Ultrasonic Sensor Diagnostic Checklist: Drift, Dead Zone, And Echoes

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensing Technology Background and Objectives

Ultrasonic sensing technology has evolved significantly since its inception in the early 20th century, with major advancements occurring after World War II when sonar applications demonstrated its potential. The fundamental principle remains unchanged: these sensors emit high-frequency sound waves (typically 20kHz-200kHz) and measure the time taken for echoes to return after striking objects, calculating distance through the speed of sound in the medium.

The technology has progressed from simple distance measurement to sophisticated systems capable of material characterization, flow measurement, and complex object detection. Modern ultrasonic sensors incorporate advanced signal processing algorithms, improved transducer materials, and miniaturized electronics, enabling higher accuracy, reduced power consumption, and enhanced reliability across diverse environmental conditions.

Current technological trends in ultrasonic sensing include the integration with IoT platforms, development of MEMS-based ultrasonic transducers, implementation of machine learning algorithms for signal interpretation, and the creation of multi-element array sensors for improved spatial resolution. These advancements are pushing the boundaries of what ultrasonic sensing can achieve in terms of precision, reliability, and application scope.

The diagnostic challenges of drift, dead zone, and echo management represent critical areas requiring attention in ultrasonic sensor technology. Sensor drift—the gradual deviation of measurements over time—compromises long-term reliability in industrial applications. Dead zones, where sensors cannot detect objects within a minimum distance, limit close-range detection capabilities. Echo management challenges, including multiple reflections and signal attenuation, affect measurement accuracy in complex environments.

The primary objectives of ultrasonic sensing technology development focus on addressing these limitations through several approaches. These include developing advanced calibration techniques to mitigate drift effects, creating innovative transducer designs to reduce dead zones, implementing sophisticated signal processing algorithms to distinguish between primary and secondary echoes, and enhancing environmental adaptability to maintain performance across varying conditions.

Future technological goals include achieving sub-millimeter accuracy across extended ranges, eliminating dead zones entirely, developing self-calibrating sensors that maintain accuracy without manual intervention, creating sensors with adaptive frequency capabilities to optimize performance based on environmental conditions, and integrating ultrasonic technology with complementary sensing modalities for comprehensive detection systems.

The evolution of ultrasonic sensing technology continues to be driven by demands from automotive, industrial automation, healthcare, and consumer electronics sectors, each requiring specific improvements in sensor performance, reliability, and diagnostic capabilities to address their unique application challenges.

The technology has progressed from simple distance measurement to sophisticated systems capable of material characterization, flow measurement, and complex object detection. Modern ultrasonic sensors incorporate advanced signal processing algorithms, improved transducer materials, and miniaturized electronics, enabling higher accuracy, reduced power consumption, and enhanced reliability across diverse environmental conditions.

Current technological trends in ultrasonic sensing include the integration with IoT platforms, development of MEMS-based ultrasonic transducers, implementation of machine learning algorithms for signal interpretation, and the creation of multi-element array sensors for improved spatial resolution. These advancements are pushing the boundaries of what ultrasonic sensing can achieve in terms of precision, reliability, and application scope.

The diagnostic challenges of drift, dead zone, and echo management represent critical areas requiring attention in ultrasonic sensor technology. Sensor drift—the gradual deviation of measurements over time—compromises long-term reliability in industrial applications. Dead zones, where sensors cannot detect objects within a minimum distance, limit close-range detection capabilities. Echo management challenges, including multiple reflections and signal attenuation, affect measurement accuracy in complex environments.

The primary objectives of ultrasonic sensing technology development focus on addressing these limitations through several approaches. These include developing advanced calibration techniques to mitigate drift effects, creating innovative transducer designs to reduce dead zones, implementing sophisticated signal processing algorithms to distinguish between primary and secondary echoes, and enhancing environmental adaptability to maintain performance across varying conditions.

Future technological goals include achieving sub-millimeter accuracy across extended ranges, eliminating dead zones entirely, developing self-calibrating sensors that maintain accuracy without manual intervention, creating sensors with adaptive frequency capabilities to optimize performance based on environmental conditions, and integrating ultrasonic technology with complementary sensing modalities for comprehensive detection systems.

The evolution of ultrasonic sensing technology continues to be driven by demands from automotive, industrial automation, healthcare, and consumer electronics sectors, each requiring specific improvements in sensor performance, reliability, and diagnostic capabilities to address their unique application challenges.

