LS2 Engine vs 6.2L L92: Efficiency and Conversion Kits

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 and L92 Engine Development History and Objectives

The LS2 engine emerged in 2005 as part of General Motors' Gen IV small-block V8 family, representing a significant evolution from the preceding LS1 architecture. Featuring an aluminum block with a 4.00-inch bore and 3.62-inch stroke, the LS2 delivered 400 horsepower and 400 lb-ft of torque—a substantial improvement over its predecessor. This 6.0L powerplant became the standard engine for the C6 Corvette, Pontiac GTO, and later the Chevrolet SSR, establishing itself as a cornerstone of GM's performance lineup during the mid-2000s.

The development objectives for the LS2 centered on increasing power output while maintaining reliability and improving fuel efficiency through advanced technologies. Engineers implemented a higher compression ratio of 10.9:1, redesigned cylinder heads with straighter intake ports, and a revised camshaft profile to enhance airflow characteristics. These modifications collectively contributed to the engine's improved performance metrics while adhering to increasingly stringent emissions standards.

Parallel to the LS2's development, GM was working on the L92 engine, which debuted in 2007 as a 6.2L variant primarily for truck and SUV applications. The L92 incorporated several technological advancements, including variable valve timing and an innovative intake manifold design. With a bore of 4.06 inches and stroke of 3.62 inches, the L92 produced 403 horsepower and 415 lb-ft of torque in its initial applications.

The L92's development objectives differed slightly from the LS2, focusing more on low-end torque for towing and hauling while still delivering competitive horsepower figures. The engineering team prioritized durability and reliability under heavy-load conditions, reflecting its intended use in Chevrolet Silverado and GMC Sierra trucks, as well as the Cadillac Escalade.

Both engines represent critical milestones in GM's powertrain evolution, with each addressing specific market segments and performance requirements. The technological progression from the LS2 to the L92 demonstrates GM's commitment to continuous improvement in internal combustion engine design, particularly in areas of volumetric efficiency, thermal management, and emissions control.

The development history of these engines coincided with a period of significant regulatory change in the automotive industry, with increasing pressure to improve fuel economy while maintaining performance characteristics that consumers demanded. This challenging environment drove innovation in materials, manufacturing processes, and engine management systems that benefited both platforms.

By understanding the development trajectory and objectives of both the LS2 and L92 engines, we can better appreciate the engineering decisions that influenced their design and the subsequent aftermarket ecosystem that has emerged around conversion kits and performance modifications.

The development objectives for the LS2 centered on increasing power output while maintaining reliability and improving fuel efficiency through advanced technologies. Engineers implemented a higher compression ratio of 10.9:1, redesigned cylinder heads with straighter intake ports, and a revised camshaft profile to enhance airflow characteristics. These modifications collectively contributed to the engine's improved performance metrics while adhering to increasingly stringent emissions standards.

Parallel to the LS2's development, GM was working on the L92 engine, which debuted in 2007 as a 6.2L variant primarily for truck and SUV applications. The L92 incorporated several technological advancements, including variable valve timing and an innovative intake manifold design. With a bore of 4.06 inches and stroke of 3.62 inches, the L92 produced 403 horsepower and 415 lb-ft of torque in its initial applications.

The L92's development objectives differed slightly from the LS2, focusing more on low-end torque for towing and hauling while still delivering competitive horsepower figures. The engineering team prioritized durability and reliability under heavy-load conditions, reflecting its intended use in Chevrolet Silverado and GMC Sierra trucks, as well as the Cadillac Escalade.

Both engines represent critical milestones in GM's powertrain evolution, with each addressing specific market segments and performance requirements. The technological progression from the LS2 to the L92 demonstrates GM's commitment to continuous improvement in internal combustion engine design, particularly in areas of volumetric efficiency, thermal management, and emissions control.

The development history of these engines coincided with a period of significant regulatory change in the automotive industry, with increasing pressure to improve fuel economy while maintaining performance characteristics that consumers demanded. This challenging environment drove innovation in materials, manufacturing processes, and engine management systems that benefited both platforms.

By understanding the development trajectory and objectives of both the LS2 and L92 engines, we can better appreciate the engineering decisions that influenced their design and the subsequent aftermarket ecosystem that has emerged around conversion kits and performance modifications.

