Comparing LS2 Engine's Overhead Cam vs Pushrod in Performance

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Architecture Evolution and Performance Goals

The LS2 engine represents a significant milestone in General Motors' small-block V8 evolution, building upon the legacy of the original small-block introduced in 1955. Developed as part of the Gen IV small-block family, the LS2 emerged in 2005 as a 6.0-liter powerplant that balanced traditional pushrod architecture with modern performance demands. This engine architecture was designed to meet increasingly stringent emissions standards while delivering enhanced power output and fuel efficiency compared to its predecessors.

The evolutionary path of the LS2 reflects GM's commitment to refining rather than revolutionizing its successful small-block formula. While European and Japanese manufacturers increasingly adopted overhead cam designs, GM deliberately maintained the pushrod configuration, focusing on optimizing this architecture through advanced materials, improved breathing capabilities, and enhanced combustion efficiency. This approach allowed GM to preserve the compact dimensions and lower center of gravity that characterize pushrod engines while still meeting contemporary performance targets.

A primary goal in the LS2's development was achieving higher specific output without sacrificing reliability or drivability. Engineers targeted approximately 400 horsepower from the 6.0-liter displacement—a significant improvement over previous generations—while maintaining the broad, accessible torque curve that GM V8s were known for. This represented a specific output of about 67 hp per liter, competitive with many overhead cam designs of the era while retaining the packaging and weight advantages of pushrod architecture.

The LS2 design incorporated numerous technological advancements, including an aluminum block with cast-in-place iron cylinder liners, redesigned cylinder heads with straighter intake ports, and a higher compression ratio of 10.9:1. These improvements were aimed at enhancing volumetric efficiency and combustion characteristics while maintaining the engine's compact dimensions. The intake manifold was also redesigned to improve airflow dynamics, contributing to the engine's improved breathing capabilities.

Manufacturing efficiency and cost-effectiveness were additional considerations in the LS2's development. The pushrod design, with its significantly fewer moving parts compared to overhead cam configurations, offered advantages in production simplicity and long-term reliability. This aligned with GM's strategic goal of delivering high-performance engines that could be economically manufactured at scale and easily serviced throughout their operational life.

The LS2 architecture was also developed with versatility in mind, serving as a platform that could be deployed across multiple vehicle applications from performance cars to trucks. This adaptability represented a key strategic advantage for GM, allowing the company to leverage a single engine architecture across diverse product lines while maintaining competitive performance metrics in each application.

The evolutionary path of the LS2 reflects GM's commitment to refining rather than revolutionizing its successful small-block formula. While European and Japanese manufacturers increasingly adopted overhead cam designs, GM deliberately maintained the pushrod configuration, focusing on optimizing this architecture through advanced materials, improved breathing capabilities, and enhanced combustion efficiency. This approach allowed GM to preserve the compact dimensions and lower center of gravity that characterize pushrod engines while still meeting contemporary performance targets.

A primary goal in the LS2's development was achieving higher specific output without sacrificing reliability or drivability. Engineers targeted approximately 400 horsepower from the 6.0-liter displacement—a significant improvement over previous generations—while maintaining the broad, accessible torque curve that GM V8s were known for. This represented a specific output of about 67 hp per liter, competitive with many overhead cam designs of the era while retaining the packaging and weight advantages of pushrod architecture.

The LS2 design incorporated numerous technological advancements, including an aluminum block with cast-in-place iron cylinder liners, redesigned cylinder heads with straighter intake ports, and a higher compression ratio of 10.9:1. These improvements were aimed at enhancing volumetric efficiency and combustion characteristics while maintaining the engine's compact dimensions. The intake manifold was also redesigned to improve airflow dynamics, contributing to the engine's improved breathing capabilities.

Manufacturing efficiency and cost-effectiveness were additional considerations in the LS2's development. The pushrod design, with its significantly fewer moving parts compared to overhead cam configurations, offered advantages in production simplicity and long-term reliability. This aligned with GM's strategic goal of delivering high-performance engines that could be economically manufactured at scale and easily serviced throughout their operational life.

The LS2 architecture was also developed with versatility in mind, serving as a platform that could be deployed across multiple vehicle applications from performance cars to trucks. This adaptability represented a key strategic advantage for GM, allowing the company to leverage a single engine architecture across diverse product lines while maintaining competitive performance metrics in each application.

Market Demand Analysis for High-Performance Engine Technologies

The high-performance engine market has witnessed significant growth over the past decade, driven by increasing consumer demand for vehicles that deliver superior power, efficiency, and driving experience. The global high-performance engine market was valued at approximately $27 billion in 2022 and is projected to reach $38 billion by 2028, growing at a CAGR of 6.5% during the forecast period.

The comparison between overhead cam and pushrod engine technologies, particularly in the context of the LS2 engine, represents a critical decision point for manufacturers targeting performance-oriented consumers. Market research indicates that consumer preferences are increasingly segmented, with distinct demand patterns emerging across different regions and vehicle categories.

