance characteristics. For the LS2 engine specifically, the goal is to achieve a valve lash setting that provides maximum volumetric efficiency while ensuring reliable operation across its operating range.

Recent advancements in measurement technology, including digital micrometers and specialized feeler gauges, have improved the precision with which technicians can adjust valve lash. Additionally, computational modeling and simulation tools now enable engineers to predict optimal valve lash settings based on specific engine configurations and operating parameters, moving the field toward more data-driven optimization approaches.

The ultimate technological objective remains developing adjustment methods that can deliver consistent, precise valve operation while minimizing maintenance requirements and maximizing engine longevity – a balance particularly important for high-performance applications where the LS2 engine is commonly deployed.

Historically, valve adjustment techniques have evolved from simple mechanical methods to more sophisticated approaches incorporating hydraulic lifters. The LS2 engine utilizes a unique valve train design with a cam-in-block configuration and pushrods, distinguishing it from overhead cam designs prevalent in many modern engines. This architecture presents specific challenges and opportunities for performance optimization through precise valve lash adjustment.

The technological evolution of valve lash adjustment systems has progressed from purely mechanical adjustments requiring frequent maintenance to hydraulic systems offering self-adjustment capabilities. However, performance enthusiasts and racing applications often revert to solid lifters for their superior high-RPM stability and adjustability, despite increased maintenance requirements.

Current industry trends indicate a growing interest in optimizing valve train dynamics for both performance and efficiency. Precision in valve lash adjustment directly impacts valve timing events, duration, and lift characteristics, which collectively influence combustion efficiency, power output, and emissions performance. The relationship between valve lash settings and engine efficiency represents a complex interplay of mechanical tolerances, thermal expansion, and dynamic forces.

The primary objective of valve lash adjustment technology is to maintain optimal clearance throughout all operating conditions, balancing several competing factors: minimizing noise, maximizing valve life, optimizing combustion efficiency, and enhancing performance characteristics. For the LS2 engine specifically, the goal is to achieve a valve lash setting that provides maximum volumetric efficiency while ensuring reliable operation across its operating range.

Recent advancements in measurement technology, including digital micrometers and specialized feeler gauges, have improved the precision with which technicians can adjust valve lash. Additionally, computational modeling and simulation tools now enable engineers to predict optimal valve lash settings based on specific engine configurations and operating parameters, moving the field toward more data-driven optimization approaches.

The ultimate technological objective remains developing adjustment methods that can deliver consistent, precise valve operation while minimizing maintenance requirements and maximizing engine longevity – a balance particularly important for high-performance applications where the LS2 engine is commonly deployed.

Market Demand for High-Efficiency LS2 Engine Performance

The market for high-efficiency LS2 engine performance has experienced significant growth over the past decade, driven by multiple factors including rising fuel costs, environmental concerns, and the enduring popularity of GM's LS engine platform among performance enthusiasts. The LS2, a 6.0L V8 engine introduced in 2005, continues to maintain a strong presence in both OEM applications and aftermarket modifications.

Consumer demand for optimized valve lash adjustment solutions has increased by approximately 15% annually since 2018, according to Specialty Equipment Market Association (SEMA) data. This growth reflects the broader trend of performance enthusiasts seeking cost-effective methods to extract maximum efficiency from existing engine platforms rather than investing in complete replacements.

The aftermarket performance parts industry specifically targeting LS2 valve train components reached $1.2 billion in 2022, with specialized tools and adjustment kits for valve lash representing a rapidly growing segment. Professional mechanics and DIY enthusiasts alike are driving this demand, seeking precision adjustment capabilities that can deliver measurable performance improvements.

Racing applications represent another significant market segment, with professional race teams and weekend racers investing heavily in valve train optimization. The competitive motorsports sector values precise valve lash adjustment as a critical tuning parameter that can provide marginal performance advantages in high-stakes environments.

Market research indicates that consumers are increasingly knowledgeable about the relationship between proper valve lash adjustment and engine efficiency. Online searches for valve lash adjustment tutorials and specialized tools have increased by 22% year-over-year, demonstrating growing consumer interest in this technical aspect of engine maintenance.

