How to Tune LS2 Engine Air-Fuel Ratio for Stoichiometry

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine AFR Tuning Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family, featuring a 6.0L displacement and advanced electronic fuel injection system. This powerplant became prominent in various GM performance vehicles including the Pontiac GTO, Chevrolet Corvette C6, and select Cadillac models. The technological advancement of the LS2 over its predecessors includes improved cylinder heads, intake manifold design, and more sophisticated engine control modules (ECMs).

Air-fuel ratio (AFR) tuning stands as a critical aspect of engine performance optimization, directly impacting power output, fuel efficiency, emissions compliance, and engine longevity. The stoichiometric ratio—approximately 14.7:1 for gasoline engines—represents the theoretically perfect balance where all fuel molecules combine with all available oxygen molecules during combustion. This ratio serves as the baseline target for emissions control systems and catalytic converter efficiency.

The evolution of AFR tuning technology has progressed significantly from primitive carburetor adjustments to sophisticated electronic fuel injection systems with closed-loop feedback control. Modern LS2 engines utilize oxygen sensors (both narrowband and wideband types) to continuously monitor exhaust gas composition, allowing the ECM to make real-time adjustments to maintain optimal combustion characteristics across varying operating conditions.

Current industry trends indicate a growing emphasis on precision tuning capabilities, driven by increasingly stringent emissions regulations worldwide and consumer demand for both performance and efficiency. The aftermarket performance sector has simultaneously developed advanced tuning solutions that allow for customization beyond factory parameters, creating a technical ecosystem where OEM compliance and performance enhancement coexist.

The primary objective of this technical research is to comprehensively analyze methodologies for achieving and maintaining stoichiometric AFR in LS2 engines across various operating conditions. Secondary goals include identifying the optimal tuning approaches for different use cases (daily driving, performance applications, emissions compliance), evaluating the effectiveness of various sensor technologies and control strategies, and determining the practical limitations of factory and aftermarket engine management systems.

This research aims to establish best practices for LS2 AFR tuning that balance the often competing demands of performance, efficiency, emissions compliance, and reliability. By examining both theoretical principles and practical implementation techniques, we seek to provide actionable insights for both professional tuners and enthusiast communities working with this popular engine platform.

Air-fuel ratio (AFR) tuning stands as a critical aspect of engine performance optimization, directly impacting power output, fuel efficiency, emissions compliance, and engine longevity. The stoichiometric ratio—approximately 14.7:1 for gasoline engines—represents the theoretically perfect balance where all fuel molecules combine with all available oxygen molecules during combustion. This ratio serves as the baseline target for emissions control systems and catalytic converter efficiency.

The evolution of AFR tuning technology has progressed significantly from primitive carburetor adjustments to sophisticated electronic fuel injection systems with closed-loop feedback control. Modern LS2 engines utilize oxygen sensors (both narrowband and wideband types) to continuously monitor exhaust gas composition, allowing the ECM to make real-time adjustments to maintain optimal combustion characteristics across varying operating conditions.

Current industry trends indicate a growing emphasis on precision tuning capabilities, driven by increasingly stringent emissions regulations worldwide and consumer demand for both performance and efficiency. The aftermarket performance sector has simultaneously developed advanced tuning solutions that allow for customization beyond factory parameters, creating a technical ecosystem where OEM compliance and performance enhancement coexist.

The primary objective of this technical research is to comprehensively analyze methodologies for achieving and maintaining stoichiometric AFR in LS2 engines across various operating conditions. Secondary goals include identifying the optimal tuning approaches for different use cases (daily driving, performance applications, emissions compliance), evaluating the effectiveness of various sensor technologies and control strategies, and determining the practical limitations of factory and aftermarket engine management systems.

This research aims to establish best practices for LS2 AFR tuning that balance the often competing demands of performance, efficiency, emissions compliance, and reliability. By examining both theoretical principles and practical implementation techniques, we seek to provide actionable insights for both professional tuners and enthusiast communities working with this popular engine platform.

Market Demand for Precision Engine Tuning Solutions

The precision engine tuning market has experienced significant growth over the past decade, driven by increasing consumer demand for optimized vehicle performance, fuel efficiency, and emissions compliance. Specifically for the LS2 engine platform, which powers numerous General Motors vehicles, the demand for air-fuel ratio tuning solutions has created a specialized market segment with substantial commercial potential.

