Ultrasonic Sensor Selection For Proximity Detection: A Practical Guide

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensing Technology Background and Objectives

Ultrasonic sensing technology has evolved significantly since its inception in the early 20th century, with its roots tracing back to sonar systems developed during World War I. The fundamental principle behind this technology relies on the emission and reception of high-frequency sound waves (typically above 20 kHz) that are beyond human hearing range. When these waves encounter an object, they reflect back to the sensor, allowing for distance calculation based on the time-of-flight principle.

The evolution of ultrasonic sensing has been marked by continuous miniaturization, increased precision, and enhanced reliability. Early industrial applications in the 1960s and 1970s utilized bulky equipment with limited accuracy, whereas modern ultrasonic sensors are compact, energy-efficient, and capable of millimeter-level precision in ideal conditions. This progression has been driven by advancements in piezoelectric materials, signal processing algorithms, and integrated circuit technology.

In proximity detection applications, ultrasonic sensing offers distinct advantages over alternative technologies such as infrared, capacitive, or optical sensing. These advantages include immunity to environmental factors like dust, smoke, and varying light conditions, as well as the ability to detect objects regardless of their material composition or color. This versatility has positioned ultrasonic sensors as critical components in automotive parking systems, industrial automation, robotics, and various consumer electronics.

Current technological trends in ultrasonic sensing include the development of multi-element array sensors for improved spatial resolution, integration with complementary sensing technologies for enhanced reliability, and implementation of advanced signal processing techniques to mitigate environmental interference. The industry is also witnessing a shift toward smart ultrasonic sensors with embedded processing capabilities, enabling edge computing and reducing the burden on central processing units.

The primary objectives of modern ultrasonic sensor selection for proximity detection include optimizing detection range, minimizing blind zones, enhancing angular coverage, improving resistance to environmental variables, and reducing power consumption. Additionally, there is growing emphasis on sensor fusion approaches that combine ultrasonic data with information from other sensing modalities to create more robust detection systems.

As applications continue to diversify, particularly in emerging fields such as autonomous vehicles, human-robot interaction, and smart infrastructure, the demands on ultrasonic sensing technology are becoming increasingly sophisticated. This necessitates a comprehensive understanding of sensor characteristics, environmental constraints, and application-specific requirements to ensure optimal performance in proximity detection scenarios.

The evolution of ultrasonic sensing has been marked by continuous miniaturization, increased precision, and enhanced reliability. Early industrial applications in the 1960s and 1970s utilized bulky equipment with limited accuracy, whereas modern ultrasonic sensors are compact, energy-efficient, and capable of millimeter-level precision in ideal conditions. This progression has been driven by advancements in piezoelectric materials, signal processing algorithms, and integrated circuit technology.

In proximity detection applications, ultrasonic sensing offers distinct advantages over alternative technologies such as infrared, capacitive, or optical sensing. These advantages include immunity to environmental factors like dust, smoke, and varying light conditions, as well as the ability to detect objects regardless of their material composition or color. This versatility has positioned ultrasonic sensors as critical components in automotive parking systems, industrial automation, robotics, and various consumer electronics.

Current technological trends in ultrasonic sensing include the development of multi-element array sensors for improved spatial resolution, integration with complementary sensing technologies for enhanced reliability, and implementation of advanced signal processing techniques to mitigate environmental interference. The industry is also witnessing a shift toward smart ultrasonic sensors with embedded processing capabilities, enabling edge computing and reducing the burden on central processing units.

The primary objectives of modern ultrasonic sensor selection for proximity detection include optimizing detection range, minimizing blind zones, enhancing angular coverage, improving resistance to environmental variables, and reducing power consumption. Additionally, there is growing emphasis on sensor fusion approaches that combine ultrasonic data with information from other sensing modalities to create more robust detection systems.

As applications continue to diversify, particularly in emerging fields such as autonomous vehicles, human-robot interaction, and smart infrastructure, the demands on ultrasonic sensing technology are becoming increasingly sophisticated. This necessitates a comprehensive understanding of sensor characteristics, environmental constraints, and application-specific requirements to ensure optimal performance in proximity detection scenarios.

