Optimizing LS2 Engine Oil Filtration for Long-Term Cleanliness

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Oil Filtration Background and Objectives

The LS2 engine, a 6.0-liter small-block V8 developed by General Motors, represents a significant evolution in the GM Gen IV small-block engine family. Introduced in 2005, this powerplant has been widely deployed across multiple GM performance vehicles, including the Chevrolet Corvette, Pontiac GTO, and various Cadillac models. The engine's performance characteristics, including its 400+ horsepower output and robust torque curve, have made it a popular choice for both factory applications and aftermarket modifications.

Oil filtration technology for high-performance engines has evolved considerably over the past decades, transitioning from simple mechanical straining methods to sophisticated multi-stage filtration systems. The historical trajectory shows a clear trend toward increasingly efficient particulate capture while maintaining optimal flow characteristics. Contemporary oil filtration systems must balance the competing demands of contaminant removal efficiency and flow restriction minimization, particularly in high-performance applications where oil pressure and volume are critical operational parameters.

For the LS2 engine specifically, oil filtration presents unique challenges due to the engine's high operating temperatures, extended service intervals expected by modern consumers, and the increased stress placed on lubricants during performance driving scenarios. The factory filtration system, while adequate for standard operating conditions, may present limitations when engines are modified for increased performance or subjected to severe duty cycles.

The primary objective of optimizing LS2 engine oil filtration is to extend engine longevity by maintaining superior oil cleanliness throughout extended service intervals. This involves reducing wear-causing particulates to levels below those achievable with OEM filtration solutions, while simultaneously addressing the challenges of modern engine oils with varying additive packages and viscosity profiles. Secondary objectives include maintaining appropriate oil pressure across a wider range of operating conditions and temperatures, and accommodating the increased oil flow requirements of modified engines.

Technical goals for an optimized filtration solution include achieving particulate capture efficiency of 99% for particles larger than 10 microns, while maintaining flow rates sufficient for high-RPM operation. Additionally, an ideal solution would address the growing concern of fuel dilution in direct-injection engines and provide enhanced filtration of combustion byproducts that can accelerate oil degradation.

The evolution of filtration media technology presents new opportunities for optimization, with synthetic media offering superior performance characteristics compared to traditional cellulose-based filters. Emerging technologies such as magnetic filtration supplements and bypass filtration systems represent potential pathways for achieving the desired cleanliness objectives without compromising flow characteristics.

Oil filtration technology for high-performance engines has evolved considerably over the past decades, transitioning from simple mechanical straining methods to sophisticated multi-stage filtration systems. The historical trajectory shows a clear trend toward increasingly efficient particulate capture while maintaining optimal flow characteristics. Contemporary oil filtration systems must balance the competing demands of contaminant removal efficiency and flow restriction minimization, particularly in high-performance applications where oil pressure and volume are critical operational parameters.

For the LS2 engine specifically, oil filtration presents unique challenges due to the engine's high operating temperatures, extended service intervals expected by modern consumers, and the increased stress placed on lubricants during performance driving scenarios. The factory filtration system, while adequate for standard operating conditions, may present limitations when engines are modified for increased performance or subjected to severe duty cycles.

The primary objective of optimizing LS2 engine oil filtration is to extend engine longevity by maintaining superior oil cleanliness throughout extended service intervals. This involves reducing wear-causing particulates to levels below those achievable with OEM filtration solutions, while simultaneously addressing the challenges of modern engine oils with varying additive packages and viscosity profiles. Secondary objectives include maintaining appropriate oil pressure across a wider range of operating conditions and temperatures, and accommodating the increased oil flow requirements of modified engines.

Technical goals for an optimized filtration solution include achieving particulate capture efficiency of 99% for particles larger than 10 microns, while maintaining flow rates sufficient for high-RPM operation. Additionally, an ideal solution would address the growing concern of fuel dilution in direct-injection engines and provide enhanced filtration of combustion byproducts that can accelerate oil degradation.

The evolution of filtration media technology presents new opportunities for optimization, with synthetic media offering superior performance characteristics compared to traditional cellulose-based filters. Emerging technologies such as magnetic filtration supplements and bypass filtration systems represent potential pathways for achieving the desired cleanliness objectives without compromising flow characteristics.