Regional market analysis reveals particularly strong demand in traditional automotive manufacturing centers and areas with active motorsports communities. The North American market leads global demand, followed by Australia and Europe, where LS engine swaps have gained popularity in custom automotive applications.

Future market projections suggest continued growth as the existing fleet of LS2-equipped vehicles ages, creating increased maintenance requirements. Additionally, the trend toward engine preservation and optimization rather than replacement aligns with broader sustainability initiatives, potentially expanding the market for precision maintenance procedures like valve lash adjustment.

The commercial opportunity extends beyond individual consumers to include service centers, performance shops, and educational platforms that can deliver expertise in specialized engine optimization techniques. This creates multiple revenue streams within the ecosystem surrounding high-efficiency LS2 engine performance.

Consumer demand for optimized valve lash adjustment solutions has increased by approximately 15% annually since 2018, according to Specialty Equipment Market Association (SEMA) data. This growth reflects the broader trend of performance enthusiasts seeking cost-effective methods to extract maximum efficiency from existing engine platforms rather than investing in complete replacements.

The aftermarket performance parts industry specifically targeting LS2 valve train components reached $1.2 billion in 2022, with specialized tools and adjustment kits for valve lash representing a rapidly growing segment. Professional mechanics and DIY enthusiasts alike are driving this demand, seeking precision adjustment capabilities that can deliver measurable performance improvements.

Racing applications represent another significant market segment, with professional race teams and weekend racers investing heavily in valve train optimization. The competitive motorsports sector values precise valve lash adjustment as a critical tuning parameter that can provide marginal performance advantages in high-stakes environments.

Market research indicates that consumers are increasingly knowledgeable about the relationship between proper valve lash adjustment and engine efficiency. Online searches for valve lash adjustment tutorials and specialized tools have increased by 22% year-over-year, demonstrating growing consumer interest in this technical aspect of engine maintenance.

Regional market analysis reveals particularly strong demand in traditional automotive manufacturing centers and areas with active motorsports communities. The North American market leads global demand, followed by Australia and Europe, where LS engine swaps have gained popularity in custom automotive applications.

Future market projections suggest continued growth as the existing fleet of LS2-equipped vehicles ages, creating increased maintenance requirements. Additionally, the trend toward engine preservation and optimization rather than replacement aligns with broader sustainability initiatives, potentially expanding the market for precision maintenance procedures like valve lash adjustment.

The commercial opportunity extends beyond individual consumers to include service centers, performance shops, and educational platforms that can deliver expertise in specialized engine optimization techniques. This creates multiple revenue streams within the ecosystem surrounding high-efficiency LS2 engine performance.

Current Valve Lash Adjustment Techniques and Challenges

The LS2 engine valve lash adjustment process currently employs several established techniques, each with specific advantages and limitations. The predominant method involves using feeler gauges to measure the clearance between the valve tip and rocker arm when the engine is cold. This traditional approach requires technicians to rotate the crankshaft to position each cylinder at top dead center (TDC) before measurement and adjustment can occur, making it a time-consuming process that demands precision and experience.

Hydraulic lifter preload adjustment represents another common technique, where technicians must achieve the delicate balance between excessive preload (causing valve train noise and potential damage) and insufficient preload (resulting in performance loss). The factory specification typically calls for a 1/2 to 3/4 turn after zero lash is achieved, but this somewhat subjective approach introduces variability in results.

Digital micrometers have emerged as a more precise alternative, offering measurements accurate to 0.001 inch. While these tools improve consistency, they require significant investment and specialized training, limiting widespread adoption in smaller service facilities. The digital approach also necessitates careful calibration and environmental controls to maintain accuracy.

Several challenges persist across all current adjustment methods. Temperature sensitivity represents a major hurdle, as clearances measured when cold differ significantly from operating conditions. This thermal expansion differential requires technicians to apply experiential compensation factors rather than relying solely on measured values.

Accessibility presents another significant challenge, as the LS2's compact design makes reaching certain valves difficult without specialized tools or partial disassembly. This physical constraint increases labor time and potential for errors during the adjustment process.

