Best Practices For Ultrasonic Level Measurement In Tanks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Level Measurement Technology Background and Objectives

Ultrasonic level measurement technology emerged in the industrial sector during the 1960s as a non-contact method for monitoring liquid levels. The technology evolved significantly in the 1980s with the introduction of microprocessor-based systems, which dramatically improved accuracy and reliability. Over the past four decades, ultrasonic level measurement has transformed from a niche solution to a mainstream technology widely adopted across various industries including water treatment, chemical processing, oil and gas, and food and beverage.

The fundamental principle behind ultrasonic level measurement involves emitting high-frequency sound waves from a transducer mounted at the top of a tank. These waves travel through the air, reflect off the liquid surface, and return to the transducer. By measuring the time-of-flight between emission and reception, the system calculates the distance to the liquid surface and consequently determines the level within the tank.

Recent technological advancements have focused on overcoming traditional limitations such as foam interference, vapor presence, and turbulent surfaces. Modern ultrasonic sensors incorporate sophisticated signal processing algorithms, temperature compensation mechanisms, and advanced filtering techniques to ensure accurate measurements under challenging conditions. The integration of digital communication protocols like HART, Profibus, and Modbus has further enhanced the capabilities of these systems, enabling seamless integration with industrial automation networks.

The current technological trajectory points toward smarter, more connected ultrasonic level measurement systems. Industry 4.0 initiatives are driving the development of sensors with enhanced diagnostic capabilities, predictive maintenance features, and cloud connectivity. These innovations aim to reduce downtime, optimize maintenance schedules, and provide real-time insights into process efficiency.

The primary objectives of ultrasonic level measurement technology development include improving measurement accuracy across diverse media, enhancing reliability in challenging environments, extending operational lifespan, reducing power consumption, and minimizing installation and maintenance costs. There is also a growing emphasis on developing systems that can function effectively in extreme temperature conditions and corrosive environments.

Another significant goal is the miniaturization of sensors without compromising performance, allowing for deployment in smaller tanks and confined spaces. Simultaneously, there is a push toward developing multi-parameter sensors that can measure not only level but also temperature, pressure, and other process variables, providing a more comprehensive monitoring solution.

As environmental regulations become more stringent, there is also an increasing focus on developing energy-efficient sensors with minimal environmental impact throughout their lifecycle. This includes using sustainable materials, reducing power consumption, and ensuring recyclability at end-of-life.

The fundamental principle behind ultrasonic level measurement involves emitting high-frequency sound waves from a transducer mounted at the top of a tank. These waves travel through the air, reflect off the liquid surface, and return to the transducer. By measuring the time-of-flight between emission and reception, the system calculates the distance to the liquid surface and consequently determines the level within the tank.

Recent technological advancements have focused on overcoming traditional limitations such as foam interference, vapor presence, and turbulent surfaces. Modern ultrasonic sensors incorporate sophisticated signal processing algorithms, temperature compensation mechanisms, and advanced filtering techniques to ensure accurate measurements under challenging conditions. The integration of digital communication protocols like HART, Profibus, and Modbus has further enhanced the capabilities of these systems, enabling seamless integration with industrial automation networks.

The current technological trajectory points toward smarter, more connected ultrasonic level measurement systems. Industry 4.0 initiatives are driving the development of sensors with enhanced diagnostic capabilities, predictive maintenance features, and cloud connectivity. These innovations aim to reduce downtime, optimize maintenance schedules, and provide real-time insights into process efficiency.

The primary objectives of ultrasonic level measurement technology development include improving measurement accuracy across diverse media, enhancing reliability in challenging environments, extending operational lifespan, reducing power consumption, and minimizing installation and maintenance costs. There is also a growing emphasis on developing systems that can function effectively in extreme temperature conditions and corrosive environments.

Another significant goal is the miniaturization of sensors without compromising performance, allowing for deployment in smaller tanks and confined spaces. Simultaneously, there is a push toward developing multi-parameter sensors that can measure not only level but also temperature, pressure, and other process variables, providing a more comprehensive monitoring solution.

