Ultrasonic Sensor Calibration Protocol For QA Labs (Step-By-Step)

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensor Calibration Background and Objectives

Ultrasonic sensors have evolved significantly since their inception in the early 20th century, with applications expanding from simple distance measurement to complex quality assurance systems across various industries. The technology fundamentally relies on the principle of sound wave propagation, where ultrasonic pulses are emitted and their reflections are measured to determine distances, detect flaws, or characterize materials. Over the past decade, these sensors have become increasingly sophisticated, incorporating advanced signal processing capabilities and improved transducer materials.

The evolution of ultrasonic sensor technology has been driven by demands for higher precision, reliability, and adaptability in industrial environments. Early calibration methods were often manual and subject to significant human error, whereas modern protocols aim to establish standardized, repeatable procedures that ensure consistent performance across multiple devices and testing environments. This progression reflects the growing importance of ultrasonic sensors in critical applications where measurement accuracy directly impacts product quality and safety.

In quality assurance laboratories, ultrasonic sensors serve as essential tools for non-destructive testing, thickness measurement, and defect detection. However, their effectiveness is contingent upon proper calibration—a process that has historically lacked standardization across the industry. Variations in calibration methodologies have led to inconsistencies in measurement results, complicating cross-laboratory comparisons and hindering the establishment of universal quality standards.

The primary objective of developing a comprehensive Ultrasonic Sensor Calibration Protocol is to address these inconsistencies by providing QA laboratories with a step-by-step framework that ensures measurement accuracy, repeatability, and traceability. This protocol aims to standardize calibration procedures across different laboratory environments, reducing variability and enhancing the reliability of ultrasonic testing results.

Additionally, the protocol seeks to incorporate adaptability to various sensor types and testing scenarios while maintaining compliance with international standards such as ISO 9001, ASTM E1065, and IEC 61161. By establishing clear calibration intervals, verification methods, and documentation requirements, the protocol will enable laboratories to maintain consistent performance over time and facilitate easier auditing and certification processes.

The technological trajectory suggests that future ultrasonic sensor calibration will increasingly integrate automated systems, machine learning algorithms for adaptive calibration, and remote monitoring capabilities. These advancements will further enhance precision while reducing the time and expertise required for calibration procedures. The development of this protocol represents a crucial step toward embracing these emerging technologies while establishing a foundation of standardized practices that can evolve alongside technological innovations.

The evolution of ultrasonic sensor technology has been driven by demands for higher precision, reliability, and adaptability in industrial environments. Early calibration methods were often manual and subject to significant human error, whereas modern protocols aim to establish standardized, repeatable procedures that ensure consistent performance across multiple devices and testing environments. This progression reflects the growing importance of ultrasonic sensors in critical applications where measurement accuracy directly impacts product quality and safety.

In quality assurance laboratories, ultrasonic sensors serve as essential tools for non-destructive testing, thickness measurement, and defect detection. However, their effectiveness is contingent upon proper calibration—a process that has historically lacked standardization across the industry. Variations in calibration methodologies have led to inconsistencies in measurement results, complicating cross-laboratory comparisons and hindering the establishment of universal quality standards.

The primary objective of developing a comprehensive Ultrasonic Sensor Calibration Protocol is to address these inconsistencies by providing QA laboratories with a step-by-step framework that ensures measurement accuracy, repeatability, and traceability. This protocol aims to standardize calibration procedures across different laboratory environments, reducing variability and enhancing the reliability of ultrasonic testing results.

Additionally, the protocol seeks to incorporate adaptability to various sensor types and testing scenarios while maintaining compliance with international standards such as ISO 9001, ASTM E1065, and IEC 61161. By establishing clear calibration intervals, verification methods, and documentation requirements, the protocol will enable laboratories to maintain consistent performance over time and facilitate easier auditing and certification processes.