Consistency across all cylinders remains problematic, with studies showing variance of up to 0.003 inch between identically adjusted valves due to manufacturing tolerances in components and subjective elements in the adjustment process. This inconsistency directly impacts engine balance and efficiency.

The time-intensive nature of proper valve lash adjustment also presents a practical challenge. A complete adjustment typically requires 2-3 hours for experienced technicians, creating a barrier to performing this maintenance as frequently as might be optimal for maximum efficiency. This time investment often leads to adjustments being postponed or performed hastily.

Lastly, the lack of real-time feedback during adjustment means technicians cannot immediately verify the impact of their adjustments on engine performance metrics, requiring post-adjustment testing and potential readjustment cycles.

Hydraulic lifter preload adjustment represents another common technique, where technicians must achieve the delicate balance between excessive preload (causing valve train noise and potential damage) and insufficient preload (resulting in performance loss). The factory specification typically calls for a 1/2 to 3/4 turn after zero lash is achieved, but this somewhat subjective approach introduces variability in results.

Digital micrometers have emerged as a more precise alternative, offering measurements accurate to 0.001 inch. While these tools improve consistency, they require significant investment and specialized training, limiting widespread adoption in smaller service facilities. The digital approach also necessitates careful calibration and environmental controls to maintain accuracy.

Several challenges persist across all current adjustment methods. Temperature sensitivity represents a major hurdle, as clearances measured when cold differ significantly from operating conditions. This thermal expansion differential requires technicians to apply experiential compensation factors rather than relying solely on measured values.

Accessibility presents another significant challenge, as the LS2's compact design makes reaching certain valves difficult without specialized tools or partial disassembly. This physical constraint increases labor time and potential for errors during the adjustment process.

Consistency across all cylinders remains problematic, with studies showing variance of up to 0.003 inch between identically adjusted valves due to manufacturing tolerances in components and subjective elements in the adjustment process. This inconsistency directly impacts engine balance and efficiency.

The time-intensive nature of proper valve lash adjustment also presents a practical challenge. A complete adjustment typically requires 2-3 hours for experienced technicians, creating a barrier to performing this maintenance as frequently as might be optimal for maximum efficiency. This time investment often leads to adjustments being postponed or performed hastily.

Lastly, the lack of real-time feedback during adjustment means technicians cannot immediately verify the impact of their adjustments on engine performance metrics, requiring post-adjustment testing and potential readjustment cycles.

Contemporary Valve Lash Adjustment Procedures and Tools

01 Hydraulic valve lash adjustment systems

Hydraulic valve lash adjusters are used in LS2 engines to automatically maintain proper valve clearance during operation. These systems use oil pressure to compensate for thermal expansion and component wear, eliminating the need for manual adjustments. The hydraulic elements consist of a plunger and oil chamber that automatically adjust the clearance between the valve stem and rocker arm, improving engine efficiency and reducing maintenance requirements.- Hydraulic valve lash adjustment systems: Hydraulic valve lash adjusters are used in LS2 engines to automatically maintain proper valve clearance. These systems use oil pressure to compensate for thermal expansion and wear, eliminating the need for manual adjustments. The hydraulic elements consist of a plunger and oil chamber that maintain constant contact between valve train components, improving engine efficiency and reducing maintenance requirements.

- Mechanical valve lash adjustment methods: Mechanical methods for adjusting valve lash in LS2 engines involve the use of specialized tools and procedures to set precise clearances between valve train components. These methods typically require measuring the gap between the rocker arm and valve stem, then installing appropriately sized shims or adjusting screws to achieve the manufacturer's specifications. Proper mechanical adjustment ensures optimal valve timing and engine performance.

- Electronic monitoring and control systems: Advanced electronic systems are employed to monitor and control valve lash in modern LS2 engines. These systems use sensors to continuously measure valve clearances during engine operation and can make real-time adjustments to maintain optimal performance. Electronic control units process data from multiple engine parameters to determine ideal valve timing and clearance, improving combustion efficiency and reducing emissions.

