Ultrasonic Sensor Beam Patterns: Modeling, Measurement, And Alignment

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensor Technology Evolution and Objectives

Ultrasonic sensing technology has evolved significantly since its inception in the early 20th century, initially developed for underwater detection during World War I. The fundamental principle of ultrasonic sensing involves emitting high-frequency sound waves and measuring the time taken for echoes to return after hitting objects. This technology has progressed from simple distance measurement applications to sophisticated systems capable of detailed object recognition and environmental mapping.

The 1950s and 1960s marked the beginning of industrial applications for ultrasonic sensors, primarily in manufacturing for quality control and thickness measurement. By the 1980s, miniaturization of components and advances in signal processing enabled the integration of ultrasonic sensors into consumer products and automotive systems, particularly for parking assistance and obstacle detection.

Recent decades have witnessed exponential growth in ultrasonic sensor capabilities, driven by improvements in transducer materials, microelectronics, and computational algorithms. Modern ultrasonic sensors feature enhanced precision, reduced power consumption, and increased resistance to environmental interference, making them suitable for diverse applications ranging from medical imaging to autonomous navigation systems.

Beam pattern technology represents a critical aspect of ultrasonic sensor development. The beam pattern—the spatial distribution of acoustic energy emitted by a sensor—determines detection range, resolution, and accuracy. Early sensors produced relatively simple, wide beam patterns with limited directional control, whereas contemporary designs can generate highly focused, steerable beams that enable precise target identification and tracking.

The modeling of ultrasonic beam patterns has evolved from basic geometric approximations to sophisticated computational methods incorporating wave physics and material interactions. Advanced simulation tools now allow engineers to predict beam behavior in complex environments, accounting for factors such as diffraction, refraction, and absorption.

Measurement techniques have similarly progressed from rudimentary amplitude readings to comprehensive characterization methods that capture the full spatial and temporal characteristics of acoustic fields. Modern measurement systems employ arrays of microphones or hydrophones, coupled with high-speed data acquisition systems, to create detailed three-dimensional maps of beam patterns.

Alignment technologies have advanced from manual calibration procedures to automated systems that continuously optimize sensor positioning and beam direction. These developments have been particularly important for multi-sensor arrays and mobile platforms where precise alignment is essential for accurate environmental perception.

The primary objectives in ultrasonic beam pattern research today include enhancing spatial resolution, extending effective range, improving performance in challenging environments (such as high-noise or multi-path scenarios), and developing adaptive beam-forming techniques that can dynamically adjust to changing conditions. Additionally, there is significant focus on reducing the computational complexity of beam pattern modeling to enable real-time processing in resource-constrained applications.

The 1950s and 1960s marked the beginning of industrial applications for ultrasonic sensors, primarily in manufacturing for quality control and thickness measurement. By the 1980s, miniaturization of components and advances in signal processing enabled the integration of ultrasonic sensors into consumer products and automotive systems, particularly for parking assistance and obstacle detection.

Recent decades have witnessed exponential growth in ultrasonic sensor capabilities, driven by improvements in transducer materials, microelectronics, and computational algorithms. Modern ultrasonic sensors feature enhanced precision, reduced power consumption, and increased resistance to environmental interference, making them suitable for diverse applications ranging from medical imaging to autonomous navigation systems.

Beam pattern technology represents a critical aspect of ultrasonic sensor development. The beam pattern—the spatial distribution of acoustic energy emitted by a sensor—determines detection range, resolution, and accuracy. Early sensors produced relatively simple, wide beam patterns with limited directional control, whereas contemporary designs can generate highly focused, steerable beams that enable precise target identification and tracking.

The modeling of ultrasonic beam patterns has evolved from basic geometric approximations to sophisticated computational methods incorporating wave physics and material interactions. Advanced simulation tools now allow engineers to predict beam behavior in complex environments, accounting for factors such as diffraction, refraction, and absorption.

