Designing A Robust Ultrasonic Proximity System For Dusty Environments

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Proximity Sensing Background and Objectives

Ultrasonic proximity sensing technology has evolved significantly since its inception in the early 1960s, initially developed for industrial automation and obstacle detection. The fundamental principle relies on measuring the time-of-flight for ultrasonic waves to travel to an object and return, enabling distance calculation. Over decades, this technology has transitioned from simple presence detection to sophisticated distance measurement systems with millimeter-level accuracy.

The evolution trajectory shows a clear trend toward miniaturization, increased reliability, and enhanced environmental adaptability. Early systems were bulky, power-hungry, and highly susceptible to environmental interference. Modern ultrasonic sensors have overcome many of these limitations through advanced signal processing algorithms, improved transducer materials, and intelligent filtering techniques.

Recent technological advancements have focused on addressing performance degradation in challenging environments, particularly those with high particulate matter. Traditional ultrasonic systems suffer significant accuracy and reliability issues in dusty environments due to signal attenuation, false echoes, and transducer contamination. These challenges have limited their application in industries such as mining, construction, agriculture, and manufacturing where dust is prevalent.

The global market for ultrasonic sensors is projected to reach $9.5 billion by 2025, with robust growth in automotive, industrial automation, and healthcare sectors. However, the segment specifically addressing harsh environment applications remains underserved, representing a significant opportunity for technological innovation.

The primary objective of developing a robust ultrasonic proximity system for dusty environments is to overcome the inherent limitations of conventional ultrasonic technology when exposed to airborne particulates. This includes designing systems that maintain measurement accuracy, reliability, and operational longevity despite continuous exposure to dust particles of varying compositions and concentrations.

Secondary objectives include minimizing maintenance requirements, reducing false readings, extending sensor lifespan, and ensuring consistent performance across varying environmental conditions. The ideal system should maintain specified accuracy levels even when dust concentration exceeds 10mg/m³, a threshold where conventional systems typically fail.

From a technical perspective, achieving these objectives requires innovations in transducer design, signal processing algorithms, mechanical protection systems, and self-cleaning mechanisms. The solution must balance technical sophistication with cost-effectiveness to ensure commercial viability across multiple industry applications.

The successful development of such technology would significantly expand the application scope of ultrasonic sensing, enabling its use in previously unsuitable environments and potentially disrupting existing market dynamics in proximity sensing technologies.

The evolution trajectory shows a clear trend toward miniaturization, increased reliability, and enhanced environmental adaptability. Early systems were bulky, power-hungry, and highly susceptible to environmental interference. Modern ultrasonic sensors have overcome many of these limitations through advanced signal processing algorithms, improved transducer materials, and intelligent filtering techniques.

Recent technological advancements have focused on addressing performance degradation in challenging environments, particularly those with high particulate matter. Traditional ultrasonic systems suffer significant accuracy and reliability issues in dusty environments due to signal attenuation, false echoes, and transducer contamination. These challenges have limited their application in industries such as mining, construction, agriculture, and manufacturing where dust is prevalent.

The global market for ultrasonic sensors is projected to reach $9.5 billion by 2025, with robust growth in automotive, industrial automation, and healthcare sectors. However, the segment specifically addressing harsh environment applications remains underserved, representing a significant opportunity for technological innovation.

The primary objective of developing a robust ultrasonic proximity system for dusty environments is to overcome the inherent limitations of conventional ultrasonic technology when exposed to airborne particulates. This includes designing systems that maintain measurement accuracy, reliability, and operational longevity despite continuous exposure to dust particles of varying compositions and concentrations.

Secondary objectives include minimizing maintenance requirements, reducing false readings, extending sensor lifespan, and ensuring consistent performance across varying environmental conditions. The ideal system should maintain specified accuracy levels even when dust concentration exceeds 10mg/m³, a threshold where conventional systems typically fail.

From a technical perspective, achieving these objectives requires innovations in transducer design, signal processing algorithms, mechanical protection systems, and self-cleaning mechanisms. The solution must balance technical sophistication with cost-effectiveness to ensure commercial viability across multiple industry applications.

The successful development of such technology would significantly expand the application scope of ultrasonic sensing, enabling its use in previously unsuitable environments and potentially disrupting existing market dynamics in proximity sensing technologies.