Market Applications and Demand Analysis for Proximity Detection

The proximity detection market has witnessed substantial growth in recent years, driven primarily by increasing automation across multiple industries. The global proximity sensor market was valued at approximately $3.8 billion in 2022 and is projected to reach $6.9 billion by 2028, growing at a CAGR of 8.9% during the forecast period. Ultrasonic sensors represent a significant segment within this market, particularly valued for their reliability in challenging environmental conditions.

Automotive applications constitute the largest market segment for ultrasonic proximity sensors, accounting for roughly 35% of the total market share. These sensors are extensively deployed in parking assistance systems, blind-spot detection, and collision avoidance mechanisms. The automotive industry's rapid shift toward advanced driver-assistance systems (ADAS) and autonomous vehicles has substantially increased demand for high-precision ultrasonic sensors capable of accurate distance measurement in various weather conditions.

Industrial automation represents the second-largest application segment, comprising approximately 28% of the market. Manufacturing facilities utilize ultrasonic proximity sensors for object detection, level measurement, and machine safeguarding. The Industry 4.0 revolution has accelerated adoption rates as factories increasingly implement smart manufacturing processes requiring reliable sensing technologies for automation and safety compliance.

Consumer electronics applications have emerged as the fastest-growing segment, with a growth rate exceeding 12% annually. Smartphones, smart home devices, and wearable technology increasingly incorporate ultrasonic sensors for gesture recognition, presence detection, and automated control systems. This trend is expected to continue as consumer demand for touchless interfaces grows, particularly following global health concerns that have heightened interest in contactless technologies.

Healthcare applications represent a specialized but rapidly expanding market segment. Ultrasonic proximity sensors are utilized in medical equipment for fluid level detection, air bubble detection in IV lines, and patient monitoring systems. The market for medical-grade ultrasonic sensors is projected to grow at 10.5% annually through 2028, driven by increasing healthcare automation and remote patient monitoring requirements.

Regionally, Asia-Pacific dominates the ultrasonic proximity sensor market with approximately 42% share, followed by North America (27%) and Europe (23%). China and South Korea lead manufacturing capacity, while significant R&D investments come from Japan, Germany, and the United States. Emerging economies in Southeast Asia and India are experiencing the fastest adoption rates as their manufacturing sectors modernize and automotive production increases.

Automotive applications constitute the largest market segment for ultrasonic proximity sensors, accounting for roughly 35% of the total market share. These sensors are extensively deployed in parking assistance systems, blind-spot detection, and collision avoidance mechanisms. The automotive industry's rapid shift toward advanced driver-assistance systems (ADAS) and autonomous vehicles has substantially increased demand for high-precision ultrasonic sensors capable of accurate distance measurement in various weather conditions.

Industrial automation represents the second-largest application segment, comprising approximately 28% of the market. Manufacturing facilities utilize ultrasonic proximity sensors for object detection, level measurement, and machine safeguarding. The Industry 4.0 revolution has accelerated adoption rates as factories increasingly implement smart manufacturing processes requiring reliable sensing technologies for automation and safety compliance.

Consumer electronics applications have emerged as the fastest-growing segment, with a growth rate exceeding 12% annually. Smartphones, smart home devices, and wearable technology increasingly incorporate ultrasonic sensors for gesture recognition, presence detection, and automated control systems. This trend is expected to continue as consumer demand for touchless interfaces grows, particularly following global health concerns that have heightened interest in contactless technologies.

Healthcare applications represent a specialized but rapidly expanding market segment. Ultrasonic proximity sensors are utilized in medical equipment for fluid level detection, air bubble detection in IV lines, and patient monitoring systems. The market for medical-grade ultrasonic sensors is projected to grow at 10.5% annually through 2028, driven by increasing healthcare automation and remote patient monitoring requirements.

Regionally, Asia-Pacific dominates the ultrasonic proximity sensor market with approximately 42% share, followed by North America (27%) and Europe (23%). China and South Korea lead manufacturing capacity, while significant R&D investments come from Japan, Germany, and the United States. Emerging economies in Southeast Asia and India are experiencing the fastest adoption rates as their manufacturing sectors modernize and automotive production increases.