Market Applications and Demand Analysis

The ultrasonic sensor market has experienced significant growth in recent years, driven by increasing automation across multiple industries. The global ultrasonic sensor market was valued at approximately $4.9 billion in 2021 and is projected to reach $9.0 billion by 2026, growing at a CAGR of 12.8% during the forecast period. This growth trajectory underscores the critical importance of diagnostic capabilities for issues like drift, dead zone management, and echo processing.

Industrial automation represents the largest application segment, accounting for nearly 35% of the total market share. Manufacturing facilities increasingly rely on ultrasonic sensors for precise distance measurement, object detection, and level monitoring in production lines. The ability to diagnose and correct sensor drift is particularly valuable in this sector, where even minor measurement inaccuracies can result in significant production losses or quality issues.

The automotive industry constitutes another major market segment, with ultrasonic sensors being integral components in advanced driver assistance systems (ADAS) and parking assistance technologies. Market research indicates that the average modern vehicle contains between 8-12 ultrasonic sensors, with premium models featuring up to 16 sensors. Effective dead zone management is crucial in this application to ensure pedestrian safety and accurate proximity detection.

Healthcare applications represent the fastest-growing segment, with a projected CAGR of 15.3% through 2026. Ultrasonic sensors are increasingly utilized in medical imaging, fluid level monitoring in medical devices, and non-invasive diagnostic equipment. Echo processing capabilities are particularly important in these high-precision applications where signal clarity directly impacts diagnostic accuracy.

Consumer electronics applications have also expanded significantly, with ultrasonic sensors being incorporated into smartphones, smart home devices, and wearable technology. This segment values miniaturization and power efficiency alongside reliable performance, creating demand for sophisticated diagnostic tools that can identify and compensate for environmental interference.

Geographically, North America and Europe currently lead in market share due to high industrial automation rates and automotive manufacturing presence. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, alongside strong electronics manufacturing sectors in South Korea, Japan, and Taiwan.

Market research indicates that end-users increasingly prioritize sensors with built-in self-diagnostic capabilities, with 78% of procurement specialists citing reliability and maintenance reduction as key purchasing factors. This trend is driving demand for comprehensive diagnostic solutions addressing drift compensation, dead zone optimization, and advanced echo processing algorithms.

Industrial automation represents the largest application segment, accounting for nearly 35% of the total market share. Manufacturing facilities increasingly rely on ultrasonic sensors for precise distance measurement, object detection, and level monitoring in production lines. The ability to diagnose and correct sensor drift is particularly valuable in this sector, where even minor measurement inaccuracies can result in significant production losses or quality issues.

The automotive industry constitutes another major market segment, with ultrasonic sensors being integral components in advanced driver assistance systems (ADAS) and parking assistance technologies. Market research indicates that the average modern vehicle contains between 8-12 ultrasonic sensors, with premium models featuring up to 16 sensors. Effective dead zone management is crucial in this application to ensure pedestrian safety and accurate proximity detection.

Healthcare applications represent the fastest-growing segment, with a projected CAGR of 15.3% through 2026. Ultrasonic sensors are increasingly utilized in medical imaging, fluid level monitoring in medical devices, and non-invasive diagnostic equipment. Echo processing capabilities are particularly important in these high-precision applications where signal clarity directly impacts diagnostic accuracy.

Consumer electronics applications have also expanded significantly, with ultrasonic sensors being incorporated into smartphones, smart home devices, and wearable technology. This segment values miniaturization and power efficiency alongside reliable performance, creating demand for sophisticated diagnostic tools that can identify and compensate for environmental interference.

Geographically, North America and Europe currently lead in market share due to high industrial automation rates and automotive manufacturing presence. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, alongside strong electronics manufacturing sectors in South Korea, Japan, and Taiwan.

Market research indicates that end-users increasingly prioritize sensors with built-in self-diagnostic capabilities, with 78% of procurement specialists citing reliability and maintenance reduction as key purchasing factors. This trend is driving demand for comprehensive diagnostic solutions addressing drift compensation, dead zone optimization, and advanced echo processing algorithms.

