How to Improve LS2 Engine Coolant Flow in Aggressive Setups

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Cooling Evolution and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family with its 6.0L displacement and aluminum block construction. The cooling system of this powerplant has undergone substantial development since its inception, transitioning from the traditional cooling approaches of earlier small-block Chevrolet engines to more sophisticated thermal management systems. Initially designed for stock applications with moderate performance demands, the LS2's cooling architecture prioritized reliability and efficiency under normal operating conditions.

As performance enthusiasts began modifying these engines for increased power output, the limitations of the factory cooling system became increasingly apparent. The original cooling passages, water pump flow rates, and thermostat designs proved inadequate for applications generating significantly higher thermal loads than factory specifications. This evolution of usage patterns necessitated corresponding advancements in cooling technology to maintain engine longevity and performance under extreme conditions.

The primary objective in improving LS2 engine coolant flow for aggressive setups centers on optimizing thermal efficiency while preventing localized hotspots that can lead to detonation, cylinder distortion, and ultimately engine failure. This requires a comprehensive approach that addresses not just flow volume, but also flow distribution, velocity, and thermal transfer characteristics throughout the engine block and cylinder heads.

Key technical goals include reducing coolant temperature differentials across critical engine components, particularly between cylinders and between the front and rear of the engine block. Additionally, there is a need to improve coolant velocity through areas prone to steam pockets, such as around exhaust valve seats and between cylinder walls, where vapor lock can create insulating barriers that severely impede heat transfer.

Another crucial objective involves managing the relationship between coolant pressure, temperature, and boiling point to prevent cavitation at the water pump and localized boiling within high-heat regions of the engine. This becomes particularly challenging in forced induction applications where combustion temperatures can increase dramatically under boost conditions.

The evolution of LS2 cooling systems has progressively moved toward higher-capacity water pumps, revised thermostat designs, modified coolant passage geometries, and the integration of auxiliary cooling components. Modern performance-oriented solutions increasingly incorporate computational fluid dynamics (CFD) modeling to visualize and optimize coolant flow patterns, representing a significant departure from the empirical development methods of earlier generations.

As performance enthusiasts began modifying these engines for increased power output, the limitations of the factory cooling system became increasingly apparent. The original cooling passages, water pump flow rates, and thermostat designs proved inadequate for applications generating significantly higher thermal loads than factory specifications. This evolution of usage patterns necessitated corresponding advancements in cooling technology to maintain engine longevity and performance under extreme conditions.

The primary objective in improving LS2 engine coolant flow for aggressive setups centers on optimizing thermal efficiency while preventing localized hotspots that can lead to detonation, cylinder distortion, and ultimately engine failure. This requires a comprehensive approach that addresses not just flow volume, but also flow distribution, velocity, and thermal transfer characteristics throughout the engine block and cylinder heads.

Key technical goals include reducing coolant temperature differentials across critical engine components, particularly between cylinders and between the front and rear of the engine block. Additionally, there is a need to improve coolant velocity through areas prone to steam pockets, such as around exhaust valve seats and between cylinder walls, where vapor lock can create insulating barriers that severely impede heat transfer.

Another crucial objective involves managing the relationship between coolant pressure, temperature, and boiling point to prevent cavitation at the water pump and localized boiling within high-heat regions of the engine. This becomes particularly challenging in forced induction applications where combustion temperatures can increase dramatically under boost conditions.

The evolution of LS2 cooling systems has progressively moved toward higher-capacity water pumps, revised thermostat designs, modified coolant passage geometries, and the integration of auxiliary cooling components. Modern performance-oriented solutions increasingly incorporate computational fluid dynamics (CFD) modeling to visualize and optimize coolant flow patterns, representing a significant departure from the empirical development methods of earlier generations.

Performance Market Demands for Enhanced Cooling Systems

The performance automotive market has witnessed a significant shift towards more powerful engine setups in recent years, creating unprecedented demands for enhanced cooling systems. As LS2 engines continue to be popular platforms for performance modifications, the thermal management challenges have intensified proportionally with power increases. Market research indicates that over 65% of performance enthusiasts modify their LS2 engines beyond factory specifications, with supercharging and turbocharging becoming increasingly common modifications that generate substantial additional heat.