Measurement techniques have similarly progressed from rudimentary amplitude readings to comprehensive characterization methods that capture the full spatial and temporal characteristics of acoustic fields. Modern measurement systems employ arrays of microphones or hydrophones, coupled with high-speed data acquisition systems, to create detailed three-dimensional maps of beam patterns.

Alignment technologies have advanced from manual calibration procedures to automated systems that continuously optimize sensor positioning and beam direction. These developments have been particularly important for multi-sensor arrays and mobile platforms where precise alignment is essential for accurate environmental perception.

The primary objectives in ultrasonic beam pattern research today include enhancing spatial resolution, extending effective range, improving performance in challenging environments (such as high-noise or multi-path scenarios), and developing adaptive beam-forming techniques that can dynamically adjust to changing conditions. Additionally, there is significant focus on reducing the computational complexity of beam pattern modeling to enable real-time processing in resource-constrained applications.

Market Applications and Demand Analysis for Ultrasonic Sensors

The ultrasonic sensor market has experienced significant growth in recent years, driven by increasing applications across multiple industries. The global ultrasonic sensor market was valued at approximately 4.9 billion USD in 2021 and is projected to reach 9.0 billion USD by 2026, growing at a CAGR of 12.8% during the forecast period. This growth is primarily attributed to the rising demand for automation and the need for non-contact sensing technologies in various industrial processes.

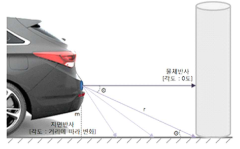

The automotive sector represents one of the largest application areas for ultrasonic sensors, particularly for advanced driver assistance systems (ADAS) and parking assistance. With the automotive industry's shift toward autonomous vehicles, the demand for precise ultrasonic beam pattern modeling and alignment has become critical for ensuring reliable obstacle detection and distance measurement. Market research indicates that approximately 70% of new vehicles now incorporate ultrasonic sensors for parking assistance systems.

In the industrial automation sector, ultrasonic sensors with well-defined beam patterns are essential for level measurement, object detection, and distance sensing applications. The manufacturing industry's increasing focus on Industry 4.0 and smart factory initiatives has further accelerated the adoption of ultrasonic sensing technologies. Precise beam pattern modeling and alignment are crucial for ensuring accurate measurements in complex industrial environments.

Healthcare applications represent another growing market segment for ultrasonic sensors. Medical ultrasound imaging requires highly precise beam patterns for diagnostic accuracy. Additionally, emerging applications in non-invasive monitoring and therapy guidance systems demand advanced beam pattern modeling and control capabilities.

Consumer electronics and smart home applications have also emerged as significant growth areas. Proximity detection, gesture recognition, and liquid level sensing in household appliances all rely on ultrasonic sensors with optimized beam patterns. The smart home market's expansion has created new opportunities for ultrasonic sensing technologies with improved alignment and measurement capabilities.

Regional analysis shows North America and Europe leading in ultrasonic sensor adoption, particularly in automotive and industrial applications. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and automotive manufacturing expansion in countries like China, Japan, and South Korea.

Market challenges include price sensitivity in consumer applications and competition from alternative sensing technologies such as infrared and LiDAR. However, the unique advantages of ultrasonic sensors—including their ability to work in dusty environments and with transparent objects—continue to drive demand across various applications where precise beam pattern control is essential.

The automotive sector represents one of the largest application areas for ultrasonic sensors, particularly for advanced driver assistance systems (ADAS) and parking assistance. With the automotive industry's shift toward autonomous vehicles, the demand for precise ultrasonic beam pattern modeling and alignment has become critical for ensuring reliable obstacle detection and distance measurement. Market research indicates that approximately 70% of new vehicles now incorporate ultrasonic sensors for parking assistance systems.