As environmental regulations become more stringent, there is also an increasing focus on developing energy-efficient sensors with minimal environmental impact throughout their lifecycle. This includes using sustainable materials, reducing power consumption, and ensuring recyclability at end-of-life.

Market Analysis for Tank Level Measurement Solutions

The global tank level measurement market is experiencing robust growth, valued at approximately 3.2 billion USD in 2022 and projected to reach 4.7 billion USD by 2028, representing a compound annual growth rate of 6.5%. This growth is primarily driven by increasing automation in industrial processes, stringent regulatory requirements for storage tank monitoring, and the rising adoption of Industry 4.0 technologies across various sectors.

Ultrasonic level measurement solutions specifically account for roughly 18% of the total tank level measurement market, showing steady growth due to their non-contact measurement capabilities and suitability for diverse applications. The technology has gained significant traction in water and wastewater management, chemical processing, and oil and gas industries, where accurate level monitoring is critical for operational efficiency and safety compliance.

Regional analysis reveals North America and Europe as the dominant markets for ultrasonic level measurement technologies, collectively holding approximately 55% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 8.2% annually, driven by rapid industrialization in countries like China and India, and increasing investments in water infrastructure projects.

The demand landscape for ultrasonic level measurement solutions is segmented by industry verticals. The water and wastewater sector represents the largest application area (29% market share), followed by chemical processing (23%), oil and gas (19%), food and beverage (12%), and pharmaceuticals (8%). The remaining 9% is distributed across various other industries including mining, power generation, and pulp and paper.

Customer requirements are evolving toward more sophisticated solutions that offer higher accuracy, reliability in challenging environments, and integration capabilities with existing industrial control systems. There is a growing demand for smart ultrasonic sensors that provide remote monitoring capabilities, predictive maintenance features, and compatibility with Industrial Internet of Things (IIoT) platforms.

Price sensitivity varies significantly across different market segments. While large enterprises in oil and gas or chemical industries prioritize accuracy and reliability over cost, small and medium-sized businesses in sectors like food processing or water treatment demonstrate higher price sensitivity, creating opportunities for tiered product offerings in the market.

The competitive landscape is characterized by both established industrial automation companies and specialized measurement technology providers. Recent market trends indicate increasing customer preference for comprehensive solution providers who can offer not just the measurement devices but also installation services, calibration, maintenance, and data analytics capabilities.

Ultrasonic level measurement solutions specifically account for roughly 18% of the total tank level measurement market, showing steady growth due to their non-contact measurement capabilities and suitability for diverse applications. The technology has gained significant traction in water and wastewater management, chemical processing, and oil and gas industries, where accurate level monitoring is critical for operational efficiency and safety compliance.

Regional analysis reveals North America and Europe as the dominant markets for ultrasonic level measurement technologies, collectively holding approximately 55% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 8.2% annually, driven by rapid industrialization in countries like China and India, and increasing investments in water infrastructure projects.

The demand landscape for ultrasonic level measurement solutions is segmented by industry verticals. The water and wastewater sector represents the largest application area (29% market share), followed by chemical processing (23%), oil and gas (19%), food and beverage (12%), and pharmaceuticals (8%). The remaining 9% is distributed across various other industries including mining, power generation, and pulp and paper.

Customer requirements are evolving toward more sophisticated solutions that offer higher accuracy, reliability in challenging environments, and integration capabilities with existing industrial control systems. There is a growing demand for smart ultrasonic sensors that provide remote monitoring capabilities, predictive maintenance features, and compatibility with Industrial Internet of Things (IIoT) platforms.

Price sensitivity varies significantly across different market segments. While large enterprises in oil and gas or chemical industries prioritize accuracy and reliability over cost, small and medium-sized businesses in sectors like food processing or water treatment demonstrate higher price sensitivity, creating opportunities for tiered product offerings in the market.

The competitive landscape is characterized by both established industrial automation companies and specialized measurement technology providers. Recent market trends indicate increasing customer preference for comprehensive solution providers who can offer not just the measurement devices but also installation services, calibration, maintenance, and data analytics capabilities.