Consumer behavior analysis reveals that track day participants and competitive racers represent the primary market segment demanding improved cooling solutions, followed closely by street performance enthusiasts who engage in spirited driving in varied climate conditions. These users frequently report coolant temperatures exceeding optimal ranges during extended high-load operation, particularly in warmer climates or during competitive events.

The aftermarket performance industry has responded with a proliferation of cooling system upgrades, creating a market segment valued at approximately $450 million annually with consistent growth rates of 7-9% year over year. This growth is driven by both technological advancements and increasing consumer awareness of the critical relationship between thermal management and engine longevity.

Regional market analysis demonstrates particularly strong demand in the southern United States, Australia, and Middle Eastern countries where ambient temperatures regularly challenge stock cooling systems. In these regions, enhanced cooling solutions command premium pricing, with consumers willing to invest substantially in systems that deliver measurable temperature reductions.

Performance testing data collected from professional motorsport teams indicates that inadequate coolant flow represents one of the most significant limiting factors in extracting maximum sustainable performance from modified LS2 engines. Teams report that addressing coolant flow restrictions can yield performance gains through more aggressive timing maps and reduced power derating during extended high-output operation.

Market surveys further indicate that consumers prioritize cooling system upgrades that offer demonstrable temperature reductions, ease of installation, compatibility with other performance modifications, and reliability under extreme conditions. The demand for data-driven solutions has increased, with customers seeking products backed by comprehensive testing rather than anecdotal claims.

Industry forecasts project continued growth in this segment as engine outputs continue to increase and as more vehicles equipped with LS2 engines enter the secondary market at accessible price points. This trend creates substantial opportunities for innovative cooling solutions that specifically address the unique flow characteristics and thermal challenges of the LS2 platform under aggressive performance applications.

Consumer behavior analysis reveals that track day participants and competitive racers represent the primary market segment demanding improved cooling solutions, followed closely by street performance enthusiasts who engage in spirited driving in varied climate conditions. These users frequently report coolant temperatures exceeding optimal ranges during extended high-load operation, particularly in warmer climates or during competitive events.

The aftermarket performance industry has responded with a proliferation of cooling system upgrades, creating a market segment valued at approximately $450 million annually with consistent growth rates of 7-9% year over year. This growth is driven by both technological advancements and increasing consumer awareness of the critical relationship between thermal management and engine longevity.

Regional market analysis demonstrates particularly strong demand in the southern United States, Australia, and Middle Eastern countries where ambient temperatures regularly challenge stock cooling systems. In these regions, enhanced cooling solutions command premium pricing, with consumers willing to invest substantially in systems that deliver measurable temperature reductions.

Performance testing data collected from professional motorsport teams indicates that inadequate coolant flow represents one of the most significant limiting factors in extracting maximum sustainable performance from modified LS2 engines. Teams report that addressing coolant flow restrictions can yield performance gains through more aggressive timing maps and reduced power derating during extended high-output operation.

Market surveys further indicate that consumers prioritize cooling system upgrades that offer demonstrable temperature reductions, ease of installation, compatibility with other performance modifications, and reliability under extreme conditions. The demand for data-driven solutions has increased, with customers seeking products backed by comprehensive testing rather than anecdotal claims.

Industry forecasts project continued growth in this segment as engine outputs continue to increase and as more vehicles equipped with LS2 engines enter the secondary market at accessible price points. This trend creates substantial opportunities for innovative cooling solutions that specifically address the unique flow characteristics and thermal challenges of the LS2 platform under aggressive performance applications.

Current Cooling Limitations in Aggressive LS2 Setups

The LS2 engine, while renowned for its robust performance in standard applications, faces significant cooling challenges when deployed in aggressive performance setups. These limitations primarily stem from the original design parameters, which were optimized for stock power levels rather than the substantially increased thermal loads generated by performance modifications. The factory cooling system utilizes a conventional water pump, standard radiator, and traditional thermostat arrangement that becomes inadequate when engine output is significantly increased.