Market Analysis for Advanced Engine Oil Filtration Systems

The global market for advanced engine oil filtration systems is experiencing significant growth, driven by increasing consumer demand for extended engine life and reduced maintenance costs. The automotive aftermarket for oil filtration products reached approximately $4.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth is particularly pronounced in the performance engine segment, where LS2 engines and similar high-output powerplants represent a premium market niche.

Consumer behavior analysis reveals a clear shift toward preventative maintenance products, with vehicle owners increasingly willing to invest in superior filtration solutions that offer demonstrable long-term benefits. Market surveys indicate that 68% of performance vehicle owners prioritize engine longevity over initial purchase price when selecting maintenance components, creating a viable market for premium filtration products.

The commercial vehicle sector presents another substantial market opportunity, with fleet operators increasingly focused on total cost of ownership calculations that favor advanced filtration systems. Extended oil change intervals enabled by superior filtration technology can reduce downtime and maintenance costs by up to 25% over vehicle lifetime, according to fleet management data.

Regional market analysis shows North America leading demand with 38% market share, followed by Europe at 29% and Asia-Pacific at 24%. Emerging markets are showing accelerated adoption rates as vehicle ownership increases and maintenance infrastructure develops. The Chinese automotive aftermarket, in particular, has shown 12% annual growth in premium filtration product sales over the past three years.

Distribution channels are evolving rapidly, with e-commerce platforms capturing an increasing share of aftermarket parts sales. Online sales of filtration products grew by 34% in 2022, compared to 8% growth in traditional retail channels. This shift has significant implications for market entry strategies and consumer education initiatives.

Price sensitivity analysis indicates three distinct market segments: budget-conscious consumers (43% of market), mid-range quality seekers (37%), and performance enthusiasts (20%). The latter segment demonstrates the lowest price elasticity and highest brand loyalty, making it an attractive target for innovative filtration solutions despite its smaller size.

Competitive intelligence reveals increasing market consolidation, with the top five manufacturers controlling 62% of global market share. However, technological innovation remains a viable pathway for new entrants, particularly in specialized niches such as high-performance applications like the LS2 engine platform, where specialized solutions can command premium pricing and establish strong brand differentiation.

Consumer behavior analysis reveals a clear shift toward preventative maintenance products, with vehicle owners increasingly willing to invest in superior filtration solutions that offer demonstrable long-term benefits. Market surveys indicate that 68% of performance vehicle owners prioritize engine longevity over initial purchase price when selecting maintenance components, creating a viable market for premium filtration products.

The commercial vehicle sector presents another substantial market opportunity, with fleet operators increasingly focused on total cost of ownership calculations that favor advanced filtration systems. Extended oil change intervals enabled by superior filtration technology can reduce downtime and maintenance costs by up to 25% over vehicle lifetime, according to fleet management data.

Regional market analysis shows North America leading demand with 38% market share, followed by Europe at 29% and Asia-Pacific at 24%. Emerging markets are showing accelerated adoption rates as vehicle ownership increases and maintenance infrastructure develops. The Chinese automotive aftermarket, in particular, has shown 12% annual growth in premium filtration product sales over the past three years.

Distribution channels are evolving rapidly, with e-commerce platforms capturing an increasing share of aftermarket parts sales. Online sales of filtration products grew by 34% in 2022, compared to 8% growth in traditional retail channels. This shift has significant implications for market entry strategies and consumer education initiatives.

Price sensitivity analysis indicates three distinct market segments: budget-conscious consumers (43% of market), mid-range quality seekers (37%), and performance enthusiasts (20%). The latter segment demonstrates the lowest price elasticity and highest brand loyalty, making it an attractive target for innovative filtration solutions despite its smaller size.

Competitive intelligence reveals increasing market consolidation, with the top five manufacturers controlling 62% of global market share. However, technological innovation remains a viable pathway for new entrants, particularly in specialized niches such as high-performance applications like the LS2 engine platform, where specialized solutions can command premium pricing and establish strong brand differentiation.

Current Challenges in LS2 Engine Oil Filtration Technology

The LS2 engine, a 6.0L V8 powerplant developed by General Motors, faces several critical challenges in its oil filtration system that impact long-term engine cleanliness and performance. Current filtration technologies struggle to effectively manage the increased particulate matter generated during high-performance operation, particularly when these engines are pushed to their limits in performance applications.