Market Demand Analysis for Dust-Resistant Proximity Systems

The global market for dust-resistant proximity sensing systems is experiencing significant growth, driven by increasing automation across multiple industries. Current market research indicates that the industrial automation sector alone represents a substantial portion of this demand, with manufacturing facilities seeking reliable sensing solutions that can operate in harsh environments. Particularly in industries such as mining, construction, agriculture, and heavy manufacturing, where dust particles are prevalent, conventional proximity sensors often fail to deliver consistent performance.

Market analysis reveals that facilities operating in dusty environments face significant operational challenges when standard ultrasonic sensors malfunction due to particulate interference. These failures result in costly downtime, with maintenance expenses reaching substantial figures annually across affected industries. The economic impact extends beyond direct repair costs to include production losses and safety concerns, creating a compelling case for dust-resistant alternatives.

Regional demand patterns show particularly strong growth in regions with extensive mining operations and heavy industrial activity. Countries with large manufacturing sectors in Asia-Pacific, particularly China and India, are showing the fastest adoption rates for advanced proximity sensing technologies. North American and European markets demonstrate steady demand growth, primarily driven by automation upgrades in established industrial facilities.

End-user surveys indicate that reliability in adverse conditions ranks as the primary purchasing consideration for proximity sensing systems, surpassing initial cost concerns. This represents a significant shift in buyer priorities, with maintenance reduction and operational continuity gaining prominence in procurement decisions. Industry reports suggest that customers are increasingly willing to invest in premium solutions that offer demonstrated resilience in challenging environments.

The automotive manufacturing sector presents a particularly promising vertical market, as production environments combine dust challenges with precision requirements. Similarly, food processing facilities, where flour and other particulates are common, represent another high-potential application area requiring reliable proximity detection systems that can withstand contamination.

Competitive analysis indicates that while several manufacturers offer proximity sensors with basic dust protection features, few provide comprehensive solutions specifically engineered for high-particulate environments. This gap between market needs and available solutions presents a significant opportunity for specialized offerings with demonstrated performance advantages in dusty conditions.

Market forecasts project continued growth for dust-resistant sensing technologies, with particular acceleration in IoT-enabled smart sensors that can provide predictive maintenance capabilities alongside robust environmental performance. As Industry 4.0 initiatives expand globally, the integration of reliable proximity sensing into broader automation ecosystems will likely drive further market expansion.

Market analysis reveals that facilities operating in dusty environments face significant operational challenges when standard ultrasonic sensors malfunction due to particulate interference. These failures result in costly downtime, with maintenance expenses reaching substantial figures annually across affected industries. The economic impact extends beyond direct repair costs to include production losses and safety concerns, creating a compelling case for dust-resistant alternatives.

Regional demand patterns show particularly strong growth in regions with extensive mining operations and heavy industrial activity. Countries with large manufacturing sectors in Asia-Pacific, particularly China and India, are showing the fastest adoption rates for advanced proximity sensing technologies. North American and European markets demonstrate steady demand growth, primarily driven by automation upgrades in established industrial facilities.

End-user surveys indicate that reliability in adverse conditions ranks as the primary purchasing consideration for proximity sensing systems, surpassing initial cost concerns. This represents a significant shift in buyer priorities, with maintenance reduction and operational continuity gaining prominence in procurement decisions. Industry reports suggest that customers are increasingly willing to invest in premium solutions that offer demonstrated resilience in challenging environments.

The automotive manufacturing sector presents a particularly promising vertical market, as production environments combine dust challenges with precision requirements. Similarly, food processing facilities, where flour and other particulates are common, represent another high-potential application area requiring reliable proximity detection systems that can withstand contamination.

Competitive analysis indicates that while several manufacturers offer proximity sensors with basic dust protection features, few provide comprehensive solutions specifically engineered for high-particulate environments. This gap between market needs and available solutions presents a significant opportunity for specialized offerings with demonstrated performance advantages in dusty conditions.

Market forecasts project continued growth for dust-resistant sensing technologies, with particular acceleration in IoT-enabled smart sensors that can provide predictive maintenance capabilities alongside robust environmental performance. As Industry 4.0 initiatives expand globally, the integration of reliable proximity sensing into broader automation ecosystems will likely drive further market expansion.