Current Challenges in Ultrasonic Sensor Performance

Ultrasonic sensors face several significant performance challenges that impact their reliability and accuracy in various applications. One of the most persistent issues is signal drift, where sensor readings gradually deviate from true values over time. This phenomenon occurs due to component aging, environmental factors such as temperature and humidity fluctuations, and mechanical stress on the transducer elements. Studies indicate that high-quality industrial sensors may experience drift rates of 0.5-2% annually, while consumer-grade devices can show deviations up to 5-8% within the same timeframe.

Dead zones represent another critical limitation in ultrasonic sensing technology. These are minimum detection distances where sensors cannot reliably detect objects. Typically ranging from 15cm to 60cm depending on sensor design, dead zones occur because the transducer requires time to stop vibrating after emitting a pulse before it can switch to receiving mode. This limitation severely restricts applications requiring close-range detection, such as robotics and automotive parking systems, forcing engineers to implement complementary sensing technologies for complete coverage.

Echo interference presents a multifaceted challenge that manifests in several forms. Multiple reflections from complex surfaces can create false readings, while acoustic shadows from obstructions can prevent detection of objects behind them. Cross-talk between adjacent sensors in multi-sensor arrays further complicates reliable operation in densely instrumented environments. These echo-related issues become particularly problematic in environments with irregular geometries or multiple reflective surfaces.

Environmental factors significantly impact ultrasonic sensor performance. Air temperature variations affect sound propagation speed by approximately 0.6 m/s per degree Celsius, introducing measurement errors unless compensated. Humidity, air pressure, and airflow create additional variables that can degrade measurement accuracy by 2-15% under extreme conditions. Dust, water droplets, and other airborne particles can attenuate signals and create spurious reflections.

Material properties of target objects also influence detection reliability. Soft, sound-absorbing materials may not return sufficient echo energy for detection, while highly angled surfaces can deflect signals away from the receiver. Recent research indicates that surfaces with inclinations exceeding 35° from perpendicular orientation may become undetectable with standard sensors, requiring specialized configurations or alternative technologies.

Power supply stability represents an often overlooked challenge. Voltage fluctuations can alter transducer excitation characteristics, leading to inconsistent pulse generation and detection thresholds. Laboratory tests demonstrate that a 10% voltage variation can produce measurement discrepancies of 3-7%, highlighting the need for regulated power supplies in precision applications.

Dead zones represent another critical limitation in ultrasonic sensing technology. These are minimum detection distances where sensors cannot reliably detect objects. Typically ranging from 15cm to 60cm depending on sensor design, dead zones occur because the transducer requires time to stop vibrating after emitting a pulse before it can switch to receiving mode. This limitation severely restricts applications requiring close-range detection, such as robotics and automotive parking systems, forcing engineers to implement complementary sensing technologies for complete coverage.

Echo interference presents a multifaceted challenge that manifests in several forms. Multiple reflections from complex surfaces can create false readings, while acoustic shadows from obstructions can prevent detection of objects behind them. Cross-talk between adjacent sensors in multi-sensor arrays further complicates reliable operation in densely instrumented environments. These echo-related issues become particularly problematic in environments with irregular geometries or multiple reflective surfaces.

Environmental factors significantly impact ultrasonic sensor performance. Air temperature variations affect sound propagation speed by approximately 0.6 m/s per degree Celsius, introducing measurement errors unless compensated. Humidity, air pressure, and airflow create additional variables that can degrade measurement accuracy by 2-15% under extreme conditions. Dust, water droplets, and other airborne particles can attenuate signals and create spurious reflections.

Material properties of target objects also influence detection reliability. Soft, sound-absorbing materials may not return sufficient echo energy for detection, while highly angled surfaces can deflect signals away from the receiver. Recent research indicates that surfaces with inclinations exceeding 35° from perpendicular orientation may become undetectable with standard sensors, requiring specialized configurations or alternative technologies.

Power supply stability represents an often overlooked challenge. Voltage fluctuations can alter transducer excitation characteristics, leading to inconsistent pulse generation and detection thresholds. Laboratory tests demonstrate that a 10% voltage variation can produce measurement discrepancies of 3-7%, highlighting the need for regulated power supplies in precision applications.