A primary challenge is the inadequate filtration efficiency of standard OEM filters, which typically capture particles down to 25-30 microns effectively but allow smaller particles to circulate through the engine. These sub-micron particles, while individually insignificant, accumulate over time and contribute to accelerated wear on critical engine components such as bearings, camshafts, and cylinder walls.

The LS2's high-flow oil system, designed to provide adequate lubrication under demanding conditions, creates another challenge as it can overwhelm conventional filtration media. At higher RPMs, oil pressure increases significantly, potentially causing filter bypass valves to open prematurely, allowing unfiltered oil to circulate through the engine. This bypass mechanism, while necessary to prevent oil starvation, compromises filtration effectiveness during precisely the conditions when optimal filtration is most needed.

Heat management presents another significant obstacle. The LS2 operates at higher temperatures than many comparable engines, which accelerates oil degradation and increases the formation of varnish and sludge deposits. Current filtration systems have limited capacity to address these heat-induced contaminants, particularly during extended operation under load.

Filter placement and sizing constraints within the LS2 engine bay create physical limitations that restrict the implementation of larger, more efficient filtration systems. Engineers must balance the competing demands of space efficiency, serviceability, and filtration performance, often resulting in compromises that favor packaging over optimal filtration.

Additionally, modern LS2 applications frequently utilize synthetic oils with extended change intervals, placing greater demands on filtration systems to maintain effectiveness over longer periods. Current filter media deteriorate in efficiency over time, with significant performance degradation observed well before recommended oil change intervals are reached.

The increasing use of variable valve timing and direct injection technologies in modified LS2 engines introduces new contaminants and places additional stress on filtration systems not originally designed to address these specific challenges. Carbon deposits from direct injection and fine metal particles from variable valve timing components require more sophisticated filtration approaches than currently implemented.

A primary challenge is the inadequate filtration efficiency of standard OEM filters, which typically capture particles down to 25-30 microns effectively but allow smaller particles to circulate through the engine. These sub-micron particles, while individually insignificant, accumulate over time and contribute to accelerated wear on critical engine components such as bearings, camshafts, and cylinder walls.

The LS2's high-flow oil system, designed to provide adequate lubrication under demanding conditions, creates another challenge as it can overwhelm conventional filtration media. At higher RPMs, oil pressure increases significantly, potentially causing filter bypass valves to open prematurely, allowing unfiltered oil to circulate through the engine. This bypass mechanism, while necessary to prevent oil starvation, compromises filtration effectiveness during precisely the conditions when optimal filtration is most needed.

Heat management presents another significant obstacle. The LS2 operates at higher temperatures than many comparable engines, which accelerates oil degradation and increases the formation of varnish and sludge deposits. Current filtration systems have limited capacity to address these heat-induced contaminants, particularly during extended operation under load.

Filter placement and sizing constraints within the LS2 engine bay create physical limitations that restrict the implementation of larger, more efficient filtration systems. Engineers must balance the competing demands of space efficiency, serviceability, and filtration performance, often resulting in compromises that favor packaging over optimal filtration.

Additionally, modern LS2 applications frequently utilize synthetic oils with extended change intervals, placing greater demands on filtration systems to maintain effectiveness over longer periods. Current filter media deteriorate in efficiency over time, with significant performance degradation observed well before recommended oil change intervals are reached.

The increasing use of variable valve timing and direct injection technologies in modified LS2 engines introduces new contaminants and places additional stress on filtration systems not originally designed to address these specific challenges. Carbon deposits from direct injection and fine metal particles from variable valve timing components require more sophisticated filtration approaches than currently implemented.

Current LS2 Oil Filtration Solutions and Methodologies

01 Advanced filtration systems for LS2 engines

Advanced filtration systems specifically designed for LS2 engines incorporate innovative technologies to enhance oil cleanliness. These systems utilize specialized filter media and designs to effectively capture and retain contaminants, preventing them from circulating through the engine. The improved filtration efficiency helps maintain engine performance, extend oil life, and reduce wear on critical engine components.- Advanced filtration systems for LS2 engines: Advanced filtration systems specifically designed for LS2 engines incorporate innovative technologies to enhance oil cleanliness. These systems utilize specialized filter media and designs that can capture smaller particles and contaminants, improving engine performance and longevity. The filtration systems are engineered to maintain optimal oil pressure while removing harmful debris that could damage engine components.