Current Challenges in Ultrasonic Level Sensing

Despite significant advancements in ultrasonic level measurement technology, several persistent challenges continue to impact measurement accuracy and reliability in tank applications. Signal attenuation remains a primary concern, particularly in tanks containing foaming liquids, viscous substances, or materials with suspended particles. These conditions can significantly weaken the ultrasonic signal, resulting in poor echo returns and unreliable measurements.

Temperature variations within tanks present another substantial challenge. Ultrasonic waves travel at different speeds depending on the ambient temperature, and fluctuations can lead to measurement errors if not properly compensated. Many existing systems struggle to maintain accuracy when faced with rapid or extreme temperature changes, especially in outdoor installations or process tanks with variable contents.

Acoustic noise interference from nearby equipment, agitators, or filling operations can mask the return echo signal. This problem is particularly acute in industrial environments where multiple processes occur simultaneously, creating a complex acoustic landscape that ultrasonic sensors must navigate.

Vapor and condensation issues pose significant difficulties for ultrasonic measurement systems. Dense vapors above the liquid surface can absorb or scatter ultrasonic signals, while condensation on the sensor face can attenuate or completely block signal transmission. These conditions are common in tanks containing volatile liquids or in environments with significant temperature differentials.

Beam divergence and false echoes represent another set of challenges. As ultrasonic waves propagate through a tank, they naturally spread out, potentially reflecting off tank walls, internal structures, or agitators rather than the actual liquid surface. These false echoes can confuse measurement algorithms, leading to erroneous level readings.

Installation constraints further complicate ultrasonic level sensing. Optimal sensor positioning is not always possible due to tank design limitations, access restrictions, or the presence of internal obstructions. Compromised installation locations can significantly impact measurement performance.

Power consumption remains a concern for remote or battery-operated installations. While ultrasonic technology has become more energy-efficient, achieving the optimal balance between measurement frequency, accuracy, and power usage continues to challenge system designers, particularly for wireless monitoring applications.

Finally, calibration and maintenance requirements present ongoing operational challenges. Many ultrasonic systems require regular recalibration to maintain accuracy, especially when tank contents or process conditions change. This necessity increases the total cost of ownership and can lead to measurement drift if not properly addressed.

Temperature variations within tanks present another substantial challenge. Ultrasonic waves travel at different speeds depending on the ambient temperature, and fluctuations can lead to measurement errors if not properly compensated. Many existing systems struggle to maintain accuracy when faced with rapid or extreme temperature changes, especially in outdoor installations or process tanks with variable contents.

Acoustic noise interference from nearby equipment, agitators, or filling operations can mask the return echo signal. This problem is particularly acute in industrial environments where multiple processes occur simultaneously, creating a complex acoustic landscape that ultrasonic sensors must navigate.

Vapor and condensation issues pose significant difficulties for ultrasonic measurement systems. Dense vapors above the liquid surface can absorb or scatter ultrasonic signals, while condensation on the sensor face can attenuate or completely block signal transmission. These conditions are common in tanks containing volatile liquids or in environments with significant temperature differentials.

Beam divergence and false echoes represent another set of challenges. As ultrasonic waves propagate through a tank, they naturally spread out, potentially reflecting off tank walls, internal structures, or agitators rather than the actual liquid surface. These false echoes can confuse measurement algorithms, leading to erroneous level readings.

Installation constraints further complicate ultrasonic level sensing. Optimal sensor positioning is not always possible due to tank design limitations, access restrictions, or the presence of internal obstructions. Compromised installation locations can significantly impact measurement performance.

Power consumption remains a concern for remote or battery-operated installations. While ultrasonic technology has become more energy-efficient, achieving the optimal balance between measurement frequency, accuracy, and power usage continues to challenge system designers, particularly for wireless monitoring applications.

Finally, calibration and maintenance requirements present ongoing operational challenges. Many ultrasonic systems require regular recalibration to maintain accuracy, especially when tank contents or process conditions change. This necessity increases the total cost of ownership and can lead to measurement drift if not properly addressed.