Technical Challenges in Dusty Environment Sensing

Ultrasonic proximity sensing in dusty environments presents significant technical challenges that must be addressed to ensure reliable operation. Dust particles suspended in the air can scatter, absorb, and reflect ultrasonic waves, leading to signal degradation and false readings. The severity of these effects varies with particle size, concentration, and composition, creating a complex problem space that requires sophisticated solutions.

The primary challenge lies in signal attenuation, where dust particles absorb and scatter the ultrasonic waves, reducing the effective range and sensitivity of the system. This attenuation follows an exponential decay pattern relative to dust concentration, making detection particularly difficult in environments with variable dust levels such as construction sites, mining operations, and industrial processing facilities.

Signal reflection from dust particles creates another significant hurdle, generating multiple echo paths that can confuse the sensor's timing mechanisms. These spurious reflections often result in phantom objects being detected or actual objects being missed entirely. Traditional time-of-flight calculations become unreliable as the speed of sound varies in dust-laden air compared to clean environments.

Temperature and humidity fluctuations, which commonly accompany dusty conditions, further complicate sensing accuracy. These environmental factors alter the propagation characteristics of ultrasonic waves, requiring dynamic calibration systems that can adapt to changing conditions. Without such adaptability, proximity measurements may drift significantly over time.

Mechanical fouling represents another critical challenge, as dust accumulation on transducer surfaces can dampen both transmission and reception capabilities. This progressive degradation necessitates either robust self-cleaning mechanisms or transducer designs that minimize dust adhesion while maintaining acoustic efficiency.

Power consumption optimization becomes particularly important in dusty environments, as these conditions often require higher signal power to overcome attenuation, yet many applications demand battery-powered operation for extended periods. This creates a fundamental tension between performance requirements and energy constraints.

Signal processing algorithms face unique challenges in dusty environments, requiring more sophisticated filtering and pattern recognition capabilities to distinguish valid targets from noise. Traditional threshold-based detection methods prove inadequate, necessitating adaptive algorithms that can continuously recalibrate based on environmental conditions.

Cross-sensitivity to other environmental factors such as airflow, vibration, and electromagnetic interference compounds these challenges, as dusty environments often coincide with these additional disturbances. A robust system must therefore incorporate multi-factor compensation techniques to maintain accuracy across diverse operating conditions.

The primary challenge lies in signal attenuation, where dust particles absorb and scatter the ultrasonic waves, reducing the effective range and sensitivity of the system. This attenuation follows an exponential decay pattern relative to dust concentration, making detection particularly difficult in environments with variable dust levels such as construction sites, mining operations, and industrial processing facilities.

Signal reflection from dust particles creates another significant hurdle, generating multiple echo paths that can confuse the sensor's timing mechanisms. These spurious reflections often result in phantom objects being detected or actual objects being missed entirely. Traditional time-of-flight calculations become unreliable as the speed of sound varies in dust-laden air compared to clean environments.

Temperature and humidity fluctuations, which commonly accompany dusty conditions, further complicate sensing accuracy. These environmental factors alter the propagation characteristics of ultrasonic waves, requiring dynamic calibration systems that can adapt to changing conditions. Without such adaptability, proximity measurements may drift significantly over time.

Mechanical fouling represents another critical challenge, as dust accumulation on transducer surfaces can dampen both transmission and reception capabilities. This progressive degradation necessitates either robust self-cleaning mechanisms or transducer designs that minimize dust adhesion while maintaining acoustic efficiency.

Power consumption optimization becomes particularly important in dusty environments, as these conditions often require higher signal power to overcome attenuation, yet many applications demand battery-powered operation for extended periods. This creates a fundamental tension between performance requirements and energy constraints.

Signal processing algorithms face unique challenges in dusty environments, requiring more sophisticated filtering and pattern recognition capabilities to distinguish valid targets from noise. Traditional threshold-based detection methods prove inadequate, necessitating adaptive algorithms that can continuously recalibrate based on environmental conditions.

Cross-sensitivity to other environmental factors such as airflow, vibration, and electromagnetic interference compounds these challenges, as dusty environments often coincide with these additional disturbances. A robust system must therefore incorporate multi-factor compensation techniques to maintain accuracy across diverse operating conditions.