In North America, pushrod engines like the LS2 continue to maintain strong market demand, particularly in muscle cars, trucks, and performance vehicles where torque delivery and packaging efficiency are prioritized. The aftermarket for pushrod engine modifications and upgrades represents a $3.2 billion industry, with annual growth rates exceeding 4%.

Conversely, European and Asian markets show stronger preference for overhead cam designs, which dominate in sports cars, luxury performance vehicles, and high-revving applications. This regional divergence creates distinct market opportunities for manufacturers who can effectively position their engine technologies to match local preferences.

The racing and motorsport segment represents a particularly influential market driver, with technologies developed for competition frequently trickling down to consumer vehicles. Professional racing teams' adoption of either overhead cam or pushrod designs significantly impacts consumer perception and market trends, creating halo effects for related consumer products.

Industry surveys reveal that 68% of performance vehicle enthusiasts consider engine technology a primary purchase factor, with 42% specifically evaluating the cam design when making buying decisions. This indicates substantial market awareness of the technical differences between these engine architectures.

Emerging trends in electrification are reshaping market dynamics, with hybrid performance vehicles increasingly incorporating specialized combustion engines. This has created new demand for compact, efficient high-performance engines where the packaging advantages of pushrod designs like the LS2 offer competitive benefits against traditional overhead cam configurations.

The aftermarket modification sector shows particularly strong demand growth, with consumers spending an average of $4,800 on performance engine upgrades. This represents a significant opportunity for component manufacturers specializing in either engine architecture, with specialized camshafts, valvetrain components, and intake systems being the most frequently purchased upgrades.

The comparison between overhead cam and pushrod engine technologies, particularly in the context of the LS2 engine, represents a critical decision point for manufacturers targeting performance-oriented consumers. Market research indicates that consumer preferences are increasingly segmented, with distinct demand patterns emerging across different regions and vehicle categories.

In North America, pushrod engines like the LS2 continue to maintain strong market demand, particularly in muscle cars, trucks, and performance vehicles where torque delivery and packaging efficiency are prioritized. The aftermarket for pushrod engine modifications and upgrades represents a $3.2 billion industry, with annual growth rates exceeding 4%.

Conversely, European and Asian markets show stronger preference for overhead cam designs, which dominate in sports cars, luxury performance vehicles, and high-revving applications. This regional divergence creates distinct market opportunities for manufacturers who can effectively position their engine technologies to match local preferences.

The racing and motorsport segment represents a particularly influential market driver, with technologies developed for competition frequently trickling down to consumer vehicles. Professional racing teams' adoption of either overhead cam or pushrod designs significantly impacts consumer perception and market trends, creating halo effects for related consumer products.

Industry surveys reveal that 68% of performance vehicle enthusiasts consider engine technology a primary purchase factor, with 42% specifically evaluating the cam design when making buying decisions. This indicates substantial market awareness of the technical differences between these engine architectures.

Emerging trends in electrification are reshaping market dynamics, with hybrid performance vehicles increasingly incorporating specialized combustion engines. This has created new demand for compact, efficient high-performance engines where the packaging advantages of pushrod designs like the LS2 offer competitive benefits against traditional overhead cam configurations.

The aftermarket modification sector shows particularly strong demand growth, with consumers spending an average of $4,800 on performance engine upgrades. This represents a significant opportunity for component manufacturers specializing in either engine architecture, with specialized camshafts, valvetrain components, and intake systems being the most frequently purchased upgrades.

Current State and Technical Challenges of OHC vs Pushrod Systems

The global engine market continues to witness a fascinating dichotomy between overhead cam (OHC) and pushrod valve actuation systems. Currently, OHC designs dominate the international automotive landscape, particularly in European and Asian markets, while pushrod systems maintain significant presence in American vehicles, especially in performance and truck applications. This technological divide represents different engineering philosophies with distinct advantages and limitations.

The current state of OHC technology showcases remarkable advancements in high-RPM performance, with variable valve timing and lift systems becoming increasingly sophisticated. Manufacturers like Toyota, BMW, and Honda have developed intelligent VTEC, VANOS, and VVT-i systems that optimize valve operation across the entire RPM range. These systems typically achieve higher specific output (horsepower per liter) compared to pushrod counterparts, with many modern OHC engines capable of safely operating beyond 7,000 RPM.

Conversely, pushrod technology has experienced a renaissance through General Motors' LS/LT engine families. The LS2, specifically, demonstrates how modern materials and computer-aided design have addressed traditional pushrod limitations. Current pushrod engines deliver impressive power density while maintaining compact dimensions and lower center of gravity compared to equivalent OHC designs.

The primary technical challenges facing OHC systems include complexity, cost, and packaging constraints. The additional components required—including camshafts, bearings, and timing mechanisms—increase both manufacturing expenses and potential failure points. OHC designs typically result in taller, wider engine packages that present integration challenges in modern vehicle architectures with stringent pedestrian safety requirements.

For pushrod systems like the LS2, technical limitations center around valve control precision and RPM capability. The elongated valvetrain with its pushrods and rocker arms introduces increased reciprocating mass and potential for valve float at higher engine speeds. Additionally, the fixed valve timing and lift characteristics of most pushrod designs limit optimization across varying operating conditions.