Current Ultrasonic Sensor Technologies and Limitations

Ultrasonic sensor technology has evolved significantly over the past decades, with current solutions offering varying degrees of accuracy, range, and reliability for proximity detection applications. The predominant technology in the market utilizes piezoelectric transducers that convert electrical energy into ultrasonic waves and vice versa. These sensors typically operate in the frequency range of 40 kHz to 400 kHz, with lower frequencies providing longer detection ranges but reduced resolution.

The market currently offers three main types of ultrasonic sensors for proximity detection: through-beam sensors, retro-reflective sensors, and diffuse reflection sensors. Through-beam sensors consist of separate transmitter and receiver units, offering high reliability but requiring more complex installation. Retro-reflective sensors combine the transmitter and receiver in one unit but require a reflector on the opposite side. Diffuse reflection sensors are the most commonly used, as they rely on the target object itself to reflect the ultrasonic waves back to the sensor.

Despite their widespread adoption, current ultrasonic sensor technologies face several limitations. Environmental factors significantly impact performance, with temperature fluctuations causing variations in the speed of sound and consequently affecting measurement accuracy. Humidity levels and air pressure changes can similarly distort readings, requiring compensation algorithms in advanced models. Additionally, highly absorbent materials like foam or fabric may not reflect sufficient ultrasonic energy for reliable detection.

Another critical limitation is the "blind zone" phenomenon, where objects too close to the sensor cannot be detected due to transducer ringing effects. This zone typically ranges from a few millimeters to several centimeters depending on the sensor design. Cross-talk interference between multiple sensors operating in proximity presents another challenge, particularly in applications requiring sensor arrays.

Resolution constraints also affect current technologies, with most commercial sensors offering resolution in the millimeter range, which may be insufficient for high-precision applications. Response time limitations further restrict their use in scenarios requiring real-time detection of fast-moving objects, as most sensors have response times in the tens of milliseconds.

Power consumption remains a concern for battery-operated applications, with most ultrasonic sensors requiring between 20-100mA during operation. Miniaturization efforts have produced smaller sensors, but often at the cost of reduced range or accuracy. Recent advancements include the integration of temperature compensation, multi-point calibration, and digital signal processing to mitigate some of these limitations, but fundamental physical constraints of ultrasonic wave propagation continue to present challenges for next-generation applications.

The market currently offers three main types of ultrasonic sensors for proximity detection: through-beam sensors, retro-reflective sensors, and diffuse reflection sensors. Through-beam sensors consist of separate transmitter and receiver units, offering high reliability but requiring more complex installation. Retro-reflective sensors combine the transmitter and receiver in one unit but require a reflector on the opposite side. Diffuse reflection sensors are the most commonly used, as they rely on the target object itself to reflect the ultrasonic waves back to the sensor.

Despite their widespread adoption, current ultrasonic sensor technologies face several limitations. Environmental factors significantly impact performance, with temperature fluctuations causing variations in the speed of sound and consequently affecting measurement accuracy. Humidity levels and air pressure changes can similarly distort readings, requiring compensation algorithms in advanced models. Additionally, highly absorbent materials like foam or fabric may not reflect sufficient ultrasonic energy for reliable detection.

Another critical limitation is the "blind zone" phenomenon, where objects too close to the sensor cannot be detected due to transducer ringing effects. This zone typically ranges from a few millimeters to several centimeters depending on the sensor design. Cross-talk interference between multiple sensors operating in proximity presents another challenge, particularly in applications requiring sensor arrays.

Resolution constraints also affect current technologies, with most commercial sensors offering resolution in the millimeter range, which may be insufficient for high-precision applications. Response time limitations further restrict their use in scenarios requiring real-time detection of fast-moving objects, as most sensors have response times in the tens of milliseconds.

Power consumption remains a concern for battery-operated applications, with most ultrasonic sensors requiring between 20-100mA during operation. Miniaturization efforts have produced smaller sensors, but often at the cost of reduced range or accuracy. Recent advancements include the integration of temperature compensation, multi-point calibration, and digital signal processing to mitigate some of these limitations, but fundamental physical constraints of ultrasonic wave propagation continue to present challenges for next-generation applications.