Current Dust-Mitigation Solutions for Ultrasonic Sensors

01 Noise reduction techniques for ultrasonic proximity systems

Various noise reduction techniques can be implemented to enhance the robustness of ultrasonic proximity systems. These include signal filtering algorithms, frequency modulation, and adaptive threshold mechanisms that can distinguish between actual proximity signals and environmental noise. By implementing these techniques, the system can maintain accurate detection even in noisy environments, improving overall reliability and reducing false positives.- Noise reduction techniques for ultrasonic proximity systems: Various noise reduction techniques can be implemented to enhance the robustness of ultrasonic proximity systems. These include signal filtering algorithms, adaptive threshold adjustments, and frequency modulation methods that help distinguish genuine signals from environmental noise. By implementing these techniques, ultrasonic proximity systems can maintain reliable detection capabilities even in noisy environments, improving overall system robustness and reducing false readings.

- Environmental compensation mechanisms: Ultrasonic proximity systems can be made more robust through environmental compensation mechanisms that adjust for changing conditions. These include temperature and humidity sensors that provide data for automatic calibration, pressure variation compensation algorithms, and adaptive gain control systems. These mechanisms allow the proximity system to maintain consistent performance across varying environmental conditions, enhancing system reliability in real-world applications.

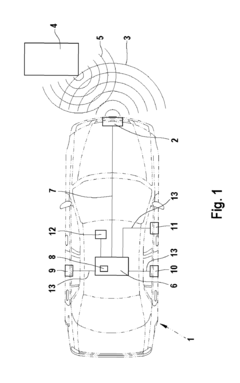

- Multi-sensor fusion for improved reliability: Combining ultrasonic sensors with other sensing technologies creates redundant detection systems that improve overall robustness. By integrating data from multiple sensor types such as infrared, radar, or optical sensors, the system can cross-validate proximity readings and maintain functionality even if one sensing modality is compromised. This sensor fusion approach enables more reliable object detection across diverse operating conditions and reduces vulnerability to single-point failures.

- Advanced signal processing algorithms: Sophisticated signal processing algorithms significantly enhance ultrasonic proximity system robustness. These include machine learning-based pattern recognition, adaptive filtering techniques, and digital signal processing methods that can identify and compensate for interference patterns. By implementing these advanced algorithms, systems can better distinguish between actual targets and false echoes, improving detection accuracy in complex environments.

- Physical design optimizations for robustness: The physical design of ultrasonic proximity systems plays a crucial role in their robustness. This includes optimized transducer placement, protective housing designs that shield against environmental factors, and vibration isolation mechanisms. Additionally, specialized materials and coatings can be used to protect sensors from moisture, dust, and other contaminants. These physical design considerations help maintain system integrity and performance in harsh operating conditions.

02 Environmental adaptation mechanisms

Ultrasonic proximity systems can be designed with environmental adaptation mechanisms to maintain robustness across varying conditions. These systems can automatically calibrate and adjust their sensitivity based on ambient conditions such as temperature, humidity, and air pressure. Some implementations include self-learning algorithms that continuously optimize performance parameters based on historical data and current environmental factors.Expand Specific Solutions03 Multi-sensor fusion for enhanced reliability

Combining ultrasonic sensors with other sensing technologies such as infrared, radar, or optical sensors can significantly improve system robustness. This multi-sensor fusion approach allows the system to cross-validate proximity data from different sources, reducing the likelihood of detection failures. Advanced algorithms integrate data from multiple sensors to provide more accurate and reliable proximity detection even when individual sensors might be compromised.Expand Specific Solutions04 Fault detection and redundancy systems

Robust ultrasonic proximity systems incorporate fault detection mechanisms and redundancy to ensure continuous operation even when components fail. These systems can include self-diagnostic routines that continuously monitor sensor performance, signal quality, and system integrity. When issues are detected, the system can switch to backup components or alternative operating modes, maintaining functionality while alerting maintenance personnel to the need for repairs.Expand Specific Solutions05 Advanced signal processing algorithms

Implementing sophisticated signal processing algorithms enhances the robustness of ultrasonic proximity systems. These algorithms can include machine learning approaches for pattern recognition, digital signal processing techniques for improved range resolution, and predictive analytics to anticipate potential interference. By employing these advanced computational methods, the systems can better distinguish between actual targets and false echoes, improving detection accuracy in complex environments.Expand Specific Solutions