- Thermal compensation mechanisms: Thermal compensation mechanisms are integrated into LS2 engine valve trains to account for expansion and contraction of components during temperature fluctuations. These systems maintain proper valve lash across varying operating conditions by using materials with specific thermal expansion properties or incorporating design elements that automatically adjust clearances as temperatures change. This ensures consistent engine performance from cold start to full operating temperature.

- Innovative rocker arm designs: Advanced rocker arm designs enhance valve lash adjustment efficiency in LS2 engines. These innovations include roller-tipped rockers that reduce friction, lightweight materials that decrease reciprocating mass, and integrated adjustment mechanisms that simplify maintenance. Some designs incorporate needle bearings or specialized pivot points to maintain precise valve actuation while minimizing wear and power losses throughout the valve train system.

02 Mechanical valve lash adjustment mechanisms

Mechanical valve lash adjustment systems for LS2 engines utilize adjustable components such as screws, nuts, or shims to set the proper clearance between valve train components. These systems require periodic manual adjustment but offer precise control over valve timing and lift. The adjustment process typically involves measuring the gap between components when the engine is cold and adjusting to manufacturer specifications to ensure optimal engine performance and efficiency.Expand Specific Solutions03 Electronic and automated valve lash adjustment

Advanced electronic systems for valve lash adjustment in LS2 engines incorporate sensors and actuators to monitor and adjust valve clearance in real-time. These systems can adapt to different operating conditions, optimizing engine performance across various speeds and loads. Electronic control units process data from multiple sensors to determine the ideal valve lash settings, automatically making adjustments to improve combustion efficiency, reduce emissions, and enhance overall engine performance.Expand Specific Solutions04 Tools and methods for valve lash adjustment

Specialized tools and methodologies have been developed to improve the efficiency of valve lash adjustment procedures on LS2 engines. These include precision measuring instruments, feeler gauges, and custom wrenches designed specifically for accessing the adjustment points on these engines. Proper adjustment sequences and techniques ensure accurate and consistent settings across all cylinders, while reducing the time required for maintenance operations and improving the longevity of valve train components.Expand Specific Solutions05 Variable valve timing integration with lash adjustment

Integration of valve lash adjustment with variable valve timing systems in LS2 engines allows for dynamic control of valve operation throughout different engine operating conditions. These combined systems can adjust both the timing of valve events and the clearance between components to optimize performance. The coordination between these systems enables improvements in fuel efficiency, power output, and emissions control by ensuring proper valve operation across the engine's entire operating range.Expand Specific Solutions

Major Manufacturers and Aftermarket Solutions Providers

The LS2 engine valve lash adjustment market is currently in a mature growth phase, with an estimated global market size of $1.2-1.5 billion annually. The competitive landscape features established OEMs like GM Global Technology Operations and Caterpillar alongside specialized component manufacturers such as Schaeffler Technologies and NITTAN Corp. Technical maturity varies significantly across players, with automotive giants Toyota, Honda, and Hyundai demonstrating advanced valve train optimization technologies through extensive patent portfolios. Specialized engineering firms like FEV Motorentechnik and Delphi Technologies offer cutting-edge solutions incorporating electronic valve actuation and real-time adjustment capabilities. The market is experiencing technological convergence as traditional mechanical systems evolve toward integrated mechatronic solutions that optimize efficiency across diverse operating conditions.

Schaeffler AG

Technical Solution: Schaeffler AG has developed an innovative approach to valve lash adjustment for pushrod engines like the LS2 through their INA brand components. Their system incorporates precision-manufactured roller lifters with tight tolerance specifications (±0.0005") and specialized hardened adjustment screws with fine-thread pitch for more precise adjustments. Schaeffler's methodology focuses on dynamic valve train behavior, accounting for not just static clearance but deflection under operating loads. Their engineers have developed specific adjustment sequences that minimize the impact of cylinder head bolt torque on valve lash measurements. For LS2 applications, Schaeffler recommends a "hot setting" procedure where adjustments are made with the engine at specific operating temperatures to account for thermal expansion characteristics of different materials in the valve train. This approach is complemented by advanced surface treatments on valve train components that reduce friction and wear, maintaining consistent valve lash for longer periods.