In the industrial automation sector, ultrasonic sensors with well-defined beam patterns are essential for level measurement, object detection, and distance sensing applications. The manufacturing industry's increasing focus on Industry 4.0 and smart factory initiatives has further accelerated the adoption of ultrasonic sensing technologies. Precise beam pattern modeling and alignment are crucial for ensuring accurate measurements in complex industrial environments.

Healthcare applications represent another growing market segment for ultrasonic sensors. Medical ultrasound imaging requires highly precise beam patterns for diagnostic accuracy. Additionally, emerging applications in non-invasive monitoring and therapy guidance systems demand advanced beam pattern modeling and control capabilities.

Consumer electronics and smart home applications have also emerged as significant growth areas. Proximity detection, gesture recognition, and liquid level sensing in household appliances all rely on ultrasonic sensors with optimized beam patterns. The smart home market's expansion has created new opportunities for ultrasonic sensing technologies with improved alignment and measurement capabilities.

Regional analysis shows North America and Europe leading in ultrasonic sensor adoption, particularly in automotive and industrial applications. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and automotive manufacturing expansion in countries like China, Japan, and South Korea.

Market challenges include price sensitivity in consumer applications and competition from alternative sensing technologies such as infrared and LiDAR. However, the unique advantages of ultrasonic sensors—including their ability to work in dusty environments and with transparent objects—continue to drive demand across various applications where precise beam pattern control is essential.

Current Beam Pattern Modeling Challenges and Limitations

Despite significant advancements in ultrasonic sensor technology, current beam pattern modeling approaches face several critical limitations that impede accurate performance prediction and optimal system design. Traditional mathematical models often rely on simplified assumptions that fail to account for the complex acoustic interactions in real-world environments. The widely used piston model, while mathematically elegant, inadequately represents the actual behavior of ultrasonic transducers, particularly in near-field regions where complex interference patterns emerge.

Material property variations in transducer manufacturing introduce inconsistencies that current models struggle to incorporate. Even minor deviations in piezoelectric material properties, bonding layers, or housing characteristics can significantly alter beam patterns, yet these variations remain difficult to parameterize in existing models. This manufacturing variability creates a gap between theoretical predictions and actual sensor performance.

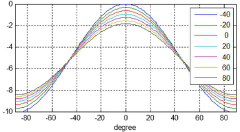

Environmental factors pose another significant modeling challenge. Temperature fluctuations, humidity variations, and air turbulence all affect sound propagation in ways that current models oversimplify. Most models assume homogeneous propagation media, whereas real-world conditions involve complex gradients and boundaries that distort beam patterns unpredictably.

Computational limitations further constrain modeling capabilities. High-fidelity finite element analysis (FEA) and boundary element methods (BEM) can provide more accurate representations but demand excessive computational resources for routine design work. This forces engineers to choose between model accuracy and practical usability, often resulting in compromised design decisions.

Multi-path reflections and interference effects remain particularly challenging to model effectively. When ultrasonic waves encounter complex geometries or multiple reflective surfaces, the resulting interference patterns become extraordinarily difficult to predict with current mathematical frameworks. This limitation is especially problematic in confined spaces or cluttered environments where sensors must operate reliably.

Current validation methodologies also present limitations. The correlation between simulated beam patterns and empirical measurements often shows discrepancies that cannot be fully explained by existing models. The lack of standardized measurement protocols further complicates model validation, making it difficult to establish confidence in modeling results across different research groups and applications.

Integration challenges arise when attempting to incorporate beam pattern models into larger system simulations. The computational complexity of accurate beam models often makes them impractical for system-level simulations where multiple sensors interact with dynamic environments. This forces designers to use oversimplified models that may miss critical interaction effects.

Material property variations in transducer manufacturing introduce inconsistencies that current models struggle to incorporate. Even minor deviations in piezoelectric material properties, bonding layers, or housing characteristics can significantly alter beam patterns, yet these variations remain difficult to parameterize in existing models. This manufacturing variability creates a gap between theoretical predictions and actual sensor performance.

