Ultrasonic Transducer Failure Modes And Field Repair Procedures

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Transducer Technology Evolution and Objectives

Ultrasonic transducer technology has evolved significantly since its inception in the early 20th century, with major advancements occurring after World War II when piezoelectric materials became more widely available. The fundamental operating principle—converting electrical energy into mechanical vibrations and vice versa—has remained consistent, but the materials, designs, and applications have undergone substantial transformation. Early transducers utilized quartz crystals, which were later replaced by more efficient barium titanate ceramics in the 1950s, and subsequently by lead zirconate titanate (PZT) in the 1960s, which remains the dominant material today due to its superior piezoelectric properties.

The evolution of ultrasonic transducer technology has been driven by demands for higher sensitivity, broader frequency ranges, improved durability, and enhanced reliability in increasingly diverse operating environments. Modern transducers incorporate sophisticated composite materials, multi-layer structures, and advanced backing materials to optimize acoustic impedance matching and energy transfer efficiency. The miniaturization trend has enabled the development of high-frequency micro-transducers for medical imaging and precision industrial applications, while advancements in manufacturing techniques have improved consistency and reduced production costs.

Failure modes in ultrasonic transducers have historically presented significant challenges to reliability and performance longevity. Common failure mechanisms include piezoelectric element fracture, delamination between layers, electrical connection deterioration, housing seal failures leading to moisture ingress, and acoustic coupling degradation. These failure modes are often exacerbated by extreme operating conditions such as thermal cycling, mechanical shock, chemical exposure, and continuous high-power operation. Understanding these failure mechanisms has been crucial in driving technological improvements in transducer design and materials selection.

The primary objectives in ultrasonic transducer technology development are focused on several key areas. First, enhancing reliability through improved resistance to common failure modes, particularly in harsh operating environments. Second, extending operational lifespan while maintaining consistent performance characteristics throughout the service life. Third, developing field-serviceable designs that allow for cost-effective repair rather than complete replacement when failures occur. Fourth, implementing predictive maintenance capabilities through integrated health monitoring systems that can detect early signs of degradation before catastrophic failure.

Future technological trajectories aim to address these objectives through materials innovation, including lead-free piezoelectric alternatives to meet environmental regulations, self-healing composite structures, and advanced polymer encapsulants with superior moisture resistance. Design innovations are exploring modular architectures that facilitate field replacement of individual components, while manufacturing advancements are focusing on improved quality control and non-destructive testing methods to identify potential failure points before deployment. These evolutionary paths collectively support the development of more reliable, maintainable, and environmentally sustainable ultrasonic transducer technologies.

The evolution of ultrasonic transducer technology has been driven by demands for higher sensitivity, broader frequency ranges, improved durability, and enhanced reliability in increasingly diverse operating environments. Modern transducers incorporate sophisticated composite materials, multi-layer structures, and advanced backing materials to optimize acoustic impedance matching and energy transfer efficiency. The miniaturization trend has enabled the development of high-frequency micro-transducers for medical imaging and precision industrial applications, while advancements in manufacturing techniques have improved consistency and reduced production costs.

Failure modes in ultrasonic transducers have historically presented significant challenges to reliability and performance longevity. Common failure mechanisms include piezoelectric element fracture, delamination between layers, electrical connection deterioration, housing seal failures leading to moisture ingress, and acoustic coupling degradation. These failure modes are often exacerbated by extreme operating conditions such as thermal cycling, mechanical shock, chemical exposure, and continuous high-power operation. Understanding these failure mechanisms has been crucial in driving technological improvements in transducer design and materials selection.

The primary objectives in ultrasonic transducer technology development are focused on several key areas. First, enhancing reliability through improved resistance to common failure modes, particularly in harsh operating environments. Second, extending operational lifespan while maintaining consistent performance characteristics throughout the service life. Third, developing field-serviceable designs that allow for cost-effective repair rather than complete replacement when failures occur. Fourth, implementing predictive maintenance capabilities through integrated health monitoring systems that can detect early signs of degradation before catastrophic failure.

Future technological trajectories aim to address these objectives through materials innovation, including lead-free piezoelectric alternatives to meet environmental regulations, self-healing composite structures, and advanced polymer encapsulants with superior moisture resistance. Design innovations are exploring modular architectures that facilitate field replacement of individual components, while manufacturing advancements are focusing on improved quality control and non-destructive testing methods to identify potential failure points before deployment. These evolutionary paths collectively support the development of more reliable, maintainable, and environmentally sustainable ultrasonic transducer technologies.