Diagnostic Solutions for Drift, Dead Zone, and Echo Issues

01 Ultrasonic sensor dead zone management

Ultrasonic sensors have inherent dead zones - areas close to the sensor where detection is unreliable. Various techniques are employed to manage this limitation, including specialized transducer designs, signal processing algorithms, and complementary sensor arrangements. These approaches help minimize the blind spot area and improve detection capabilities at close ranges, which is particularly important in applications requiring precise proximity sensing.- Ultrasonic sensor dead zone management: Ultrasonic sensors have inherent dead zones where they cannot accurately detect objects that are too close to the sensor. Various techniques have been developed to address this limitation, including the use of multiple transducers with overlapping detection ranges, specialized signal processing algorithms, and structural modifications to the sensor design. These approaches help minimize the blind spot and improve detection capabilities at close ranges.

- Echo interference reduction techniques: Unwanted echoes can cause false readings in ultrasonic sensors. Advanced signal processing methods are employed to distinguish between primary echoes and secondary reflections. These include time-gating techniques, frequency filtering, amplitude thresholding, and pattern recognition algorithms. By implementing these methods, the sensor can better identify and filter out spurious echoes, improving measurement accuracy in complex environments with multiple reflective surfaces.

- Sensor drift compensation methods: Ultrasonic sensors experience drift due to environmental factors such as temperature, humidity, and aging of components. Compensation methods include real-time calibration using reference measurements, temperature sensing and correction algorithms, adaptive filtering techniques, and digital signal processing. These approaches continuously adjust sensor parameters to maintain accuracy despite changing conditions, extending the sensor's useful life and reliability in varying environments.

- MEMS-based ultrasonic sensor designs: Micro-Electro-Mechanical Systems (MEMS) technology has enabled the development of miniaturized ultrasonic sensors with improved performance characteristics. These designs feature reduced drift, smaller dead zones, and better echo handling through integrated circuit fabrication techniques. MEMS ultrasonic sensors incorporate specialized membrane structures, piezoelectric materials, and on-chip signal processing to achieve higher sensitivity and stability compared to conventional designs.

- Multi-sensor fusion for improved accuracy: Combining ultrasonic sensors with complementary sensing technologies helps overcome individual limitations including drift, dead zones, and echo interference. Sensor fusion approaches integrate data from ultrasonic sensors with information from infrared, optical, or radar sensors. Advanced algorithms process the combined data to provide more reliable measurements by leveraging the strengths of each sensing modality while compensating for their respective weaknesses.

02 Echo interference reduction techniques

Unwanted echoes can significantly impact ultrasonic sensor performance by creating false readings or masking actual targets. Advanced signal processing methods are implemented to filter out spurious echoes, including time-gating techniques, frequency analysis, and adaptive filtering algorithms. These methods help distinguish between primary target echoes and secondary reflections, improving measurement accuracy in complex environments with multiple reflective surfaces.Expand Specific Solutions03 Sensor drift compensation mechanisms

Environmental factors such as temperature, humidity, and aging can cause ultrasonic sensor drift over time. Compensation mechanisms include temperature sensors with calibration algorithms, self-calibration routines that periodically adjust baseline measurements, and reference signal comparison techniques. These approaches help maintain measurement accuracy and reliability throughout the sensor's operational lifetime under varying environmental conditions.Expand Specific Solutions04 MEMS-based ultrasonic sensor designs

Micro-Electro-Mechanical Systems (MEMS) technology offers advantages for ultrasonic sensing, including miniaturization, improved sensitivity, and reduced drift. MEMS-based ultrasonic sensors incorporate specialized membrane structures, piezoelectric materials, and integrated signal processing. These designs can achieve better performance in terms of dead zone reduction, echo management, and long-term stability compared to conventional ultrasonic sensors.Expand Specific Solutions05 Multi-sensor fusion for improved accuracy