In high-performance applications, the LS2 cooling system encounters several critical bottlenecks. The OEM water pump impeller design creates flow restrictions at higher RPM ranges, resulting in decreased coolant velocity precisely when thermal management becomes most crucial. This limitation is exacerbated by the restrictive factory thermostat housing, which creates a flow constriction point that impedes optimal coolant circulation throughout the engine block.

Another significant limitation lies in the cylinder head cooling passages, which were designed with adequate but not optimal flow characteristics for stock applications. When subjected to increased combustion temperatures from forced induction, higher compression ratios, or aggressive camshaft profiles, these passages cannot efficiently dissipate the additional heat load, leading to localized hotspots particularly around exhaust valves and between cylinders.

The factory radiator presents another constraint, with insufficient surface area and fin density to reject the increased heat generated by modified engines. This inadequacy becomes particularly evident during extended high-load operation or in stop-and-go traffic conditions, where airflow across the radiator is limited. The OEM fan clutch system also lacks the necessary cooling capacity for sustained high-output scenarios, failing to maintain optimal operating temperatures under these demanding conditions.

Coolant composition itself becomes a limiting factor in aggressive setups. The standard ethylene glycol mixtures used in factory applications have lower thermal capacity and heat transfer coefficients compared to specialized racing coolants, contributing to reduced cooling efficiency when thermal loads increase substantially. This limitation is compounded by air pockets that can form in the factory cooling system design during extreme operating conditions, creating insulated areas that prevent effective heat transfer.

The integrated bypass circuit in the LS2 cooling system, while beneficial for quick warm-up in stock applications, can become problematic in high-performance scenarios by allowing a portion of coolant to circulate without passing through the radiator, reducing overall cooling efficiency when maximum heat rejection is required. This design compromise reflects the original engineering focus on emissions compliance and daily driveability rather than sustained high-output performance.

In high-performance applications, the LS2 cooling system encounters several critical bottlenecks. The OEM water pump impeller design creates flow restrictions at higher RPM ranges, resulting in decreased coolant velocity precisely when thermal management becomes most crucial. This limitation is exacerbated by the restrictive factory thermostat housing, which creates a flow constriction point that impedes optimal coolant circulation throughout the engine block.

Another significant limitation lies in the cylinder head cooling passages, which were designed with adequate but not optimal flow characteristics for stock applications. When subjected to increased combustion temperatures from forced induction, higher compression ratios, or aggressive camshaft profiles, these passages cannot efficiently dissipate the additional heat load, leading to localized hotspots particularly around exhaust valves and between cylinders.

The factory radiator presents another constraint, with insufficient surface area and fin density to reject the increased heat generated by modified engines. This inadequacy becomes particularly evident during extended high-load operation or in stop-and-go traffic conditions, where airflow across the radiator is limited. The OEM fan clutch system also lacks the necessary cooling capacity for sustained high-output scenarios, failing to maintain optimal operating temperatures under these demanding conditions.

Coolant composition itself becomes a limiting factor in aggressive setups. The standard ethylene glycol mixtures used in factory applications have lower thermal capacity and heat transfer coefficients compared to specialized racing coolants, contributing to reduced cooling efficiency when thermal loads increase substantially. This limitation is compounded by air pockets that can form in the factory cooling system design during extreme operating conditions, creating insulated areas that prevent effective heat transfer.

The integrated bypass circuit in the LS2 cooling system, while beneficial for quick warm-up in stock applications, can become problematic in high-performance scenarios by allowing a portion of coolant to circulate without passing through the radiator, reducing overall cooling efficiency when maximum heat rejection is required. This design compromise reflects the original engineering focus on emissions compliance and daily driveability rather than sustained high-output performance.