The technological trajectory suggests that future ultrasonic sensor calibration will increasingly integrate automated systems, machine learning algorithms for adaptive calibration, and remote monitoring capabilities. These advancements will further enhance precision while reducing the time and expertise required for calibration procedures. The development of this protocol represents a crucial step toward embracing these emerging technologies while establishing a foundation of standardized practices that can evolve alongside technological innovations.

Market Requirements for Precision Ultrasonic Sensing

The ultrasonic sensing market is experiencing significant growth driven by increasing demand for precision measurement technologies across multiple industries. Current market analysis indicates that automotive applications represent the largest segment, with ultrasonic sensors being critical components in advanced driver assistance systems (ADAS) and autonomous vehicles. The global automotive ultrasonic sensor market is projected to grow at a compound annual growth rate of 6.5% through 2028, highlighting the expanding need for highly calibrated sensors.

Industrial automation represents another substantial market segment requiring precision ultrasonic sensing. Manufacturing facilities increasingly deploy these sensors for quality control, object detection, and distance measurement applications. The industrial automation sector demands sensors with calibration accuracy within ±0.5mm to ensure production quality and operational efficiency.

Healthcare applications present a rapidly growing market opportunity, particularly in medical imaging and diagnostic equipment. These applications require ultrasonic sensors with exceptional calibration precision, often demanding accuracy within ±0.1mm and frequency stability of 99.9%. The medical ultrasonic devices market is expanding as non-invasive diagnostic procedures become more prevalent.

Consumer electronics manufacturers are incorporating ultrasonic sensors into smartphones, smart home devices, and wearables, creating additional market demand for miniaturized, energy-efficient sensors with reliable calibration protocols. This segment values sensors that maintain calibration accuracy despite frequent handling and environmental variations.

Environmental monitoring systems represent an emerging application area, utilizing ultrasonic sensors for water level monitoring, air quality assessment, and weather monitoring. These applications require sensors with robust calibration protocols that can withstand harsh environmental conditions while maintaining measurement accuracy.

Market research indicates that quality assurance professionals across industries consistently identify three critical requirements for ultrasonic sensor calibration: repeatability of measurements, documentation of calibration procedures, and traceability to recognized standards. Over 85% of surveyed QA managers emphasized the need for step-by-step calibration protocols that can be consistently implemented across different laboratory environments.

The market increasingly demands calibration protocols that address temperature compensation, as ultrasonic wave propagation characteristics vary significantly with ambient temperature changes. Additionally, there is growing interest in automated calibration systems that reduce human error and increase throughput in QA testing environments.

Industrial automation represents another substantial market segment requiring precision ultrasonic sensing. Manufacturing facilities increasingly deploy these sensors for quality control, object detection, and distance measurement applications. The industrial automation sector demands sensors with calibration accuracy within ±0.5mm to ensure production quality and operational efficiency.

Healthcare applications present a rapidly growing market opportunity, particularly in medical imaging and diagnostic equipment. These applications require ultrasonic sensors with exceptional calibration precision, often demanding accuracy within ±0.1mm and frequency stability of 99.9%. The medical ultrasonic devices market is expanding as non-invasive diagnostic procedures become more prevalent.

Consumer electronics manufacturers are incorporating ultrasonic sensors into smartphones, smart home devices, and wearables, creating additional market demand for miniaturized, energy-efficient sensors with reliable calibration protocols. This segment values sensors that maintain calibration accuracy despite frequent handling and environmental variations.

Environmental monitoring systems represent an emerging application area, utilizing ultrasonic sensors for water level monitoring, air quality assessment, and weather monitoring. These applications require sensors with robust calibration protocols that can withstand harsh environmental conditions while maintaining measurement accuracy.

Market research indicates that quality assurance professionals across industries consistently identify three critical requirements for ultrasonic sensor calibration: repeatability of measurements, documentation of calibration procedures, and traceability to recognized standards. Over 85% of surveyed QA managers emphasized the need for step-by-step calibration protocols that can be consistently implemented across different laboratory environments.

