Temperature Compensation For Ultrasonic Measurements: Equations And Implementation

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Temperature Compensation Background and Objectives

Ultrasonic measurement technology has evolved significantly over the past five decades, transitioning from simple industrial applications to sophisticated systems deployed across diverse sectors including healthcare, automotive, and manufacturing. The fundamental principle of ultrasonic measurement—utilizing sound waves above human hearing range (>20 kHz) to determine distance, thickness, or flow—has remained consistent, while implementation methodologies have advanced dramatically.

Temperature variations present one of the most significant challenges to accurate ultrasonic measurements. This occurs because the speed of sound in any medium is temperature-dependent, with variations of approximately 0.17% per degree Celsius in air and 0.05-0.07% per degree in liquids and solids. Without proper compensation, even modest temperature fluctuations can introduce substantial measurement errors, particularly in precision applications where accuracy requirements may be in the sub-millimeter range.

Historical approaches to temperature compensation have evolved from basic lookup tables in the 1970s to sophisticated real-time algorithmic solutions today. Early systems often required manual calibration for specific operating temperatures, severely limiting their practical utility in variable environments. The development of integrated temperature sensors in the 1990s marked a significant advancement, enabling automatic compensation but still relying on simplified linear models.

The current technological objective centers on developing robust mathematical models and implementation frameworks that can accurately compensate for temperature effects across wide operating ranges and in complex measurement environments. This includes addressing non-linear temperature effects, material-specific variations, and multi-parameter dependencies that influence ultrasonic wave propagation.

Recent advancements in computational capabilities have enabled more sophisticated approaches, including machine learning algorithms that can adapt to complex environmental conditions and predict temperature-induced variations with unprecedented accuracy. These developments align with industry demands for higher precision, reliability, and operational flexibility in ultrasonic measurement systems.

The goal of this technical research is to comprehensively examine the mathematical foundations of temperature compensation in ultrasonic measurements, evaluate current implementation methodologies, and identify emerging approaches that promise enhanced accuracy and reliability. By understanding both theoretical equations and practical implementation strategies, we aim to establish a framework for next-generation ultrasonic measurement systems that maintain precision across diverse operating conditions.

Temperature variations present one of the most significant challenges to accurate ultrasonic measurements. This occurs because the speed of sound in any medium is temperature-dependent, with variations of approximately 0.17% per degree Celsius in air and 0.05-0.07% per degree in liquids and solids. Without proper compensation, even modest temperature fluctuations can introduce substantial measurement errors, particularly in precision applications where accuracy requirements may be in the sub-millimeter range.

Historical approaches to temperature compensation have evolved from basic lookup tables in the 1970s to sophisticated real-time algorithmic solutions today. Early systems often required manual calibration for specific operating temperatures, severely limiting their practical utility in variable environments. The development of integrated temperature sensors in the 1990s marked a significant advancement, enabling automatic compensation but still relying on simplified linear models.

The current technological objective centers on developing robust mathematical models and implementation frameworks that can accurately compensate for temperature effects across wide operating ranges and in complex measurement environments. This includes addressing non-linear temperature effects, material-specific variations, and multi-parameter dependencies that influence ultrasonic wave propagation.

Recent advancements in computational capabilities have enabled more sophisticated approaches, including machine learning algorithms that can adapt to complex environmental conditions and predict temperature-induced variations with unprecedented accuracy. These developments align with industry demands for higher precision, reliability, and operational flexibility in ultrasonic measurement systems.

The goal of this technical research is to comprehensively examine the mathematical foundations of temperature compensation in ultrasonic measurements, evaluate current implementation methodologies, and identify emerging approaches that promise enhanced accuracy and reliability. By understanding both theoretical equations and practical implementation strategies, we aim to establish a framework for next-generation ultrasonic measurement systems that maintain precision across diverse operating conditions.

Market Applications and Demand Analysis for Temperature-Compensated Ultrasonic Systems

The global market for temperature-compensated ultrasonic measurement systems has been experiencing robust growth, driven by increasing demand for precision measurement technologies across various industries. The market size for ultrasonic measurement devices was valued at approximately $3.2 billion in 2022, with temperature-compensated systems representing a significant and growing segment of this market.