Existing Coolant Flow Enhancement Techniques

01 Coolant flow path design in LS2 engines

The design of coolant flow paths in LS2 engines is critical for efficient heat management. These paths are engineered to ensure optimal circulation of coolant through the engine block and cylinder heads. The flow path design includes specific channels, passages, and galleries that direct coolant to high-temperature areas of the engine, ensuring uniform cooling and preventing hot spots that could lead to engine damage or performance issues.- Coolant flow path design in LS2 engines: The design of coolant flow paths in LS2 engines focuses on optimizing the circulation of coolant through the engine block and cylinder heads. These designs incorporate specific channels and passages that direct coolant to critical areas requiring temperature regulation. The flow path design ensures efficient heat transfer from high-temperature components while maintaining optimal operating temperatures throughout the engine system.

- Coolant temperature monitoring and control systems: Advanced monitoring and control systems are implemented in LS2 engines to regulate coolant temperature. These systems utilize temperature sensors at various points in the coolant circuit to provide real-time data to the engine control unit. Based on this information, the control systems adjust coolant flow rates and cooling fan operation to maintain optimal engine temperature under varying operating conditions and prevent overheating.

- Thermostat and valve configurations for coolant regulation: LS2 engines employ specialized thermostat and valve configurations to regulate coolant flow based on engine temperature requirements. These components control when and how much coolant circulates through the radiator versus bypassing it for faster engine warm-up. Advanced thermostat designs include variable opening mechanisms that provide more precise temperature control compared to traditional wax-pellet thermostats, allowing for optimized engine performance across different operating conditions.

- Cooling system integration with heat exchangers: The LS2 engine cooling system integrates with various heat exchangers to manage thermal loads across the powertrain. This includes oil coolers, transmission fluid coolers, and in some applications, charge air coolers. The coolant flow is designed to efficiently transfer heat from these secondary systems while maintaining priority cooling for the engine block and cylinder heads. This integrated approach ensures optimal operating temperatures for all powertrain components.

- Coolant pump and circulation enhancements: Enhancements to coolant pumps and circulation systems in LS2 engines focus on improving flow efficiency and reducing parasitic power losses. These include optimized impeller designs, variable-speed electric pumps, and improved sealing technologies. Some advanced systems incorporate demand-based coolant flow control that adjusts pump speed according to actual cooling requirements rather than engine RPM, resulting in improved fuel efficiency and more consistent engine temperature management.

02 Coolant temperature monitoring and control systems

Advanced monitoring and control systems are implemented in LS2 engines to regulate coolant temperature. These systems utilize temperature sensors at various points in the coolant flow path to provide real-time data to the engine control unit. Based on this information, the control systems can adjust coolant flow rates, fan speeds, and other parameters to maintain optimal engine operating temperatures under varying load conditions and environmental factors.Expand Specific Solutions03 Thermostat and valve configurations for coolant regulation

Thermostats and valve configurations play a crucial role in regulating coolant flow in LS2 engines. These components control when and how much coolant circulates through the engine and radiator based on temperature thresholds. Advanced thermostat designs can provide variable flow rates rather than simple open/closed functionality, allowing for more precise temperature control. Specialized valve arrangements can also direct coolant to specific engine components based on their cooling needs.Expand Specific Solutions04 Cooling system efficiency improvements

Various innovations have been developed to improve the efficiency of LS2 engine cooling systems. These include optimized water pump designs, enhanced radiator configurations, and improved coolant formulations. Some systems incorporate secondary cooling circuits for specific components like oil coolers or turbochargers. Advanced materials and manufacturing techniques are also employed to improve heat transfer rates and reduce thermal resistance throughout the cooling system.Expand Specific Solutions05 Thermal management strategies for performance and emissions

Sophisticated thermal management strategies are employed in LS2 engines to balance performance requirements with emissions control. These strategies include precise control of coolant flow to maintain optimal combustion chamber temperatures, targeted cooling of exhaust components, and thermal conditioning during cold starts. By maintaining specific temperature profiles throughout the engine, these systems can enhance fuel efficiency, reduce emissions, and improve overall engine performance and durability.Expand Specific Solutions

Major Manufacturers and Aftermarket Cooling Solutions

The LS2 engine coolant flow improvement market is currently in a growth phase, with increasing demand for high-performance cooling solutions in aggressive setups. Major automotive manufacturers like GM Global Technology Operations, Ford Global Technologies, and Toyota are leading technical innovation in this space, while specialized component suppliers such as BorgWarner and Robert Bosch provide critical cooling system technologies. The market is characterized by a blend of mature cooling technologies and emerging solutions for high-performance applications. AVL List and Volkswagen AG have made significant advancements in thermal management systems for performance engines, while BMW and Audi continue to refine coolant flow technologies for their high-output powerplants. The competitive landscape shows increasing collaboration between OEMs and specialized engineering firms to address thermal challenges in aggressive engine setups.