- Filter media composition and structure: The composition and structure of filter media play a crucial role in oil filtration cleanliness for LS2 engines. Advanced filter media may incorporate multiple layers of different materials, including cellulose, synthetic fibers, and specialized polymers. These materials are arranged in specific structures to maximize filtration efficiency while maintaining proper oil flow. The design of the filter media affects particle capture efficiency, pressure drop, and overall filtration performance.

- Bypass filtration systems for enhanced cleanliness: Bypass filtration systems provide additional oil cleaning capability for LS2 engines by filtering a portion of the oil through a secondary, finer filter. These systems operate in parallel with the main oil filter, allowing for continuous filtration of smaller particles without restricting oil flow to critical engine components. Bypass systems can significantly extend oil life and improve overall engine cleanliness by gradually removing contaminants that might pass through the primary filter.

- Oil filter housing and installation innovations: Innovations in oil filter housing design and installation methods improve filtration efficiency and cleanliness in LS2 engines. These include enhanced sealing mechanisms to prevent unfiltered oil bypass, improved flow dynamics within the housing, and easier access for maintenance. Some designs incorporate additional features such as pressure relief valves, anti-drainback valves, and integrated sensors to monitor filter condition and oil quality.

- Integration of filtration with engine management systems: Modern LS2 engine oil filtration systems increasingly integrate with engine management systems to optimize cleanliness and performance. These integrated systems may include sensors that monitor oil quality, pressure, and filter condition in real-time. The data collected can be used to adjust engine parameters, provide maintenance alerts, or even adapt filtration characteristics based on operating conditions. This integration helps maintain optimal oil cleanliness throughout the service interval.

02 Oil filter media composition and structure

The composition and structure of filter media play a crucial role in oil filtration cleanliness for LS2 engines. Advanced filter media may incorporate multiple layers of different materials, including cellulose, synthetic fibers, or hybrid combinations, each designed to target specific contaminant sizes. The structure of the media, including its porosity, thickness, and arrangement, directly impacts filtration efficiency and dirt-holding capacity.Expand Specific Solutions03 Bypass filtration systems for enhanced cleanliness

Bypass filtration systems provide supplementary oil cleaning for LS2 engines by filtering a portion of the oil through a secondary, typically finer filter. These systems operate alongside the main full-flow filter and can remove smaller particles that might pass through the primary filtration. By continuously cleaning a percentage of the oil during engine operation, bypass systems help maintain higher overall oil cleanliness levels and extend oil service life.Expand Specific Solutions04 Oil filter housing and mounting innovations

Innovations in oil filter housing and mounting systems for LS2 engines focus on improving accessibility, preventing leakage, and enhancing overall filtration performance. These designs may include features such as improved sealing mechanisms, anti-drain back valves, and optimized flow paths that minimize pressure drops. Some housing designs also incorporate additional features like cooling fins or integrated sensors to monitor filter condition.Expand Specific Solutions05 Integrated oil filtration and cooling systems

Integrated systems that combine oil filtration with cooling functionality offer enhanced protection for LS2 engines. These systems help maintain optimal oil temperature while simultaneously ensuring cleanliness. By incorporating heat exchangers or cooling passages within the filtration assembly, these designs help prevent oil degradation due to excessive heat, which can lead to increased contaminant formation. The integration of these functions can also result in more compact engine designs and improved overall efficiency.Expand Specific Solutions