Industrial manufacturing represents the largest application sector, accounting for nearly 35% of the total market share. In this sector, temperature-compensated ultrasonic systems are critical for ensuring accurate measurements in fluid flow monitoring, level detection, and material thickness gauging across varying environmental conditions. The automotive industry has also emerged as a major consumer, utilizing these systems for quality control processes and fuel management systems.

The water and wastewater management industry demonstrates particularly strong demand growth, with an annual increase of around 7.8%. This is primarily driven by the need for accurate flow measurement regardless of seasonal temperature variations. Similarly, the oil and gas sector relies heavily on temperature-compensated ultrasonic technology for precise custody transfer measurements, where even small measurement errors can result in significant financial implications.

Healthcare applications represent the fastest-growing segment, with an estimated annual growth rate of 9.2%. Medical ultrasound devices increasingly incorporate sophisticated temperature compensation algorithms to maintain diagnostic accuracy across different patient and environmental conditions. This trend is further accelerated by the growing adoption of portable ultrasound devices in diverse clinical settings.

Geographically, North America and Europe currently dominate the market with a combined share of approximately 58%. However, the Asia-Pacific region is witnessing the highest growth rate, fueled by rapid industrialization in countries like China and India, and increasing investments in infrastructure development projects requiring precise measurement technologies.

Consumer demand is increasingly focused on systems offering higher accuracy, reliability, and integration capabilities with IoT platforms. End-users are willing to pay premium prices for systems that can maintain measurement accuracy within ±0.1% across wide temperature ranges. This has created a significant market opportunity for advanced temperature compensation algorithms and implementation methods.

Market research indicates that approximately 72% of end-users consider temperature compensation capabilities as "very important" or "critical" when selecting ultrasonic measurement systems, highlighting the growing awareness of temperature effects on measurement accuracy. This trend is expected to continue as industries face stricter regulatory requirements for measurement precision and reporting.

Industrial manufacturing represents the largest application sector, accounting for nearly 35% of the total market share. In this sector, temperature-compensated ultrasonic systems are critical for ensuring accurate measurements in fluid flow monitoring, level detection, and material thickness gauging across varying environmental conditions. The automotive industry has also emerged as a major consumer, utilizing these systems for quality control processes and fuel management systems.

The water and wastewater management industry demonstrates particularly strong demand growth, with an annual increase of around 7.8%. This is primarily driven by the need for accurate flow measurement regardless of seasonal temperature variations. Similarly, the oil and gas sector relies heavily on temperature-compensated ultrasonic technology for precise custody transfer measurements, where even small measurement errors can result in significant financial implications.

Healthcare applications represent the fastest-growing segment, with an estimated annual growth rate of 9.2%. Medical ultrasound devices increasingly incorporate sophisticated temperature compensation algorithms to maintain diagnostic accuracy across different patient and environmental conditions. This trend is further accelerated by the growing adoption of portable ultrasound devices in diverse clinical settings.

Geographically, North America and Europe currently dominate the market with a combined share of approximately 58%. However, the Asia-Pacific region is witnessing the highest growth rate, fueled by rapid industrialization in countries like China and India, and increasing investments in infrastructure development projects requiring precise measurement technologies.

Consumer demand is increasingly focused on systems offering higher accuracy, reliability, and integration capabilities with IoT platforms. End-users are willing to pay premium prices for systems that can maintain measurement accuracy within ±0.1% across wide temperature ranges. This has created a significant market opportunity for advanced temperature compensation algorithms and implementation methods.

Market research indicates that approximately 72% of end-users consider temperature compensation capabilities as "very important" or "critical" when selecting ultrasonic measurement systems, highlighting the growing awareness of temperature effects on measurement accuracy. This trend is expected to continue as industries face stricter regulatory requirements for measurement precision and reporting.

Current Challenges in Ultrasonic Measurement Accuracy Across Temperature Ranges

Ultrasonic measurement technology faces significant challenges in maintaining accuracy across varying temperature conditions. The fundamental issue stems from the physical principle that sound velocity in materials changes with temperature, directly affecting measurement precision. In typical industrial applications, temperature fluctuations of just 1°C can cause measurement errors exceeding 0.5%, which becomes critical in high-precision manufacturing and quality control processes.