Current Ultrasonic Level Measurement Implementation Methods

01 Temperature compensation techniques for accuracy improvement

Temperature variations can significantly affect the accuracy of ultrasonic level measurements. By implementing temperature compensation techniques, such as using temperature sensors and correction algorithms, the measurement accuracy can be improved. These techniques adjust the speed of sound calculation based on the measured temperature, ensuring more precise level measurements across varying environmental conditions.- Sensor configuration and placement optimization: The accuracy of ultrasonic level measurement can be significantly improved by optimizing sensor configuration and placement. This includes proper positioning of ultrasonic transducers to minimize interference from tank walls or internal structures, using multiple sensors for cross-verification, and implementing strategic mounting techniques to reduce the impact of environmental factors. Proper alignment and installation angle of sensors can reduce signal distortion and improve measurement reliability.

- Signal processing and filtering techniques: Advanced signal processing algorithms and filtering techniques can enhance the accuracy of ultrasonic level measurements. These include digital signal processing to filter out noise, echo detection algorithms to identify true reflections from false ones, and adaptive filtering to compensate for changing environmental conditions. Time-of-flight calculations with temperature compensation and frequency analysis methods can further improve measurement precision in challenging environments.

- Temperature and environmental compensation: Environmental factors significantly affect ultrasonic level measurement accuracy. Systems that incorporate temperature sensors and compensation algorithms can adjust for variations in sound velocity caused by temperature changes. Additional compensation mechanisms for humidity, pressure, and gas composition in the measurement space help maintain accuracy across varying operating conditions. Some advanced systems include real-time environmental monitoring and automatic calibration features.

- Calibration and reference systems: Proper calibration procedures and reference systems are essential for maintaining high accuracy in ultrasonic level measurement. This includes initial factory calibration, periodic field calibration, and the use of reference targets or standards. Self-calibrating systems that can automatically adjust based on known reference points help maintain measurement accuracy over time. Multi-point calibration techniques can compensate for non-linear responses across the measurement range.

- Integrated multi-sensor systems: Combining ultrasonic sensors with other measurement technologies can significantly improve overall accuracy. Hybrid systems that integrate ultrasonic measurements with radar, capacitive, or pressure-based sensors provide redundancy and cross-validation. These multi-sensor approaches can overcome the limitations of any single technology, particularly in challenging measurement environments with foam, turbulence, or vapor. Data fusion algorithms combine inputs from multiple sensors to produce more reliable and accurate level measurements.

02 Multi-sensor integration and data fusion

Integrating multiple ultrasonic sensors and implementing data fusion algorithms can enhance measurement accuracy. By combining readings from several sensors positioned at different angles or locations, systematic errors can be reduced. Advanced signal processing techniques help filter out noise and inconsistencies, resulting in more reliable and accurate level measurements even in challenging environments.Expand Specific Solutions03 Advanced signal processing algorithms

Sophisticated signal processing algorithms play a crucial role in improving ultrasonic level measurement accuracy. These algorithms can effectively filter out noise, detect and eliminate false echoes, and enhance signal quality. Techniques such as digital filtering, echo verification, and adaptive threshold detection contribute to more precise measurements, particularly in environments with interference or multiple reflective surfaces.Expand Specific Solutions04 Structural design optimization for sensors

The physical design and structure of ultrasonic level sensors significantly impact measurement accuracy. Optimized transducer designs, improved housing configurations, and strategic positioning of components can reduce interference and enhance signal quality. Innovations in sensor materials and construction techniques help minimize measurement errors caused by physical limitations or environmental factors.Expand Specific Solutions05 Calibration and self-diagnostic systems

Implementing advanced calibration methods and self-diagnostic systems ensures consistent accuracy in ultrasonic level measurements. Automatic calibration routines can compensate for drift and aging effects in sensors. Self-diagnostic capabilities allow the system to detect measurement anomalies, verify sensor health, and alert operators to potential accuracy issues, maintaining measurement reliability over time.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

Ultrasonic level measurement in tanks is currently in a mature growth phase, with the global market estimated at $1.2 billion and projected to expand at 6-7% CAGR through 2027. The competitive landscape features established industrial automation leaders like Siemens AG, Rosemount (Emerson), and Robert Bosch GmbH offering comprehensive solutions with advanced features, while specialized players such as Ultraflux SA and Rosemount Tank Radar AB focus on niche applications. Technology maturity varies across applications, with major innovations coming from research collaborations between industry leaders and institutions like Xiamen University and King Fahd University of Petroleum & Minerals, particularly in challenging environments like oil and gas (PetroChina) and nuclear facilities (Korea Hydro & Nuclear Power).