Environmental factors pose another significant modeling challenge. Temperature fluctuations, humidity variations, and air turbulence all affect sound propagation in ways that current models oversimplify. Most models assume homogeneous propagation media, whereas real-world conditions involve complex gradients and boundaries that distort beam patterns unpredictably.

Computational limitations further constrain modeling capabilities. High-fidelity finite element analysis (FEA) and boundary element methods (BEM) can provide more accurate representations but demand excessive computational resources for routine design work. This forces engineers to choose between model accuracy and practical usability, often resulting in compromised design decisions.

Multi-path reflections and interference effects remain particularly challenging to model effectively. When ultrasonic waves encounter complex geometries or multiple reflective surfaces, the resulting interference patterns become extraordinarily difficult to predict with current mathematical frameworks. This limitation is especially problematic in confined spaces or cluttered environments where sensors must operate reliably.

Current validation methodologies also present limitations. The correlation between simulated beam patterns and empirical measurements often shows discrepancies that cannot be fully explained by existing models. The lack of standardized measurement protocols further complicates model validation, making it difficult to establish confidence in modeling results across different research groups and applications.

Integration challenges arise when attempting to incorporate beam pattern models into larger system simulations. The computational complexity of accurate beam models often makes them impractical for system-level simulations where multiple sensors interact with dynamic environments. This forces designers to use oversimplified models that may miss critical interaction effects.

Contemporary Beam Pattern Modeling and Measurement Methodologies

01 Beam pattern formation and control in ultrasonic sensors

Ultrasonic sensors can be designed to form specific beam patterns for different applications. The beam pattern can be controlled through the design of the transducer, the frequency of operation, and the use of acoustic lenses or reflectors. By manipulating these parameters, engineers can create narrow, wide, or shaped beam patterns to optimize detection capabilities for specific use cases. Advanced control techniques allow for dynamic beam steering and focusing to improve detection accuracy and range.- Beam pattern formation and control in ultrasonic sensors: Ultrasonic sensors can be designed to form specific beam patterns for different applications. The beam pattern can be controlled through various techniques such as using multiple transducers, adjusting the frequency, or implementing specific array configurations. These methods allow for directional control of the ultrasonic waves, enabling more precise detection and measurement capabilities in various environments.

- Medical applications of ultrasonic beam patterns: Ultrasonic beam patterns are utilized in medical imaging and diagnostic applications. These systems employ specific beam forming techniques to create detailed images of internal body structures. The controlled beam patterns allow for improved resolution and accuracy in medical diagnostics, enabling better visualization of tissues and organs for clinical assessment and treatment planning.

- Industrial and measurement applications of ultrasonic beam patterns: Ultrasonic sensors with specific beam patterns are used in industrial applications for distance measurement, object detection, and quality control. The beam pattern characteristics determine the sensor's ability to detect objects of different sizes and materials at various distances. These sensors can be optimized for specific industrial environments by adjusting the beam width, focus, and intensity to improve detection accuracy and reliability.

- Advanced signal processing for ultrasonic beam pattern optimization: Signal processing techniques are employed to optimize ultrasonic beam patterns for improved performance. These methods include digital filtering, phase manipulation, and adaptive algorithms that can adjust the beam characteristics based on environmental conditions. Advanced processing enables the reduction of noise, enhancement of target signals, and improved discrimination between multiple targets within the beam pattern.

- Novel transducer designs for specialized beam patterns: Innovative transducer designs can create specialized ultrasonic beam patterns for specific applications. These designs may incorporate unique physical structures, materials with specific acoustic properties, or novel arrangements of multiple transducer elements. Such specialized designs enable the creation of beam patterns with characteristics such as narrow focus, wide coverage, or specific directional properties that conventional transducers cannot achieve.