Market Demand Analysis for Reliable Ultrasonic Transducers

The global market for ultrasonic transducers continues to expand significantly, driven by increasing applications across multiple industries. The demand for reliable ultrasonic transducers is particularly strong in sectors such as healthcare, industrial manufacturing, automotive, and energy production, where equipment failure can result in substantial operational disruptions and financial losses.

In the healthcare sector, ultrasonic transducers are critical components in diagnostic imaging equipment, with the global medical ultrasound market projected to reach $9 billion by 2025. Hospitals and medical facilities require transducers with minimal downtime, as equipment failures directly impact patient care and diagnostic capabilities. The growing adoption of point-of-care ultrasound further intensifies the need for durable, field-serviceable transducers.

Industrial manufacturing represents another major market segment, where ultrasonic transducers are extensively used in non-destructive testing, quality control, and precision cleaning applications. Manufacturing facilities typically operate on tight production schedules, making rapid field repair capabilities essential to minimize costly production interruptions. Market research indicates that manufacturing downtime costs can exceed $10,000 per hour in high-volume production environments.

The automotive industry increasingly relies on ultrasonic technology for various applications including distance measurement, object detection, and automated driving systems. As vehicles incorporate more advanced driver assistance systems (ADAS), the demand for highly reliable ultrasonic sensors continues to grow. Industry analysts estimate that the automotive ultrasonic sensor market will expand at a compound annual growth rate of 7% through 2027.

Energy sector applications, particularly in oil and gas exploration and production, represent a significant market for industrial-grade ultrasonic transducers. These environments subject equipment to extreme conditions, accelerating failure rates and necessitating robust field repair procedures. The offshore oil and gas industry alone spends approximately $300 million annually on ultrasonic inspection equipment and maintenance.

Market research indicates that end-users across all sectors are increasingly prioritizing total cost of ownership over initial purchase price when selecting ultrasonic equipment. This shift has created growing demand for transducers designed with serviceability in mind, along with comprehensive field repair procedures that can be implemented by on-site technicians rather than requiring factory returns.

The aftermarket for ultrasonic transducer repair and replacement parts is also expanding, with specialized service providers reporting annual growth rates exceeding 8%. This trend reflects both the growing installed base of ultrasonic equipment and the economic advantages of repair versus replacement for high-value transducer assemblies.

In the healthcare sector, ultrasonic transducers are critical components in diagnostic imaging equipment, with the global medical ultrasound market projected to reach $9 billion by 2025. Hospitals and medical facilities require transducers with minimal downtime, as equipment failures directly impact patient care and diagnostic capabilities. The growing adoption of point-of-care ultrasound further intensifies the need for durable, field-serviceable transducers.

Industrial manufacturing represents another major market segment, where ultrasonic transducers are extensively used in non-destructive testing, quality control, and precision cleaning applications. Manufacturing facilities typically operate on tight production schedules, making rapid field repair capabilities essential to minimize costly production interruptions. Market research indicates that manufacturing downtime costs can exceed $10,000 per hour in high-volume production environments.

The automotive industry increasingly relies on ultrasonic technology for various applications including distance measurement, object detection, and automated driving systems. As vehicles incorporate more advanced driver assistance systems (ADAS), the demand for highly reliable ultrasonic sensors continues to grow. Industry analysts estimate that the automotive ultrasonic sensor market will expand at a compound annual growth rate of 7% through 2027.

Energy sector applications, particularly in oil and gas exploration and production, represent a significant market for industrial-grade ultrasonic transducers. These environments subject equipment to extreme conditions, accelerating failure rates and necessitating robust field repair procedures. The offshore oil and gas industry alone spends approximately $300 million annually on ultrasonic inspection equipment and maintenance.

Market research indicates that end-users across all sectors are increasingly prioritizing total cost of ownership over initial purchase price when selecting ultrasonic equipment. This shift has created growing demand for transducers designed with serviceability in mind, along with comprehensive field repair procedures that can be implemented by on-site technicians rather than requiring factory returns.

The aftermarket for ultrasonic transducer repair and replacement parts is also expanding, with specialized service providers reporting annual growth rates exceeding 8%. This trend reflects both the growing installed base of ultrasonic equipment and the economic advantages of repair versus replacement for high-value transducer assemblies.