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed sophisticated ultrasonic level measurement systems primarily for automotive and industrial applications. Their technology employs piezoelectric transducers operating at frequencies between 40-400 kHz, optimized for different tank sizes and materials. Bosch's approach incorporates advanced temperature compensation algorithms that adjust for variations in sound velocity across different ambient conditions, ensuring measurement accuracy across a wide operating range (-40°C to +125°C). Their proprietary signal processing techniques include adaptive gain control and dynamic threshold detection to maintain measurement reliability despite varying surface conditions or turbulence. For automotive applications, Bosch has implemented specialized algorithms to account for vehicle movement and acceleration effects on fluid surfaces. Their systems feature self-diagnostic capabilities that continuously monitor sensor performance and detect potential measurement anomalies. Bosch's ultrasonic level sensors are designed with IP67/IP69K protection ratings, making them suitable for harsh environments with exposure to dust, moisture, and high-pressure washing.

Strengths: Exceptional reliability in dynamic conditions like moving vehicles; robust environmental protection for harsh operating conditions; sophisticated temperature compensation for wide operating ranges. Weaknesses: Solutions primarily optimized for automotive rather than large industrial tanks; limited measurement range compared to radar-based alternatives; may have accuracy limitations with highly foaming or vaporous liquids.

Rosemount Tank Radar AB

Technical Solution: Rosemount Tank Radar AB has developed advanced frequency-modulated continuous wave (FMCW) radar technology for ultrasonic level measurement in tanks. Their solution employs high-frequency electromagnetic waves (typically 6-26 GHz) that provide non-contact measurement with exceptional accuracy (±1mm). The system incorporates advanced signal processing algorithms to filter out noise and false echoes caused by tank internals, turbulence, or foam. Their proprietary Tank Mapping technology creates a digital profile of the tank interior, allowing the system to distinguish between actual level readings and interference. For challenging environments, they've implemented automatic gain control that dynamically adjusts signal strength based on measurement conditions. The technology also features temperature compensation mechanisms to account for variations in sound velocity due to temperature gradients within tanks.

Strengths: Superior accuracy even in challenging conditions like turbulence or foam; excellent reliability with minimal maintenance requirements; comprehensive digital tank mapping capability for complex vessel geometries. Weaknesses: Higher initial investment compared to simpler ultrasonic solutions; requires more sophisticated setup and calibration; may need specialized technical support for complex installations.

Key Patents and Technical Innovations in Ultrasonic Sensing

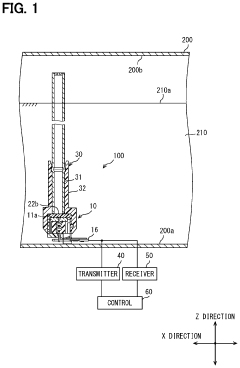

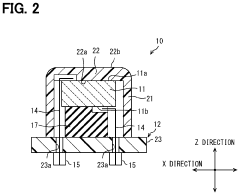

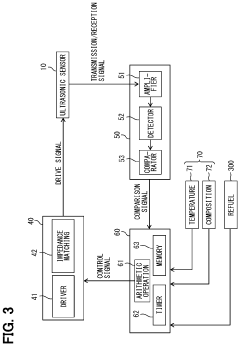

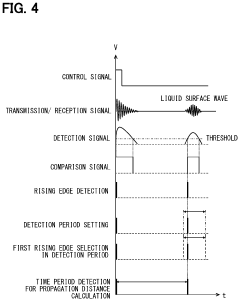

Ultrasonic distance measuring device

PatentActiveUS20210010846A1

Innovation

- The ultrasonic distance measuring device generates and detects ultrasonic waves, calculates the liquid surface level based on the time difference between wave output and reception, and sets a propagation path detection period to filter out noise, using a medium sensor to detect temperature and composition for accurate propagation speed determination.