Strengths: Superior component manufacturing precision; excellent long-term stability of adjustments; comprehensive consideration of dynamic operating conditions. Weaknesses: More complex adjustment procedures requiring temperature-specific settings; higher component costs; requires more specialized knowledge for implementation.

GM Global Technology Operations LLC

Technical Solution: GM's approach to LS2 valve lash adjustment focuses on precision engineering and advanced measurement techniques. Their method involves using specialized feeler gauges (typically 0.006" for intake and 0.012" for exhaust) with the engine cold, following a specific cylinder adjustment sequence based on the firing order. GM has developed a proprietary "zero-lash plus" methodology where technicians first achieve zero lash (where no resistance is felt) and then add the specified amount of rotation to achieve optimal clearance. This technique ensures consistent valve timing across all cylinders while compensating for thermal expansion during operation. GM also implements computer-aided valve train analysis during development to predict wear patterns and optimal adjustment intervals, typically recommending inspection every 150,000 miles for LS2 engines, significantly longer than older engine designs.

Strengths: Precise factory-specified clearances optimized through extensive testing; longer service intervals than competitors; excellent balance between performance and longevity. Weaknesses: Requires specialized tools and training for proper adjustment; less accessible for DIY mechanics compared to simpler valve systems; potential for increased noise if specifications aren't precisely followed.

Critical Patents and Technical Literature on Valve Train Optimization

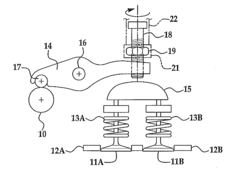

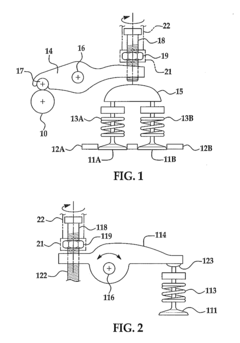

Lash adjuster and valve system

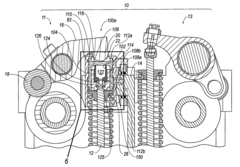

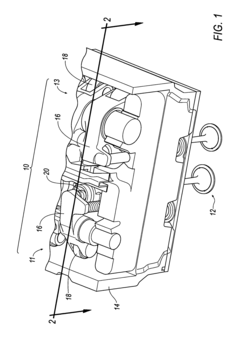

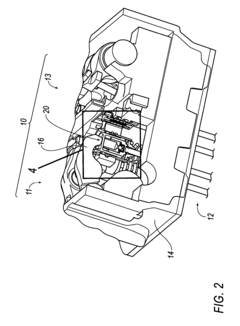

PatentActiveUS7350491B2

Innovation

- An added-motion hydraulic lash adjuster system that includes a lash adjuster assembly with a plunger and piston arrangement, which controls clearances between the rocker arm and plunger using fluid communication and a stop mechanism to maintain desired seating performance, and can operate in conjunction with mechanical lash adjusters to reduce lash and accommodate temperature changes.

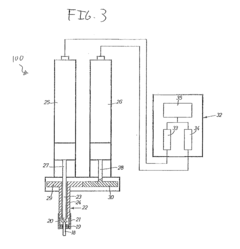

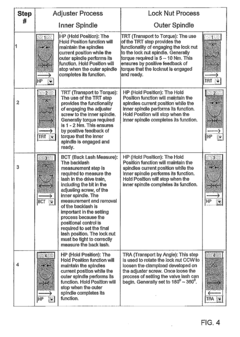

Valve Lash Setting Process

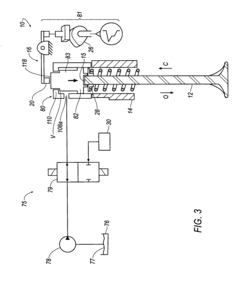

PatentActiveUS20110061621A1

Innovation

- An automated torque device with a programmable control unit and sensors is used to measure and adjust valve lash by determining the zero lash position through a linear regression analysis of torque versus angular displacement data, allowing for precise and consistent valve lash settings across varying engine conditions.

