Ultrasonic Sensor Versus Infrared: Accuracy, Range, And Cost Comparison

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic vs IR Sensing Technology Background

Sensing technology has evolved significantly over the past decades, with ultrasonic and infrared (IR) sensors emerging as two prominent solutions for distance measurement, object detection, and proximity sensing. These technologies, while serving similar purposes, operate on fundamentally different physical principles that define their capabilities and limitations.

Ultrasonic sensing technology, first developed in the early 20th century, utilizes sound waves beyond human hearing range (typically 20kHz to 200kHz) to detect objects and measure distances. The principle operates similar to echolocation used by bats and dolphins, where the sensor emits ultrasonic pulses and measures the time taken for echoes to return after reflecting off objects. This technology gained significant commercial traction in the 1980s with applications in automotive parking assistance systems.

Infrared sensing, conversely, leverages electromagnetic radiation in the infrared spectrum. IR sensing technologies primarily fall into two categories: active IR, which emits and detects reflected infrared light, and passive IR, which only detects infrared radiation emitted by objects. The foundations of IR technology date back to Sir William Herschel's discovery of infrared radiation in 1800, but practical sensing applications emerged in the mid-20th century.

The evolution of both technologies has been driven by miniaturization, cost reduction, and increasing precision. Ultrasonic sensors have progressed from bulky, expensive units to compact, affordable modules with improved range and accuracy. Similarly, IR sensors have evolved from simple thermopiles to sophisticated arrays capable of detailed thermal imaging and precise distance measurement.

Recent technological advancements have further refined these sensing modalities. Modern ultrasonic sensors incorporate temperature compensation, multi-echo processing, and advanced signal filtering to enhance reliability. IR sensing has benefited from developments in semiconductor technology, resulting in higher resolution, better thermal sensitivity, and more compact form factors.

The application landscape for both technologies has expanded dramatically. Ultrasonic sensors now feature prominently in industrial automation, robotics, healthcare, and smart home devices. IR sensing has become ubiquitous in motion detection, thermal imaging, remote controls, and increasingly in advanced driver-assistance systems (ADAS).

Understanding the historical development and technical foundations of these sensing technologies provides crucial context for comparing their performance characteristics. The fundamental differences in their operating principles—sound waves versus electromagnetic radiation—create distinct advantages and limitations that influence their suitability for specific applications, particularly when considering factors such as accuracy, range capabilities, and implementation costs.

Ultrasonic sensing technology, first developed in the early 20th century, utilizes sound waves beyond human hearing range (typically 20kHz to 200kHz) to detect objects and measure distances. The principle operates similar to echolocation used by bats and dolphins, where the sensor emits ultrasonic pulses and measures the time taken for echoes to return after reflecting off objects. This technology gained significant commercial traction in the 1980s with applications in automotive parking assistance systems.

Infrared sensing, conversely, leverages electromagnetic radiation in the infrared spectrum. IR sensing technologies primarily fall into two categories: active IR, which emits and detects reflected infrared light, and passive IR, which only detects infrared radiation emitted by objects. The foundations of IR technology date back to Sir William Herschel's discovery of infrared radiation in 1800, but practical sensing applications emerged in the mid-20th century.

The evolution of both technologies has been driven by miniaturization, cost reduction, and increasing precision. Ultrasonic sensors have progressed from bulky, expensive units to compact, affordable modules with improved range and accuracy. Similarly, IR sensors have evolved from simple thermopiles to sophisticated arrays capable of detailed thermal imaging and precise distance measurement.

Recent technological advancements have further refined these sensing modalities. Modern ultrasonic sensors incorporate temperature compensation, multi-echo processing, and advanced signal filtering to enhance reliability. IR sensing has benefited from developments in semiconductor technology, resulting in higher resolution, better thermal sensitivity, and more compact form factors.

The application landscape for both technologies has expanded dramatically. Ultrasonic sensors now feature prominently in industrial automation, robotics, healthcare, and smart home devices. IR sensing has become ubiquitous in motion detection, thermal imaging, remote controls, and increasingly in advanced driver-assistance systems (ADAS).

Understanding the historical development and technical foundations of these sensing technologies provides crucial context for comparing their performance characteristics. The fundamental differences in their operating principles—sound waves versus electromagnetic radiation—create distinct advantages and limitations that influence their suitability for specific applications, particularly when considering factors such as accuracy, range capabilities, and implementation costs.