A significant challenge for both technologies lies in meeting increasingly stringent emissions and efficiency standards while maintaining performance characteristics. OHC systems generally offer greater flexibility for implementing advanced combustion strategies but at higher complexity. Pushrod designs must overcome their inherent limitations in valve control precision to achieve comparable efficiency.

The geographical distribution of these technologies reflects both engineering traditions and market demands. OHC systems predominate in space-constrained European and Asian vehicles, while pushrod designs maintain strongholds in American performance cars and trucks where their torque characteristics and packaging advantages remain valuable.

The current state of OHC technology showcases remarkable advancements in high-RPM performance, with variable valve timing and lift systems becoming increasingly sophisticated. Manufacturers like Toyota, BMW, and Honda have developed intelligent VTEC, VANOS, and VVT-i systems that optimize valve operation across the entire RPM range. These systems typically achieve higher specific output (horsepower per liter) compared to pushrod counterparts, with many modern OHC engines capable of safely operating beyond 7,000 RPM.

Conversely, pushrod technology has experienced a renaissance through General Motors' LS/LT engine families. The LS2, specifically, demonstrates how modern materials and computer-aided design have addressed traditional pushrod limitations. Current pushrod engines deliver impressive power density while maintaining compact dimensions and lower center of gravity compared to equivalent OHC designs.

The primary technical challenges facing OHC systems include complexity, cost, and packaging constraints. The additional components required—including camshafts, bearings, and timing mechanisms—increase both manufacturing expenses and potential failure points. OHC designs typically result in taller, wider engine packages that present integration challenges in modern vehicle architectures with stringent pedestrian safety requirements.

For pushrod systems like the LS2, technical limitations center around valve control precision and RPM capability. The elongated valvetrain with its pushrods and rocker arms introduces increased reciprocating mass and potential for valve float at higher engine speeds. Additionally, the fixed valve timing and lift characteristics of most pushrod designs limit optimization across varying operating conditions.

A significant challenge for both technologies lies in meeting increasingly stringent emissions and efficiency standards while maintaining performance characteristics. OHC systems generally offer greater flexibility for implementing advanced combustion strategies but at higher complexity. Pushrod designs must overcome their inherent limitations in valve control precision to achieve comparable efficiency.

The geographical distribution of these technologies reflects both engineering traditions and market demands. OHC systems predominate in space-constrained European and Asian vehicles, while pushrod designs maintain strongholds in American performance cars and trucks where their torque characteristics and packaging advantages remain valuable.

Comparative Analysis of OHC and Pushrod Implementation in LS2

01 Engine control systems for improved performance

Advanced control systems are implemented to optimize the LS2 engine performance through electronic management of fuel injection, ignition timing, and air-fuel ratio. These systems utilize sensors and microprocessors to continuously monitor engine conditions and make real-time adjustments to maximize power output, fuel efficiency, and emissions control. The control systems can adapt to different driving conditions and driver behaviors to provide optimal performance across various operating scenarios.- Engine Control Systems for Performance Optimization: Advanced control systems are implemented to optimize LS2 engine performance through precise management of fuel injection, ignition timing, and air-fuel ratios. These systems utilize electronic control units (ECUs) that continuously monitor engine parameters and adjust settings in real-time to maximize power output while maintaining efficiency. Adaptive learning algorithms allow the system to optimize performance across various operating conditions.

- Combustion Efficiency Improvements: Various technologies focus on enhancing the combustion process in LS2 engines to improve performance. These include optimized cylinder head designs, valve timing adjustments, and combustion chamber modifications that promote better air-fuel mixture and more complete burning. Advanced spark plug technologies and ignition systems ensure reliable combustion initiation, while specialized intake manifold designs improve airflow characteristics.

- Performance Monitoring and Diagnostics: Sophisticated monitoring systems are employed to evaluate LS2 engine performance metrics in real-time. These systems utilize various sensors to collect data on critical parameters such as temperature, pressure, and exhaust composition. Advanced diagnostic tools analyze this data to identify performance issues, optimize tuning parameters, and predict potential failures before they occur, ensuring consistent engine performance and longevity.

- Turbocharging and Forced Induction Systems: Forced induction systems, particularly turbochargers and superchargers, are implemented to significantly increase the power output of LS2 engines. These systems compress intake air, allowing more oxygen to enter the combustion chamber and enabling more fuel to be burned efficiently. Advanced designs incorporate electronic wastegate control, intercooling systems, and variable geometry technology to optimize boost pressure across different engine speeds.

- Thermal Management for Performance Enhancement: Effective thermal management systems are crucial for maintaining optimal LS2 engine performance. These include advanced cooling systems with precision-controlled coolant flow, oil cooling technologies, and heat exchanger designs that prevent power-robbing overheating. Some systems incorporate variable-speed water pumps and thermostats that adjust cooling intensity based on engine load, ensuring ideal operating temperatures under various performance conditions.