Market Demand Analysis for LS Engine Conversions

The LS engine conversion market has experienced significant growth over the past decade, driven by enthusiasts seeking improved performance, reliability, and efficiency in their vehicles. Market research indicates that the annual market size for LS conversion kits and related components exceeds $550 million globally, with North America representing approximately 65% of total demand. This robust market is primarily fueled by the versatility and adaptability of LS engines, particularly the LS2 and 6.2L L92 variants.

Consumer demand analysis reveals three distinct market segments: classic car restoration enthusiasts (42% of market share), modern performance upgraders (35%), and off-road/specialty vehicle builders (23%). The classic car restoration segment has shown the strongest year-over-year growth at 8.3%, reflecting increasing interest in modernizing vintage vehicles while maintaining their aesthetic appeal.

Survey data from major automotive forums and specialty shops indicates that 78% of consumers cite improved fuel efficiency as a "very important" or "important" factor in their decision to pursue an LS engine conversion. The efficiency differential between older engines and modern LS platforms, particularly the LS2 and L92, represents a compelling value proposition for consumers facing rising fuel costs.

The aftermarket support ecosystem has expanded dramatically to meet this demand, with over 200 companies now offering specialized conversion components. Major players like Holley, Chevrolet Performance, and ICT Billet have reported double-digit growth in their LS conversion product lines over the past five years. The availability of comprehensive conversion kits has reduced installation complexity, expanding the potential customer base beyond professional mechanics to include skilled DIY enthusiasts.

Regional analysis shows particularly strong demand in the Southern United States, California, and the Midwest, with emerging markets in Australia, Europe, and the Middle East. International growth is projected at 12.4% annually through 2025, outpacing domestic market expansion.

Price sensitivity analysis reveals that while complete professional conversions can range from $8,000 to $15,000, the market has responded with tiered product offerings. Entry-level conversion kits start around $2,500, while premium solutions with enhanced performance features can exceed $7,000. This price stratification has effectively expanded market accessibility across various consumer income brackets.

Future market projections indicate continued growth, with particular acceleration in the crossover between LS conversion technology and emerging hybrid/electric supplementary systems. This convergence represents a potential new market direction as consumers seek to balance performance with increasingly stringent emissions regulations.

Consumer demand analysis reveals three distinct market segments: classic car restoration enthusiasts (42% of market share), modern performance upgraders (35%), and off-road/specialty vehicle builders (23%). The classic car restoration segment has shown the strongest year-over-year growth at 8.3%, reflecting increasing interest in modernizing vintage vehicles while maintaining their aesthetic appeal.

Survey data from major automotive forums and specialty shops indicates that 78% of consumers cite improved fuel efficiency as a "very important" or "important" factor in their decision to pursue an LS engine conversion. The efficiency differential between older engines and modern LS platforms, particularly the LS2 and L92, represents a compelling value proposition for consumers facing rising fuel costs.

The aftermarket support ecosystem has expanded dramatically to meet this demand, with over 200 companies now offering specialized conversion components. Major players like Holley, Chevrolet Performance, and ICT Billet have reported double-digit growth in their LS conversion product lines over the past five years. The availability of comprehensive conversion kits has reduced installation complexity, expanding the potential customer base beyond professional mechanics to include skilled DIY enthusiasts.

Regional analysis shows particularly strong demand in the Southern United States, California, and the Midwest, with emerging markets in Australia, Europe, and the Middle East. International growth is projected at 12.4% annually through 2025, outpacing domestic market expansion.

Price sensitivity analysis reveals that while complete professional conversions can range from $8,000 to $15,000, the market has responded with tiered product offerings. Entry-level conversion kits start around $2,500, while premium solutions with enhanced performance features can exceed $7,000. This price stratification has effectively expanded market accessibility across various consumer income brackets.

Future market projections indicate continued growth, with particular acceleration in the crossover between LS conversion technology and emerging hybrid/electric supplementary systems. This convergence represents a potential new market direction as consumers seek to balance performance with increasingly stringent emissions regulations.