Performance enthusiasts represent a primary market driver, consistently seeking solutions that maximize horsepower and torque while maintaining reliability. This demographic is willing to invest considerably in aftermarket tuning solutions, with the average performance-focused LS2 owner spending between $500-$2,000 on engine management systems and tuning services.

The automotive repair and maintenance sector constitutes another significant market segment. Professional mechanics and service centers require precise tuning tools to restore factory specifications and address performance issues. This B2B market values reliability and consistency in tuning solutions, creating demand for professional-grade tools that deliver repeatable results.

Environmental regulations have emerged as a powerful market force. Stringent emissions standards worldwide have compelled vehicle owners to seek tuning solutions that maintain stoichiometric air-fuel ratios while preserving performance. This regulatory-driven demand has expanded beyond enthusiast markets into mainstream consumer segments concerned with emissions compliance and avoiding potential penalties.

Fleet operators represent an emerging market opportunity, as commercial vehicle fleets seek fuel efficiency improvements through optimized engine tuning. Even modest fuel economy gains of 2-3% translate to substantial operational savings across large fleets, creating compelling ROI for precision tuning solutions.

Market research indicates the global engine management system market reached $38.2 billion in 2021, with projections showing 7.3% CAGR through 2028. Within this broader market, specialized tuning solutions for platforms like the LS2 engine represent a growing niche with higher margins than generalized products.

Consumer behavior analysis reveals increasing technical sophistication among end users, with many seeking DIY tuning solutions rather than professional services. This trend has created demand for user-friendly tuning interfaces and educational resources that empower consumers to optimize their own vehicles.

The market landscape shows regional variations, with North America dominating demand for LS2-specific tuning solutions due to the platform's popularity in domestic vehicles. However, growing interest in American performance engines in international markets, particularly Australia, Europe, and parts of Asia, indicates expansion opportunities for companies offering specialized LS2 tuning expertise and products.

Performance enthusiasts represent a primary market driver, consistently seeking solutions that maximize horsepower and torque while maintaining reliability. This demographic is willing to invest considerably in aftermarket tuning solutions, with the average performance-focused LS2 owner spending between $500-$2,000 on engine management systems and tuning services.

The automotive repair and maintenance sector constitutes another significant market segment. Professional mechanics and service centers require precise tuning tools to restore factory specifications and address performance issues. This B2B market values reliability and consistency in tuning solutions, creating demand for professional-grade tools that deliver repeatable results.

Environmental regulations have emerged as a powerful market force. Stringent emissions standards worldwide have compelled vehicle owners to seek tuning solutions that maintain stoichiometric air-fuel ratios while preserving performance. This regulatory-driven demand has expanded beyond enthusiast markets into mainstream consumer segments concerned with emissions compliance and avoiding potential penalties.

Fleet operators represent an emerging market opportunity, as commercial vehicle fleets seek fuel efficiency improvements through optimized engine tuning. Even modest fuel economy gains of 2-3% translate to substantial operational savings across large fleets, creating compelling ROI for precision tuning solutions.

Market research indicates the global engine management system market reached $38.2 billion in 2021, with projections showing 7.3% CAGR through 2028. Within this broader market, specialized tuning solutions for platforms like the LS2 engine represent a growing niche with higher margins than generalized products.

Consumer behavior analysis reveals increasing technical sophistication among end users, with many seeking DIY tuning solutions rather than professional services. This trend has created demand for user-friendly tuning interfaces and educational resources that empower consumers to optimize their own vehicles.

The market landscape shows regional variations, with North America dominating demand for LS2-specific tuning solutions due to the platform's popularity in domestic vehicles. However, growing interest in American performance engines in international markets, particularly Australia, Europe, and parts of Asia, indicates expansion opportunities for companies offering specialized LS2 tuning expertise and products.

Current Challenges in LS2 Stoichiometric Calibration

Achieving stoichiometric air-fuel ratio (AFR) calibration in the LS2 engine presents several significant challenges that engineers must overcome to ensure optimal performance, emissions compliance, and fuel efficiency. The LS2's 6.0L displacement and high-performance characteristics create unique calibration demands that differ from smaller displacement engines.