02 Combustion optimization techniques

Various methods are employed to optimize the combustion process in LS2 engines, including improved cylinder head designs, valve timing adjustments, and combustion chamber modifications. These techniques enhance air-fuel mixture formation, flame propagation, and exhaust gas evacuation, resulting in more complete combustion and higher thermal efficiency. By optimizing the combustion process, these innovations contribute to increased power output, reduced fuel consumption, and lower emissions from LS2 engines.Expand Specific Solutions03 Performance monitoring and diagnostics

Sophisticated monitoring and diagnostic systems are developed to evaluate LS2 engine performance in real-time, detect potential issues, and provide feedback for optimization. These systems utilize various sensors to collect data on engine parameters such as temperature, pressure, vibration, and emissions. Advanced algorithms analyze this data to identify performance degradation, predict maintenance needs, and suggest adjustments to maintain optimal engine operation. These diagnostic capabilities help ensure consistent performance and extend engine life.Expand Specific Solutions04 Intake and exhaust system enhancements

Modifications to the intake and exhaust systems are implemented to improve airflow characteristics and enhance LS2 engine performance. These enhancements include redesigned intake manifolds, high-flow air filters, tuned exhaust headers, and performance mufflers. By reducing airflow restrictions and optimizing flow dynamics, these modifications allow the engine to breathe more efficiently, resulting in increased horsepower, improved torque delivery, and enhanced throttle response across the RPM range.Expand Specific Solutions05 Thermal management solutions

Advanced thermal management systems are developed to maintain optimal operating temperatures for LS2 engines under various load conditions. These solutions include improved cooling systems, heat exchangers, and thermal barrier coatings that help control engine temperature more effectively. By preventing overheating during high-performance operation and ensuring faster warm-up in cold conditions, these thermal management innovations contribute to consistent performance, improved efficiency, and extended engine durability.Expand Specific Solutions

Major Manufacturers and Competition in Performance Engine Market

The LS2 engine overhead cam vs pushrod performance comparison reflects a market in transition, with traditional pushrod technology competing against modern overhead cam designs. The industry is in a mature phase but experiencing innovation-driven growth, with a global market size estimated at $25-30 billion. Technology maturity varies significantly between players: GM Global Technology Operations and Ford Global Technologies maintain strong pushrod expertise, while Honda Motor and BMW lead in overhead cam technology. Companies like Cummins and Achates Power are developing hybrid approaches. Emerging players from China, including Geely Automobile Research Institute and Zhejiang Geely Holding Group, are rapidly advancing their capabilities in both technologies, challenging established market dynamics.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered overhead cam technology with their VTEC (Variable Valve Timing and Lift Electronic Control) system, which represents one of the most sophisticated implementations of OHC architecture. Their engines typically feature dual overhead camshafts (DOHC) that directly actuate the valves without intermediary components. Honda's latest iterations incorporate advanced cam phasing systems that can continuously adjust valve timing across the entire RPM range. Their high-performance engines utilize finger-follower valve actuation for reduced friction and higher RPM capability, with some models achieving over 9,000 RPM reliably. Honda has also developed compact DOHC layouts that minimize the height disadvantage traditionally associated with overhead cam designs. Their engineering approach focuses on lightweight moving components, with titanium connecting rods and valves in performance applications, allowing for exceptional throttle response and high-revving characteristics while maintaining reliability. Honda continues to refine their overhead cam technology with innovations in variable valve duration and lift profiles.

Strengths: Superior breathing capabilities at high RPM; more precise valve control allowing for variable valve timing implementation; reduced reciprocating mass in the valvetrain; greater potential for multiple valves per cylinder; better fuel efficiency and emissions performance. Weaknesses: More complex design with additional components; increased engine height affecting vehicle packaging; typically higher manufacturing costs; often requires more maintenance with timing belt/chain service intervals.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive dual approach to engine architecture, maintaining expertise in both pushrod and overhead cam technologies. Their Coyote 5.0L DOHC V8 represents their flagship overhead cam design, featuring Twin Independent Variable Camshaft Timing (Ti-VCT) that allows for precise control of both intake and exhaust valve timing. This system enables optimized performance across the entire RPM range while improving fuel efficiency. Ford's overhead cam engines utilize roller finger followers to reduce friction and improve durability at high RPMs. In contrast, their 7.3L Godzilla V8 showcases their continued innovation in pushrod technology, with a single in-block camshaft design optimized for torque production. Ford has implemented advanced manufacturing techniques like precision sand-core casting for their engine blocks, allowing for tighter tolerances and improved durability in both engine architectures. Their engineering approach focuses on application-specific optimization, selecting the appropriate valvetrain architecture based on the vehicle's intended use case and performance requirements.

Strengths: Versatile engineering approach allows for application-specific engine designs; expertise in both technologies enables cross-platform innovation; overhead cam designs offer excellent high-RPM performance for sports applications while pushrod designs provide superior torque for trucks and heavy-duty applications. Weaknesses: Maintaining dual engineering paths increases development costs; pushrod designs still face RPM limitations compared to OHC; overhead cam engines require more complex manufacturing processes; packaging challenges remain for OHC engines in certain vehicle platforms.