The market increasingly demands calibration protocols that address temperature compensation, as ultrasonic wave propagation characteristics vary significantly with ambient temperature changes. Additionally, there is growing interest in automated calibration systems that reduce human error and increase throughput in QA testing environments.

Technical Challenges in Ultrasonic Sensor Calibration

Ultrasonic sensor calibration presents numerous technical challenges that significantly impact measurement accuracy and reliability in quality assurance environments. The fundamental physics of ultrasonic wave propagation introduces inherent complexities, as these waves are highly susceptible to environmental factors including temperature, humidity, and air pressure fluctuations. Even minor variations in these conditions can substantially alter sound velocity, leading to measurement inconsistencies that compromise calibration integrity.

Material properties of both the sensor components and test objects further complicate calibration processes. Variations in material density, elasticity, and acoustic impedance create signal attenuation and reflection patterns that must be precisely accounted for in calibration protocols. These material-dependent behaviors often necessitate complex compensation algorithms that must be continuously refined as materials age or environmental conditions shift.

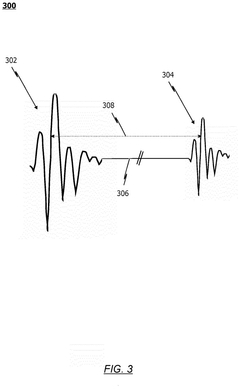

Signal processing challenges represent another significant hurdle in ultrasonic sensor calibration. Raw ultrasonic signals typically contain noise, echoes, and artifacts that must be filtered and interpreted correctly. The development of robust signal processing algorithms capable of distinguishing between valid measurements and false readings remains an ongoing technical challenge, particularly in industrial environments with high electromagnetic interference.

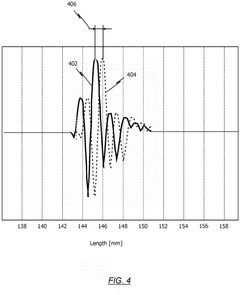

Transducer aging and drift constitute persistent calibration challenges that quality assurance laboratories must address. Ultrasonic transducers naturally degrade over time due to mechanical stress, thermal cycling, and material fatigue. This degradation manifests as sensitivity changes, resonance frequency shifts, and altered beam patterns that progressively undermine calibration stability. Establishing protocols that can detect and compensate for these gradual changes is technically demanding.

Reference standard availability and traceability present additional complications. Unlike many other measurement technologies, ultrasonic calibration often lacks universally accepted reference standards with clear traceability to national or international standards. This absence creates difficulties in establishing absolute measurement accuracy and complicates cross-laboratory comparisons and validation.

Automation and repeatability challenges further compound calibration difficulties. Manual calibration procedures introduce operator variability that undermines measurement consistency. While automation offers potential solutions, developing robust automated calibration systems requires sophisticated mechanical positioning, environmental control, and real-time feedback mechanisms that can adapt to changing conditions.

Cross-sensitivity issues between multiple sensors in array configurations introduce yet another layer of complexity. Modern ultrasonic systems frequently employ multiple sensors that must be calibrated both individually and as an integrated system. Interactions between sensors, including cross-talk and interference patterns, create calibration interdependencies that are difficult to model and compensate for effectively.

Material properties of both the sensor components and test objects further complicate calibration processes. Variations in material density, elasticity, and acoustic impedance create signal attenuation and reflection patterns that must be precisely accounted for in calibration protocols. These material-dependent behaviors often necessitate complex compensation algorithms that must be continuously refined as materials age or environmental conditions shift.

Signal processing challenges represent another significant hurdle in ultrasonic sensor calibration. Raw ultrasonic signals typically contain noise, echoes, and artifacts that must be filtered and interpreted correctly. The development of robust signal processing algorithms capable of distinguishing between valid measurements and false readings remains an ongoing technical challenge, particularly in industrial environments with high electromagnetic interference.