02 Multi-beam ultrasonic sensor configurations

Multiple ultrasonic transducers can be arranged in arrays to create complex beam patterns. These configurations allow for wider coverage areas, improved spatial resolution, and the ability to detect objects in three-dimensional space. By using phased array techniques, the beam patterns can be electronically steered without mechanical movement. Multi-beam configurations are particularly useful in applications requiring comprehensive environmental scanning or precise object localization.Expand Specific Solutions03 Beam pattern optimization for specific sensing applications

Ultrasonic beam patterns can be optimized for specific applications such as medical imaging, industrial measurement, or automotive sensing. This optimization involves tailoring the beam width, focus depth, and side lobe suppression to meet application requirements. For medical applications, beam patterns might be optimized for tissue penetration and resolution, while industrial applications might prioritize accuracy over longer distances or in harsh environments. The optimization process considers factors such as target characteristics, environmental conditions, and required detection precision.Expand Specific Solutions04 Environmental factors affecting ultrasonic beam patterns

Various environmental factors can influence ultrasonic beam patterns, including temperature, humidity, air pressure, and the presence of interfering objects. These factors can cause beam distortion, attenuation, or reflection, affecting the sensor's performance. Understanding and compensating for these environmental effects is crucial for maintaining reliable sensor operation across different conditions. Advanced sensors may include calibration mechanisms or adaptive algorithms to adjust for changing environmental parameters and maintain consistent beam pattern characteristics.Expand Specific Solutions05 Beam pattern measurement and characterization techniques

Accurate measurement and characterization of ultrasonic beam patterns are essential for sensor development and quality control. Various techniques can be employed, including acoustic scanning systems, beam profiling instruments, and computational modeling. These methods help visualize and quantify beam characteristics such as beam width, divergence angle, near-field/far-field transitions, and side lobe intensity. Standardized testing procedures ensure consistent evaluation of beam pattern performance across different sensor designs and manufacturing batches.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrasonic Sensing

Ultrasonic sensor beam pattern technology is currently in a growth phase, with the market expanding due to increasing applications in automotive, medical, and industrial sectors. The global market size is estimated to reach significant value as demand for precise sensing technologies grows. From a technical maturity perspective, established players like Hitachi, Panasonic, and Bosch have developed advanced modeling capabilities, while Samsung, Epson, and Toyota are investing in alignment optimization. Academic institutions including Chinese Academy of Sciences Institute of Acoustics and University of Washington are contributing fundamental research on measurement methodologies. Medical device manufacturers such as Mindray and Biosense Webster are focusing on specialized beam pattern applications requiring high precision, indicating the technology's evolution toward industry-specific refinements.

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Technical Solution: Mindray has developed sophisticated ultrasonic beam pattern modeling and alignment technologies specifically for medical imaging applications. Their approach incorporates multi-physics simulation models that account for tissue properties, transducer characteristics, and acoustic propagation effects to accurately predict beam patterns in biological tissues. Mindray's proprietary beam forming algorithms enable dynamic focusing and steering capabilities that optimize spatial resolution throughout the imaging depth. Their systems employ automated calibration procedures that use phantom targets with known acoustic properties to precisely align and characterize each transducer element in array configurations. Mindray has implemented real-time beam pattern correction techniques that compensate for tissue-induced aberrations, significantly improving image quality in challenging anatomical regions. Their manufacturing process includes precision alignment stations that use optical and acoustic measurements to ensure transducer elements are positioned with micron-level accuracy, critical for maintaining consistent beam patterns across production units.