Current Challenges in Ultrasonic Transducer Reliability

Ultrasonic transducers face significant reliability challenges across various industrial applications, with failure rates becoming increasingly problematic as deployment environments grow more demanding. Current reliability issues stem from multiple sources, including material degradation, electrical connection failures, and mechanical damage during operation. The piezoelectric elements at the core of these devices are particularly susceptible to performance deterioration under extreme temperature conditions, with thermal cycling causing microcracks that progressively reduce signal strength and accuracy.

Environmental factors present substantial challenges to transducer reliability. Exposure to corrosive substances in industrial settings accelerates degradation of housing materials and internal components. High humidity environments contribute to electrical shorts and impedance changes that compromise measurement accuracy. Additionally, continuous vibration in industrial applications leads to mechanical fatigue of internal connections and mounting structures, resulting in intermittent failures that are difficult to diagnose.

Manufacturing inconsistencies represent another significant challenge. Variations in piezoelectric material properties, bonding quality between layers, and assembly precision lead to unpredictable performance differences between seemingly identical transducers. These inconsistencies make quality control difficult and contribute to premature failures in field applications. The industry currently lacks standardized testing protocols that can effectively predict long-term reliability under varied operating conditions.

Electrical interface issues further complicate reliability. Cable connections remain a primary failure point, with repeated flexing and environmental exposure causing conductor breakage and insulation deterioration. Modern transducers incorporating integrated electronics face additional challenges related to component miniaturization and thermal management, as densely packed circuits generate heat that accelerates aging of nearby piezoelectric elements.

Maintenance practices present operational challenges. Many ultrasonic systems lack effective self-diagnostic capabilities, making it difficult to detect gradual performance degradation before complete failure occurs. Field repair procedures are often inadequate, with technicians lacking proper tools and training to perform effective repairs in industrial environments. The absence of standardized repair protocols results in inconsistent repair quality and shortened service life after maintenance interventions.

The economic impact of these reliability challenges is substantial. Unexpected transducer failures lead to costly production downtime, particularly in continuous manufacturing processes where ultrasonic measurements are critical for quality control. The high replacement cost of specialized transducers, combined with installation and calibration requirements, creates significant operational expenses for industries relying on ultrasonic technology.

Environmental factors present substantial challenges to transducer reliability. Exposure to corrosive substances in industrial settings accelerates degradation of housing materials and internal components. High humidity environments contribute to electrical shorts and impedance changes that compromise measurement accuracy. Additionally, continuous vibration in industrial applications leads to mechanical fatigue of internal connections and mounting structures, resulting in intermittent failures that are difficult to diagnose.

Manufacturing inconsistencies represent another significant challenge. Variations in piezoelectric material properties, bonding quality between layers, and assembly precision lead to unpredictable performance differences between seemingly identical transducers. These inconsistencies make quality control difficult and contribute to premature failures in field applications. The industry currently lacks standardized testing protocols that can effectively predict long-term reliability under varied operating conditions.

Electrical interface issues further complicate reliability. Cable connections remain a primary failure point, with repeated flexing and environmental exposure causing conductor breakage and insulation deterioration. Modern transducers incorporating integrated electronics face additional challenges related to component miniaturization and thermal management, as densely packed circuits generate heat that accelerates aging of nearby piezoelectric elements.

Maintenance practices present operational challenges. Many ultrasonic systems lack effective self-diagnostic capabilities, making it difficult to detect gradual performance degradation before complete failure occurs. Field repair procedures are often inadequate, with technicians lacking proper tools and training to perform effective repairs in industrial environments. The absence of standardized repair protocols results in inconsistent repair quality and shortened service life after maintenance interventions.

The economic impact of these reliability challenges is substantial. Unexpected transducer failures lead to costly production downtime, particularly in continuous manufacturing processes where ultrasonic measurements are critical for quality control. The high replacement cost of specialized transducers, combined with installation and calibration requirements, creates significant operational expenses for industries relying on ultrasonic technology.