Key Patents and Innovations in LS2 Valvetrain Technology

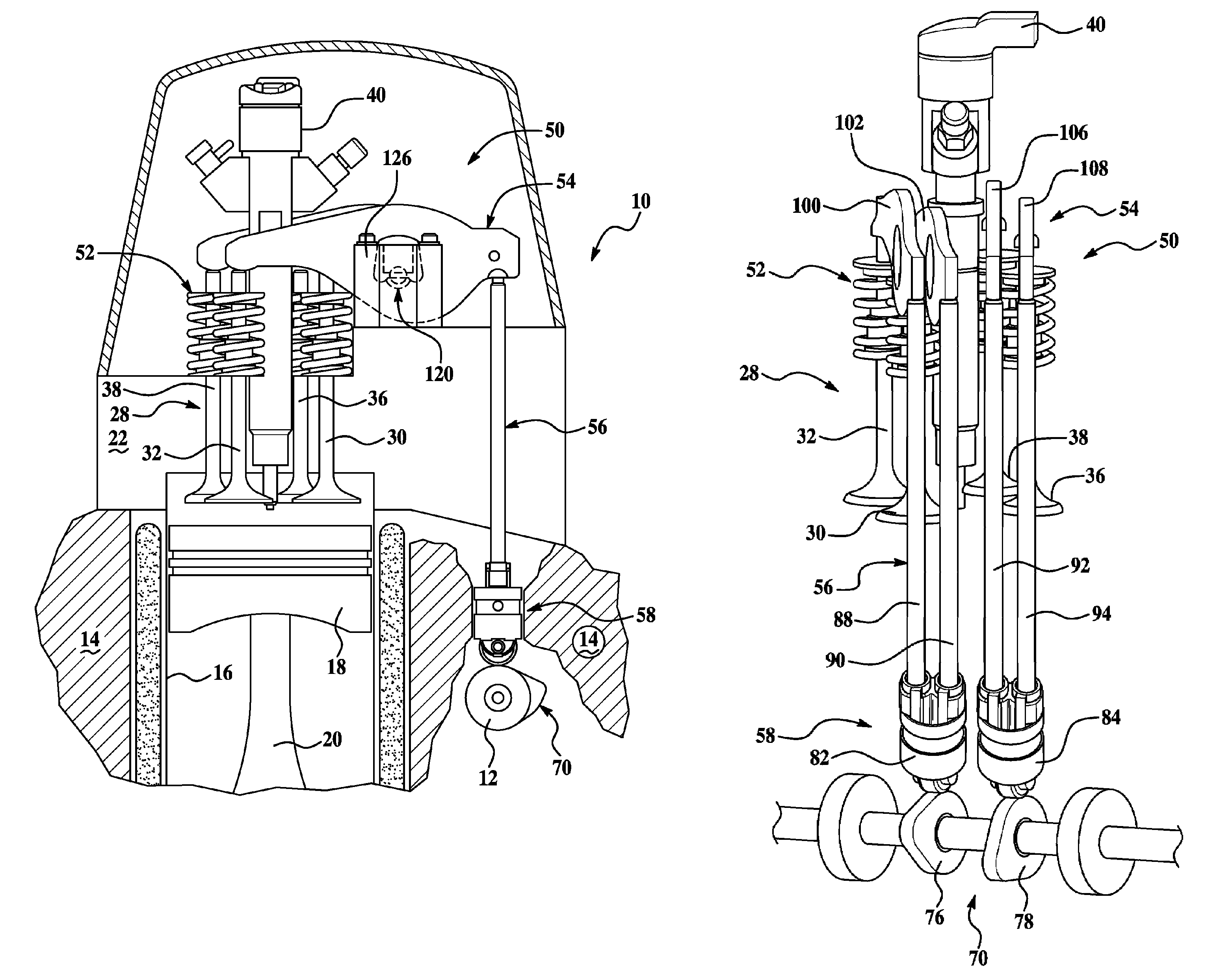

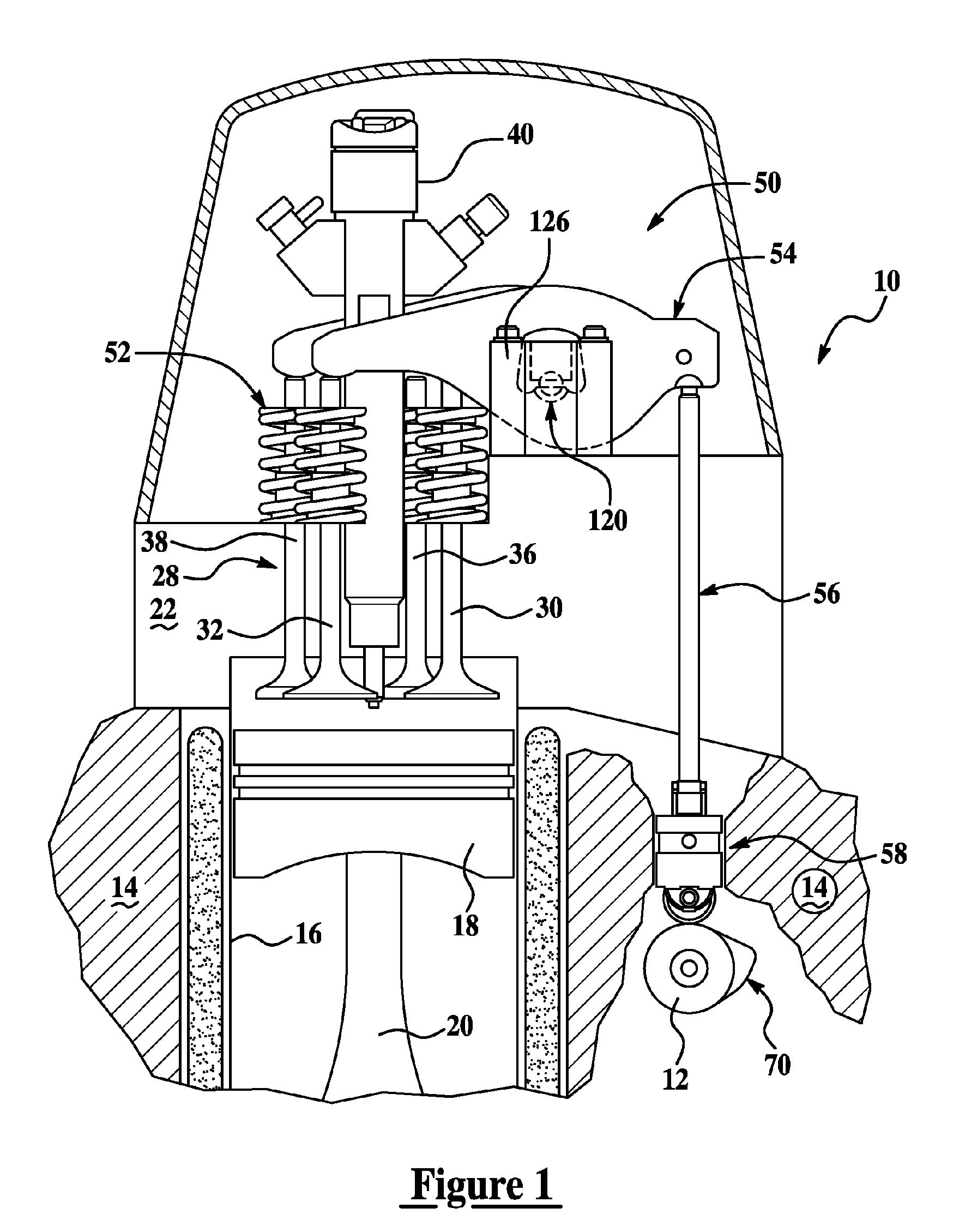

Overhead cam type diesel engine

PatentInactiveUS4448166A

Innovation

- The unit injector is positioned obliquely on the cylinder head with intake and exhaust valves angled to face it, rocker arms are placed on both sides, and a support shaft is used to integrate the lubricant feed system, allowing for a compact design with a simplified assembly and lubrication system by positioning the camshaft close to the piston axis and integrating the fuel injection and intake-exhaust systems within the rocker arm chamber.