Strengths: Highly optimized for medical imaging applications; excellent tissue penetration and resolution characteristics; comprehensive quality control and calibration systems. Weaknesses: Solutions are specialized for medical applications rather than industrial sensing; higher cost compared to general-purpose ultrasonic systems; complex setup and calibration requirements.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has developed sophisticated mathematical models for ultrasonic beam pattern prediction and optimization. Their approach combines finite element analysis with boundary element methods to accurately simulate complex wave propagation phenomena in various mediums. The Institute has created advanced beam pattern visualization tools that provide 3D representations of acoustic fields, enabling researchers to identify and mitigate side lobes and other unwanted artifacts. Their research includes innovative phased array techniques that allow for electronic beam steering without mechanical movement, achieving precise beam focusing and steering capabilities. The Institute has pioneered methods for characterizing and compensating for acoustic impedance mismatches at material boundaries, significantly improving measurement accuracy in heterogeneous materials. Their alignment methodologies incorporate automated calibration systems that use reference targets and iterative optimization algorithms to achieve sub-millimeter precision in beam positioning and focusing.

Strengths: Cutting-edge theoretical modeling capabilities; comprehensive simulation tools; advanced phased array implementations. Weaknesses: Some solutions remain primarily in research domain rather than commercial applications; complex implementations may require specialized expertise; higher computational requirements for real-time applications.

Key Patents and Research in Ultrasonic Beam Pattern Optimization

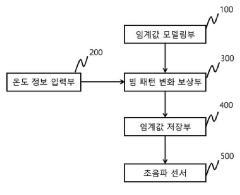

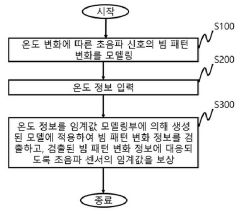

Ultrasonic sensor compensation system and method

PatentPendingKR1020230028041A

Innovation

- A compensation system that models beam pattern changes with temperature using a threshold modeling unit, adjusts threshold values based on temperature and sensor height information, and compensates for beam angle variations to maintain consistent performance across varying temperatures.

Operation of an ultrasonic sensor

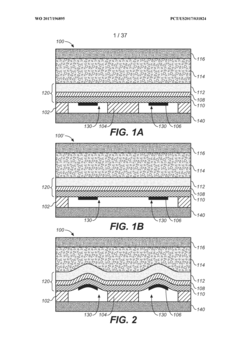

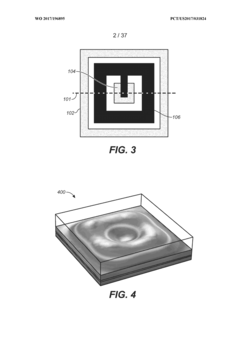

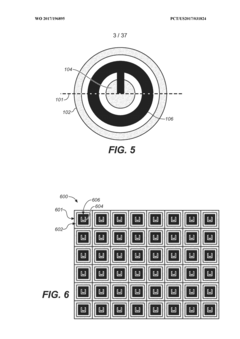

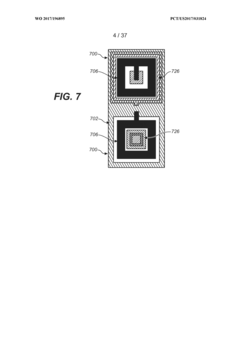

PatentWO2017196895A1

Innovation

- The development of a Piezoelectric Micromachined Ultrasonic Transducer (PMUT) device with a substrate, edge support structure, and an interior support structure, allowing for high-frequency operation with reduced acoustic diffraction and spurious reflection rejection through optimized membrane design and phase delayed transmission patterns in a two-dimensional array configuration.

Environmental Factors Affecting Ultrasonic Beam Performance

Ultrasonic sensors operate in diverse environments that significantly impact their beam performance. Temperature variations constitute a primary environmental factor, with higher temperatures increasing sound velocity and lower temperatures decreasing it. This velocity change directly affects beam propagation characteristics, potentially causing measurement inaccuracies if not properly compensated. For instance, a 20°C temperature shift can alter sound velocity by approximately 4%, necessitating calibration adjustments in precision applications.

Humidity levels similarly influence ultrasonic beam behavior by affecting atmospheric attenuation. Higher humidity typically increases attenuation of ultrasonic waves, particularly at frequencies above 100 kHz. This phenomenon occurs because water molecules in the air absorb acoustic energy, reducing the effective range and sensitivity of ultrasonic sensors. Testing has demonstrated up to 15% reduction in detection range under high humidity conditions (>80% RH) compared to standard conditions.