Transducer aging and drift constitute persistent calibration challenges that quality assurance laboratories must address. Ultrasonic transducers naturally degrade over time due to mechanical stress, thermal cycling, and material fatigue. This degradation manifests as sensitivity changes, resonance frequency shifts, and altered beam patterns that progressively undermine calibration stability. Establishing protocols that can detect and compensate for these gradual changes is technically demanding.

Reference standard availability and traceability present additional complications. Unlike many other measurement technologies, ultrasonic calibration often lacks universally accepted reference standards with clear traceability to national or international standards. This absence creates difficulties in establishing absolute measurement accuracy and complicates cross-laboratory comparisons and validation.

Automation and repeatability challenges further compound calibration difficulties. Manual calibration procedures introduce operator variability that undermines measurement consistency. While automation offers potential solutions, developing robust automated calibration systems requires sophisticated mechanical positioning, environmental control, and real-time feedback mechanisms that can adapt to changing conditions.

Cross-sensitivity issues between multiple sensors in array configurations introduce yet another layer of complexity. Modern ultrasonic systems frequently employ multiple sensors that must be calibrated both individually and as an integrated system. Interactions between sensors, including cross-talk and interference patterns, create calibration interdependencies that are difficult to model and compensate for effectively.

Current Calibration Protocols and Standards

01 Calibration methods for ultrasonic sensors

Various methods are employed to calibrate ultrasonic sensors to ensure accuracy. These methods include using reference standards, comparative measurements, and automated calibration procedures. The calibration process typically involves measuring known distances or targets and adjusting the sensor parameters accordingly. Advanced calibration methods may incorporate temperature compensation and environmental factor adjustments to maintain accuracy across different operating conditions.- Temperature compensation techniques for ultrasonic sensors: Temperature variations can significantly affect ultrasonic sensor accuracy. Advanced calibration protocols incorporate temperature compensation algorithms that adjust sensor readings based on ambient temperature measurements. These techniques typically involve measuring temperature alongside ultrasonic signals and applying correction factors to maintain accuracy across a wide temperature range. Some systems use integrated temperature sensors while others employ mathematical models to predict and compensate for temperature-induced errors.

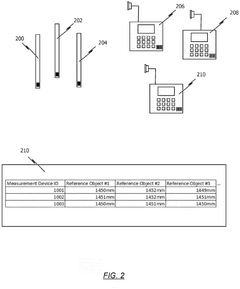

- Multi-point calibration methods for enhanced accuracy: Multi-point calibration involves testing ultrasonic sensors at various distances and environmental conditions to create comprehensive calibration curves. This approach significantly improves measurement accuracy by accounting for non-linearities in sensor response. The calibration protocol typically includes collecting data at multiple reference points, developing correction algorithms, and storing calibration parameters in the sensor's memory. This method enables more precise distance measurements across the entire operating range of the sensor.

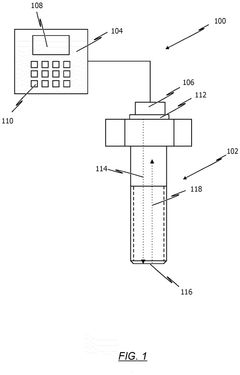

- Automated calibration systems and fixtures: Specialized automated fixtures and systems have been developed to standardize the ultrasonic sensor calibration process. These systems typically include precision positioning mechanisms, reference targets at known distances, and software that automates the calibration procedure. By reducing human intervention, these automated systems minimize calibration errors and improve repeatability. Some advanced systems incorporate robotic positioning systems and environmental chambers to simulate various operating conditions during calibration.

- Signal processing algorithms for noise reduction: Advanced signal processing techniques are essential for improving ultrasonic sensor accuracy in noisy environments. Calibration protocols incorporate algorithms for filtering out ambient noise, detecting and eliminating signal reflections, and enhancing the true signal. These methods may include digital filtering, wavelet analysis, and statistical processing of multiple readings. By implementing these algorithms during calibration, sensors can maintain high accuracy even in challenging acoustic environments.