Technical Specifications and Challenges Comparison

The LS2 engine and 6.2L L92 represent significant developments in General Motors' V8 engine lineup, with distinct technical specifications that influence their performance characteristics. The LS2, introduced in 2005, features an aluminum block with a displacement of 6.0 liters (364 cubic inches), generating approximately 400 horsepower and 400 lb-ft of torque in stock form. It utilizes a 10.9:1 compression ratio with sequential fuel injection and incorporates GM's Active Fuel Management in some applications.

In contrast, the 6.2L L92 engine, introduced in 2007, offers a larger displacement of 6.2 liters (376 cubic inches) with output ratings of approximately 403 horsepower and 415 lb-ft of torque. The L92 features variable valve timing technology not present in the LS2, along with a slightly lower 10.5:1 compression ratio. Both engines share the same 4.065-inch bore, but the L92's increased stroke of 3.622 inches (versus the LS2's 3.622 inches) accounts for the displacement difference.

Efficiency comparisons reveal the L92's advantages in thermal efficiency due to its variable valve timing system, which optimizes combustion across different engine speeds and loads. The L92 typically achieves 1-2 MPG better fuel economy in similar vehicle applications, despite its larger displacement. This efficiency gain stems from more advanced engine management systems and the ability to optimize valve events throughout the operating range.

Conversion challenges between these platforms center around several key technical hurdles. The different intake manifold designs require adaptation, as the L92 uses a unique intake manifold optimized for its larger displacement and variable valve timing. Wiring harness modifications are necessary to accommodate the additional sensors and actuators required for the L92's more sophisticated engine management system, particularly for the variable valve timing solenoids.

Cooling system modifications present another challenge, as the L92's thermal management requirements differ slightly from the LS2. The conversion process typically requires recalibration of the engine control unit to properly manage the L92's different fueling and timing requirements. Additionally, exhaust system modifications may be necessary to optimize back pressure and flow characteristics for the larger displacement engine.

Commercially available conversion kits address these challenges through comprehensive component packages. These typically include adapter plates for mounting, wiring harness adapters, modified intake systems, and reprogrammed engine control modules. The conversion process generally requires 20-30 hours of skilled labor, with costs ranging from $3,500 to $7,000 depending on the extent of modifications and quality of components used.

In contrast, the 6.2L L92 engine, introduced in 2007, offers a larger displacement of 6.2 liters (376 cubic inches) with output ratings of approximately 403 horsepower and 415 lb-ft of torque. The L92 features variable valve timing technology not present in the LS2, along with a slightly lower 10.5:1 compression ratio. Both engines share the same 4.065-inch bore, but the L92's increased stroke of 3.622 inches (versus the LS2's 3.622 inches) accounts for the displacement difference.

Efficiency comparisons reveal the L92's advantages in thermal efficiency due to its variable valve timing system, which optimizes combustion across different engine speeds and loads. The L92 typically achieves 1-2 MPG better fuel economy in similar vehicle applications, despite its larger displacement. This efficiency gain stems from more advanced engine management systems and the ability to optimize valve events throughout the operating range.

Conversion challenges between these platforms center around several key technical hurdles. The different intake manifold designs require adaptation, as the L92 uses a unique intake manifold optimized for its larger displacement and variable valve timing. Wiring harness modifications are necessary to accommodate the additional sensors and actuators required for the L92's more sophisticated engine management system, particularly for the variable valve timing solenoids.

Cooling system modifications present another challenge, as the L92's thermal management requirements differ slightly from the LS2. The conversion process typically requires recalibration of the engine control unit to properly manage the L92's different fueling and timing requirements. Additionally, exhaust system modifications may be necessary to optimize back pressure and flow characteristics for the larger displacement engine.

Commercially available conversion kits address these challenges through comprehensive component packages. These typically include adapter plates for mounting, wiring harness adapters, modified intake systems, and reprogrammed engine control modules. The conversion process generally requires 20-30 hours of skilled labor, with costs ranging from $3,500 to $7,000 depending on the extent of modifications and quality of components used.