Practical Implementation Approaches for Ultrasonic Sensors

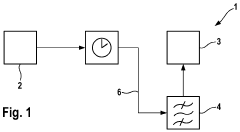

01 Ultrasonic sensor configurations for proximity detection

Various configurations of ultrasonic sensors can be implemented for proximity detection applications. These configurations include single or multiple transducer arrangements, different mounting positions, and specialized housing designs that optimize the emission and reception of ultrasonic waves. The sensor configurations can be tailored to specific environments and detection requirements, enhancing the accuracy and reliability of proximity detection systems.- Ultrasonic sensor systems for vehicle proximity detection: Ultrasonic sensors are implemented in vehicle systems to detect the proximity of objects around the vehicle. These systems use ultrasonic waves to measure distances to obstacles, helping with parking assistance, collision avoidance, and blind spot detection. The sensors emit sound waves and analyze the reflected signals to determine the distance to nearby objects, providing drivers with real-time feedback about their surroundings.

- Ultrasonic proximity detection for mobile devices: Mobile devices incorporate ultrasonic sensors for proximity detection to enable touchless interactions and presence sensing. These systems can detect when a user is near the device, allowing for features such as automatic screen activation, gesture recognition, and power management. The technology uses ultrasonic pulses to detect movement and presence within a defined range, enhancing user experience while conserving battery life.

- Industrial automation and safety applications: Ultrasonic proximity sensors are utilized in industrial settings for automation, safety monitoring, and process control. These sensors provide non-contact detection of objects, materials, or personnel in manufacturing environments. They can function reliably in harsh conditions where optical sensors might fail, such as dusty or poorly lit areas. Applications include conveyor monitoring, level detection in tanks, and safety perimeters around robotic equipment.

- Advanced signal processing techniques for ultrasonic proximity detection: Sophisticated signal processing algorithms enhance the accuracy and reliability of ultrasonic proximity detection systems. These techniques include noise filtering, echo discrimination, multi-sensor fusion, and adaptive threshold adjustment. By implementing advanced processing methods, ultrasonic sensors can provide more precise distance measurements, better object classification, and improved performance in challenging environments with multiple reflective surfaces or ambient noise.

- Miniaturized and integrated ultrasonic proximity sensors: Compact ultrasonic proximity sensors are designed for integration into small electronic devices and confined spaces. These miniaturized sensors combine transducers, control circuitry, and signal processing in space-efficient packages. Technological advancements have enabled the development of MEMS-based ultrasonic sensors that offer reduced power consumption, smaller form factors, and enhanced sensitivity, making them suitable for wearable devices, IoT applications, and consumer electronics.

02 Signal processing techniques for ultrasonic proximity sensors

Advanced signal processing techniques improve the performance of ultrasonic proximity detection systems. These techniques include filtering algorithms to reduce noise, signal amplification methods, echo analysis, and time-of-flight calculations to determine distance accurately. Digital signal processing enables the differentiation between actual targets and false echoes, enhancing the reliability of proximity detection in challenging environments.Expand Specific Solutions03 Integration of ultrasonic sensors in mobile and wearable devices

Ultrasonic sensors are increasingly integrated into mobile phones, wearable technology, and portable devices for proximity detection applications. These implementations enable gesture recognition, presence detection, and automated responses based on user proximity. The miniaturization of ultrasonic transducers allows for seamless integration into compact devices while maintaining detection accuracy and power efficiency.Expand Specific Solutions04 Automotive applications of ultrasonic proximity detection

Ultrasonic sensors play a crucial role in automotive proximity detection systems, including parking assistance, collision avoidance, and blind spot monitoring. These sensors can detect obstacles around the vehicle perimeter and provide distance information to driver assistance systems. Advanced implementations include multi-sensor arrays for comprehensive coverage and integration with other sensing technologies for enhanced situational awareness.Expand Specific Solutions05 Industrial and security applications of ultrasonic proximity sensing