Common Failure Modes and Diagnostic Techniques

01 Mechanical failure modes of ultrasonic transducers

Ultrasonic transducers can experience mechanical failures due to various factors including physical damage, delamination of piezoelectric elements, cracking of the crystal structure, and fatigue from repeated vibrations. These mechanical failures often result from excessive stress, thermal cycling, or manufacturing defects. When the mechanical integrity of the transducer is compromised, it can lead to reduced output power, inconsistent performance, or complete failure of the device.- Mechanical failure modes of ultrasonic transducers: Mechanical failures in ultrasonic transducers can occur due to various factors including physical damage, material fatigue, and structural defects. These failures may manifest as cracks in the piezoelectric elements, delamination of layers, or damage to the housing. Mechanical stress from continuous operation, thermal cycling, or external impacts can lead to degradation of transducer performance over time. Such failures typically result in reduced output power, inconsistent performance, or complete transducer failure.

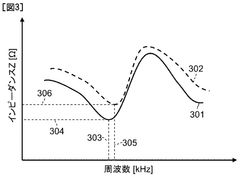

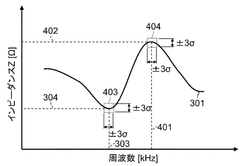

- Electrical failure modes and detection methods: Electrical failures in ultrasonic transducers include impedance mismatch, short circuits, open circuits, and degradation of electrical connections. These failures can be detected through various methods including impedance analysis, electrical signature monitoring, and performance testing. Monitoring changes in electrical parameters such as resonant frequency, impedance, and power consumption can provide early warning of impending transducer failure. Advanced detection systems may incorporate real-time monitoring to prevent catastrophic failures during operation.

- Thermal-related failure mechanisms: Thermal stress is a significant contributor to ultrasonic transducer failures. Excessive heat generation during operation can lead to depoling of piezoelectric materials, thermal expansion mismatches between components, and degradation of bonding materials. Continuous high-power operation without adequate cooling can accelerate aging and reduce transducer lifespan. Temperature monitoring and thermal management systems are essential for preventing thermal-related failures, especially in high-power applications where heat generation is substantial.

- Diagnostic and monitoring systems for failure prevention: Advanced diagnostic and monitoring systems can detect early signs of ultrasonic transducer degradation before catastrophic failure occurs. These systems may employ techniques such as acoustic emission monitoring, vibration analysis, and electrical parameter tracking to assess transducer health. Predictive maintenance algorithms can analyze performance trends to forecast potential failures and schedule maintenance interventions. Real-time monitoring systems can automatically adjust operating parameters or shut down equipment when abnormal conditions are detected, preventing further damage to the transducer or associated equipment.

- Environmental and application-specific failure modes: Environmental factors and specific application conditions can significantly impact ultrasonic transducer reliability. Exposure to corrosive substances, high humidity, pressure variations, or radiation can accelerate degradation of transducer components. In medical applications, biological fouling and sterilization processes may contribute to failure. Industrial applications may face challenges from particulate contamination, chemical exposure, or mechanical vibration. Understanding the specific environmental stressors in each application is crucial for designing appropriate protective measures and maintenance protocols to extend transducer lifespan.

02 Electrical failure modes in ultrasonic transducer systems

Electrical failures in ultrasonic transducers include issues such as short circuits, open circuits, impedance mismatching, and degradation of electrical connections. These failures can occur due to moisture ingress, insulation breakdown, or electrical overstress. Electrical failures typically manifest as signal loss, reduced sensitivity, or abnormal power consumption. Monitoring electrical parameters can help detect early signs of failure before complete system breakdown occurs.Expand Specific Solutions03 Thermal-related failure modes of ultrasonic transducers

Thermal issues represent a significant failure mode for ultrasonic transducers. Excessive heat generation during operation can lead to thermal runaway, material degradation, and altered piezoelectric properties. Continuous operation at high power levels without adequate cooling can accelerate aging and reduce the operational lifespan of transducers. Temperature fluctuations can also cause differential expansion and contraction, leading to mechanical stress and eventual failure of the transducer components.Expand Specific Solutions04 Diagnostic methods for ultrasonic transducer failure detection

Various diagnostic methods can be employed to detect and predict ultrasonic transducer failures. These include impedance analysis, acoustic output measurement, pulse-echo testing, and spectral analysis of transducer response. Advanced monitoring systems can detect changes in transducer performance parameters that indicate impending failure. Early detection allows for preventive maintenance, reducing downtime and extending the operational life of ultrasonic systems. Automated diagnostic routines can be integrated into ultrasonic equipment for continuous health monitoring.Expand Specific Solutions05 Environmental factors affecting ultrasonic transducer reliability