Combining ultrasonic sensors with complementary sensing technologies helps overcome individual limitations including drift, dead zones, and echo interference. Sensor fusion approaches integrate data from multiple ultrasonic sensors or combine ultrasonic with other sensing modalities such as infrared, optical, or radar. Advanced algorithms process the combined data to provide more reliable measurements across varying conditions and environments.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The ultrasonic sensor diagnostic market is currently in a growth phase, with increasing adoption across industrial automation, healthcare, and automotive sectors. The global market size for ultrasonic sensor diagnostics is expanding rapidly, projected to reach significant value as industries prioritize predictive maintenance and equipment reliability. From a technological maturity perspective, established players like Siemens AG, Robert Bosch GmbH, and DENSO Corp. lead with comprehensive diagnostic solutions addressing drift, dead zone, and echo challenges. Japanese manufacturers including Hitachi, Toshiba, and Panasonic hold strong positions with advanced signal processing technologies. Specialized companies like UE Systems focus exclusively on ultrasonic detection equipment, while academic institutions such as Tohoku University and Huazhong University contribute cutting-edge research to overcome existing limitations in sensor accuracy and reliability.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive ultrasonic sensor diagnostic systems specifically addressing drift, dead zone, and echo challenges. Their approach includes multi-layer self-diagnostic algorithms that continuously monitor sensor performance parameters. The system employs adaptive threshold techniques to compensate for environmental drift factors, with temperature compensation algorithms that adjust sensitivity based on ambient conditions. For dead zone management, Bosch implements specialized signal processing that enhances near-field detection capabilities through pulse shaping and advanced receiver designs. Their echo discrimination technology uses machine learning algorithms to differentiate between true obstacles and false echoes caused by cross-talk or multi-path reflections. The diagnostic system includes real-time performance monitoring that tracks sensor degradation over time, allowing predictive maintenance before complete failure occurs. Bosch's solution integrates with vehicle diagnostic systems to provide comprehensive error reporting and troubleshooting guidance for technicians.

Strengths: Industry-leading signal processing algorithms provide superior noise rejection and environmental adaptability. Their integrated diagnostic approach offers comprehensive health monitoring across the sensor lifecycle. Weaknesses: Higher implementation complexity requires more computational resources, and the advanced systems typically come at premium price points compared to simpler alternatives.

Siemens AG

Technical Solution: Siemens has engineered a comprehensive ultrasonic sensor diagnostic ecosystem addressing drift, dead zone, and echo challenges across industrial and automotive applications. Their platform employs continuous reference monitoring technology that establishes dynamic performance baselines, enabling real-time drift detection through comparative analysis against expected response patterns. For dead zone management, Siemens implements specialized transducer array designs with optimized beam forming that significantly reduces near-field blindness. Their echo discrimination system utilizes advanced signal processing with time-frequency domain analysis to differentiate between genuine obstacles and false returns from environmental interference. The diagnostic framework incorporates environmental compensation algorithms that automatically adjust sensor parameters based on temperature, humidity, and vibration conditions. Siemens' solution features predictive maintenance capabilities through trend analysis of sensor performance metrics, allowing early intervention before critical failures occur. The system integrates with broader industrial control networks to provide comprehensive diagnostic reporting and automated calibration adjustment recommendations.

Strengths: Exceptional integration capabilities with industrial automation systems and comprehensive diagnostic data collection for long-term reliability analysis. Their multi-parameter environmental compensation provides stable performance across diverse operating conditions. Weaknesses: Higher initial implementation complexity requires specialized technical expertise, and the comprehensive system architecture may be overengineered for simpler applications.

Critical Patents and Technical Literature Review

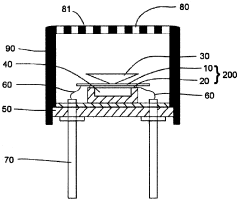

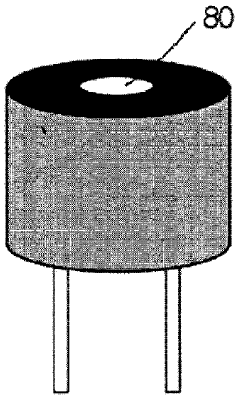

Ultrasonic sensor with different-directional directivities

PatentWO2008032982A1

Innovation

- An open ultrasonic sensor with a cylindrical housing and a unimorph diaphragm, featuring an ultrasonic emission opening that is longer in one direction and shorter in the other, allowing for different diffraction of ultrasonic waves to achieve a wide horizontal directional angle of about 180° and a limited vertical angle, preventing unnecessary signal detection.