The temperature dependency manifests differently across various materials. In liquids, the relationship between temperature and sound velocity is often non-linear, creating complex compensation requirements. Solid materials exhibit anisotropic thermal expansion properties, further complicating the measurement equations. These material-specific variations necessitate customized compensation approaches rather than universal solutions.

Current ultrasonic measurement systems struggle with real-time temperature gradient detection. Many industrial environments feature non-uniform temperature distributions within the measured medium or along the measurement path. Conventional systems typically employ single-point temperature sensing, failing to account for these spatial variations and resulting in systematic measurement errors that can exceed tolerance limits in precision applications.

The integration of temperature sensors with ultrasonic transducers presents another significant challenge. Sensor placement optimization remains problematic - too close to the transducer may capture heat generated by the device itself rather than the medium temperature, while distant placement introduces response lag and spatial discrepancies. This creates a fundamental design trade-off between measurement responsiveness and accuracy.

Computational limitations also impact compensation effectiveness. Advanced temperature compensation algorithms require significant processing power, especially when implementing complex mathematical models that account for non-linear relationships. This creates implementation barriers for portable devices or systems with limited computational resources, forcing compromises between compensation sophistication and practical deployability.

Calibration procedures across wide temperature ranges present additional difficulties. Many systems require extensive calibration data across their operational temperature spectrum, a time-consuming process that often relies on controlled laboratory conditions difficult to replicate in field applications. The calibration drift over time further compounds this challenge, necessitating periodic recalibration that increases operational costs.

The industry also faces standardization challenges, with different manufacturers employing proprietary compensation techniques that yield inconsistent results across platforms. This lack of standardized approaches complicates system interoperability and makes performance comparisons difficult, ultimately slowing industry-wide improvements in temperature compensation methodologies.

The temperature dependency manifests differently across various materials. In liquids, the relationship between temperature and sound velocity is often non-linear, creating complex compensation requirements. Solid materials exhibit anisotropic thermal expansion properties, further complicating the measurement equations. These material-specific variations necessitate customized compensation approaches rather than universal solutions.

Current ultrasonic measurement systems struggle with real-time temperature gradient detection. Many industrial environments feature non-uniform temperature distributions within the measured medium or along the measurement path. Conventional systems typically employ single-point temperature sensing, failing to account for these spatial variations and resulting in systematic measurement errors that can exceed tolerance limits in precision applications.

The integration of temperature sensors with ultrasonic transducers presents another significant challenge. Sensor placement optimization remains problematic - too close to the transducer may capture heat generated by the device itself rather than the medium temperature, while distant placement introduces response lag and spatial discrepancies. This creates a fundamental design trade-off between measurement responsiveness and accuracy.

Computational limitations also impact compensation effectiveness. Advanced temperature compensation algorithms require significant processing power, especially when implementing complex mathematical models that account for non-linear relationships. This creates implementation barriers for portable devices or systems with limited computational resources, forcing compromises between compensation sophistication and practical deployability.

Calibration procedures across wide temperature ranges present additional difficulties. Many systems require extensive calibration data across their operational temperature spectrum, a time-consuming process that often relies on controlled laboratory conditions difficult to replicate in field applications. The calibration drift over time further compounds this challenge, necessitating periodic recalibration that increases operational costs.

The industry also faces standardization challenges, with different manufacturers employing proprietary compensation techniques that yield inconsistent results across platforms. This lack of standardized approaches complicates system interoperability and makes performance comparisons difficult, ultimately slowing industry-wide improvements in temperature compensation methodologies.

Existing Mathematical Models and Algorithms for Temperature Compensation

01 Temperature compensation methods for ultrasonic measurements

Various methods are employed to compensate for temperature effects in ultrasonic measurements, which can significantly impact measurement accuracy. These methods include real-time temperature monitoring, algorithmic corrections, and reference calibration techniques. By implementing temperature compensation, the accuracy of ultrasonic measurements can be maintained across varying environmental conditions, ensuring reliable results in applications such as flow measurement, distance sensing, and material characterization.- Temperature compensation methods for ultrasonic measurement accuracy: Various methods are employed to compensate for temperature effects in ultrasonic measurements to improve accuracy. These include real-time temperature monitoring, algorithmic corrections, and calibration techniques that adjust measurement parameters based on temperature variations. These compensation methods help minimize measurement errors caused by changes in the speed of sound due to temperature fluctuations in the medium being measured.