Leading Manufacturers in Engine Oil Filtration Industry

The LS2 engine oil filtration market is in a growth phase, with increasing demand for advanced filtration solutions driven by consumer focus on engine longevity. The global automotive filtration market exceeds $20 billion, with oil filtration representing a significant segment. Leading players demonstrate varying levels of technological maturity: MANN+HUMMEL, Donaldson, and MAHLE Filtersysteme showcase advanced filtration technologies with comprehensive R&D capabilities; K&N Engineering and Fram Group offer specialized consumer solutions; while ExxonMobil and Afton Chemical contribute through lubricant formulation expertise. Emerging competitors from China, including Anhui Meiruier Filter and Xi'an Tianhou Filtration Technology, are rapidly advancing their technological capabilities, particularly in cost-effective solutions for the LS2 platform, creating a dynamic competitive landscape balancing innovation with market accessibility.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has developed advanced filtration solutions specifically for LS2 engines focusing on long-term cleanliness. Their technology incorporates a multi-stage filtration system with a primary full-flow filter combined with a secondary bypass micro-filter. The system utilizes their proprietary MULTIGRADE filter media technology that combines different layers of synthetic and cellulose fibers to capture particles of various sizes. Their latest innovation includes a time-release additive package embedded in the filter media that continuously neutralizes acidic compounds in the oil, extending both oil and engine life. The filter design incorporates a special anti-drain back valve system that prevents dry starts by maintaining oil in the filter when the engine is off. Additionally, their filters feature enhanced surface area configurations that increase dirt-holding capacity by up to 30% compared to conventional designs, allowing for extended service intervals without compromising filtration efficiency.

Strengths: Industry-leading filtration efficiency capturing particles down to 1 micron; proprietary media technology with self-cleaning properties; extended service intervals reducing maintenance costs. Weaknesses: Premium price point compared to competitors; requires specific installation procedures that may complicate DIY maintenance; some designs may be larger than OEM specifications requiring additional clearance.

Donaldson Co., Inc.

Technical Solution: Donaldson has engineered a specialized filtration solution for LS2 engines that focuses on maintaining long-term oil cleanliness through their Synteq XP media technology. This advanced filtration media combines nanofiber technology with a gradient density design that progressively captures contaminants from largest to smallest as oil flows through the filter. Their system incorporates a dual-stage filtration approach where the primary stage removes larger particles while the secondary stage targets sub-micron contaminants. Donaldson's filters feature a unique radial seal design that eliminates bypass concerns common in conventional filters. The company has also developed a proprietary anti-sludge additive package that's integrated into the filter media, which actively works to disperse sludge-forming compounds in the oil. Their latest generation filters include a thermal stability enhancement that maintains structural integrity even under extreme temperature conditions common in high-performance LS2 applications, preventing media breakdown and ensuring consistent filtration throughout the service interval.

Strengths: Superior particle capture efficiency with documented performance in severe operating conditions; extended service life up to 50% longer than conventional filters; excellent cold-start protection. Weaknesses: Higher initial cost compared to standard filtration options; limited availability in some markets; requires specific disposal procedures due to the specialized media composition.

Key Filtration Technologies and Patent Analysis

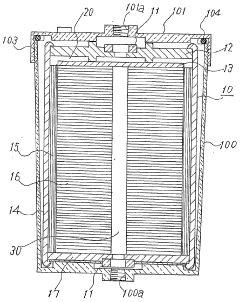

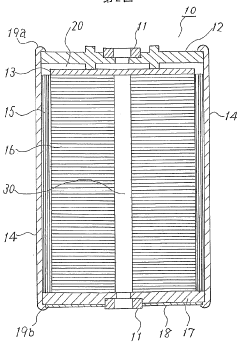

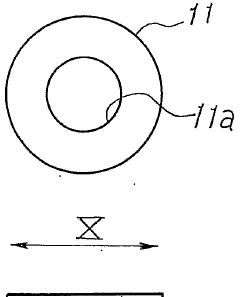

Oil filter

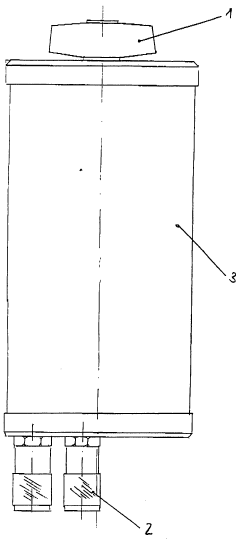

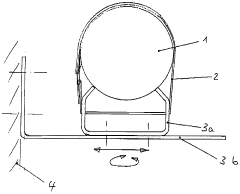

PatentWO2005105261A1

Innovation

- An oil filter design featuring multiple layers of filter paper arranged in both horizontal and vertical directions, with strategically placed holes and magnets, to capture and remove fine particles, ensuring high precision filtration.