One primary challenge is the inherent variability in fuel quality across different regions and suppliers. The LS2 engine must maintain stoichiometric operation (14.7:1 AFR) despite variations in fuel composition, octane rating, and ethanol content. This variability directly impacts the oxygen sensor readings and requires sophisticated compensation strategies in the engine control module (ECM) to maintain proper stoichiometry.

Transient operation presents another major hurdle in LS2 calibration. During rapid throttle changes, maintaining stoichiometric AFR becomes exceptionally difficult due to the engine's large displacement and corresponding air mass changes. The fuel delivery system must respond with precise timing to prevent momentary lean or rich conditions that could impact emissions or drivability.

Temperature compensation across the wide operating range of the LS2 engine creates additional calibration challenges. Cold-start enrichment must be carefully balanced against emissions requirements, while high-temperature operation demands different fueling strategies to prevent detonation while maintaining stoichiometry. The thermal characteristics of the aluminum block and heads further complicate this aspect of calibration.

Cylinder-to-cylinder variations represent a significant obstacle in achieving consistent stoichiometric operation. Manufacturing tolerances in injectors, intake runners, and combustion chambers create imbalances in air and fuel distribution. While the LS2 employs sequential fuel injection, the ECM lacks individual cylinder AFR feedback, forcing calibrators to compromise between cylinders.

The wide-band oxygen sensor limitations also present challenges. Despite advances in sensor technology, there remains a delay between actual AFR changes and sensor response. This delay becomes particularly problematic during transient conditions, requiring predictive algorithms and compensation tables in the calibration to anticipate AFR shifts before they occur.

Emissions compliance requirements add another layer of complexity. The LS2 must maintain stoichiometric operation to ensure proper catalytic converter efficiency while simultaneously delivering the performance characteristics expected from a performance V8. This balancing act requires sophisticated closed-loop control strategies and extensive validation testing across diverse operating conditions.

One primary challenge is the inherent variability in fuel quality across different regions and suppliers. The LS2 engine must maintain stoichiometric operation (14.7:1 AFR) despite variations in fuel composition, octane rating, and ethanol content. This variability directly impacts the oxygen sensor readings and requires sophisticated compensation strategies in the engine control module (ECM) to maintain proper stoichiometry.

Transient operation presents another major hurdle in LS2 calibration. During rapid throttle changes, maintaining stoichiometric AFR becomes exceptionally difficult due to the engine's large displacement and corresponding air mass changes. The fuel delivery system must respond with precise timing to prevent momentary lean or rich conditions that could impact emissions or drivability.

Temperature compensation across the wide operating range of the LS2 engine creates additional calibration challenges. Cold-start enrichment must be carefully balanced against emissions requirements, while high-temperature operation demands different fueling strategies to prevent detonation while maintaining stoichiometry. The thermal characteristics of the aluminum block and heads further complicate this aspect of calibration.

Cylinder-to-cylinder variations represent a significant obstacle in achieving consistent stoichiometric operation. Manufacturing tolerances in injectors, intake runners, and combustion chambers create imbalances in air and fuel distribution. While the LS2 employs sequential fuel injection, the ECM lacks individual cylinder AFR feedback, forcing calibrators to compromise between cylinders.

The wide-band oxygen sensor limitations also present challenges. Despite advances in sensor technology, there remains a delay between actual AFR changes and sensor response. This delay becomes particularly problematic during transient conditions, requiring predictive algorithms and compensation tables in the calibration to anticipate AFR shifts before they occur.

Emissions compliance requirements add another layer of complexity. The LS2 must maintain stoichiometric operation to ensure proper catalytic converter efficiency while simultaneously delivering the performance characteristics expected from a performance V8. This balancing act requires sophisticated closed-loop control strategies and extensive validation testing across diverse operating conditions.

Contemporary LS2 AFR Tuning Methodologies

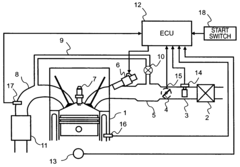

01 Air-fuel ratio control systems for LS2 engines

Control systems designed specifically for LS2 engines to maintain optimal air-fuel ratios. These systems typically include electronic control units (ECUs) that monitor various engine parameters and adjust fuel delivery accordingly. The control systems use feedback from oxygen sensors to make real-time adjustments to the air-fuel mixture, ensuring efficient combustion and power output while meeting emissions requirements.- Air-fuel ratio control systems for LS2 engines: Control systems designed specifically for LS2 engines that monitor and adjust the air-fuel ratio to optimize engine performance. These systems use various sensors and electronic control units to maintain the ideal air-fuel mixture under different operating conditions. The control systems can adjust fuel injection timing and quantity based on real-time engine parameters to ensure efficient combustion and power output.