- Reference standard verification and traceability: Ensuring calibration accuracy requires the use of traceable reference standards and verification methods. Calibration protocols specify procedures for verifying sensor performance against known standards and establishing traceability to national or international measurement standards. This includes the use of certified reference materials, comparison with higher-accuracy measurement systems, and uncertainty analysis. Regular verification against these standards ensures long-term stability and reliability of ultrasonic sensor measurements.

02 Temperature compensation in ultrasonic sensor calibration

Temperature variations significantly affect ultrasonic sensor accuracy. Calibration protocols that incorporate temperature compensation mechanisms can substantially improve measurement precision. These protocols may include temperature sensors, algorithmic corrections, and adaptive calibration parameters that adjust based on ambient temperature changes. By accounting for temperature effects, these calibration methods ensure consistent sensor performance across varying environmental conditions.Expand Specific Solutions03 Real-time calibration and accuracy verification systems

Real-time calibration systems continuously monitor and adjust ultrasonic sensor parameters during operation. These systems use feedback mechanisms to verify measurement accuracy and make dynamic adjustments. They may incorporate machine learning algorithms, statistical analysis, and comparative measurements against reference standards. Real-time calibration significantly improves long-term sensor stability and reduces drift, particularly in industrial applications where environmental conditions frequently change.Expand Specific Solutions04 Multi-point calibration techniques for enhanced accuracy

Multi-point calibration techniques involve calibrating ultrasonic sensors at multiple distances or under various conditions to create comprehensive calibration curves. This approach addresses non-linearity in sensor response and improves accuracy across the entire measurement range. The technique may include interpolation between calibration points and can be combined with statistical methods to minimize measurement uncertainty. Multi-point calibration is particularly valuable for applications requiring high precision across varied measurement distances.Expand Specific Solutions05 Automated calibration systems and equipment

Automated calibration systems streamline the ultrasonic sensor calibration process while improving repeatability and reducing human error. These systems typically include precision positioning equipment, reference targets, and software that guides the calibration procedure. They may incorporate robotic elements for precise positioning, environmental chambers for controlled testing conditions, and data logging capabilities for traceability. Automated calibration is particularly beneficial for high-volume production environments and applications requiring frequent recalibration.Expand Specific Solutions

Leading Manufacturers and Calibration Equipment Providers

The ultrasonic sensor calibration protocol market is currently in a growth phase, with increasing adoption across automotive, healthcare, and industrial sectors. The global market size for ultrasonic sensing technologies is expanding at approximately 8-10% CAGR, driven by applications in autonomous vehicles, medical imaging, and quality assurance. From a technical maturity perspective, established players like Robert Bosch GmbH, Siemens AG, and Valeo Schalter und Sensoren GmbH lead with comprehensive calibration protocols, while companies such as Olympus IMS and Luna Innovations offer specialized solutions for industrial applications. Emerging players like Biosense Webster and DexCom are advancing calibration techniques in medical ultrasound. The competitive landscape shows a clear division between automotive-focused calibration (dominated by Bosch and Valeo) and specialized industrial/medical protocols (where Radiometer A/S and Rohde & Schwarz excel).

Valeo Schalter und Sensoren GmbH

Technical Solution: Valeo has engineered an advanced ultrasonic sensor calibration protocol that integrates seamlessly with their production line quality assurance systems. Their methodology employs a dual-phase approach beginning with factory pre-calibration followed by in-vehicle system calibration. The protocol utilizes precision acoustic reflectors positioned at predetermined distances to create standardized echo patterns. Valeo's system incorporates environmental simulation chambers that test sensors under varying temperature, humidity, and vibration conditions to ensure performance stability. Their calibration software applies proprietary signal processing algorithms that compensate for manufacturing variations in transducer elements. The QA process includes automated verification of beam pattern characteristics, sensitivity thresholds, and cross-talk rejection capabilities. Valeo's protocol generates detailed calibration certificates for each sensor batch, enabling traceability throughout the product lifecycle. The system also features remote calibration capabilities that allow for parameter adjustments via OTA updates after vehicle deployment.