Ultrasonic proximity sensors are widely used in industrial automation and security systems. In industrial settings, they enable precise object detection, level measurement, and machine safety applications. For security purposes, these sensors can detect unauthorized presence, monitor restricted areas, and trigger alarm systems. The sensors can be designed to operate in harsh environments with resistance to dust, moisture, and temperature variations.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The ultrasonic sensor market for proximity detection is currently in a growth phase, with established players like Robert Bosch GmbH and Valeo Schalter und Sensoren GmbH dominating the automotive segment, while consumer electronics manufacturers such as Samsung, OPPO, and vivo are increasingly integrating this technology. The market is projected to expand significantly due to rising applications in autonomous vehicles, robotics, and IoT devices. Technologically, companies like Elliptic Laboratories and Murata Manufacturing are advancing sensor capabilities through AI integration and miniaturization, while automotive specialists like Bosch and Elmos Semiconductor lead in high-precision industrial applications. Emerging players from China are rapidly gaining market share by offering cost-effective solutions with competitive performance characteristics.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced ultrasonic sensor systems for proximity detection that utilize multiple transducers arranged in arrays to provide comprehensive coverage around vehicles and industrial equipment. Their technology employs time-of-flight measurement with proprietary signal processing algorithms that filter out environmental noise and cross-talk between sensors. Bosch's ultrasonic sensors operate in the 40-50 kHz frequency range, offering detection ranges from 2cm to 5.5m with precision of ±1cm. Their latest generation incorporates temperature compensation mechanisms to maintain accuracy across varying environmental conditions (-40°C to +85°C) and features integrated diagnostic capabilities that continuously monitor sensor performance. Bosch has also implemented adaptive power management that reduces energy consumption by up to 30% compared to previous generations while maintaining detection reliability.

Strengths: Superior noise filtering algorithms provide reliable detection even in challenging environments; comprehensive temperature compensation ensures consistent performance across extreme conditions; highly integrated design reduces implementation complexity. Weaknesses: Higher cost compared to simpler solutions; requires more sophisticated integration with host systems; power consumption still relatively high for battery-powered applications.

Valeo Schalter und Sensoren GmbH

Technical Solution: Valeo has pioneered ultrasonic sensor technology specifically optimized for automotive applications with their SCALA® sensor family. Their proximity detection system employs multiple ultrasonic transducers operating at 48kHz with specialized beam patterns designed to eliminate blind spots around vehicles. Valeo's technology incorporates advanced digital signal processing that enables precise object classification and distance measurement with accuracy of ±2cm at ranges up to 4.5m. Their sensors feature proprietary membrane technology that provides enhanced resistance to environmental contaminants such as dirt, ice, and water spray, maintaining performance in adverse weather conditions. Valeo has also developed multi-echo processing algorithms that can distinguish between multiple objects in the sensor's field of view, enabling more sophisticated proximity awareness in complex environments. The latest generation includes self-cleaning mechanisms and built-in diagnostics that continuously monitor sensor health.

Strengths: Exceptional environmental robustness suitable for harsh automotive conditions; sophisticated object classification capabilities; proven reliability with over 500 million units deployed globally. Weaknesses: Relatively narrow application focus primarily on automotive use cases; higher power requirements compared to simpler proximity sensors; integration complexity requires specialized expertise.

Key Technical Parameters and Selection Criteria

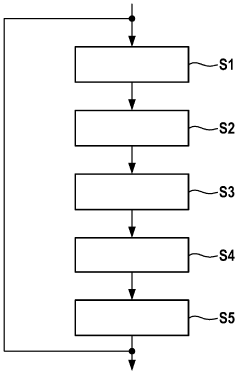

Ultrasonic sensor and method for operating an ultrasonic sensor

PatentWO2010028919A1

Innovation

- The ultrasonic sensor employs a switchable reception filter with a larger bandwidth for short-range measurements and a narrower bandwidth for long-range measurements, allowing for high-resolution distance determination by minimizing signal distortion.

Method for detecting an object in a near field of an ultrasonic sensor

PatentInactiveEP3132280A1

Innovation

- The method involves exciting an acoustic transducer with a transmission signal, detecting the decay signal, determining the deviation between the decay signal and a reference signal, and recognizing the presence of an object based on this deviation, which allows for reliable detection in the short range where echo superposition occurs.