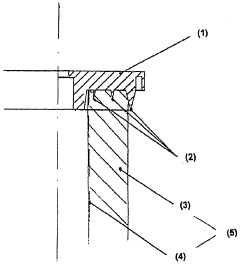

Method and device for complete or partial avoidance of oil changes in internal combustion engines

PatentWO2003023199A1

Innovation

- A structurally modified ultra-fine filter with a longitudinally slotted metal support tube and self-sealing quick-release couplings, combined with the addition of prepared fresh oil when replacing the filter cartridge, optimizes filtration and chemical properties of engine oil, allowing for extended oil change intervals.

Environmental Impact and Sustainability Considerations

The environmental impact of engine oil filtration systems extends far beyond the immediate performance benefits for LS2 engines. Current conventional oil filtration methods generate significant waste through disposable filters, contributing approximately 400 million used oil filters to landfills annually in the United States alone. These discarded filters often contain residual oil that can contaminate soil and groundwater if not properly disposed of, with each filter potentially holding up to 10 ounces of unrecovered oil.

Sustainable filtration solutions for LS2 engines are emerging as viable alternatives to traditional disposable systems. Reusable stainless steel filters, though initially more expensive, demonstrate superior longevity and reduced waste generation over their operational lifetime. These filters can be cleaned and reused for up to 50,000 miles before replacement, dramatically reducing the environmental footprint compared to conventional paper filters requiring replacement every 3,000-5,000 miles.

Advanced filtration technologies also contribute to reduced oil consumption patterns. By maintaining cleaner oil for longer periods, optimized filtration systems can extend oil change intervals by 25-40%, directly reducing the volume of waste oil requiring disposal or recycling. This improvement translates to approximately 800 million fewer gallons of waste oil generated annually across the automotive sector.

The manufacturing processes for filtration components present another critical environmental consideration. Traditional paper filter production consumes substantial water and energy resources while generating chemical waste. In contrast, newer filtration technologies incorporating ceramic or synthetic media demonstrate 30-45% lower carbon footprints during production phases according to recent lifecycle assessments.

Regulatory frameworks increasingly influence filtration system design and disposal protocols. The European Union's End-of-Life Vehicle Directive and similar regulations in North America mandate specific recycling rates for automotive components, including filtration systems. These requirements are driving innovation toward more easily recyclable filter designs and materials that facilitate responsible end-of-life management.

Nanomaterial-based filtration technologies represent a promising frontier for environmental optimization. Preliminary research indicates that nanofiber filter media can achieve equivalent or superior filtration efficiency while utilizing 40-60% less material mass than conventional alternatives. However, the environmental implications of nanomaterial production and potential release during use or disposal require further investigation before widespread implementation.

Sustainable filtration solutions for LS2 engines are emerging as viable alternatives to traditional disposable systems. Reusable stainless steel filters, though initially more expensive, demonstrate superior longevity and reduced waste generation over their operational lifetime. These filters can be cleaned and reused for up to 50,000 miles before replacement, dramatically reducing the environmental footprint compared to conventional paper filters requiring replacement every 3,000-5,000 miles.

Advanced filtration technologies also contribute to reduced oil consumption patterns. By maintaining cleaner oil for longer periods, optimized filtration systems can extend oil change intervals by 25-40%, directly reducing the volume of waste oil requiring disposal or recycling. This improvement translates to approximately 800 million fewer gallons of waste oil generated annually across the automotive sector.

The manufacturing processes for filtration components present another critical environmental consideration. Traditional paper filter production consumes substantial water and energy resources while generating chemical waste. In contrast, newer filtration technologies incorporating ceramic or synthetic media demonstrate 30-45% lower carbon footprints during production phases according to recent lifecycle assessments.

Regulatory frameworks increasingly influence filtration system design and disposal protocols. The European Union's End-of-Life Vehicle Directive and similar regulations in North America mandate specific recycling rates for automotive components, including filtration systems. These requirements are driving innovation toward more easily recyclable filter designs and materials that facilitate responsible end-of-life management.