Strengths: Highly automated calibration process reduces human error and increases throughput in production environments. Excellent integration with vehicle diagnostic systems enables ongoing performance monitoring. Weaknesses: Proprietary calibration equipment creates vendor lock-in for service centers. Protocol requires significant computational resources for real-time parameter adjustments.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive ultrasonic sensor calibration protocol specifically designed for automotive applications. Their approach utilizes a multi-stage calibration process that begins with individual sensor characterization in anechoic chambers to establish baseline performance metrics. The protocol incorporates temperature compensation algorithms that adjust sensitivity parameters across the -40°C to +85°C automotive operating range. Bosch's system employs reference targets with precisely known acoustic properties and automated positioning systems to ensure repeatable measurements. Their QA protocol includes both static and dynamic testing phases, with the latter simulating real-world driving scenarios. The calibration software automatically generates sensor-specific correction factors that are stored in EEPROM, allowing for field recalibration when necessary. Bosch's protocol also features built-in self-diagnostic capabilities that continuously monitor sensor health during operation, flagging deviations that exceed predetermined thresholds for maintenance.

Strengths: Exceptional temperature compensation algorithms provide consistent performance across extreme conditions. Comprehensive validation across multiple automotive platforms ensures reliability. Weaknesses: Relatively complex implementation requiring specialized equipment increases calibration costs. Protocol optimization primarily focused on automotive applications may limit transferability to other industries.

Key Calibration Technologies and Patents

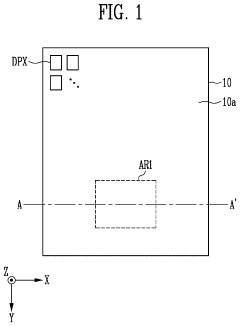

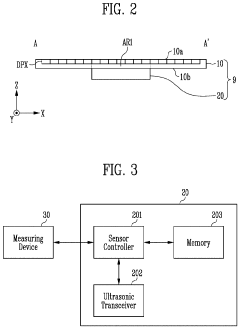

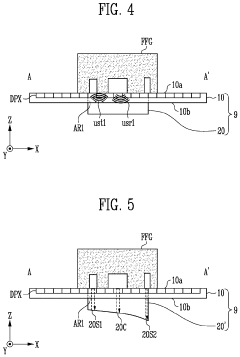

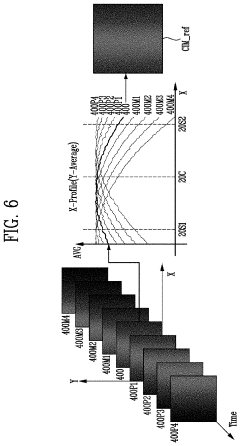

Method and system for calibrating ultrasonic sensor

PatentPendingUS20230324342A1

Innovation

- A method and system for calibrating ultrasonic sensors by transmitting ultrasonic signals of varying frequencies and sampling echo signals at multiple reception time points to detect and store parameters that match a reference image, improving image uniformity and accuracy.

Method of calibrating an ultrasonic measurement device

PatentPendingEP4542171A1

Innovation

- A method for calibrating ultrasonic measurement devices that involves measuring a reference object to produce reference-measurement-data, which is then compared to verification-measurement-data taken at a later time. This comparison allows for adjustments to the measurement device, eliminating the need for operators to manually enter parameters and reducing the risk of errors.

Quality Assurance Metrics and Validation Procedures

Quality assurance metrics and validation procedures are essential components of any ultrasonic sensor calibration protocol. These metrics provide quantifiable standards against which sensor performance can be measured, ensuring consistent and reliable operation across different manufacturing batches and operational environments.