Environmental Factors Affecting Sensor Performance

Ultrasonic sensors, while highly effective for proximity detection, are significantly influenced by various environmental factors that can alter their performance characteristics. Temperature variations represent one of the most critical factors affecting these sensors. As ambient temperature changes, the speed of sound in air fluctuates approximately 0.6 meters per second for each degree Celsius change. This variation directly impacts the accuracy of distance measurements, potentially causing significant errors in applications requiring precise detection.

Humidity levels similarly affect ultrasonic wave propagation. Higher humidity increases air density, which generally improves signal transmission efficiency. However, extreme humidity conditions, particularly condensation on the sensor surface, can dampen the ultrasonic signals and reduce detection reliability. Systems deployed in environments with fluctuating humidity levels should incorporate compensation algorithms to maintain consistent performance.

Atmospheric pressure variations, though less impactful than temperature, also influence ultrasonic sensor readings. Lower pressure at higher altitudes results in reduced air density, affecting sound wave propagation characteristics and potentially requiring calibration adjustments for accurate operation.

Air turbulence and strong air currents present another challenge for ultrasonic sensing systems. Moving air can deflect or distort ultrasonic waves, creating signal inconsistencies and false readings. In industrial environments with ventilation systems or outdoor applications exposed to wind, protective housings or strategic sensor placement may be necessary to minimize these effects.

Ambient noise poses a significant challenge, particularly in industrial settings. Machinery vibrations, pneumatic systems, and other ultrasonic sources can generate interference within the sensor's operating frequency range. Modern sensors incorporate various noise rejection techniques, including frequency filtering, signal averaging, and adaptive threshold algorithms, though particularly noisy environments may still require additional shielding or specialized sensor variants.

Dust, particulate matter, and aerosols in the detection path can absorb or scatter ultrasonic waves, reducing the effective range and reliability of proximity detection. This consideration is especially important in manufacturing environments, construction sites, or outdoor applications where air quality cannot be controlled. Regular maintenance protocols and appropriate IP-rated enclosures should be implemented to protect sensor elements from contamination.

Surface characteristics of target objects also significantly influence detection performance. Smooth, hard surfaces reflect ultrasonic waves effectively, while soft, irregular, or sound-absorbing materials may scatter or absorb signals, resulting in weak echo returns and detection failures. Understanding these material limitations is crucial when selecting appropriate sensors for specific applications.

Humidity levels similarly affect ultrasonic wave propagation. Higher humidity increases air density, which generally improves signal transmission efficiency. However, extreme humidity conditions, particularly condensation on the sensor surface, can dampen the ultrasonic signals and reduce detection reliability. Systems deployed in environments with fluctuating humidity levels should incorporate compensation algorithms to maintain consistent performance.

Atmospheric pressure variations, though less impactful than temperature, also influence ultrasonic sensor readings. Lower pressure at higher altitudes results in reduced air density, affecting sound wave propagation characteristics and potentially requiring calibration adjustments for accurate operation.

Air turbulence and strong air currents present another challenge for ultrasonic sensing systems. Moving air can deflect or distort ultrasonic waves, creating signal inconsistencies and false readings. In industrial environments with ventilation systems or outdoor applications exposed to wind, protective housings or strategic sensor placement may be necessary to minimize these effects.

Ambient noise poses a significant challenge, particularly in industrial settings. Machinery vibrations, pneumatic systems, and other ultrasonic sources can generate interference within the sensor's operating frequency range. Modern sensors incorporate various noise rejection techniques, including frequency filtering, signal averaging, and adaptive threshold algorithms, though particularly noisy environments may still require additional shielding or specialized sensor variants.

Dust, particulate matter, and aerosols in the detection path can absorb or scatter ultrasonic waves, reducing the effective range and reliability of proximity detection. This consideration is especially important in manufacturing environments, construction sites, or outdoor applications where air quality cannot be controlled. Regular maintenance protocols and appropriate IP-rated enclosures should be implemented to protect sensor elements from contamination.

Surface characteristics of target objects also significantly influence detection performance. Smooth, hard surfaces reflect ultrasonic waves effectively, while soft, irregular, or sound-absorbing materials may scatter or absorb signals, resulting in weak echo returns and detection failures. Understanding these material limitations is crucial when selecting appropriate sensors for specific applications.