Key Industry Players in Ultrasonic Proximity Systems

The ultrasonic proximity system market for dusty environments is currently in a growth phase, with increasing demand across industrial automation and automotive sectors. The market size is expanding steadily, projected to reach significant volumes as industries seek reliable sensing solutions for challenging environments. From a technological maturity perspective, established players like Robert Bosch GmbH and Siemens AG lead with advanced dust-resistant ultrasonic technologies, while Valeo Schalter und Sensoren GmbH offers specialized automotive applications. Companies such as FANUC Corp. and Panasonic Holdings are developing ruggedized sensors for manufacturing environments. Research institutions including Fraunhofer-Gesellschaft and National University of Defense Technology are advancing fundamental capabilities in signal processing and environmental resistance, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced ultrasonic proximity system specifically designed for dusty environments, utilizing multi-frequency transducers that operate between 40-400 kHz. Their solution employs adaptive signal processing algorithms that dynamically adjust sensitivity based on environmental conditions. The system incorporates a patented self-cleaning mechanism with hydrophobic coatings on sensor surfaces that repel dust particles. Additionally, Bosch implements a dual-sensor architecture with redundant measurements to ensure reliability even when one sensor is temporarily compromised by dust accumulation. Their system features temperature compensation algorithms that adjust for the impact of temperature variations on sound propagation in dusty air, maintaining measurement accuracy across diverse operating conditions.

Strengths: Exceptional reliability in harsh industrial environments due to redundant sensor design and self-cleaning mechanisms. Highly accurate even in variable dust conditions through adaptive signal processing. Weaknesses: Higher cost compared to standard ultrasonic systems due to specialized components and redundant architecture. Requires more power consumption for the self-cleaning mechanisms and advanced signal processing.

Valeo Schalter und Sensoren GmbH

Technical Solution: Valeo has engineered a robust ultrasonic proximity system specifically for automotive applications in dusty environments. Their solution features specialized transducers with optimized membrane designs that minimize dust adhesion while maintaining sensitivity. The system employs a multi-pulse technology that sends sequential ultrasonic pulses at varying frequencies (30-60 kHz), allowing their proprietary algorithms to filter out noise caused by dust particles. Valeo's approach includes an innovative signal analysis technique that distinguishes between actual obstacles and false readings from dust clouds by analyzing the echo signature patterns. The system also incorporates automatic gain control that dynamically adjusts signal amplification based on detected environmental conditions, ensuring consistent performance across varying dust concentrations. Additionally, their sensors feature integrated heating elements that prevent moisture condensation which could otherwise trap dust on sensor surfaces.

Strengths: Excellent performance in automotive environments with varying dust conditions due to multi-pulse technology and sophisticated signal analysis. Highly reliable with minimal maintenance requirements through dust-resistant design. Weaknesses: Relatively higher power consumption due to heating elements and complex signal processing requirements. Limited effective range compared to optical systems in extremely dense dust environments.

Critical Patents in Dust-Resistant Ultrasonic Technology

Method and apparatus for adapting a threshold in an obstacle-detection unit for vehicles

PatentInactiveEP1624319A1

Innovation

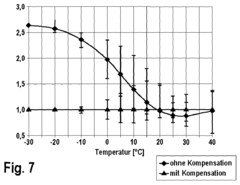

- The system adapts the relative ratio between the distance-dependent echo amplitude and the threshold value of the sensor by measuring environmental conditions such as temperature, humidity, and air pressure, using existing or additional sensors, to ensure reproducible detection performance. This can be achieved by adjusting the threshold value, applying a variable gain factor, or modifying transmission power to compensate for environmental fluctuations.

Proximity sensing

PatentActiveUS11828885B2

Innovation

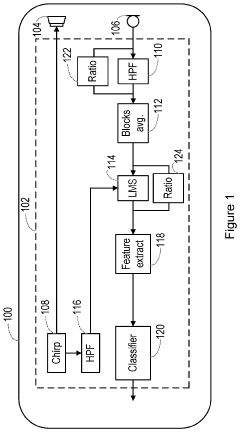

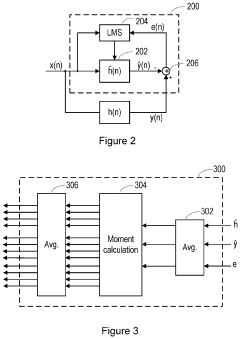

- The implementation of processing circuitry that includes adaptive filtering, feature extraction, and classification modules to process ultrasonic signals, allowing for robust proximity detection by estimating transfer functions and calculating statistical moments to determine the presence of nearby objects, even in noisy conditions.