Environmental conditions significantly impact ultrasonic transducer reliability and failure rates. Exposure to moisture, chemicals, radiation, or extreme temperatures can accelerate degradation of transducer materials. Corrosive environments can damage protective housings and electrical connections. Pressure variations and mechanical shocks can also contribute to premature failure. Designing transducers with appropriate environmental protection and selecting materials suitable for the intended operating environment can mitigate these failure modes.Expand Specific Solutions

Key Manufacturers and Service Providers Analysis

The ultrasonic transducer failure modes and field repair market is currently in a growth phase, with an estimated global market size of $3-4 billion and expanding at 5-7% annually. The competitive landscape is dominated by established medical equipment manufacturers like Philips, Siemens, and GE Precision Healthcare, who leverage their extensive R&D capabilities and global service networks. Technology maturity varies significantly across applications, with medical ultrasound being most advanced. Emerging players like Sonoscape, Lily MedTech, and Insightec are disrupting the market with innovative repair solutions and specialized transducer technologies. Traditional industrial players including Bosch and Toshiba are expanding their ultrasonic offerings, while academic institutions like Zhejiang University contribute to technological advancement through research partnerships with commercial entities.

Koninklijke Philips NV

Technical Solution: Philips has developed comprehensive ultrasonic transducer failure detection and repair protocols for their medical imaging systems. Their approach includes real-time monitoring systems that detect early signs of transducer degradation through impedance analysis and pulse-echo performance metrics. When failures are detected, Philips employs a modular repair methodology that allows field technicians to replace specific components rather than entire transducer assemblies. Their field repair kits include specialized tools for acoustic stack disassembly and precision alignment fixtures to ensure proper element positioning during reassembly. Philips has also implemented an AI-based diagnostic system that can predict potential failures before they occur by analyzing subtle changes in transducer performance parameters, allowing preventative maintenance to be scheduled before critical failures impact clinical operations.

Strengths: Advanced predictive maintenance capabilities reduce downtime; modular repair approach lowers replacement costs; comprehensive training program for field technicians. Weaknesses: Repair procedures often require specialized equipment not available to third-party service providers; some proprietary components cannot be serviced in the field.

Siemens AG

Technical Solution: Siemens has engineered a sophisticated ultrasonic transducer failure management system for their medical and industrial equipment. Their approach incorporates multi-parameter monitoring that tracks electrical impedance, bandwidth, sensitivity, and temperature variations to identify potential failure modes. For field repairs, Siemens utilizes a systematic troubleshooting methodology that first isolates whether issues originate from the transducer elements, cabling, or control electronics. Their field repair procedures include specialized connector repair kits, element re-coupling techniques, and acoustic lens replacement protocols. Siemens has developed proprietary repair compounds that can restore acoustic matching layers without complete disassembly. Their field service engineers are equipped with portable test equipment that can perform comprehensive transducer performance verification after repairs, ensuring restored functionality meets original specifications.

Strengths: Comprehensive diagnostic capabilities that precisely identify failure modes; field-replaceable components reduce repair time; portable test equipment ensures quality of repairs. Weaknesses: Complex repair procedures require extensive technician training; some advanced repairs still require return to factory service centers.

Critical Patents and Research on Transducer Durability

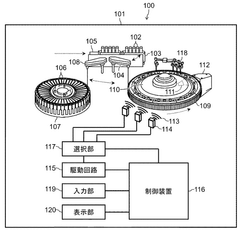

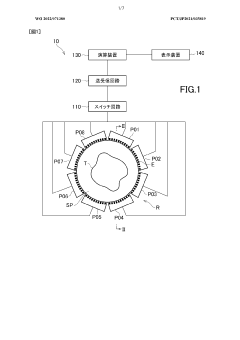

Automatic analysis apparatus, diagnosis system, and diagnosis method

PatentWO2025154360A1

Innovation

- An automated analyzer with a control device that defines a unique normal range of electrical impedance for each ultrasonic transducer based on its measured impedance, allowing for precise failure diagnosis by comparing measured values against this defined range.