Cost-Benefit Analysis of Sensor Options

When evaluating ultrasonic sensors for proximity detection applications, a comprehensive cost-benefit analysis is essential to ensure optimal selection based on project requirements and budget constraints. Initial acquisition costs vary significantly across sensor types, with basic models starting around $5-15 for simple distance measurement, while advanced industrial-grade sensors with enhanced features can range from $50 to several hundred dollars. However, focusing solely on purchase price provides an incomplete picture of the total cost of ownership.

Installation and integration expenses must be factored into the equation, including mounting hardware, wiring, and potential system modifications. Sensors requiring specialized mounting arrangements or complex integration with existing systems may incur additional costs that outweigh initial savings from cheaper models. Furthermore, maintenance requirements differ substantially between consumer and industrial-grade sensors, with the latter typically offering longer service intervals but at higher initial investment.

Power consumption represents another critical cost factor, particularly for battery-operated or energy-efficient systems. Low-power ultrasonic sensors may command premium prices but deliver significant long-term savings through reduced energy costs and extended battery life. This becomes especially relevant in remote installations or applications requiring continuous operation.

Performance benefits must be weighed against these costs to determine true value. Higher-priced sensors generally offer superior detection range, accuracy, and resolution. For instance, premium ultrasonic sensors may provide detection ranges exceeding 10 meters with accuracy within millimeters, while budget options might be limited to 2-3 meters with centimeter-level precision. Applications requiring precise object detection or fine distance measurement justify the additional investment in higher-quality sensors.

Environmental resilience presents another important consideration in the cost-benefit equation. Industrial environments with extreme temperatures, moisture, dust, or vibration demand ruggedized sensors with appropriate IP ratings. While these protected sensors command higher prices, they avoid costly failures and replacements that would plague less robust alternatives in challenging conditions.

Reliability metrics such as Mean Time Between Failures (MTBF) should be evaluated against application criticality. Mission-critical systems justify investment in sensors with proven reliability records and manufacturer support, even at premium prices. Conversely, non-critical applications may tolerate occasional sensor failures if replacement costs remain lower than investing in premium alternatives.

The optimal selection ultimately depends on balancing these factors against specific application requirements, with consideration for both immediate budget constraints and long-term operational costs. This holistic approach ensures the selected ultrasonic sensor delivers maximum value throughout its operational lifecycle.

Installation and integration expenses must be factored into the equation, including mounting hardware, wiring, and potential system modifications. Sensors requiring specialized mounting arrangements or complex integration with existing systems may incur additional costs that outweigh initial savings from cheaper models. Furthermore, maintenance requirements differ substantially between consumer and industrial-grade sensors, with the latter typically offering longer service intervals but at higher initial investment.

Power consumption represents another critical cost factor, particularly for battery-operated or energy-efficient systems. Low-power ultrasonic sensors may command premium prices but deliver significant long-term savings through reduced energy costs and extended battery life. This becomes especially relevant in remote installations or applications requiring continuous operation.

Performance benefits must be weighed against these costs to determine true value. Higher-priced sensors generally offer superior detection range, accuracy, and resolution. For instance, premium ultrasonic sensors may provide detection ranges exceeding 10 meters with accuracy within millimeters, while budget options might be limited to 2-3 meters with centimeter-level precision. Applications requiring precise object detection or fine distance measurement justify the additional investment in higher-quality sensors.

Environmental resilience presents another important consideration in the cost-benefit equation. Industrial environments with extreme temperatures, moisture, dust, or vibration demand ruggedized sensors with appropriate IP ratings. While these protected sensors command higher prices, they avoid costly failures and replacements that would plague less robust alternatives in challenging conditions.

Reliability metrics such as Mean Time Between Failures (MTBF) should be evaluated against application criticality. Mission-critical systems justify investment in sensors with proven reliability records and manufacturer support, even at premium prices. Conversely, non-critical applications may tolerate occasional sensor failures if replacement costs remain lower than investing in premium alternatives.

The optimal selection ultimately depends on balancing these factors against specific application requirements, with consideration for both immediate budget constraints and long-term operational costs. This holistic approach ensures the selected ultrasonic sensor delivers maximum value throughout its operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!