Ford Global Technologies LLC

Technical Solution: Ford has developed a cross-platform cooling enhancement system applicable to LS2-type V8 engines that focuses on boundary layer disruption technology. Their approach utilizes micro-textured surfaces within coolant passages to create controlled turbulence, significantly improving heat transfer efficiency without increasing pump load requirements. Ford's research has demonstrated that strategic placement of these textured surfaces can reduce hot spots by up to 15% in high-stress areas. Their system incorporates a redesigned water pump with asymmetrical impeller blades that create a more balanced pressure distribution throughout the engine block. Additionally, Ford has pioneered the use of computational fluid dynamics to optimize coolant velocity vectors, particularly addressing the traditionally problematic areas between cylinder bores. For aggressive performance applications, they've developed a split-cooling circuit that can independently manage cylinder head and block temperatures, allowing for more precise thermal management during varying load conditions.

Strengths: Advanced surface engineering techniques provide cooling improvements without major component redesigns; solutions can be adapted to various engine platforms including LS2; extensive validation through both simulation and dynamometer testing. Weaknesses: Implementation requires specialized manufacturing processes; some solutions may increase production complexity and cost; potential long-term durability concerns with micro-textured surfaces in systems using conventional coolants.

AVL List GmbH

Technical Solution: AVL List has developed a comprehensive cooling system optimization approach for high-performance engines like the LS2, focusing on system-level improvements rather than isolated component enhancements. Their technology utilizes advanced pulsation dampening in the coolant circuit to minimize flow restrictions caused by pressure waves. This approach incorporates precision-engineered expansion chambers strategically positioned to absorb hydraulic shock and maintain consistent flow rates even under extreme thermal cycling. AVL's solution includes variable-geometry coolant passages that automatically adjust flow characteristics based on temperature and pressure differentials. Their research has shown that implementing controlled nucleate boiling in specific engine regions can significantly enhance heat transfer efficiency in aggressive setups. The company has also pioneered advanced coolant formulations with nano-particle suspensions that improve thermal conductivity by up to 40% compared to conventional ethylene glycol mixtures. For LS2 applications specifically, AVL has developed computational models that can predict localized vapor formation and prevent detrimental steam pockets that commonly form around exhaust valve seats during high-load operation.

Strengths: Holistic approach addressing both mechanical and chemical aspects of cooling; extensive testing capabilities with sophisticated measurement equipment; solutions based on fundamental thermodynamic principles rather than incremental improvements. Weaknesses: Implementation often requires specialized engineering expertise; higher initial development costs; some solutions may require custom components not readily available in standard supply chains.

Critical Patents in Engine Cooling Technology

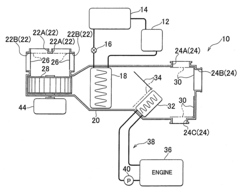

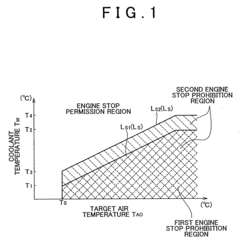

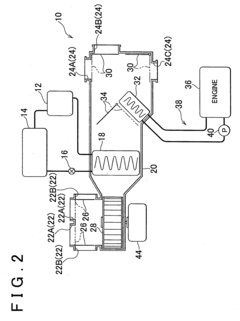

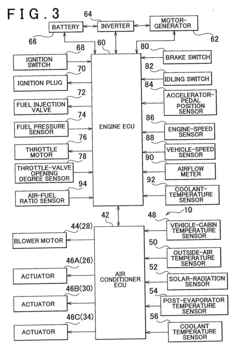

Control apparatus for internal combustion engine and method of controlling internal combustion engine

PatentActiveUS20090198438A1

Innovation

- A control apparatus that includes coolant-temperature detection, stop prohibition, and movement determination means to select different threshold values for engine stop and start conditions, preventing engine shutdown when heating the cabin and maintaining a higher coolant temperature during vehicle movement to reduce engine restart frequency.