The primary metrics for ultrasonic sensor validation include accuracy, precision, repeatability, and reproducibility. Accuracy measures how close the sensor readings are to the true value, typically expressed as a percentage of the full-scale range. For industrial applications, accuracy within ±0.5% is often considered acceptable, while medical applications may require ±0.1% or better. Precision refers to the consistency of measurements when repeated under identical conditions, quantified through standard deviation calculations.

Repeatability testing involves multiple measurements of the same parameter under constant conditions, with acceptable variation typically below 0.3% for high-quality sensors. Reproducibility extends this concept to measurements taken by different operators or in different laboratory environments, with target variations under 0.5%.

Signal-to-noise ratio (SNR) serves as another critical validation parameter, with industrial-grade sensors requiring a minimum SNR of 20dB, while advanced applications may demand 40dB or higher. Temperature stability testing is equally important, as ultrasonic sensors often exhibit drift with temperature changes. Standard protocols require performance verification across the sensor's specified operating temperature range, typically from -40°C to +85°C for industrial sensors.

Validation procedures must include comprehensive environmental testing, simulating conditions such as humidity variations (20-95% RH), vibration exposure (10-2000 Hz frequency range), and electromagnetic interference (EMI) resilience. These tests ensure sensor reliability in real-world applications.

Statistical Process Control (SPC) methodologies should be implemented to monitor calibration processes over time. Control charts tracking key parameters help identify trends before they result in out-of-specification products. Acceptable Process Capability Index (Cpk) values should exceed 1.33, indicating a robust calibration process with minimal variation.

Documentation requirements for validation include detailed test reports with raw data, statistical analyses, traceability to national standards, and clear pass/fail criteria. Each calibrated sensor must receive a unique identifier linking it to its calibration history, enabling comprehensive traceability throughout its operational lifecycle.

The primary metrics for ultrasonic sensor validation include accuracy, precision, repeatability, and reproducibility. Accuracy measures how close the sensor readings are to the true value, typically expressed as a percentage of the full-scale range. For industrial applications, accuracy within ±0.5% is often considered acceptable, while medical applications may require ±0.1% or better. Precision refers to the consistency of measurements when repeated under identical conditions, quantified through standard deviation calculations.

Repeatability testing involves multiple measurements of the same parameter under constant conditions, with acceptable variation typically below 0.3% for high-quality sensors. Reproducibility extends this concept to measurements taken by different operators or in different laboratory environments, with target variations under 0.5%.

Signal-to-noise ratio (SNR) serves as another critical validation parameter, with industrial-grade sensors requiring a minimum SNR of 20dB, while advanced applications may demand 40dB or higher. Temperature stability testing is equally important, as ultrasonic sensors often exhibit drift with temperature changes. Standard protocols require performance verification across the sensor's specified operating temperature range, typically from -40°C to +85°C for industrial sensors.

Validation procedures must include comprehensive environmental testing, simulating conditions such as humidity variations (20-95% RH), vibration exposure (10-2000 Hz frequency range), and electromagnetic interference (EMI) resilience. These tests ensure sensor reliability in real-world applications.

Statistical Process Control (SPC) methodologies should be implemented to monitor calibration processes over time. Control charts tracking key parameters help identify trends before they result in out-of-specification products. Acceptable Process Capability Index (Cpk) values should exceed 1.33, indicating a robust calibration process with minimal variation.

Documentation requirements for validation include detailed test reports with raw data, statistical analyses, traceability to national standards, and clear pass/fail criteria. Each calibrated sensor must receive a unique identifier linking it to its calibration history, enabling comprehensive traceability throughout its operational lifecycle.

Environmental Factors Affecting Calibration Accuracy

Environmental factors play a critical role in the accuracy and reliability of ultrasonic sensor calibration processes. Temperature variations represent one of the most significant environmental challenges, as they directly affect the speed of sound in air. For every degree Celsius change in ambient temperature, sound velocity changes by approximately 0.6 meters per second. This variation can introduce substantial measurement errors if not properly accounted for during calibration procedures. Quality assurance laboratories must therefore implement temperature monitoring and compensation mechanisms throughout the calibration process.