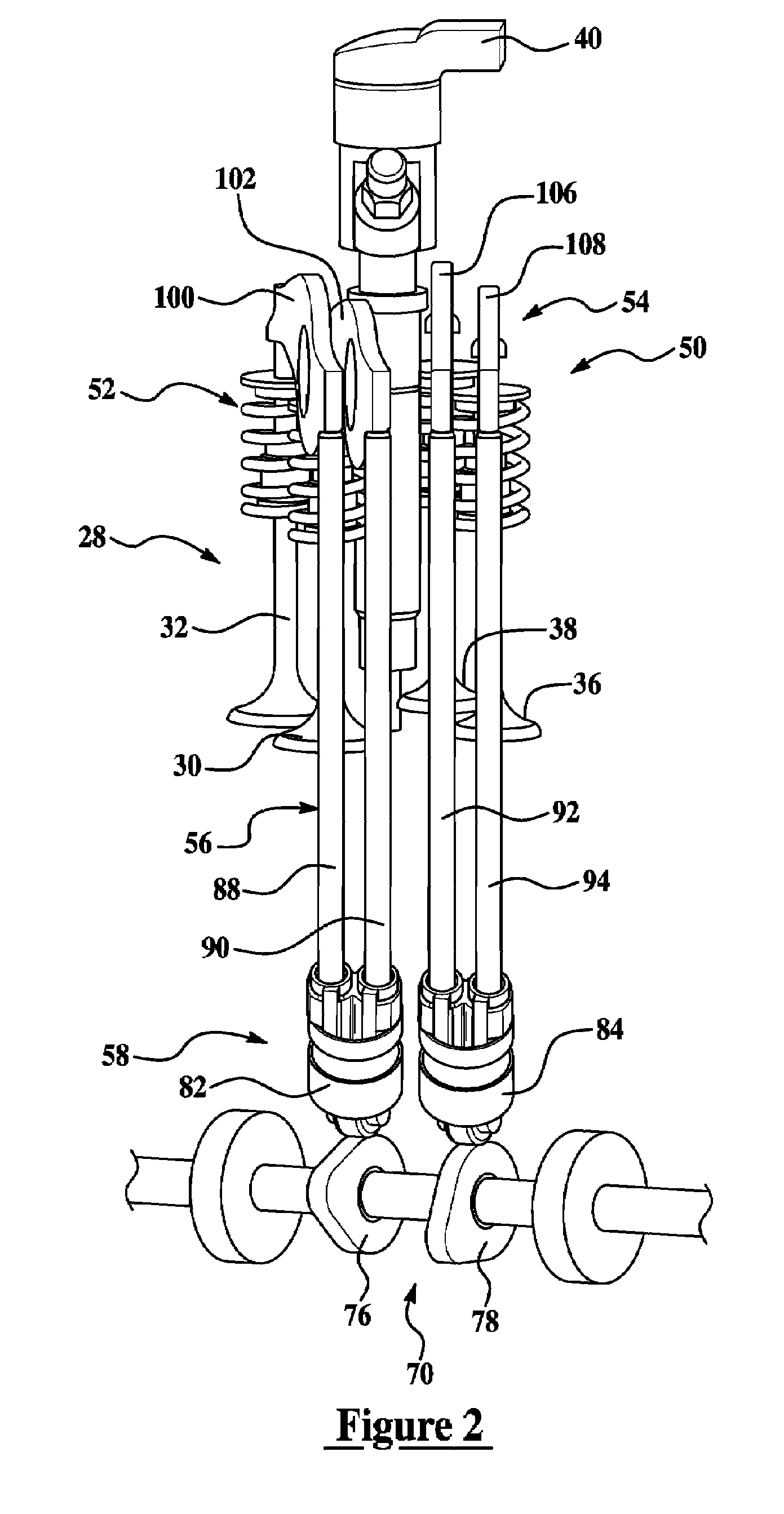

Engine and valvetrain with dual pushrod lifters and independent lash adjustment

PatentInactiveUS7617807B2

Innovation

- The implementation of a camshaft-driven valvetrain with independent dual hydraulic lash adjusters and single plane stamped-steel rocker arms, allowing for synchronized operation of two valves per cylinder with individual lash adjustment, reducing stress and wear through precise control of valve motion.

Emissions Compliance Strategies for Performance Engines

Emissions compliance represents a critical challenge for performance engine manufacturers, particularly when comparing overhead cam systems like those found in some LS2 variants versus traditional pushrod designs. The regulatory landscape continues to evolve with increasingly stringent standards across global markets, requiring sophisticated engineering solutions that maintain performance while reducing harmful emissions.

Performance engines face unique compliance challenges due to their high-output nature. The LS2's pushrod configuration offers inherent advantages in packaging and weight distribution but traditionally presents challenges in meeting modern emissions standards compared to overhead cam designs. The latter typically allow for more precise valve timing and lift control, facilitating better combustion efficiency and emissions management.

Variable valve timing (VVT) implementation differs significantly between these architectures. Overhead cam systems generally offer more sophisticated VVT capabilities, allowing for optimized combustion across a wider RPM range. Recent pushrod designs have incorporated limited VVT functionality, though typically with less flexibility than overhead cam counterparts. This distinction directly impacts emissions performance, particularly NOx and hydrocarbon outputs.

Exhaust gas recirculation (EGR) systems have been adapted differently for each configuration. The compact nature of pushrod designs creates packaging constraints for EGR components, while overhead cam arrangements often provide more space for sophisticated emissions equipment. Engineering teams have developed innovative solutions for both architectures, with modern LS2 variants incorporating advanced EGR systems despite space limitations.

Catalytic converter technology and placement strategies vary between these engine designs. Overhead cam configurations typically allow for closer catalyst positioning to the exhaust ports, reducing light-off time and improving cold-start emissions. Pushrod designs often require more creative packaging solutions to achieve similar results, though recent advancements have narrowed this performance gap.

Electronic engine management systems have evolved to compensate for the architectural differences. Modern ECUs employ sophisticated algorithms that optimize combustion parameters based on real-time sensor data, helping both engine types meet emissions targets while maintaining performance characteristics. Cylinder deactivation technology has been particularly effective in pushrod V8 applications like certain LS2 variants.

Future compliance strategies will likely involve hybridization options for both engine types, with 48V mild hybrid systems emerging as a promising solution for performance applications. These systems can provide emissions benefits while enhancing performance through electric torque supplementation, potentially offering the best of both worlds for enthusiasts and regulators alike.

Performance engines face unique compliance challenges due to their high-output nature. The LS2's pushrod configuration offers inherent advantages in packaging and weight distribution but traditionally presents challenges in meeting modern emissions standards compared to overhead cam designs. The latter typically allow for more precise valve timing and lift control, facilitating better combustion efficiency and emissions management.

Variable valve timing (VVT) implementation differs significantly between these architectures. Overhead cam systems generally offer more sophisticated VVT capabilities, allowing for optimized combustion across a wider RPM range. Recent pushrod designs have incorporated limited VVT functionality, though typically with less flexibility than overhead cam counterparts. This distinction directly impacts emissions performance, particularly NOx and hydrocarbon outputs.