Ultrasonic measuring method for liquid filling level

PatentInactiveJP2016501377A

Innovation

- A method involving ultrasonic pulses to clean the reference surface, followed by measuring the first and second propagation times of ultrasonic signals to calculate the fill level, using the same ultrasonic sensor or a separate cleaning device, with optional multiple pulses and test measurements to ensure surface cleanliness.

Environmental Factors Affecting Ultrasonic Performance

Ultrasonic level measurement performance is significantly influenced by various environmental factors that can impact accuracy and reliability. Temperature variations represent one of the most critical factors, as they directly affect the speed of sound in air. For every 1°C change in temperature, the speed of sound changes by approximately 0.6 m/s, which can lead to measurement errors if not properly compensated. Modern ultrasonic level sensors incorporate temperature sensors to apply automatic corrections, but extreme temperature gradients within tanks can still pose challenges, particularly in outdoor installations or processes involving heated materials.

Humidity levels also impact ultrasonic wave propagation, as sound travels faster in moist air than in dry conditions. In environments with fluctuating humidity, such as tanks with changing vapor conditions or condensation, measurement accuracy may drift unless appropriate compensation algorithms are implemented. High humidity environments may also lead to condensation on the sensor face, potentially attenuating the signal strength.

Pressure variations within tanks affect the density of the medium through which ultrasonic waves travel, thereby influencing wave propagation speed. This is particularly relevant in sealed tanks where pressure may fluctuate due to process conditions or environmental changes. Pressure compensation becomes essential in applications where significant pressure variations occur.

Tank atmosphere composition presents another critical factor, as different gases have varying sound propagation characteristics. Tanks containing vapors, fumes, or gases other than air require specific calibration adjustments. Particularly challenging are environments with hydrocarbon vapors, chemical fumes, or dust particles that can absorb or scatter ultrasonic signals.

Foam formation on liquid surfaces severely impacts ultrasonic measurement by absorbing and scattering the ultrasonic signals. Even thin foam layers can significantly attenuate return echoes, leading to signal loss or erroneous readings. In applications prone to foaming, alternative technologies or specialized foam-penetrating algorithms may be necessary.

Turbulence and agitation in tank contents create unstable reflection surfaces that generate multiple or inconsistent echo returns. This is common in mixing operations, filling processes, or when materials are being transferred. Advanced signal processing techniques and appropriate damping settings can help mitigate these effects, though extreme turbulence may require strategic sensor positioning or alternative measurement approaches.

Ambient noise from nearby equipment, particularly machinery operating at ultrasonic frequencies, can interfere with level measurement signals. Proper shielding, frequency filtering, and strategic sensor placement help minimize such interference in industrial environments where multiple ultrasonic devices or high-frequency equipment operate simultaneously.

Humidity levels also impact ultrasonic wave propagation, as sound travels faster in moist air than in dry conditions. In environments with fluctuating humidity, such as tanks with changing vapor conditions or condensation, measurement accuracy may drift unless appropriate compensation algorithms are implemented. High humidity environments may also lead to condensation on the sensor face, potentially attenuating the signal strength.

Pressure variations within tanks affect the density of the medium through which ultrasonic waves travel, thereby influencing wave propagation speed. This is particularly relevant in sealed tanks where pressure may fluctuate due to process conditions or environmental changes. Pressure compensation becomes essential in applications where significant pressure variations occur.

Tank atmosphere composition presents another critical factor, as different gases have varying sound propagation characteristics. Tanks containing vapors, fumes, or gases other than air require specific calibration adjustments. Particularly challenging are environments with hydrocarbon vapors, chemical fumes, or dust particles that can absorb or scatter ultrasonic signals.

Foam formation on liquid surfaces severely impacts ultrasonic measurement by absorbing and scattering the ultrasonic signals. Even thin foam layers can significantly attenuate return echoes, leading to signal loss or erroneous readings. In applications prone to foaming, alternative technologies or specialized foam-penetrating algorithms may be necessary.

Turbulence and agitation in tank contents create unstable reflection surfaces that generate multiple or inconsistent echo returns. This is common in mixing operations, filling processes, or when materials are being transferred. Advanced signal processing techniques and appropriate damping settings can help mitigate these effects, though extreme turbulence may require strategic sensor positioning or alternative measurement approaches.