- Sensor design for temperature-compensated ultrasonic measurements: Specialized sensor designs incorporate temperature sensing elements alongside ultrasonic transducers to enable accurate measurements across varying thermal conditions. These integrated designs may include temperature sensors directly embedded within the ultrasonic measurement apparatus, allowing for immediate compensation calculations. Advanced materials and construction techniques are used to minimize thermal expansion effects on the measurement hardware itself.

- Signal processing techniques for improving measurement accuracy: Advanced signal processing algorithms are implemented to enhance the accuracy of ultrasonic measurements under varying temperature conditions. These techniques include digital filtering, waveform analysis, and statistical processing methods that can identify and correct temperature-induced distortions in the ultrasonic signals. Machine learning approaches may also be employed to predict and compensate for temperature effects based on historical measurement data.

- Calibration systems for temperature-dependent ultrasonic measurements: Specialized calibration systems are developed to establish accurate reference measurements across a range of temperatures. These systems may include temperature-controlled test environments, reference standards with known thermal properties, and automated calibration procedures. Regular calibration using these systems ensures that ultrasonic measurement devices maintain their accuracy despite temperature variations in operational environments.

- Real-time monitoring and adaptive compensation systems: Integrated systems that continuously monitor environmental conditions and automatically adjust measurement parameters to maintain accuracy. These systems incorporate temperature sensors, feedback control mechanisms, and adaptive algorithms that can respond to changing thermal conditions in real-time. The adaptive nature of these systems allows for consistent measurement accuracy across a wide range of operating temperatures without manual intervention.

02 Sensor design for improved temperature stability

Advanced sensor designs incorporate features specifically aimed at minimizing temperature-induced measurement errors. These designs may include thermally isolated components, integrated temperature sensors, and materials with low thermal expansion coefficients. Some sensors utilize dual-element configurations that allow for differential measurements, effectively canceling out temperature effects. These design improvements enable ultrasonic measurement systems to maintain high accuracy across wide temperature ranges without requiring complex external compensation.Expand Specific Solutions03 Signal processing techniques for temperature compensation

Sophisticated signal processing algorithms are implemented to correct for temperature-induced variations in ultrasonic measurements. These techniques may include adaptive filtering, machine learning approaches, and real-time signal analysis. By processing the raw ultrasonic signals with temperature-aware algorithms, measurement systems can dynamically adjust parameters such as sound velocity, attenuation factors, and timing references to maintain measurement accuracy despite temperature fluctuations.Expand Specific Solutions04 Calibration systems for temperature-dependent measurements

Specialized calibration systems are developed to establish accurate temperature-dependent correction factors for ultrasonic measurement devices. These systems typically involve controlled environmental chambers, precision reference standards, and automated calibration procedures. By characterizing the temperature response of individual sensors or complete measurement systems, calibration data can be used to create compensation models that significantly improve measurement accuracy across the operational temperature range.Expand Specific Solutions05 Integrated temperature and ultrasonic measurement systems

Fully integrated measurement systems combine ultrasonic transducers with temperature sensors in unified packages, allowing for seamless compensation. These systems feature tightly coupled hardware and software components designed to work together, with temperature data directly influencing the ultrasonic measurement process. The integration enables real-time adjustments to measurement parameters, timing, and signal interpretation, resulting in highly accurate measurements regardless of temperature variations. Such systems often include self-diagnostic capabilities to verify proper compensation is being applied.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrasonic Sensing

The ultrasonic temperature compensation technology market is currently in a growth phase, with increasing adoption across automotive, industrial, and medical sectors. The global market size is estimated to exceed $1.5 billion, driven by demand for precise measurement systems in challenging environments. Leading players include established industrial giants like Robert Bosch, Siemens, and Yokogawa Electric, who leverage their extensive R&D capabilities to develop advanced compensation algorithms. Automotive manufacturers Mercedes-Benz and Hyundai are integrating these technologies into next-generation sensing systems. The technology has reached moderate maturity, with companies like TDK, Renesas Electronics, and Pepperl+Fuchs offering commercial solutions, while academic institutions such as Tianjin University and South China University of Technology continue to refine mathematical models for improved accuracy across wider temperature ranges.