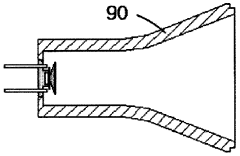

Method for detecting an object in a near field of an ultrasonic sensor

PatentWO2015158443A1

Innovation

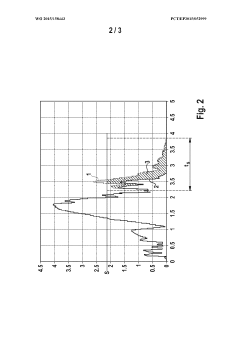

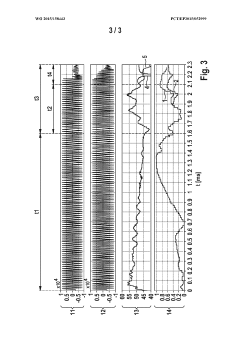

- The method involves exciting a sound transducer, detecting the decay signal, and determining deviations between the decay signal and a reference decay signal to reliably detect objects in close range, using a signal-adapted filter and varying the transmission signal frequency to differentiate between environmental and object-induced deviations.

Environmental Factors Affecting Sensor Reliability

Ultrasonic sensors operate in diverse environments that significantly impact their reliability and performance. Temperature variations represent one of the most critical environmental factors, as they directly affect the speed of sound in air. For every degree Celsius increase, sound velocity increases by approximately 0.6 meters per second. This variation can lead to measurement drift in ultrasonic sensors, particularly in applications requiring high precision or those exposed to significant temperature fluctuations throughout operational cycles.

Humidity levels similarly influence ultrasonic wave propagation. Higher humidity increases air density, which can enhance signal transmission but simultaneously increase absorption rates. This dual effect creates complex performance patterns where sensors may exhibit improved range detection in moderately humid conditions but degraded performance in extremely humid environments where water vapor attenuates the signal.

Atmospheric pressure fluctuations, though often overlooked, contribute to measurement inconsistencies by altering the acoustic impedance of the transmission medium. Barometric pressure changes of 1% can result in measurement variations of approximately 0.5%, which becomes significant in precision applications such as liquid level monitoring in pressurized vessels.

Airborne particulates present substantial challenges to ultrasonic sensor reliability. Dust, smoke, and aerosols scatter ultrasonic waves, creating false echoes or attenuating the primary signal. Industrial environments with high particulate concentrations may require specialized sensor designs with protective features or compensation algorithms to maintain measurement integrity.

Ambient noise pollution constitutes another significant reliability factor. Mechanical vibrations from nearby machinery, acoustic interference from compressed air systems, or ultrasonic emissions from other equipment can generate false triggers or mask legitimate return signals. The frequency spectrum of these noise sources determines their impact severity, with interference closest to the sensor's operating frequency causing the most significant disruption.

Wind and air currents directly affect wave propagation paths, potentially deflecting ultrasonic pulses away from intended targets or return paths. Wind speeds exceeding 10 m/s can introduce measurable errors in distance calculations, particularly in outdoor applications or ventilated industrial spaces where air movement patterns are unpredictable.

Chemical environments pose unique challenges through corrosive effects on transducer materials and acoustic coupling media. Exposure to solvents, acids, or oxidizing agents can gradually degrade sensor components, leading to sensitivity reduction or complete failure. Additionally, certain chemical vapors alter the acoustic properties of air, introducing measurement errors that standard calibration procedures may not address adequately.

Humidity levels similarly influence ultrasonic wave propagation. Higher humidity increases air density, which can enhance signal transmission but simultaneously increase absorption rates. This dual effect creates complex performance patterns where sensors may exhibit improved range detection in moderately humid conditions but degraded performance in extremely humid environments where water vapor attenuates the signal.

Atmospheric pressure fluctuations, though often overlooked, contribute to measurement inconsistencies by altering the acoustic impedance of the transmission medium. Barometric pressure changes of 1% can result in measurement variations of approximately 0.5%, which becomes significant in precision applications such as liquid level monitoring in pressurized vessels.

Airborne particulates present substantial challenges to ultrasonic sensor reliability. Dust, smoke, and aerosols scatter ultrasonic waves, creating false echoes or attenuating the primary signal. Industrial environments with high particulate concentrations may require specialized sensor designs with protective features or compensation algorithms to maintain measurement integrity.

Ambient noise pollution constitutes another significant reliability factor. Mechanical vibrations from nearby machinery, acoustic interference from compressed air systems, or ultrasonic emissions from other equipment can generate false triggers or mask legitimate return signals. The frequency spectrum of these noise sources determines their impact severity, with interference closest to the sensor's operating frequency causing the most significant disruption.

Wind and air currents directly affect wave propagation paths, potentially deflecting ultrasonic pulses away from intended targets or return paths. Wind speeds exceeding 10 m/s can introduce measurable errors in distance calculations, particularly in outdoor applications or ventilated industrial spaces where air movement patterns are unpredictable.