Exhaust gas recirculation (EGR) systems have been adapted differently for each configuration. The compact nature of pushrod designs creates packaging constraints for EGR components, while overhead cam arrangements often provide more space for sophisticated emissions equipment. Engineering teams have developed innovative solutions for both architectures, with modern LS2 variants incorporating advanced EGR systems despite space limitations.

Catalytic converter technology and placement strategies vary between these engine designs. Overhead cam configurations typically allow for closer catalyst positioning to the exhaust ports, reducing light-off time and improving cold-start emissions. Pushrod designs often require more creative packaging solutions to achieve similar results, though recent advancements have narrowed this performance gap.

Electronic engine management systems have evolved to compensate for the architectural differences. Modern ECUs employ sophisticated algorithms that optimize combustion parameters based on real-time sensor data, helping both engine types meet emissions targets while maintaining performance characteristics. Cylinder deactivation technology has been particularly effective in pushrod V8 applications like certain LS2 variants.

Future compliance strategies will likely involve hybridization options for both engine types, with 48V mild hybrid systems emerging as a promising solution for performance applications. These systems can provide emissions benefits while enhancing performance through electric torque supplementation, potentially offering the best of both worlds for enthusiasts and regulators alike.

Manufacturing Cost Analysis of OHC vs Pushrod Systems

The manufacturing cost analysis of overhead cam (OHC) versus pushrod systems reveals significant economic differences that influence automotive manufacturers' design choices. Pushrod systems demonstrate a clear cost advantage in production, requiring approximately 25-40% less investment than comparable OHC systems. This cost differential stems primarily from the reduced component count and simpler manufacturing processes associated with pushrod designs.

Material costs represent a substantial factor in this equation. Pushrod systems typically utilize fewer components—approximately 35-50 parts compared to 80-120 parts in OHC systems. The simplified valve actuation mechanism eliminates the need for expensive timing chains, multiple camshafts, and complex bearing assemblies that characterize OHC designs. Additionally, the cast iron construction commonly used in pushrod blocks offers material cost savings over the aluminum often required for OHC cylinder heads.

Production tooling and manufacturing infrastructure investments also favor pushrod technology. Assembly line configurations for pushrod engines require less specialized equipment and fewer precision machining operations. Industry data indicates that setting up a production line for OHC engines demands 30-45% higher capital expenditure, primarily due to the increased complexity of camshaft positioning and timing system installation.

Labor costs further contribute to the economic advantage of pushrod systems. Assembly time analyses show that pushrod engines typically require 15-25% fewer labor hours during production. The simplified valve train architecture reduces the number of critical tolerance adjustments and complex assembly procedures necessary during manufacturing.

Maintenance considerations also impact lifetime cost calculations. While OHC systems often require more frequent service intervals for timing belt/chain replacement (typically every 60,000-100,000 miles), pushrod systems generally demonstrate longer service intervals for valve train components, reducing warranty costs for manufacturers by an estimated 10-18%.

These cost differentials explain why pushrod designs remain prevalent in certain market segments despite their technical limitations. Manufacturers of high-volume, cost-sensitive vehicles—particularly in the American truck and muscle car segments—continue to leverage pushrod technology's economic advantages while engineering solutions to mitigate its performance constraints. The cost-benefit analysis ultimately influences strategic decisions regarding engine architecture selection based on specific market positioning and performance requirements.

Material costs represent a substantial factor in this equation. Pushrod systems typically utilize fewer components—approximately 35-50 parts compared to 80-120 parts in OHC systems. The simplified valve actuation mechanism eliminates the need for expensive timing chains, multiple camshafts, and complex bearing assemblies that characterize OHC designs. Additionally, the cast iron construction commonly used in pushrod blocks offers material cost savings over the aluminum often required for OHC cylinder heads.

Production tooling and manufacturing infrastructure investments also favor pushrod technology. Assembly line configurations for pushrod engines require less specialized equipment and fewer precision machining operations. Industry data indicates that setting up a production line for OHC engines demands 30-45% higher capital expenditure, primarily due to the increased complexity of camshaft positioning and timing system installation.

Labor costs further contribute to the economic advantage of pushrod systems. Assembly time analyses show that pushrod engines typically require 15-25% fewer labor hours during production. The simplified valve train architecture reduces the number of critical tolerance adjustments and complex assembly procedures necessary during manufacturing.

Maintenance considerations also impact lifetime cost calculations. While OHC systems often require more frequent service intervals for timing belt/chain replacement (typically every 60,000-100,000 miles), pushrod systems generally demonstrate longer service intervals for valve train components, reducing warranty costs for manufacturers by an estimated 10-18%.

These cost differentials explain why pushrod designs remain prevalent in certain market segments despite their technical limitations. Manufacturers of high-volume, cost-sensitive vehicles—particularly in the American truck and muscle car segments—continue to leverage pushrod technology's economic advantages while engineering solutions to mitigate its performance constraints. The cost-benefit analysis ultimately influences strategic decisions regarding engine architecture selection based on specific market positioning and performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!