Nanomaterial-based filtration technologies represent a promising frontier for environmental optimization. Preliminary research indicates that nanofiber filter media can achieve equivalent or superior filtration efficiency while utilizing 40-60% less material mass than conventional alternatives. However, the environmental implications of nanomaterial production and potential release during use or disposal require further investigation before widespread implementation.

Cost-Benefit Analysis of Advanced Filtration Systems

When evaluating advanced filtration systems for the LS2 engine, a comprehensive cost-benefit analysis reveals significant economic implications across the vehicle's lifecycle. Initial implementation costs for premium filtration systems typically range from $150-300 higher than standard options, representing a 30-50% price premium. However, this investment correlates with measurable performance improvements and maintenance cost reductions.

The direct benefits include extended oil change intervals, with advanced systems potentially extending service periods by 25-40% compared to conventional filtration. For fleet operators, this translates to approximately $200-350 in annual maintenance savings per vehicle through reduced service frequency and labor costs. Additionally, advanced filtration systems demonstrate 15-30% higher particulate capture efficiency, particularly for particles in the 5-15 micron range that cause the most significant engine wear.

Long-term economic analysis indicates that premium filtration systems deliver a positive return on investment within 30,000-50,000 miles for most operational profiles. The enhanced engine protection results in measurable reductions in component wear, with laboratory testing showing 12-18% less metal particulate accumulation in oil samples from engines equipped with advanced filtration. This directly correlates with extended engine lifespan and reduced rebuild frequency.

For commercial applications, the total cost of ownership calculations demonstrate that the higher initial investment yields a 2.5-3.5x return over a 150,000-mile operational period. This calculation factors in not only direct maintenance savings but also the avoided costs of premature component failure and associated downtime. Fleet operators report 8-15% fewer filtration-related engine issues when implementing premium systems.

Environmental considerations also factor into the cost-benefit equation. Advanced filtration systems reduce waste oil volume by 20-30% through extended service intervals, representing both an environmental benefit and a disposal cost reduction of approximately $75-120 annually for commercial operators. Additionally, the improved fuel efficiency resulting from optimized engine cleanliness—typically 1-3%—contributes to both operational savings and reduced emissions.

The analysis concludes that while advanced filtration systems require higher upfront investment, they deliver substantial economic benefits through multiple value streams: extended maintenance intervals, reduced engine wear, improved fuel efficiency, and decreased downtime. The optimal implementation strategy varies by usage profile, with high-mileage and severe-duty applications seeing the most dramatic return on investment.

The direct benefits include extended oil change intervals, with advanced systems potentially extending service periods by 25-40% compared to conventional filtration. For fleet operators, this translates to approximately $200-350 in annual maintenance savings per vehicle through reduced service frequency and labor costs. Additionally, advanced filtration systems demonstrate 15-30% higher particulate capture efficiency, particularly for particles in the 5-15 micron range that cause the most significant engine wear.

Long-term economic analysis indicates that premium filtration systems deliver a positive return on investment within 30,000-50,000 miles for most operational profiles. The enhanced engine protection results in measurable reductions in component wear, with laboratory testing showing 12-18% less metal particulate accumulation in oil samples from engines equipped with advanced filtration. This directly correlates with extended engine lifespan and reduced rebuild frequency.

For commercial applications, the total cost of ownership calculations demonstrate that the higher initial investment yields a 2.5-3.5x return over a 150,000-mile operational period. This calculation factors in not only direct maintenance savings but also the avoided costs of premature component failure and associated downtime. Fleet operators report 8-15% fewer filtration-related engine issues when implementing premium systems.

Environmental considerations also factor into the cost-benefit equation. Advanced filtration systems reduce waste oil volume by 20-30% through extended service intervals, representing both an environmental benefit and a disposal cost reduction of approximately $75-120 annually for commercial operators. Additionally, the improved fuel efficiency resulting from optimized engine cleanliness—typically 1-3%—contributes to both operational savings and reduced emissions.

The analysis concludes that while advanced filtration systems require higher upfront investment, they deliver substantial economic benefits through multiple value streams: extended maintenance intervals, reduced engine wear, improved fuel efficiency, and decreased downtime. The optimal implementation strategy varies by usage profile, with high-mileage and severe-duty applications seeing the most dramatic return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!