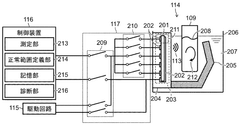

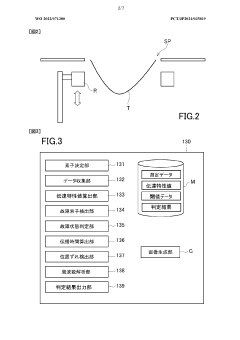

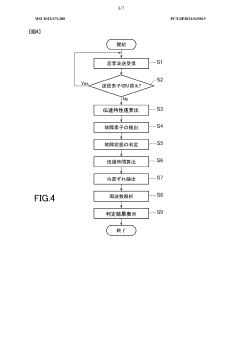

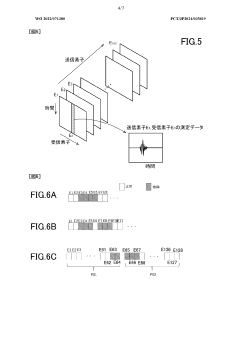

Malfunction inspection method for ultrasonic imaging system, and ultrasonic imaging system

PatentWO2022071380A1

Innovation

- A failure inspection method that automatically detects faulty elements by calculating transmission and reception characteristics, determining transfer values, and classifying failure states, using a system with a switch circuit and arithmetic device to identify and diagnose issues in ultrasonic transducers and circuits, allowing for periodic monitoring and prediction of repair needs.

Field Repair Methodologies and Best Practices

Field repair of ultrasonic transducers requires systematic approaches that balance technical precision with practical constraints of on-site environments. The most effective repair methodologies follow a structured diagnostic-to-resolution pathway, beginning with non-invasive testing procedures to identify the specific failure mode before proceeding to intervention.

Standard field repair protocols typically include signal path verification, impedance measurement, and pulse-echo testing as preliminary diagnostic steps. These methods allow technicians to differentiate between electronic failures, acoustic coupling issues, and physical damage to the piezoelectric elements without disassembling the transducer unit.

For common failure modes such as cable damage or connector issues, repair procedures focus on component replacement using field-ready kits containing pre-calibrated parts. When addressing acoustic coupling deterioration, technicians employ specialized coupling gel replacement techniques that maintain the precise spacing requirements between transducer elements and housing.

Best practices emphasize the importance of environmental controls during field repairs. Temporary clean zones should be established using portable enclosures with controlled temperature and humidity, particularly when exposing sensitive piezoelectric elements. Documentation indicates that maintaining conditions within ±5°C of standard operating temperature significantly improves repair success rates.

Calibration procedures represent a critical component of field repair methodologies. Post-repair validation must include both electrical parameter verification and acoustic performance testing against reference standards. Field-portable calibration equipment has evolved to provide near-laboratory precision, with modern units achieving measurement accuracy within 2-3% of bench testing results.

Training requirements for field technicians have been standardized across the industry, with certification programs focusing on failure mode recognition and repair technique selection. The most successful repair programs implement a tiered approach, where technicians are certified for specific repair types based on complexity and risk.

Recent innovations in field repair include augmented reality guidance systems that provide real-time procedural assistance and remote expert consultation. These systems have demonstrated a 27% improvement in first-time repair success rates and a 35% reduction in average repair time when deployed in challenging field environments.

Cost-benefit analyses of field repair versus replacement strategies indicate that on-site repairs are economically advantageous for approximately 68% of ultrasonic transducer failures, with the decision threshold primarily determined by the specific failure mode and the operational criticality of the equipment.

Standard field repair protocols typically include signal path verification, impedance measurement, and pulse-echo testing as preliminary diagnostic steps. These methods allow technicians to differentiate between electronic failures, acoustic coupling issues, and physical damage to the piezoelectric elements without disassembling the transducer unit.

For common failure modes such as cable damage or connector issues, repair procedures focus on component replacement using field-ready kits containing pre-calibrated parts. When addressing acoustic coupling deterioration, technicians employ specialized coupling gel replacement techniques that maintain the precise spacing requirements between transducer elements and housing.

Best practices emphasize the importance of environmental controls during field repairs. Temporary clean zones should be established using portable enclosures with controlled temperature and humidity, particularly when exposing sensitive piezoelectric elements. Documentation indicates that maintaining conditions within ±5°C of standard operating temperature significantly improves repair success rates.

Calibration procedures represent a critical component of field repair methodologies. Post-repair validation must include both electrical parameter verification and acoustic performance testing against reference standards. Field-portable calibration equipment has evolved to provide near-laboratory precision, with modern units achieving measurement accuracy within 2-3% of bench testing results.

Training requirements for field technicians have been standardized across the industry, with certification programs focusing on failure mode recognition and repair technique selection. The most successful repair programs implement a tiered approach, where technicians are certified for specific repair types based on complexity and risk.