Thermal Considerations in Valve Lash Setting

Thermal dynamics play a crucial role in the precision of valve lash adjustments for the LS2 engine. When an engine operates, thermal expansion significantly alters the physical dimensions of engine components, directly impacting valve clearances. The LS2 engine, with its aluminum cylinder heads and cast iron block, experiences differential thermal expansion rates that must be accounted for during valve lash setting procedures.

At cold temperatures (typically 20-25°C), the valve lash measurements will differ substantially from those at operating temperature (90-105°C). This temperature differential can result in clearance variations of 0.002-0.004 inches, which is significant considering the precision required for optimal engine performance. Engineers have determined that for every 10°C increase in temperature, valve components in the LS2 engine expand approximately 0.001 inches.

The thermal expansion coefficient of aluminum (approximately 23 × 10^-6/°C) versus cast iron (approximately 12 × 10^-6/°C) creates a complex thermal relationship that must be factored into valve adjustment procedures. This differential expansion means that clearances set at ambient temperature will tighten as the engine reaches operating temperature, potentially leading to valve seating issues if not properly compensated for.

Manufacturers typically specify valve lash settings based on either "cold" or "hot" adjustment protocols. For the LS2 engine, General Motors recommends cold setting specifications of 0.020 inches for intake valves and 0.024 inches for exhaust valves. These specifications are designed to provide optimal clearance once the engine reaches normal operating temperature.

Temperature stabilization is another critical consideration. Before making hot adjustments, the engine should be run until it reaches full operating temperature, then allowed to cool for approximately 15-20 minutes to achieve a semi-stabilized thermal state. This partial cooling period allows for more consistent measurements while still accounting for the thermal expansion characteristics of the engine components.

Advanced thermal imaging technology has been employed in research settings to map the temperature gradients across the cylinder head during operation. These studies reveal that exhaust valve areas can reach temperatures up to 30°C higher than intake valve regions, explaining why exhaust valve lash specifications typically allow for greater clearance.

Seasonal ambient temperature variations also impact valve lash settings. Adjustments performed in winter conditions may require different compensation factors compared to those done in summer months, particularly for engines operated in extreme climate conditions. Professional engine builders often develop seasonal adjustment protocols to account for these variations.

At cold temperatures (typically 20-25°C), the valve lash measurements will differ substantially from those at operating temperature (90-105°C). This temperature differential can result in clearance variations of 0.002-0.004 inches, which is significant considering the precision required for optimal engine performance. Engineers have determined that for every 10°C increase in temperature, valve components in the LS2 engine expand approximately 0.001 inches.

The thermal expansion coefficient of aluminum (approximately 23 × 10^-6/°C) versus cast iron (approximately 12 × 10^-6/°C) creates a complex thermal relationship that must be factored into valve adjustment procedures. This differential expansion means that clearances set at ambient temperature will tighten as the engine reaches operating temperature, potentially leading to valve seating issues if not properly compensated for.

Manufacturers typically specify valve lash settings based on either "cold" or "hot" adjustment protocols. For the LS2 engine, General Motors recommends cold setting specifications of 0.020 inches for intake valves and 0.024 inches for exhaust valves. These specifications are designed to provide optimal clearance once the engine reaches normal operating temperature.

Temperature stabilization is another critical consideration. Before making hot adjustments, the engine should be run until it reaches full operating temperature, then allowed to cool for approximately 15-20 minutes to achieve a semi-stabilized thermal state. This partial cooling period allows for more consistent measurements while still accounting for the thermal expansion characteristics of the engine components.

Advanced thermal imaging technology has been employed in research settings to map the temperature gradients across the cylinder head during operation. These studies reveal that exhaust valve areas can reach temperatures up to 30°C higher than intake valve regions, explaining why exhaust valve lash specifications typically allow for greater clearance.

Seasonal ambient temperature variations also impact valve lash settings. Adjustments performed in winter conditions may require different compensation factors compared to those done in summer months, particularly for engines operated in extreme climate conditions. Professional engine builders often develop seasonal adjustment protocols to account for these variations.