Chemical environments pose unique challenges through corrosive effects on transducer materials and acoustic coupling media. Exposure to solvents, acids, or oxidizing agents can gradually degrade sensor components, leading to sensitivity reduction or complete failure. Additionally, certain chemical vapors alter the acoustic properties of air, introducing measurement errors that standard calibration procedures may not address adequately.

Calibration and Maintenance Best Practices

Effective calibration and maintenance practices are essential for ensuring the optimal performance and longevity of ultrasonic sensors in industrial applications. Regular calibration schedules should be established based on the specific operating environment, with more frequent calibrations recommended for sensors exposed to harsh conditions such as extreme temperatures, humidity, or chemical exposure. The calibration process should follow a standardized procedure that includes verification against known reference distances and adjustment of gain settings to compensate for any detected drift.

Preventive maintenance protocols should incorporate periodic cleaning of the sensor face using appropriate non-abrasive materials and solvents that won't damage the transducer membrane. Accumulated dirt, dust, or moisture can significantly impact the sensor's performance by altering the acoustic properties of the transmitted signal. For sensors deployed in dusty environments, protective housings with air purge systems may be implemented to minimize maintenance frequency.

Documentation of calibration and maintenance activities is crucial for tracking sensor performance over time. Each sensor should have an individual maintenance log recording calibration dates, measured drift values, adjustments made, and the technician responsible. This historical data enables trend analysis to predict potential failures before they occur and optimize maintenance intervals based on actual performance degradation rates rather than fixed schedules.

Advanced diagnostic tools can enhance maintenance efficiency by providing real-time monitoring of sensor health parameters. These tools typically analyze signal strength, noise levels, and echo profile characteristics to detect early signs of sensor degradation. Some modern ultrasonic sensing systems incorporate self-diagnostic capabilities that automatically alert operators when performance falls outside acceptable parameters.

Environmental compensation techniques should be incorporated into maintenance practices to address factors affecting sensor accuracy. Temperature compensation algorithms should be regularly verified and updated if necessary, particularly for applications where significant temperature fluctuations occur. Similarly, cross-talk interference between adjacent sensors should be periodically assessed, especially after any changes to the installation configuration.

Training maintenance personnel on the specific failure modes of ultrasonic sensors—particularly drift, dead zone issues, and false echo detection—ensures more effective troubleshooting. Technicians should be equipped with specialized knowledge regarding the interpretation of echo profiles and recognition of common interference patterns that may indicate specific environmental or mechanical issues affecting sensor performance.

Preventive maintenance protocols should incorporate periodic cleaning of the sensor face using appropriate non-abrasive materials and solvents that won't damage the transducer membrane. Accumulated dirt, dust, or moisture can significantly impact the sensor's performance by altering the acoustic properties of the transmitted signal. For sensors deployed in dusty environments, protective housings with air purge systems may be implemented to minimize maintenance frequency.

Documentation of calibration and maintenance activities is crucial for tracking sensor performance over time. Each sensor should have an individual maintenance log recording calibration dates, measured drift values, adjustments made, and the technician responsible. This historical data enables trend analysis to predict potential failures before they occur and optimize maintenance intervals based on actual performance degradation rates rather than fixed schedules.

Advanced diagnostic tools can enhance maintenance efficiency by providing real-time monitoring of sensor health parameters. These tools typically analyze signal strength, noise levels, and echo profile characteristics to detect early signs of sensor degradation. Some modern ultrasonic sensing systems incorporate self-diagnostic capabilities that automatically alert operators when performance falls outside acceptable parameters.

Environmental compensation techniques should be incorporated into maintenance practices to address factors affecting sensor accuracy. Temperature compensation algorithms should be regularly verified and updated if necessary, particularly for applications where significant temperature fluctuations occur. Similarly, cross-talk interference between adjacent sensors should be periodically assessed, especially after any changes to the installation configuration.

Training maintenance personnel on the specific failure modes of ultrasonic sensors—particularly drift, dead zone issues, and false echo detection—ensures more effective troubleshooting. Technicians should be equipped with specialized knowledge regarding the interpretation of echo profiles and recognition of common interference patterns that may indicate specific environmental or mechanical issues affecting sensor performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!