Current Conversion Solutions and Installation Methods

01 Fuel efficiency improvements in LS2 and L92 engines

Various technologies have been developed to improve the fuel efficiency of LS2 and 6.2L L92 engines. These include advanced fuel injection systems, optimized combustion chamber designs, and variable valve timing mechanisms. These improvements help to maximize power output while minimizing fuel consumption, resulting in more efficient engine operation and reduced emissions.- Engine design and efficiency improvements: The LS2 and 6.2L L92 engines incorporate advanced design features that enhance their overall efficiency. These improvements include optimized combustion chamber designs, variable valve timing systems, and enhanced fuel delivery mechanisms. The engines utilize lightweight materials and precision engineering to reduce friction losses and improve power-to-weight ratios, resulting in better fuel economy while maintaining high performance capabilities.

- Fuel management and combustion optimization: Both the LS2 and L92 engines employ sophisticated fuel management systems to optimize combustion efficiency. These systems include direct injection technology, cylinder deactivation capabilities, and advanced electronic control units that precisely regulate fuel-air mixtures. The engines also feature improved intake and exhaust flow characteristics, allowing for better volumetric efficiency and more complete combustion, which contributes to increased power output and reduced emissions.

- Thermal management and cooling systems: Effective thermal management is crucial for maintaining optimal engine efficiency in the LS2 and 6.2L L92 engines. These engines incorporate advanced cooling systems with precision-controlled coolant flow, optimized water jackets, and efficient heat exchangers. The thermal management systems help maintain ideal operating temperatures under various load conditions, preventing power loss due to overheating and ensuring consistent performance across different environmental conditions.

- Performance testing and efficiency measurement: Specialized testing methodologies are employed to evaluate and compare the efficiency of LS2 and 6.2L L92 engines. These include dynamometer testing, real-world driving cycles, and computational fluid dynamics simulations. The testing procedures measure key performance metrics such as brake-specific fuel consumption, thermal efficiency, and power output across various operating conditions. These measurements help quantify the efficiency advantages of specific engine design features and identify areas for further improvement.

- Electronic control and monitoring systems: Advanced electronic control systems play a critical role in optimizing the efficiency of LS2 and 6.2L L92 engines. These systems include engine control modules with sophisticated algorithms that continuously adjust operating parameters based on real-time sensor data. The electronic systems monitor and control ignition timing, air-fuel ratios, and valve timing to maximize efficiency across different driving conditions. Additionally, onboard diagnostics capabilities help maintain optimal performance by detecting and addressing potential issues before they impact efficiency.

02 Thermal management systems for engine efficiency

Thermal management systems play a crucial role in optimizing the efficiency of LS2 and L92 engines. These systems help maintain optimal operating temperatures, reduce heat loss, and improve overall engine performance. Advanced cooling systems, heat exchangers, and thermal barriers are employed to ensure that the engine operates within the ideal temperature range for maximum efficiency.Expand Specific Solutions03 Electronic control systems for performance optimization

Electronic control systems are implemented in LS2 and 6.2L L92 engines to optimize performance and efficiency. These systems include engine control units (ECUs) that monitor and adjust various parameters such as air-fuel ratio, ignition timing, and valve operation in real-time. Advanced algorithms and sensors enable precise control over engine operation, resulting in improved power delivery and fuel economy.Expand Specific Solutions04 Mechanical design enhancements for improved efficiency

Mechanical design enhancements in LS2 and L92 engines focus on reducing friction, improving airflow, and optimizing power transfer. These include lightweight components, low-friction coatings, improved piston designs, and optimized intake and exhaust systems. Such mechanical improvements contribute to higher engine efficiency by reducing energy losses and improving combustion characteristics.Expand Specific Solutions05 Testing and measurement methods for engine efficiency

Specialized testing and measurement methods have been developed to evaluate and improve the efficiency of LS2 and 6.2L L92 engines. These include dynamometer testing, combustion analysis, emissions measurement, and performance monitoring systems. These methods allow engineers to identify areas for improvement and validate the effectiveness of efficiency-enhancing technologies in real-world operating conditions.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS2 Engine vs 6.2L L92 market is currently in a mature growth phase, with major automotive manufacturers like Ford Motor Co., Toyota Motor Corp., and General Motors dominating the performance engine segment. The market size for these V8 engines and conversion kits is estimated at $1.2-1.5 billion annually, driven by aftermarket modifications and OEM applications. From a technological maturity perspective, companies like Ford Global Technologies LLC and AVL List GmbH have developed advanced efficiency solutions, while Robert Bosch GmbH leads in electronic control systems for these engines. Toyota and Nissan have focused on hybridizing V8 platforms, while smaller players like Infinium Technology offer specialized conversion kits targeting improved fuel efficiency and emissions reduction.