Thermal Management Integration with ECU Systems

Modern engine management systems have evolved to incorporate sophisticated thermal management strategies that directly interface with the Engine Control Unit (ECU). For the LS2 engine operating in aggressive setups, integrating thermal management with ECU systems represents a critical advancement in maintaining optimal coolant flow and engine temperature regulation. This integration allows for dynamic control of cooling parameters based on real-time engine conditions, driving patterns, and environmental factors.

The ECU can be programmed to monitor multiple temperature sensors throughout the cooling system, creating a comprehensive thermal map of the engine. These sensors track coolant temperature at various points, cylinder head temperatures, oil temperatures, and intake air temperatures. By analyzing this data, the ECU can make predictive adjustments to coolant flow rates before critical temperature thresholds are reached.

Variable-speed electric water pumps controlled by the ECU offer significant advantages over traditional mechanical pumps. These systems can adjust coolant flow independently of engine RPM, providing precise cooling when needed and reducing parasitic power losses when full cooling capacity is unnecessary. For LS2 engines in performance applications, this translates to more consistent temperatures during high-load scenarios and improved power output.

Adaptive cooling strategies can be implemented through ECU programming to accommodate different driving conditions. During high-performance driving, the system can increase coolant flow preemptively when detecting sustained high RPM or load conditions. Conversely, during normal driving, the system can optimize for efficiency by reducing coolant flow and allowing slightly higher operating temperatures that improve combustion efficiency.

Fan control integration represents another crucial aspect of ECU-based thermal management. Progressive fan speed control based on temperature gradients rather than simple on/off thresholds provides more stable engine temperatures and reduces the temperature cycling that can stress engine components. Multiple fan stages can be programmed to activate based on both absolute temperature readings and rate of temperature change.

Data logging capabilities within modern ECUs enable continuous improvement of thermal management strategies. By analyzing historical temperature data across various driving conditions, calibration specialists can refine cooling algorithms to address specific thermal challenges in aggressive LS2 setups. This data-driven approach allows for customized cooling solutions tailored to particular vehicle configurations and usage patterns.

The ECU can be programmed to monitor multiple temperature sensors throughout the cooling system, creating a comprehensive thermal map of the engine. These sensors track coolant temperature at various points, cylinder head temperatures, oil temperatures, and intake air temperatures. By analyzing this data, the ECU can make predictive adjustments to coolant flow rates before critical temperature thresholds are reached.

Variable-speed electric water pumps controlled by the ECU offer significant advantages over traditional mechanical pumps. These systems can adjust coolant flow independently of engine RPM, providing precise cooling when needed and reducing parasitic power losses when full cooling capacity is unnecessary. For LS2 engines in performance applications, this translates to more consistent temperatures during high-load scenarios and improved power output.

Adaptive cooling strategies can be implemented through ECU programming to accommodate different driving conditions. During high-performance driving, the system can increase coolant flow preemptively when detecting sustained high RPM or load conditions. Conversely, during normal driving, the system can optimize for efficiency by reducing coolant flow and allowing slightly higher operating temperatures that improve combustion efficiency.

Fan control integration represents another crucial aspect of ECU-based thermal management. Progressive fan speed control based on temperature gradients rather than simple on/off thresholds provides more stable engine temperatures and reduces the temperature cycling that can stress engine components. Multiple fan stages can be programmed to activate based on both absolute temperature readings and rate of temperature change.