Humidity levels similarly impact ultrasonic wave propagation characteristics. Higher humidity increases the density of air, which consequently alters sound wave velocity. Research indicates that a 10% change in relative humidity can result in measurement deviations of up to 0.3%. Calibration protocols must incorporate humidity monitoring and establish acceptable ranges for valid calibration operations, typically between 30-70% relative humidity for optimal results.

Atmospheric pressure fluctuations, though often overlooked, constitute another critical environmental factor. Barometric pressure changes affect air density and consequently sound propagation speed. Calibration laboratories located at different altitudes must account for these baseline differences, with pressure variations of 1 kPa potentially causing measurement errors of approximately 0.1%.

Acoustic interference from surrounding equipment represents a significant challenge in industrial QA environments. Background noise in frequency ranges similar to the ultrasonic sensor's operating frequency can introduce signal distortion and false readings. Calibration protocols should specify maximum acceptable ambient noise levels (typically <50 dB) and recommend acoustic isolation measures when necessary.

Air currents and ventilation systems can create localized variations in air properties, resulting in inconsistent sound wave propagation. These effects are particularly pronounced in large industrial spaces with active HVAC systems. Calibration procedures should include provisions for shielding the calibration setup from direct air flows and maintaining stable air conditions throughout the process.

Electromagnetic interference (EMI) can affect the electronic components of ultrasonic sensing systems, particularly the signal processing elements. Sources of EMI include nearby power lines, motors, and wireless communication devices. Calibration protocols should establish minimum distances from known EMI sources and incorporate appropriate shielding techniques when necessary.

Dust and particulate matter suspended in air can scatter ultrasonic waves, reducing signal strength and potentially introducing measurement errors. Clean room standards appropriate to the sensor's application environment should be established, with particular attention to particulate size distributions that correspond to the ultrasonic wavelength being utilized.

Humidity levels similarly impact ultrasonic wave propagation characteristics. Higher humidity increases the density of air, which consequently alters sound wave velocity. Research indicates that a 10% change in relative humidity can result in measurement deviations of up to 0.3%. Calibration protocols must incorporate humidity monitoring and establish acceptable ranges for valid calibration operations, typically between 30-70% relative humidity for optimal results.

Atmospheric pressure fluctuations, though often overlooked, constitute another critical environmental factor. Barometric pressure changes affect air density and consequently sound propagation speed. Calibration laboratories located at different altitudes must account for these baseline differences, with pressure variations of 1 kPa potentially causing measurement errors of approximately 0.1%.

Acoustic interference from surrounding equipment represents a significant challenge in industrial QA environments. Background noise in frequency ranges similar to the ultrasonic sensor's operating frequency can introduce signal distortion and false readings. Calibration protocols should specify maximum acceptable ambient noise levels (typically <50 dB) and recommend acoustic isolation measures when necessary.

Air currents and ventilation systems can create localized variations in air properties, resulting in inconsistent sound wave propagation. These effects are particularly pronounced in large industrial spaces with active HVAC systems. Calibration procedures should include provisions for shielding the calibration setup from direct air flows and maintaining stable air conditions throughout the process.

Electromagnetic interference (EMI) can affect the electronic components of ultrasonic sensing systems, particularly the signal processing elements. Sources of EMI include nearby power lines, motors, and wireless communication devices. Calibration protocols should establish minimum distances from known EMI sources and incorporate appropriate shielding techniques when necessary.

Dust and particulate matter suspended in air can scatter ultrasonic waves, reducing signal strength and potentially introducing measurement errors. Clean room standards appropriate to the sensor's application environment should be established, with particular attention to particulate size distributions that correspond to the ultrasonic wavelength being utilized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!