Ambient noise from nearby equipment, particularly machinery operating at ultrasonic frequencies, can interfere with level measurement signals. Proper shielding, frequency filtering, and strategic sensor placement help minimize such interference in industrial environments where multiple ultrasonic devices or high-frequency equipment operate simultaneously.

Installation and Calibration Best Practices

Proper installation and calibration are critical factors that determine the accuracy and reliability of ultrasonic level measurement systems in tanks. The mounting position of the sensor requires careful consideration to avoid interference from tank walls, internal structures, or filling streams. Ideally, the sensor should be positioned at least 200-300mm away from the tank wall and perpendicular to the liquid surface to ensure optimal signal reflection. For tanks with agitators or mixers, installing the sensor in a stilling well or standpipe can minimize turbulence effects and provide more consistent readings.

The beam angle of ultrasonic sensors typically ranges from 5° to 12°, necessitating a clear "line of sight" to the measured surface. Any obstructions within this beam path, such as ladders, heating coils, or baffles, can cause false echoes and measurement errors. Advanced sensors incorporate mapping functions during installation to identify and filter out these fixed obstructions from the signal processing.

Temperature compensation is another crucial installation consideration, as sound velocity varies with air temperature. Modern ultrasonic level transmitters include integrated temperature sensors, but these must be properly positioned to accurately represent the temperature of the entire vapor space. In environments with significant temperature gradients, multiple temperature sensors may be necessary.

Calibration procedures for ultrasonic level measurement systems involve both empty and full-tank calibration points. The empty calibration establishes the maximum measuring distance (tank bottom), while the full calibration sets the minimum measuring distance (maximum fill level). Most modern systems allow for "dry calibration," eliminating the need to physically fill and empty tanks during setup. However, verification with actual process conditions is recommended whenever possible.

Signal processing parameters require optimization during calibration, including damping settings to filter out surface turbulence, echo threshold adjustments to distinguish true echoes from noise, and update rate configuration based on the application's dynamics. For challenging applications with foam, turbulence, or multiple interfaces, advanced calibration techniques such as echo mapping and adaptive filtering may be necessary.

Regular recalibration schedules should be established based on the criticality of the measurement and the stability of the process environment. Typically, verification checks are recommended quarterly, with full recalibration performed annually or after any significant process changes. Documentation of calibration procedures, including as-found and as-left values, ensures measurement traceability and supports quality assurance requirements.

The beam angle of ultrasonic sensors typically ranges from 5° to 12°, necessitating a clear "line of sight" to the measured surface. Any obstructions within this beam path, such as ladders, heating coils, or baffles, can cause false echoes and measurement errors. Advanced sensors incorporate mapping functions during installation to identify and filter out these fixed obstructions from the signal processing.

Temperature compensation is another crucial installation consideration, as sound velocity varies with air temperature. Modern ultrasonic level transmitters include integrated temperature sensors, but these must be properly positioned to accurately represent the temperature of the entire vapor space. In environments with significant temperature gradients, multiple temperature sensors may be necessary.

Calibration procedures for ultrasonic level measurement systems involve both empty and full-tank calibration points. The empty calibration establishes the maximum measuring distance (tank bottom), while the full calibration sets the minimum measuring distance (maximum fill level). Most modern systems allow for "dry calibration," eliminating the need to physically fill and empty tanks during setup. However, verification with actual process conditions is recommended whenever possible.

Signal processing parameters require optimization during calibration, including damping settings to filter out surface turbulence, echo threshold adjustments to distinguish true echoes from noise, and update rate configuration based on the application's dynamics. For challenging applications with foam, turbulence, or multiple interfaces, advanced calibration techniques such as echo mapping and adaptive filtering may be necessary.

Regular recalibration schedules should be established based on the criticality of the measurement and the stability of the process environment. Typically, verification checks are recommended quarterly, with full recalibration performed annually or after any significant process changes. Documentation of calibration procedures, including as-found and as-left values, ensures measurement traceability and supports quality assurance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!