Atmospheric pressure variations, though less impactful than temperature, still warrant consideration in high-precision applications. Pressure changes modify air density, subsequently altering sound propagation characteristics. This effect becomes particularly relevant in applications spanning significant altitude differences or in pressurized environments.

Air turbulence and flow patterns create unpredictable refraction effects that can deflect ultrasonic beams from their intended path. Industrial environments with ventilation systems, outdoor applications with wind, or process monitoring near thermal gradients all experience these challenges. Research indicates that air currents exceeding 10 m/s can cause beam deflection sufficient to produce measurement errors exceeding 5% in typical sensing applications.

Particulate matter suspended in the transmission medium presents another significant challenge. Dust, aerosols, and other airborne particles scatter ultrasonic waves, reducing signal strength and potentially creating false echoes. This effect becomes particularly pronounced in industrial environments with high particulate concentrations, where signal attenuation can exceed 20 dB/m in extreme cases.

Surface characteristics of target objects also influence beam reflection properties. Smooth surfaces provide specular reflection with predictable angles, while rough or porous surfaces create diffuse reflections that scatter energy in multiple directions. This scattering effect reduces the energy returning to the sensor, potentially limiting detection capability for textured objects at longer ranges.

Understanding these environmental factors enables more robust ultrasonic sensing system design through implementation of appropriate compensation mechanisms, environmental controls, or algorithm adjustments that maintain measurement accuracy across varying conditions.

Humidity levels similarly influence ultrasonic beam behavior by affecting atmospheric attenuation. Higher humidity typically increases attenuation of ultrasonic waves, particularly at frequencies above 100 kHz. This phenomenon occurs because water molecules in the air absorb acoustic energy, reducing the effective range and sensitivity of ultrasonic sensors. Testing has demonstrated up to 15% reduction in detection range under high humidity conditions (>80% RH) compared to standard conditions.

Atmospheric pressure variations, though less impactful than temperature, still warrant consideration in high-precision applications. Pressure changes modify air density, subsequently altering sound propagation characteristics. This effect becomes particularly relevant in applications spanning significant altitude differences or in pressurized environments.

Air turbulence and flow patterns create unpredictable refraction effects that can deflect ultrasonic beams from their intended path. Industrial environments with ventilation systems, outdoor applications with wind, or process monitoring near thermal gradients all experience these challenges. Research indicates that air currents exceeding 10 m/s can cause beam deflection sufficient to produce measurement errors exceeding 5% in typical sensing applications.

Particulate matter suspended in the transmission medium presents another significant challenge. Dust, aerosols, and other airborne particles scatter ultrasonic waves, reducing signal strength and potentially creating false echoes. This effect becomes particularly pronounced in industrial environments with high particulate concentrations, where signal attenuation can exceed 20 dB/m in extreme cases.

Surface characteristics of target objects also influence beam reflection properties. Smooth surfaces provide specular reflection with predictable angles, while rough or porous surfaces create diffuse reflections that scatter energy in multiple directions. This scattering effect reduces the energy returning to the sensor, potentially limiting detection capability for textured objects at longer ranges.

Understanding these environmental factors enables more robust ultrasonic sensing system design through implementation of appropriate compensation mechanisms, environmental controls, or algorithm adjustments that maintain measurement accuracy across varying conditions.

Calibration Standards and Quality Assurance Protocols

Calibration standards for ultrasonic sensor beam patterns represent a critical framework for ensuring measurement accuracy and reliability across different applications. The International Electrotechnical Commission (IEC) has established standard IEC 60854 specifically addressing ultrasonic transducer calibration procedures, which provides baseline requirements for beam pattern characterization. Additionally, the American Society for Testing and Materials (ASTM) offers complementary standards focusing on non-destructive testing applications that incorporate ultrasonic beam pattern validation protocols.