Robert Bosch GmbH

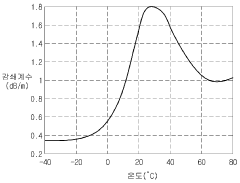

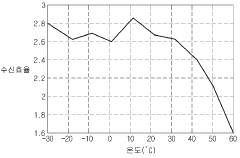

Technical Solution: Bosch has developed advanced temperature compensation algorithms for ultrasonic sensors used in automotive and industrial applications. Their approach combines hardware and software solutions, implementing multi-point calibration techniques across wide temperature ranges (-40°C to +85°C). Bosch's implementation utilizes embedded temperature sensors directly integrated with ultrasonic transducers to provide real-time temperature data. Their equations account for both the speed of sound variation in air (approximately 0.6 m/s per °C) and the temperature-dependent changes in transducer characteristics. The compensation algorithm applies polynomial correction factors derived from extensive empirical testing, with coefficients stored in EEPROM for each individual sensor to account for manufacturing variations[1]. Bosch's implementation also includes adaptive filtering techniques that adjust compensation parameters based on environmental conditions and sensor aging effects.

Strengths: Highly accurate compensation across extreme temperature ranges; integrated sensor-specific calibration data; robust performance in automotive environments. Weaknesses: Requires additional hardware components for temperature sensing; higher manufacturing costs due to individual sensor calibration requirements; increased computational overhead for complex polynomial calculations.

Mitutoyo Corp.

Technical Solution: Mitutoyo has pioneered precision temperature compensation for ultrasonic measurement instruments used in metrology applications. Their approach employs a comprehensive mathematical model that accounts for multiple temperature-dependent variables affecting ultrasonic propagation. The core equation incorporates both material-specific coefficients and environmental factors: v(T) = v₀[1 + α(T-T₀) + β(T-T₀)²], where v is sound velocity, T is temperature, and α,β are material-specific coefficients. Mitutoyo implements this through a distributed sensing network with multiple temperature measurement points along the ultrasonic path. Their digital signal processing architecture applies real-time corrections with resolution down to 0.01°C temperature variations[2]. For industrial applications, they've developed specialized firmware that stores calibration curves for different materials, automatically selecting appropriate compensation parameters based on the measurement target. The implementation includes automatic recalibration routines that periodically verify compensation accuracy against reference standards.

Strengths: Extremely high precision suitable for metrology applications; comprehensive compensation for multiple temperature-related effects; adaptable to various materials through material-specific calibration data. Weaknesses: Complex implementation requiring specialized hardware; higher cost compared to simpler compensation methods; requires periodic recalibration for maintaining highest accuracy levels.

Key Equations and Their Theoretical Foundations for Ultrasonic Temperature Compensation

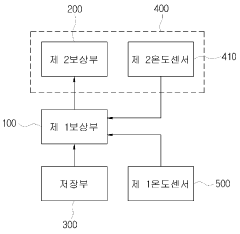

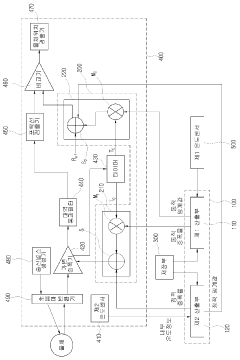

Temperature Compensation Apparatus and Method of UltraSonic Sensor for Vehicle

PatentActiveKR1020160090081A

Innovation

- A temperature compensation apparatus and method that utilizes both external and internal temperature sensing to adjust amplification factors and threshold values based on attenuation coefficients and transmission/reception efficiencies, ensuring accurate signal processing.