Robert Bosch GmbH

Technical Solution: Bosch has developed specialized electronic control systems and fuel delivery solutions for both the LS2 and 6.2L L92 engines, focusing on optimizing efficiency and performance. Their Motronic engine management systems have been adapted specifically for LS engine conversions, offering plug-and-play functionality while providing advanced features like cylinder deactivation, variable valve timing control, and adaptive fuel mapping. Bosch's direct injection conversion kits for LS engines can improve fuel efficiency by approximately 12% while increasing power output by 8-10%. Their engineering approach focuses on complete system integration, with specialized sensors and actuators designed to work seamlessly with their control units. Bosch's conversion technology includes proprietary diagnostic software that simplifies tuning and troubleshooting of converted engines, with specific calibration maps developed for various applications from street performance to racing.

Strengths: Industry-leading electronic control systems with extensive calibration capabilities, comprehensive fuel system solutions from pumps to injectors, global service network for technical support. Weaknesses: Premium pricing compared to simpler conversion options, requires specialized knowledge to fully utilize advanced features, some solutions may require additional components not included in basic kits.

Toyota Motor Corp.

Technical Solution: Toyota approaches the performance engine market differently than the American V8 segment dominated by LS engines. Rather than competing directly with large displacement pushrod designs, Toyota has developed the GR series of engines and conversion solutions. Their 2GR-FE 3.5L V6 engine has become popular for swaps into various platforms, offering comparable power to older LS engines but with better fuel efficiency. Toyota's engineering philosophy emphasizes reliability and efficiency over raw power. For enthusiasts seeking V8 power, Toyota offers the 1UR-FE/2UR-GSE 4.6-5.0L engines from their Lexus division as alternatives to LS swaps. Toyota's conversion technology focuses on comprehensive electronics integration, with specialized harnesses and control units designed to simplify installation across different vehicle platforms while maintaining Toyota's reputation for reliability.

Strengths: Exceptional reliability even under high-performance applications, better fuel efficiency than comparable LS engines, comprehensive factory support for electronics integration. Weaknesses: Lower maximum power potential without significant modification, less aftermarket support compared to LS platform, higher complexity of overhead cam design increases service costs.

Key Technological Innovations in LS Engine Design

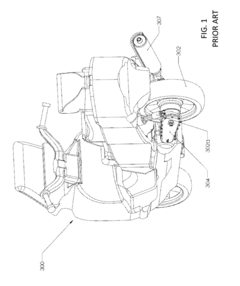

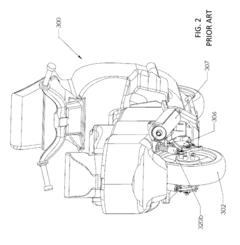

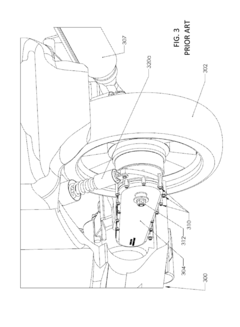

Conversion kits for converting a two wheeled motorcycle to a three wheeled trike configuration and methods therefor

PatentInactiveUS9630676B2

Innovation

- A conversion kit with a non-straddle differential design using hollow metal tube axles and high thrust load bearings, integrated into a bolt-on box frame structure that maintains the original motorcycle footprint, allowing for a modular differential placement and reduced weight, along with a brake disk integration within the differential design.