Quality assurance for ultrasonic beam pattern measurement requires systematic verification against traceable reference standards. The National Institute of Standards and Technology (NIST) maintains primary calibration facilities that serve as the foundation for ultrasonic measurement traceability chains. These facilities utilize precision hydrophones and specialized acoustic tanks to characterize beam patterns with uncertainties below 0.5 dB across the 40 kHz to 5 MHz frequency range commonly used in industrial and medical applications.

Implementation of effective quality assurance protocols necessitates regular verification of measurement systems against known reference targets. Standard reflectors with precisely characterized acoustic properties, such as tungsten carbide spheres and flat-bottom holes in metal blocks, provide consistent reference points for beam pattern validation. The measurement uncertainty must be quantified through statistical analysis of repeated measurements, with acceptance criteria typically requiring reproducibility within ±2% for beam width parameters and ±1 dB for amplitude measurements.

Environmental factors significantly impact calibration validity, requiring strict control protocols. Temperature variations must be maintained within ±1°C during calibration procedures, as ultrasonic velocity in most media changes approximately 0.2% per degree Celsius. Similarly, water purity in immersion testing environments must meet specific conductivity standards (<5 μS/cm) to prevent acoustic impedance variations that could distort beam pattern measurements.

Documentation requirements form an essential component of calibration standards, mandating comprehensive records of equipment configuration, environmental conditions, and measurement uncertainties. ISO/IEC 17025 certification provides a framework for laboratory quality management systems that support ultrasonic sensor calibration, requiring documented procedures for equipment maintenance, calibration intervals, and personnel qualification.

Emerging calibration methodologies incorporate automated measurement systems that can characterize complete three-dimensional beam patterns with higher spatial resolution than traditional methods. These systems employ robotic positioning systems with precision better than 10 μm, coupled with digital signal processing algorithms that can detect subtle beam pattern anomalies indicative of sensor misalignment or manufacturing defects.

Quality assurance for ultrasonic beam pattern measurement requires systematic verification against traceable reference standards. The National Institute of Standards and Technology (NIST) maintains primary calibration facilities that serve as the foundation for ultrasonic measurement traceability chains. These facilities utilize precision hydrophones and specialized acoustic tanks to characterize beam patterns with uncertainties below 0.5 dB across the 40 kHz to 5 MHz frequency range commonly used in industrial and medical applications.

Implementation of effective quality assurance protocols necessitates regular verification of measurement systems against known reference targets. Standard reflectors with precisely characterized acoustic properties, such as tungsten carbide spheres and flat-bottom holes in metal blocks, provide consistent reference points for beam pattern validation. The measurement uncertainty must be quantified through statistical analysis of repeated measurements, with acceptance criteria typically requiring reproducibility within ±2% for beam width parameters and ±1 dB for amplitude measurements.

Environmental factors significantly impact calibration validity, requiring strict control protocols. Temperature variations must be maintained within ±1°C during calibration procedures, as ultrasonic velocity in most media changes approximately 0.2% per degree Celsius. Similarly, water purity in immersion testing environments must meet specific conductivity standards (<5 μS/cm) to prevent acoustic impedance variations that could distort beam pattern measurements.

Documentation requirements form an essential component of calibration standards, mandating comprehensive records of equipment configuration, environmental conditions, and measurement uncertainties. ISO/IEC 17025 certification provides a framework for laboratory quality management systems that support ultrasonic sensor calibration, requiring documented procedures for equipment maintenance, calibration intervals, and personnel qualification.

Emerging calibration methodologies incorporate automated measurement systems that can characterize complete three-dimensional beam patterns with higher spatial resolution than traditional methods. These systems employ robotic positioning systems with precision better than 10 μm, coupled with digital signal processing algorithms that can detect subtle beam pattern anomalies indicative of sensor misalignment or manufacturing defects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!