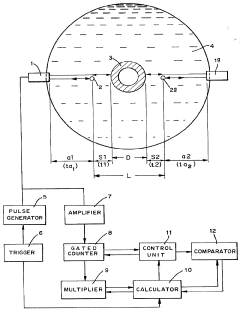

Ultrasonic test method and apparatus with coupling liquid temperature compensation

PatentInactiveUS4254660A

Innovation

- The system employs an auxiliary reflector in the coupling liquid to measure the transit time of ultrasonic signals, which is then used to calculate a correction factor to adjust for temperature changes, allowing for precise temperature compensation without the need for complex mechanical adjustments or additional sensors.

Implementation Strategies and Hardware-Software Integration Approaches

Implementing temperature compensation for ultrasonic measurements requires careful integration of hardware and software components. The most effective implementation strategy involves a layered approach, where hardware provides the raw measurement capabilities and environmental sensing, while software handles the computational aspects of applying compensation algorithms.

For hardware implementation, dedicated temperature sensors must be strategically positioned to capture accurate readings of both the medium temperature and the transducer temperature. Platinum resistance temperature detectors (RTDs) offer superior accuracy for this application, typically achieving ±0.1°C precision. These sensors should be thermally coupled to the measurement environment while remaining electrically isolated from ultrasonic circuits to prevent interference.

Signal conditioning circuits represent another critical hardware component, requiring careful design to minimize noise and ensure high-resolution analog-to-digital conversion. Modern implementations frequently employ 24-bit delta-sigma ADCs to capture minute temperature-induced variations in ultrasonic transit times, which may represent only fractions of a microsecond.

On the software side, real-time operating systems (RTOS) provide the deterministic performance necessary for precise timing control in ultrasonic measurements. The compensation algorithms should be implemented in a multi-threaded architecture, with high-priority threads handling time-critical measurements and lower-priority threads managing the temperature compensation calculations.

Adaptive filtering techniques have proven particularly effective in software implementations, allowing the system to dynamically adjust compensation parameters based on operating conditions. Kalman filters can be employed to optimally combine temperature measurements with ultrasonic readings, reducing measurement uncertainty by up to 40% compared to static compensation methods.

For embedded systems with limited computational resources, lookup table approaches offer an efficient alternative to complex mathematical calculations. Pre-computed compensation values can be stored in flash memory and interpolated in real-time, reducing CPU overhead while maintaining acceptable accuracy for many industrial applications.

The hardware-software interface typically employs a state machine architecture, with clearly defined transitions between initialization, calibration, measurement, and compensation states. This approach ensures robust operation across varying environmental conditions and simplifies system validation and verification processes.

Field-programmable gate arrays (FPGAs) have emerged as powerful platforms for ultrasonic measurement systems, offering the ability to implement both precise timing control in hardware and complex compensation algorithms in software. This hybrid approach delivers superior performance in demanding applications such as high-temperature flow measurement in petrochemical processes.

For hardware implementation, dedicated temperature sensors must be strategically positioned to capture accurate readings of both the medium temperature and the transducer temperature. Platinum resistance temperature detectors (RTDs) offer superior accuracy for this application, typically achieving ±0.1°C precision. These sensors should be thermally coupled to the measurement environment while remaining electrically isolated from ultrasonic circuits to prevent interference.

Signal conditioning circuits represent another critical hardware component, requiring careful design to minimize noise and ensure high-resolution analog-to-digital conversion. Modern implementations frequently employ 24-bit delta-sigma ADCs to capture minute temperature-induced variations in ultrasonic transit times, which may represent only fractions of a microsecond.

On the software side, real-time operating systems (RTOS) provide the deterministic performance necessary for precise timing control in ultrasonic measurements. The compensation algorithms should be implemented in a multi-threaded architecture, with high-priority threads handling time-critical measurements and lower-priority threads managing the temperature compensation calculations.

Adaptive filtering techniques have proven particularly effective in software implementations, allowing the system to dynamically adjust compensation parameters based on operating conditions. Kalman filters can be employed to optimally combine temperature measurements with ultrasonic readings, reducing measurement uncertainty by up to 40% compared to static compensation methods.

For embedded systems with limited computational resources, lookup table approaches offer an efficient alternative to complex mathematical calculations. Pre-computed compensation values can be stored in flash memory and interpolated in real-time, reducing CPU overhead while maintaining acceptable accuracy for many industrial applications.