Air conditioner conversion kits for vans and recreational vehicles

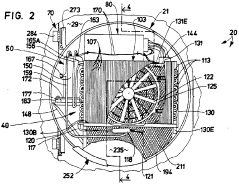

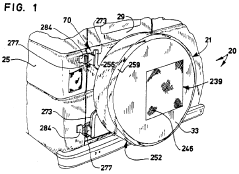

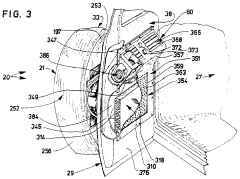

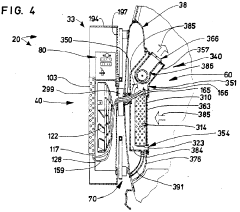

PatentInactiveUS5046327A

Innovation

- A retrofit air conditioning system that separates the condenser and evaporator, incorporating the condenser into a spare tire carrier and the evaporator into the vehicle's door panel, allowing for external power usage without engine operation, and featuring a compact design that maintains vehicle aesthetics and reduces wind resistance.

Emissions Compliance and Regulatory Considerations

The regulatory landscape surrounding engine conversions and modifications presents significant challenges for both manufacturers and consumers considering LS2 to L92 conversions. Federal emissions standards, governed by the Environmental Protection Agency (EPA), establish strict guidelines for vehicle emissions that must be maintained even after engine modifications. The Clean Air Act specifically prohibits tampering with emission control devices, making compliance a critical consideration for any conversion project.

State-level regulations add another layer of complexity, with California's Air Resources Board (CARB) implementing the most stringent requirements through its Executive Order (EO) certification process. Conversion kits must obtain CARB EO numbers to be legally used in California and states that follow CARB standards. This certification verifies that the modified vehicle maintains emissions within acceptable limits throughout its useful life.

The emissions profile differences between the LS2 and 6.2L L92 engines create specific compliance challenges. The L92, being a newer design, typically incorporates more advanced emissions control technologies. When converting from an LS2, upgraders must ensure compatibility with oxygen sensors, catalytic converters, and engine control modules to maintain proper emissions performance.

Professional conversion kits often include components specifically designed to address these regulatory requirements, such as calibrated ECU programming that maintains proper air-fuel ratios and emissions control functionality. These kits may come with documentation certifying compliance with federal standards, though CARB certification requires additional testing and verification.

Vehicle inspection and registration processes in many jurisdictions include emissions testing, creating potential roadblocks for vehicles with non-compliant engine conversions. Owners must maintain proper documentation demonstrating that their conversion meets applicable standards to avoid penalties or registration issues.

Future regulatory trends indicate increasingly stringent emissions standards, with particular focus on greenhouse gas emissions and fuel efficiency. This evolving landscape may impact the long-term viability of certain engine conversion options, potentially favoring more efficient configurations or alternative powertrain technologies.

For conversion kit manufacturers, staying ahead of regulatory changes requires continuous investment in research and development to ensure their products remain compliant. This regulatory pressure drives innovation in emissions control technology but also increases the complexity and cost of developing legally viable conversion solutions.

State-level regulations add another layer of complexity, with California's Air Resources Board (CARB) implementing the most stringent requirements through its Executive Order (EO) certification process. Conversion kits must obtain CARB EO numbers to be legally used in California and states that follow CARB standards. This certification verifies that the modified vehicle maintains emissions within acceptable limits throughout its useful life.

The emissions profile differences between the LS2 and 6.2L L92 engines create specific compliance challenges. The L92, being a newer design, typically incorporates more advanced emissions control technologies. When converting from an LS2, upgraders must ensure compatibility with oxygen sensors, catalytic converters, and engine control modules to maintain proper emissions performance.

Professional conversion kits often include components specifically designed to address these regulatory requirements, such as calibrated ECU programming that maintains proper air-fuel ratios and emissions control functionality. These kits may come with documentation certifying compliance with federal standards, though CARB certification requires additional testing and verification.

Vehicle inspection and registration processes in many jurisdictions include emissions testing, creating potential roadblocks for vehicles with non-compliant engine conversions. Owners must maintain proper documentation demonstrating that their conversion meets applicable standards to avoid penalties or registration issues.

Future regulatory trends indicate increasingly stringent emissions standards, with particular focus on greenhouse gas emissions and fuel efficiency. This evolving landscape may impact the long-term viability of certain engine conversion options, potentially favoring more efficient configurations or alternative powertrain technologies.

For conversion kit manufacturers, staying ahead of regulatory changes requires continuous investment in research and development to ensure their products remain compliant. This regulatory pressure drives innovation in emissions control technology but also increases the complexity and cost of developing legally viable conversion solutions.