Performance Testing and Validation Protocols

To validate the effectiveness of valve lash adjustment procedures for the LS2 engine, comprehensive performance testing and validation protocols must be established. These protocols should encompass both laboratory and real-world testing environments to ensure reliability and reproducibility of results. The testing methodology begins with baseline dynamometer testing, where engine performance metrics are recorded before any valve lash adjustments. Key parameters to monitor include horsepower, torque curves, volumetric efficiency, and fuel consumption across various RPM ranges.

Following baseline establishment, incremental valve lash adjustments should be performed according to a predetermined matrix, with performance testing conducted after each adjustment. This systematic approach allows for precise correlation between specific valve lash settings and performance outcomes. Temperature variation testing is particularly critical, as thermal expansion significantly affects valve train geometry. Tests should be conducted at cold start, normal operating temperature, and high-load conditions to capture the full spectrum of operational scenarios.

Vibration analysis using accelerometers mounted on valve covers provides valuable data on valve train stability and potential harmonics issues resulting from different lash settings. This data should be correlated with acoustic measurements to identify optimal settings that minimize noise while maximizing performance. Exhaust gas analysis offers another critical validation metric, with emissions composition and temperature providing insights into combustion efficiency at various valve lash settings.

Long-duration endurance testing represents an essential component of the validation protocol. Selected valve lash settings should undergo extended testing cycles simulating real-world driving conditions, including varied load profiles and temperature fluctuations. During these tests, valve train components should be periodically inspected for wear patterns, with particular attention to valve seats, valve tips, and rocker arms.

Data acquisition systems must maintain sampling rates sufficient to capture high-frequency events within the valve train, typically requiring capabilities of at least 10 kHz. Statistical analysis of collected data should employ both parametric and non-parametric methods to account for potential non-linear relationships between valve lash settings and performance metrics. Confidence intervals should be established for all key findings, with repeatability verified through multiple test cycles.

Final validation should include on-vehicle testing under controlled conditions, preferably on both chassis dynamometers and closed-course testing facilities. This transition from laboratory to vehicle validation ensures that theoretical improvements translate to real-world performance gains. Documentation of all testing protocols, raw data, and analysis methods is essential for future reference and continuous improvement of valve lash adjustment procedures.

Following baseline establishment, incremental valve lash adjustments should be performed according to a predetermined matrix, with performance testing conducted after each adjustment. This systematic approach allows for precise correlation between specific valve lash settings and performance outcomes. Temperature variation testing is particularly critical, as thermal expansion significantly affects valve train geometry. Tests should be conducted at cold start, normal operating temperature, and high-load conditions to capture the full spectrum of operational scenarios.

Vibration analysis using accelerometers mounted on valve covers provides valuable data on valve train stability and potential harmonics issues resulting from different lash settings. This data should be correlated with acoustic measurements to identify optimal settings that minimize noise while maximizing performance. Exhaust gas analysis offers another critical validation metric, with emissions composition and temperature providing insights into combustion efficiency at various valve lash settings.

Long-duration endurance testing represents an essential component of the validation protocol. Selected valve lash settings should undergo extended testing cycles simulating real-world driving conditions, including varied load profiles and temperature fluctuations. During these tests, valve train components should be periodically inspected for wear patterns, with particular attention to valve seats, valve tips, and rocker arms.

Data acquisition systems must maintain sampling rates sufficient to capture high-frequency events within the valve train, typically requiring capabilities of at least 10 kHz. Statistical analysis of collected data should employ both parametric and non-parametric methods to account for potential non-linear relationships between valve lash settings and performance metrics. Confidence intervals should be established for all key findings, with repeatability verified through multiple test cycles.

Final validation should include on-vehicle testing under controlled conditions, preferably on both chassis dynamometers and closed-course testing facilities. This transition from laboratory to vehicle validation ensures that theoretical improvements translate to real-world performance gains. Documentation of all testing protocols, raw data, and analysis methods is essential for future reference and continuous improvement of valve lash adjustment procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!