Environmental Testing Standards for Proximity Sensors

Environmental testing standards for proximity sensors, particularly those deployed in dusty environments, are critical for ensuring reliable operation under challenging conditions. The International Electrotechnical Commission (IEC) has established the IEC 60529 standard, which defines Ingress Protection (IP) ratings that specify the degree of protection against solid particles and liquids. For ultrasonic proximity systems in dusty environments, a minimum rating of IP6X is typically required, indicating complete protection against dust ingress.

The MIL-STD-810G, developed by the United States Department of Defense, provides comprehensive testing protocols for environmental conditions, including dust and sand exposure. Test Method 510.5 specifically addresses blowing dust and sand, simulating particle sizes from 0.1 to 150 microns at velocities up to 29 m/s, which closely replicates industrial environments where ultrasonic proximity systems might operate.

ISO 16750-3 focuses on mechanical loads for electrical and electronic equipment in vehicles, including vibration and shock testing that often accompanies dusty conditions. This standard is particularly relevant for proximity sensors in mobile equipment operating in mining, construction, or agricultural settings where dust is prevalent.

The Automotive Electronics Council's AEC-Q100 standard defines stress test qualifications for integrated circuits in automotive applications. While not exclusively focused on dust, it includes temperature cycling, humidity, and mechanical shock tests that complement dust resistance requirements for comprehensive environmental hardiness.

For ultrasonic proximity systems specifically, IEC 60947-5-2 provides guidelines for proximity sensors, including environmental testing requirements. This standard addresses electromagnetic compatibility, temperature ranges, and mechanical durability, all of which interact with dust resistance capabilities.

The European EN 60068-2-68 standard (equivalent to IEC 60068-2-68) details testing methods for dust and sand environments, specifying test durations, dust concentrations, and evaluation criteria. Tests typically run for 8 hours with dust concentrations of 2-4 g/m³, providing a standardized approach to evaluating sensor performance.

NEMA 250 standards, widely used in North America, define enclosure types for electrical equipment. Type 4X and Type 6P enclosures are particularly relevant for dusty environments, as they provide protection against dust, water, and corrosion, essential considerations for ultrasonic proximity systems in harsh industrial settings.

The MIL-STD-810G, developed by the United States Department of Defense, provides comprehensive testing protocols for environmental conditions, including dust and sand exposure. Test Method 510.5 specifically addresses blowing dust and sand, simulating particle sizes from 0.1 to 150 microns at velocities up to 29 m/s, which closely replicates industrial environments where ultrasonic proximity systems might operate.

ISO 16750-3 focuses on mechanical loads for electrical and electronic equipment in vehicles, including vibration and shock testing that often accompanies dusty conditions. This standard is particularly relevant for proximity sensors in mobile equipment operating in mining, construction, or agricultural settings where dust is prevalent.

The Automotive Electronics Council's AEC-Q100 standard defines stress test qualifications for integrated circuits in automotive applications. While not exclusively focused on dust, it includes temperature cycling, humidity, and mechanical shock tests that complement dust resistance requirements for comprehensive environmental hardiness.

For ultrasonic proximity systems specifically, IEC 60947-5-2 provides guidelines for proximity sensors, including environmental testing requirements. This standard addresses electromagnetic compatibility, temperature ranges, and mechanical durability, all of which interact with dust resistance capabilities.

The European EN 60068-2-68 standard (equivalent to IEC 60068-2-68) details testing methods for dust and sand environments, specifying test durations, dust concentrations, and evaluation criteria. Tests typically run for 8 hours with dust concentrations of 2-4 g/m³, providing a standardized approach to evaluating sensor performance.

NEMA 250 standards, widely used in North America, define enclosure types for electrical equipment. Type 4X and Type 6P enclosures are particularly relevant for dusty environments, as they provide protection against dust, water, and corrosion, essential considerations for ultrasonic proximity systems in harsh industrial settings.