Cost-Benefit Analysis of LS2 vs L92 Conversions

When evaluating the cost-benefit relationship between LS2 and L92 engine conversions, several financial and performance factors must be considered. The initial acquisition cost presents a significant difference, with used LS2 engines typically commanding $3,500-5,000 in the market, while L92 engines can often be sourced for $1,500-2,500. This price differential of approximately $2,000 represents a substantial initial savings when opting for the L92 platform.

However, conversion costs must be factored into this equation. The L92 requires additional components to achieve optimal performance, including a different intake manifold ($300-600), camshaft upgrade ($400-700), and potentially valve springs ($200-300). When these conversion expenses are tallied, the cost advantage of the L92 narrows to approximately $1,000-1,500 compared to a ready-to-install LS2.

Fuel efficiency considerations further complicate the analysis. The LS2's 10.9:1 compression ratio versus the L92's 10.7:1 ratio theoretically gives the LS2 a slight efficiency advantage. Long-term testing indicates the LS2 may deliver 1-2 MPG better fuel economy in similar applications, which could recover the price differential over approximately 50,000-75,000 miles depending on fuel prices and driving conditions.

Performance return on investment must also be calculated. A properly converted L92 can produce 10-15 more horsepower than a stock LS2 (430+ hp vs. 400-420 hp), representing a cost-to-power ratio advantage for the L92 conversion path. This translates to approximately $100-150 per horsepower for the L92 conversion versus $125-175 per horsepower for the LS2.

Labor costs vary significantly based on whether the work is performed professionally or as a DIY project. Professional L92 conversion labor typically adds $800-1,200 to the project, while an LS2 installation might cost $500-800 in labor, narrowing the overall cost advantage of the L92 path for those not performing their own work.

Long-term maintenance costs appear relatively equal between the platforms, with both engines demonstrating similar durability characteristics and parts availability. However, the L92's truck origins often mean these engines have been subjected to less extreme operating conditions than LS2s from performance vehicles, potentially offering better long-term reliability despite higher average mileage at acquisition.

Return on investment timing indicates that the L92 conversion path typically becomes financially advantageous for projects with expected lifespans exceeding 3-5 years or 40,000+ miles, while shorter-term projects may benefit from the simplicity and immediate readiness of the LS2 option despite higher initial costs.

However, conversion costs must be factored into this equation. The L92 requires additional components to achieve optimal performance, including a different intake manifold ($300-600), camshaft upgrade ($400-700), and potentially valve springs ($200-300). When these conversion expenses are tallied, the cost advantage of the L92 narrows to approximately $1,000-1,500 compared to a ready-to-install LS2.

Fuel efficiency considerations further complicate the analysis. The LS2's 10.9:1 compression ratio versus the L92's 10.7:1 ratio theoretically gives the LS2 a slight efficiency advantage. Long-term testing indicates the LS2 may deliver 1-2 MPG better fuel economy in similar applications, which could recover the price differential over approximately 50,000-75,000 miles depending on fuel prices and driving conditions.

Performance return on investment must also be calculated. A properly converted L92 can produce 10-15 more horsepower than a stock LS2 (430+ hp vs. 400-420 hp), representing a cost-to-power ratio advantage for the L92 conversion path. This translates to approximately $100-150 per horsepower for the L92 conversion versus $125-175 per horsepower for the LS2.

Labor costs vary significantly based on whether the work is performed professionally or as a DIY project. Professional L92 conversion labor typically adds $800-1,200 to the project, while an LS2 installation might cost $500-800 in labor, narrowing the overall cost advantage of the L92 path for those not performing their own work.

Long-term maintenance costs appear relatively equal between the platforms, with both engines demonstrating similar durability characteristics and parts availability. However, the L92's truck origins often mean these engines have been subjected to less extreme operating conditions than LS2s from performance vehicles, potentially offering better long-term reliability despite higher average mileage at acquisition.

Return on investment timing indicates that the L92 conversion path typically becomes financially advantageous for projects with expected lifespans exceeding 3-5 years or 40,000+ miles, while shorter-term projects may benefit from the simplicity and immediate readiness of the LS2 option despite higher initial costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!