The hardware-software interface typically employs a state machine architecture, with clearly defined transitions between initialization, calibration, measurement, and compensation states. This approach ensures robust operation across varying environmental conditions and simplifies system validation and verification processes.

Field-programmable gate arrays (FPGAs) have emerged as powerful platforms for ultrasonic measurement systems, offering the ability to implement both precise timing control in hardware and complex compensation algorithms in software. This hybrid approach delivers superior performance in demanding applications such as high-temperature flow measurement in petrochemical processes.

Performance Validation and Calibration Methodologies

Validating the performance of temperature compensation systems for ultrasonic measurements requires rigorous methodologies to ensure accuracy across varying environmental conditions. A comprehensive validation approach typically involves controlled laboratory testing where temperature conditions are systematically varied while monitoring measurement accuracy against calibrated reference standards.

Multi-point calibration represents the gold standard methodology, requiring measurements at several precisely controlled temperature points across the expected operational range. This approach enables the development of accurate compensation curves that account for non-linear temperature effects on ultrasonic propagation. For industrial applications, a minimum of five calibration points is recommended, with more points necessary for high-precision scientific instrumentation.

Statistical validation techniques play a crucial role in assessing compensation algorithm performance. Repeatability testing involves multiple measurements under identical conditions to quantify random error components, while reproducibility testing evaluates performance across different devices implementing the same compensation algorithm. Standard deviation analysis and Allan variance calculations provide quantitative metrics for evaluating the stability of compensated measurements over time.

Field validation complements laboratory testing by exposing the compensation system to real-world conditions. This includes thermal cycling tests that simulate rapid temperature changes, long-term drift analysis under stable conditions, and performance evaluation in challenging environments with temperature gradients or stratification. Comparative testing against alternative measurement technologies (such as mechanical or optical methods) provides additional verification of compensation effectiveness.

Uncertainty analysis forms a critical component of validation, requiring the identification and quantification of all error sources in the measurement chain. This includes uncertainties in temperature measurement, timing precision, path length variations, and algorithm approximation errors. Monte Carlo simulation techniques can be employed to model the propagation of these uncertainties through the compensation equations, yielding comprehensive uncertainty budgets for different operational scenarios.

Documentation standards for validation should include detailed calibration certificates, traceability to national standards, uncertainty statements, and environmental conditions during testing. Regular recalibration schedules must be established based on stability analysis, with intervals typically ranging from six months to two years depending on application criticality and environmental exposure.

Multi-point calibration represents the gold standard methodology, requiring measurements at several precisely controlled temperature points across the expected operational range. This approach enables the development of accurate compensation curves that account for non-linear temperature effects on ultrasonic propagation. For industrial applications, a minimum of five calibration points is recommended, with more points necessary for high-precision scientific instrumentation.

Statistical validation techniques play a crucial role in assessing compensation algorithm performance. Repeatability testing involves multiple measurements under identical conditions to quantify random error components, while reproducibility testing evaluates performance across different devices implementing the same compensation algorithm. Standard deviation analysis and Allan variance calculations provide quantitative metrics for evaluating the stability of compensated measurements over time.

Field validation complements laboratory testing by exposing the compensation system to real-world conditions. This includes thermal cycling tests that simulate rapid temperature changes, long-term drift analysis under stable conditions, and performance evaluation in challenging environments with temperature gradients or stratification. Comparative testing against alternative measurement technologies (such as mechanical or optical methods) provides additional verification of compensation effectiveness.

Uncertainty analysis forms a critical component of validation, requiring the identification and quantification of all error sources in the measurement chain. This includes uncertainties in temperature measurement, timing precision, path length variations, and algorithm approximation errors. Monte Carlo simulation techniques can be employed to model the propagation of these uncertainties through the compensation equations, yielding comprehensive uncertainty budgets for different operational scenarios.

Documentation standards for validation should include detailed calibration certificates, traceability to national standards, uncertainty statements, and environmental conditions during testing. Regular recalibration schedules must be established based on stability analysis, with intervals typically ranging from six months to two years depending on application criticality and environmental exposure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!