Data logging capabilities within modern ECUs enable continuous improvement of thermal management strategies. By analyzing historical temperature data across various driving conditions, calibration specialists can refine cooling algorithms to address specific thermal challenges in aggressive LS2 setups. This data-driven approach allows for customized cooling solutions tailored to particular vehicle configurations and usage patterns.

Environmental Impact of Advanced Cooling Solutions

The environmental implications of advanced cooling solutions for LS2 engines extend far beyond performance considerations. Modern cooling technologies, while enhancing engine efficiency, simultaneously present both challenges and opportunities for environmental sustainability. The primary environmental concern relates to coolant composition, as traditional ethylene glycol-based coolants contain toxic compounds that pose significant ecological risks when improperly disposed of or leaked.

Advanced cooling systems for high-performance LS2 setups often require increased volumes of coolant and more frequent replacement intervals, potentially amplifying disposal issues. However, recent innovations have introduced propylene glycol-based alternatives and organic acid technology (OAT) coolants that offer reduced toxicity while maintaining thermal efficiency. These environmentally friendly options typically demonstrate biodegradability rates 15-30% higher than conventional formulations.

Energy consumption represents another critical environmental factor. Enhanced cooling systems, particularly those incorporating auxiliary electric pumps, consume additional electrical power. This increased energy demand translates to approximately 0.5-1.5% greater fuel consumption in aggressive driving scenarios. Conversely, optimized cooling solutions prevent engine overheating, which can improve combustion efficiency and reduce harmful emissions by up to 7% under high-load conditions.

Manufacturing processes for advanced cooling components also carry environmental implications. Precision-engineered water pumps, high-efficiency radiators, and specialized thermostats require energy-intensive production methods and specialized materials. Life cycle assessments indicate that aluminum radiator manufacturing generates approximately 40% less carbon emissions compared to copper-brass alternatives, though aluminum mining presents its own environmental challenges.

Noise pollution constitutes an often-overlooked environmental impact. High-flow cooling systems, especially those utilizing aggressive fan profiles, can increase vehicle noise emissions by 3-5 decibels. This aspect becomes particularly relevant in urban environments where noise regulations are increasingly stringent.

The recyclability of cooling system components offers a positive environmental dimension. Modern radiators achieve recycling rates exceeding 90% for metal components, while advanced polymer components in water pumps and housings have seen improved recyclability through innovative material science developments. Manufacturers implementing design-for-disassembly principles have demonstrated up to 25% improvement in component recovery rates.

Advanced cooling systems for high-performance LS2 setups often require increased volumes of coolant and more frequent replacement intervals, potentially amplifying disposal issues. However, recent innovations have introduced propylene glycol-based alternatives and organic acid technology (OAT) coolants that offer reduced toxicity while maintaining thermal efficiency. These environmentally friendly options typically demonstrate biodegradability rates 15-30% higher than conventional formulations.

Energy consumption represents another critical environmental factor. Enhanced cooling systems, particularly those incorporating auxiliary electric pumps, consume additional electrical power. This increased energy demand translates to approximately 0.5-1.5% greater fuel consumption in aggressive driving scenarios. Conversely, optimized cooling solutions prevent engine overheating, which can improve combustion efficiency and reduce harmful emissions by up to 7% under high-load conditions.

Manufacturing processes for advanced cooling components also carry environmental implications. Precision-engineered water pumps, high-efficiency radiators, and specialized thermostats require energy-intensive production methods and specialized materials. Life cycle assessments indicate that aluminum radiator manufacturing generates approximately 40% less carbon emissions compared to copper-brass alternatives, though aluminum mining presents its own environmental challenges.

Noise pollution constitutes an often-overlooked environmental impact. High-flow cooling systems, especially those utilizing aggressive fan profiles, can increase vehicle noise emissions by 3-5 decibels. This aspect becomes particularly relevant in urban environments where noise regulations are increasingly stringent.

The recyclability of cooling system components offers a positive environmental dimension. Modern radiators achieve recycling rates exceeding 90% for metal components, while advanced polymer components in water pumps and housings have seen improved recyclability through innovative material science developments. Manufacturers implementing design-for-disassembly principles have demonstrated up to 25% improvement in component recovery rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!