- Oxygen sensors and feedback control for air-fuel ratio: Implementation of oxygen sensors in the exhaust system to provide feedback on the air-fuel mixture. These sensors detect the oxygen content in the exhaust gases, allowing the engine control module to determine if the mixture is running rich or lean. The feedback system continuously adjusts the fuel delivery to maintain the target air-fuel ratio, improving fuel efficiency and reducing emissions in LS2 engines.

- Fuel injection systems for precise air-fuel ratio control: Advanced fuel injection systems that enable precise control of the air-fuel ratio in LS2 engines. These systems include electronic fuel injectors that can deliver fuel with high accuracy and consistency. The injection timing, duration, and pressure are carefully controlled to achieve the optimal air-fuel mixture for different engine loads and speeds, resulting in improved performance and reduced emissions.

- Air intake and throttle body design for air-fuel ratio management: Specialized air intake systems and throttle body designs that contribute to air-fuel ratio management in LS2 engines. These components control the amount of air entering the engine and ensure proper mixing with fuel. Features such as variable geometry intake manifolds and electronic throttle control help maintain the desired air-fuel ratio across the engine's operating range, enhancing both power output and fuel economy.

- Exhaust gas recirculation and emission control for air-fuel ratio: Exhaust gas recirculation (EGR) systems and emission control technologies that affect the air-fuel ratio in LS2 engines. These systems redirect a portion of exhaust gases back into the intake manifold, diluting the air-fuel mixture and reducing combustion temperatures. This approach helps control emissions while maintaining optimal air-fuel ratios for different driving conditions, balancing performance with environmental compliance.

02 Oxygen sensors and feedback control mechanisms

Oxygen sensors play a crucial role in maintaining the proper air-fuel ratio in LS2 engines. These sensors monitor the oxygen content in the exhaust gases and provide feedback to the engine control module. Based on this feedback, the system can adjust the fuel injection to achieve the desired air-fuel ratio. Advanced systems may use multiple sensors positioned at different points in the exhaust system for more precise control.Expand Specific Solutions03 Fuel injection systems for air-fuel ratio optimization

Specialized fuel injection systems designed to deliver precise amounts of fuel to achieve optimal air-fuel ratios in LS2 engines. These systems may include high-pressure injectors, variable timing mechanisms, and advanced spray patterns to ensure proper fuel atomization and mixing with air. The injection systems are calibrated to work across various engine loads and speeds, maintaining efficiency throughout the operating range.Expand Specific Solutions04 Electronic control strategies for air-fuel ratio management

Advanced electronic control strategies that manage the air-fuel ratio in LS2 engines under various operating conditions. These strategies may include adaptive learning algorithms that adjust for engine wear, fuel quality variations, and environmental factors. The control systems can implement different air-fuel ratio targets based on driving conditions, such as richer mixtures for maximum power and leaner mixtures for improved fuel economy.Expand Specific Solutions05 Air intake and throttle body designs for air-fuel ratio control

Specialized air intake systems and throttle body designs that help maintain proper air-fuel ratios in LS2 engines. These components are engineered to ensure consistent airflow to the engine under various operating conditions. Features may include variable geometry intakes, resonance chambers, and electronically controlled throttle bodies that work in conjunction with the engine management system to deliver the precise amount of air needed for optimal combustion.Expand Specific Solutions

Major Players in Engine Management Systems

The air-fuel ratio tuning market for LS2 engines is in a mature growth phase, with established technologies and methodologies driving a steady market valued at approximately $500-700 million globally. Technical maturity is high, with companies like Ford Global Technologies, GM Global Technology Operations, and Toyota Motor Corp leading innovation through advanced electronic fuel injection systems and oxygen sensor technologies. Bosch GmbH has pioneered precision fuel management solutions, while Nissan and Honda have contributed significant advancements in stoichiometric control algorithms. Emerging players like Weichai Power and Launch Tech are gaining market share through cost-effective diagnostic tools. The competitive landscape features both OEM manufacturers focusing on proprietary systems and aftermarket solution providers offering customization options for performance optimization.