Recent innovations in field repair include augmented reality guidance systems that provide real-time procedural assistance and remote expert consultation. These systems have demonstrated a 27% improvement in first-time repair success rates and a 35% reduction in average repair time when deployed in challenging field environments.

Cost-benefit analyses of field repair versus replacement strategies indicate that on-site repairs are economically advantageous for approximately 68% of ultrasonic transducer failures, with the decision threshold primarily determined by the specific failure mode and the operational criticality of the equipment.

Environmental Factors Affecting Transducer Performance

Ultrasonic transducers operate in diverse environments that significantly impact their performance and longevity. Temperature variations represent one of the most critical environmental factors affecting these devices. When exposed to extreme heat, the piezoelectric materials within transducers may experience depolarization, resulting in diminished sensitivity and output power. Conversely, extremely cold conditions can cause brittleness in bonding materials and increase the risk of mechanical failure during operation. Temperature cycling—frequent transitions between hot and cold states—creates thermal stress that can accelerate fatigue in internal components and connection points.

Humidity and moisture exposure constitute another major environmental challenge. Water ingress into transducer housings can cause electrical shorts, corrosion of internal components, and degradation of backing materials. In marine or offshore applications, salt water exposure presents an even greater threat due to its highly corrosive nature, which can rapidly deteriorate electrical connections and metallic components within the transducer assembly.

Chemical exposure represents a significant risk factor in industrial settings. Acids, bases, solvents, and other aggressive chemicals can attack transducer housing materials, compromise seals, and degrade internal components. The specific vulnerability depends on the materials used in construction, with some polymers offering superior chemical resistance compared to others. Even seemingly benign substances can, over time, cause material degradation that compromises transducer integrity.

Mechanical factors, including vibration and shock, contribute substantially to transducer wear and failure. Continuous vibration can loosen internal connections, create microfractures in piezoelectric elements, and cause fatigue failure in mounting hardware. Impact events may result in immediate catastrophic failure or create hidden damage that manifests later during operation.

Pressure variations, particularly relevant in underwater or pressurized system applications, can stress transducer housings and seals beyond their design limits. Rapid pressure changes may cause mechanical stress on internal components or allow fluid ingress through temporarily compromised seals. Prolonged operation at pressures exceeding design specifications accelerates wear and increases failure probability.

Radiation exposure in nuclear environments degrades both electronic components and housing materials through ionization effects and material property changes. This specialized environmental factor requires specially designed transducers with radiation-hardened components and housing materials.

Human factors, while not strictly environmental, significantly impact transducer performance through improper handling, installation errors, and maintenance oversights. These factors often interact with environmental conditions to accelerate failure modes or create new vulnerabilities in otherwise robust systems.

Humidity and moisture exposure constitute another major environmental challenge. Water ingress into transducer housings can cause electrical shorts, corrosion of internal components, and degradation of backing materials. In marine or offshore applications, salt water exposure presents an even greater threat due to its highly corrosive nature, which can rapidly deteriorate electrical connections and metallic components within the transducer assembly.

Chemical exposure represents a significant risk factor in industrial settings. Acids, bases, solvents, and other aggressive chemicals can attack transducer housing materials, compromise seals, and degrade internal components. The specific vulnerability depends on the materials used in construction, with some polymers offering superior chemical resistance compared to others. Even seemingly benign substances can, over time, cause material degradation that compromises transducer integrity.

Mechanical factors, including vibration and shock, contribute substantially to transducer wear and failure. Continuous vibration can loosen internal connections, create microfractures in piezoelectric elements, and cause fatigue failure in mounting hardware. Impact events may result in immediate catastrophic failure or create hidden damage that manifests later during operation.

Pressure variations, particularly relevant in underwater or pressurized system applications, can stress transducer housings and seals beyond their design limits. Rapid pressure changes may cause mechanical stress on internal components or allow fluid ingress through temporarily compromised seals. Prolonged operation at pressures exceeding design specifications accelerates wear and increases failure probability.

Radiation exposure in nuclear environments degrades both electronic components and housing materials through ionization effects and material property changes. This specialized environmental factor requires specially designed transducers with radiation-hardened components and housing materials.

Human factors, while not strictly environmental, significantly impact transducer performance through improper handling, installation errors, and maintenance oversights. These factors often interact with environmental conditions to accelerate failure modes or create new vulnerabilities in otherwise robust systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!