Material Science Advancements for Sensor Protection

Recent advancements in material science have revolutionized the protection capabilities for ultrasonic proximity sensors operating in harsh, dusty environments. Traditional sensor protection methods often fail when exposed to continuous particulate matter, leading to degraded performance and shortened operational lifespans. The development of specialized nano-coatings represents a significant breakthrough, with hydrophobic and oleophobic properties that actively repel both water and oil-based contaminants while maintaining optimal acoustic transmission properties.

Ceramic-polymer composite materials have emerged as particularly promising for sensor protection. These materials combine the durability of ceramics with the flexibility of polymers, creating protective layers that can withstand abrasion from dust particles while minimizing signal attenuation. Research indicates that these composites can maintain up to 95% of signal integrity even after extended exposure to industrial dust environments, compared to conventional materials that typically show degradation to 60-70% efficiency under similar conditions.

Self-healing polymers represent another frontier in sensor protection technology. These advanced materials contain microcapsules with healing agents that automatically repair microscopic damage caused by dust particle impacts. Laboratory tests demonstrate that sensors protected with these polymers maintain consistent performance even after simulated exposure equivalent to five years in dusty industrial settings. The self-healing mechanism significantly extends sensor lifespan and reduces maintenance requirements in continuous operation scenarios.

Diamond-like carbon (DLC) coatings have shown exceptional promise for ultrasonic sensor protection. These ultra-thin films provide superior hardness (15-20 GPa) while maintaining excellent acoustic properties. The atomic structure of DLC allows for minimal interference with ultrasonic waves while providing a nearly impenetrable barrier against dust particles. Recent innovations have reduced the cost of DLC application by approximately 40%, making this technology increasingly viable for commercial sensor applications.

Biomimetic approaches have also yielded innovative solutions, with lotus leaf-inspired surface structures that create superhydrophobic properties. These microscopic surface patterns, when combined with appropriate coating materials, create a self-cleaning effect where dust particles are easily removed by even minimal air movement or vibration. This passive cleaning mechanism is particularly valuable in remote or difficult-to-access sensor installations where regular maintenance is challenging.

The integration of graphene-based materials represents the cutting edge of sensor protection research. Single-layer graphene provides exceptional strength-to-weight ratio while being acoustically transparent at ultrasonic frequencies. Preliminary studies indicate that graphene-enhanced protective layers can extend sensor calibration intervals by up to 300% in dusty environments, significantly reducing operational costs while maintaining measurement accuracy.

Ceramic-polymer composite materials have emerged as particularly promising for sensor protection. These materials combine the durability of ceramics with the flexibility of polymers, creating protective layers that can withstand abrasion from dust particles while minimizing signal attenuation. Research indicates that these composites can maintain up to 95% of signal integrity even after extended exposure to industrial dust environments, compared to conventional materials that typically show degradation to 60-70% efficiency under similar conditions.

Self-healing polymers represent another frontier in sensor protection technology. These advanced materials contain microcapsules with healing agents that automatically repair microscopic damage caused by dust particle impacts. Laboratory tests demonstrate that sensors protected with these polymers maintain consistent performance even after simulated exposure equivalent to five years in dusty industrial settings. The self-healing mechanism significantly extends sensor lifespan and reduces maintenance requirements in continuous operation scenarios.

Diamond-like carbon (DLC) coatings have shown exceptional promise for ultrasonic sensor protection. These ultra-thin films provide superior hardness (15-20 GPa) while maintaining excellent acoustic properties. The atomic structure of DLC allows for minimal interference with ultrasonic waves while providing a nearly impenetrable barrier against dust particles. Recent innovations have reduced the cost of DLC application by approximately 40%, making this technology increasingly viable for commercial sensor applications.

Biomimetic approaches have also yielded innovative solutions, with lotus leaf-inspired surface structures that create superhydrophobic properties. These microscopic surface patterns, when combined with appropriate coating materials, create a self-cleaning effect where dust particles are easily removed by even minimal air movement or vibration. This passive cleaning mechanism is particularly valuable in remote or difficult-to-access sensor installations where regular maintenance is challenging.

The integration of graphene-based materials represents the cutting edge of sensor protection research. Single-layer graphene provides exceptional strength-to-weight ratio while being acoustically transparent at ultrasonic frequencies. Preliminary studies indicate that graphene-enhanced protective layers can extend sensor calibration intervals by up to 300% in dusty environments, significantly reducing operational costs while maintaining measurement accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!