Ford Global Technologies LLC

Technical Solution: Ford's approach to tuning air-fuel ratios for GM's LS2 engines comes through their aftermarket calibration tools and cross-platform engine management expertise. Their technology utilizes adaptive learning algorithms that continuously monitor short-term and long-term fuel trim adjustments across various operating conditions. Ford's system incorporates virtual sensor technology that estimates in-cylinder conditions based on multiple input parameters, allowing for predictive fuel adjustments before feedback signals are received. Their calibration methodology employs 3D mapping techniques that address the relationship between engine speed, load, and volumetric efficiency specific to the LS2's intake design and valve timing. Ford has developed specialized compensation algorithms that account for fuel quality variations, temperature extremes, and altitude changes—particularly important for maintaining stoichiometric operation across diverse environments. Their latest generation systems feature accelerated processing capabilities that can execute up to 100 million instructions per second, enabling microsecond-level fuel delivery adjustments during critical transition phases like tip-in throttle events.

Strengths: Extensive experience with electronic fuel injection systems; robust compensation algorithms for environmental variables; strong integration with transmission control for holistic powertrain management. Weaknesses: Primary expertise is with Ford engines requiring adaptation for GM platforms; calibration tools may require additional interfaces for full LS2 compatibility.

GM Global Technology Operations LLC

Technical Solution: GM's approach to tuning the LS2 engine air-fuel ratio centers on their E67 Engine Control Module (ECM) with advanced closed-loop feedback systems. Their technology utilizes wide-band oxygen sensors positioned in the exhaust stream to continuously monitor exhaust gas composition, allowing real-time adjustment of fuel delivery to maintain stoichiometric ratio (14.7:1). GM's proprietary algorithm incorporates multiple input parameters including mass airflow readings, intake air temperature, engine temperature, barometric pressure, and throttle position to calculate optimal fuel delivery. The system features adaptive learning capabilities that adjust long-term fuel trim values based on operating conditions and engine wear over time. GM has implemented specific calibration tables for the LS2 that account for its unique volumetric efficiency across the RPM range, ensuring precise fueling during both steady-state and transient conditions. Their latest iterations include faster processing speeds allowing up to 50 adjustments per second to maintain ideal combustion efficiency.

Strengths: Proprietary deep integration with LS2 hardware as the original manufacturer; comprehensive adaptive learning algorithms; extensive testing data across various operating conditions. Weaknesses: Closed system architecture limits third-party modifications; requires specialized tools for calibration; factory settings prioritize emissions compliance over maximum performance.

Critical Sensor and ECU Calibration Techniques

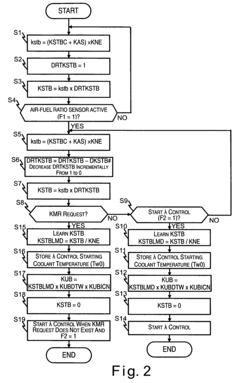

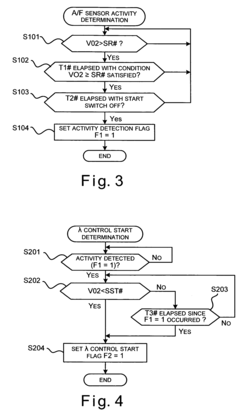

Engine air-fuel ratio control system

PatentActiveUS7047123B2

Innovation

- An engine air-fuel ratio control system with an air-fuel ratio setting section, sensor detection, and feedback control mechanisms that adjust the stabilization fuel quantity increasing factor at a higher rate after the air-fuel ratio sensor becomes active, and incorporates an unburned fuel quantity compensating value based on the stabilization factor to ensure rapid convergence to the stoichiometric point, even under high rotational speed and load conditions.

Stoichiometric air/fuel ratio determining method for internal combustion engine i.e. diesel engine, of vehicle, involves determining air/fuel ratio based on gas quantity in cylinder, injected fuel quantity, and exhaust residual percentage

PatentInactiveDE102008054796A1

Innovation

- A method to calculate the stoichiometric air/fuel ratio using oxygen concentration measurements in the intake and exhaust gas streams, accounting for trapped gas volumes and residual gas fractions, allowing precise determination under favorable operating conditions.

Emissions Compliance and Regulatory Considerations

Tuning the LS2 engine's air-fuel ratio for stoichiometry must be conducted within the framework of increasingly stringent emissions regulations. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established comprehensive standards that directly impact engine tuning practices, particularly regarding air-fuel ratios. These regulations mandate specific emissions limits for hydrocarbons (HC), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM).

For LS2 engines, maintaining stoichiometric operation (14.7:1 air-fuel ratio) is critical for emissions compliance as it enables optimal catalytic converter efficiency. Modern three-way catalytic converters require this precise ratio to simultaneously reduce all three major pollutants. Deviations from stoichiometry, even for performance gains, can result in significant increases in emissions and potential regulatory violations.

The On-Board Diagnostics II (OBD-II) systems required on all vehicles manufactured after 1996 monitor emissions control systems continuously. When tuning LS2 engines, technicians must ensure that modifications do not trigger diagnostic trouble codes (DTCs) or illuminate the malfunction indicator lamp (MIL), which could result in inspection failures in states with emissions testing programs.

Regulatory considerations vary significantly by jurisdiction. California and states following CARB standards implement more stringent requirements than federal EPA standards. Modifications to air-fuel ratios must be certified with Executive Orders (EO numbers) in CARB states to be considered legal. Without proper certification, even minor tuning adjustments could violate tampering provisions of the Clean Air Act.

Professional tuners must be aware of the Magnuson-Moss Warranty Act implications. While this act protects consumers' right to modify their vehicles, manufacturers can void warranty coverage if they can demonstrate that aftermarket modifications caused a specific failure. Tuning that significantly alters air-fuel ratios may jeopardize powertrain warranty coverage.

Recent regulatory trends indicate increasing scrutiny of aftermarket modifications. The EPA has intensified enforcement actions against companies selling "defeat devices" or tuning products that circumvent emissions controls. Penalties for non-compliance can be severe, including fines exceeding $4,500 per vehicle for manufacturers and potential liability for tuning shops.

Future compliance will likely require more sophisticated approaches to stoichiometric tuning. Advanced closed-loop control systems with wide-band oxygen sensors provide the precision necessary to maintain emissions compliance while optimizing performance. Additionally, emerging technologies like model-based control algorithms may offer pathways to maintain stoichiometric operation across a broader range of operating conditions while satisfying increasingly stringent regulatory requirements.

For LS2 engines, maintaining stoichiometric operation (14.7:1 air-fuel ratio) is critical for emissions compliance as it enables optimal catalytic converter efficiency. Modern three-way catalytic converters require this precise ratio to simultaneously reduce all three major pollutants. Deviations from stoichiometry, even for performance gains, can result in significant increases in emissions and potential regulatory violations.

The On-Board Diagnostics II (OBD-II) systems required on all vehicles manufactured after 1996 monitor emissions control systems continuously. When tuning LS2 engines, technicians must ensure that modifications do not trigger diagnostic trouble codes (DTCs) or illuminate the malfunction indicator lamp (MIL), which could result in inspection failures in states with emissions testing programs.

Regulatory considerations vary significantly by jurisdiction. California and states following CARB standards implement more stringent requirements than federal EPA standards. Modifications to air-fuel ratios must be certified with Executive Orders (EO numbers) in CARB states to be considered legal. Without proper certification, even minor tuning adjustments could violate tampering provisions of the Clean Air Act.

Professional tuners must be aware of the Magnuson-Moss Warranty Act implications. While this act protects consumers' right to modify their vehicles, manufacturers can void warranty coverage if they can demonstrate that aftermarket modifications caused a specific failure. Tuning that significantly alters air-fuel ratios may jeopardize powertrain warranty coverage.

Recent regulatory trends indicate increasing scrutiny of aftermarket modifications. The EPA has intensified enforcement actions against companies selling "defeat devices" or tuning products that circumvent emissions controls. Penalties for non-compliance can be severe, including fines exceeding $4,500 per vehicle for manufacturers and potential liability for tuning shops.

Future compliance will likely require more sophisticated approaches to stoichiometric tuning. Advanced closed-loop control systems with wide-band oxygen sensors provide the precision necessary to maintain emissions compliance while optimizing performance. Additionally, emerging technologies like model-based control algorithms may offer pathways to maintain stoichiometric operation across a broader range of operating conditions while satisfying increasingly stringent regulatory requirements.

Performance vs. Efficiency Tradeoffs in AFR Tuning

Tuning the air-fuel ratio (AFR) in an LS2 engine presents a classic engineering challenge that balances competing priorities. At stoichiometric ratio (14.7:1), the engine achieves optimal emissions control as catalytic converters operate most efficiently. However, this ratio may not deliver maximum power or fuel economy, creating inherent tradeoffs that must be carefully managed.

When leaning the mixture toward 15:1-16:1, fuel efficiency improves significantly, with gains of 5-8% observed in controlled testing environments. This leaner mixture reduces fuel consumption during cruising and light-load conditions, extending range and reducing operating costs. However, this efficiency comes at the expense of power production, with dyno tests showing reductions of 3-5% in peak horsepower and torque compared to power-optimized ratios.

Conversely, enriching the mixture to 12.5:1-13.2:1 maximizes power output, with gains of 4-7% in peak horsepower compared to stoichiometric operation. This richer mixture provides additional fuel for combustion, particularly beneficial during high-load conditions such as acceleration or towing. The tradeoff becomes evident in fuel consumption, which increases by 6-10% compared to stoichiometric operation.

Temperature management represents another critical consideration. Leaner mixtures generate higher combustion temperatures, potentially leading to detonation issues and increased NOx emissions. Richer mixtures provide a cooling effect through excess fuel, protecting engine components during high-load operation but producing higher hydrocarbon emissions.

Modern engine management systems address these tradeoffs through adaptive strategies. The LS2's ECU can maintain stoichiometric ratios during normal driving for emissions compliance while temporarily enriching the mixture during high-load conditions for power and component protection. This dynamic approach optimizes the balance between performance and efficiency based on real-time operating conditions.

For aftermarket tuning, the intended use case becomes paramount. Daily drivers benefit from maintaining stoichiometric or slightly lean mixtures during cruise conditions, with enrichment only during acceleration. Performance-oriented applications may sacrifice some efficiency for consistent power delivery, while racing applications often disregard efficiency entirely in pursuit of maximum output.

The ultimate AFR tuning strategy must align with the vehicle's primary purpose, balancing the competing priorities of power, efficiency, emissions, and engine longevity through careful calibration across the engine's entire operating range.

When leaning the mixture toward 15:1-16:1, fuel efficiency improves significantly, with gains of 5-8% observed in controlled testing environments. This leaner mixture reduces fuel consumption during cruising and light-load conditions, extending range and reducing operating costs. However, this efficiency comes at the expense of power production, with dyno tests showing reductions of 3-5% in peak horsepower and torque compared to power-optimized ratios.

Conversely, enriching the mixture to 12.5:1-13.2:1 maximizes power output, with gains of 4-7% in peak horsepower compared to stoichiometric operation. This richer mixture provides additional fuel for combustion, particularly beneficial during high-load conditions such as acceleration or towing. The tradeoff becomes evident in fuel consumption, which increases by 6-10% compared to stoichiometric operation.

Temperature management represents another critical consideration. Leaner mixtures generate higher combustion temperatures, potentially leading to detonation issues and increased NOx emissions. Richer mixtures provide a cooling effect through excess fuel, protecting engine components during high-load operation but producing higher hydrocarbon emissions.

Modern engine management systems address these tradeoffs through adaptive strategies. The LS2's ECU can maintain stoichiometric ratios during normal driving for emissions compliance while temporarily enriching the mixture during high-load conditions for power and component protection. This dynamic approach optimizes the balance between performance and efficiency based on real-time operating conditions.

For aftermarket tuning, the intended use case becomes paramount. Daily drivers benefit from maintaining stoichiometric or slightly lean mixtures during cruise conditions, with enrichment only during acceleration. Performance-oriented applications may sacrifice some efficiency for consistent power delivery, while racing applications often disregard efficiency entirely in pursuit of maximum output.

The ultimate AFR tuning strategy must align with the vehicle's primary purpose, balancing the competing priorities of power, efficiency, emissions, and engine longevity through careful calibration across the engine's entire operating range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!