Market Demand Analysis for Proximity Sensing Solutions

The proximity sensing solutions market is experiencing robust growth driven by increasing automation across multiple industries. The global market for proximity sensors was valued at approximately 3.2 billion USD in 2022 and is projected to reach 4.8 billion USD by 2027, representing a compound annual growth rate of 8.5%. This growth is primarily fueled by the expanding applications in automotive safety systems, industrial automation, consumer electronics, and smart infrastructure development.

In the automotive sector, proximity sensing technologies are critical components in advanced driver assistance systems (ADAS), with ultrasonic sensors dominating parking assistance applications while infrared sensors are increasingly utilized for interior monitoring systems. The average modern vehicle now contains between 8-12 proximity sensors, a number expected to increase as autonomous driving features become more prevalent.

Industrial automation represents another significant market segment, where proximity sensors enable precise object detection, positioning, and safety functions. Manufacturing facilities are increasingly adopting Industry 4.0 principles, creating sustained demand for both ultrasonic and infrared sensing solutions that can operate reliably in challenging industrial environments.

Consumer electronics constitute a rapidly expanding application area, particularly for infrared proximity sensors in smartphones, tablets, and wearable devices. These sensors enable features such as automatic screen dimming, gesture recognition, and power management. The miniaturization trend in consumer electronics favors infrared solutions due to their compact form factor and lower power consumption compared to ultrasonic alternatives.

Regional analysis reveals that Asia-Pacific dominates the proximity sensing market with approximately 40% share, driven by strong manufacturing bases in China, Japan, and South Korea. North America and Europe follow with approximately 25% each, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on sensor accuracy, reliability in diverse environmental conditions, and cost-effectiveness. Ultrasonic sensors are preferred in applications requiring longer detection ranges and operation in dusty or foggy conditions, while infrared sensors dominate where compact size, lower power consumption, and faster response times are prioritized.

The COVID-19 pandemic has accelerated demand for touchless technologies across public spaces, healthcare facilities, and commercial buildings, creating new market opportunities for proximity sensing solutions. This trend is expected to continue as hygiene awareness remains heightened in the post-pandemic environment.

Price sensitivity varies significantly by application segment, with automotive and industrial customers willing to pay premium prices for high reliability and precision, while consumer electronics manufacturers prioritize cost reduction to maintain competitive pricing in high-volume applications.

In the automotive sector, proximity sensing technologies are critical components in advanced driver assistance systems (ADAS), with ultrasonic sensors dominating parking assistance applications while infrared sensors are increasingly utilized for interior monitoring systems. The average modern vehicle now contains between 8-12 proximity sensors, a number expected to increase as autonomous driving features become more prevalent.

Industrial automation represents another significant market segment, where proximity sensors enable precise object detection, positioning, and safety functions. Manufacturing facilities are increasingly adopting Industry 4.0 principles, creating sustained demand for both ultrasonic and infrared sensing solutions that can operate reliably in challenging industrial environments.

Consumer electronics constitute a rapidly expanding application area, particularly for infrared proximity sensors in smartphones, tablets, and wearable devices. These sensors enable features such as automatic screen dimming, gesture recognition, and power management. The miniaturization trend in consumer electronics favors infrared solutions due to their compact form factor and lower power consumption compared to ultrasonic alternatives.

Regional analysis reveals that Asia-Pacific dominates the proximity sensing market with approximately 40% share, driven by strong manufacturing bases in China, Japan, and South Korea. North America and Europe follow with approximately 25% each, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on sensor accuracy, reliability in diverse environmental conditions, and cost-effectiveness. Ultrasonic sensors are preferred in applications requiring longer detection ranges and operation in dusty or foggy conditions, while infrared sensors dominate where compact size, lower power consumption, and faster response times are prioritized.

The COVID-19 pandemic has accelerated demand for touchless technologies across public spaces, healthcare facilities, and commercial buildings, creating new market opportunities for proximity sensing solutions. This trend is expected to continue as hygiene awareness remains heightened in the post-pandemic environment.

Price sensitivity varies significantly by application segment, with automotive and industrial customers willing to pay premium prices for high reliability and precision, while consumer electronics manufacturers prioritize cost reduction to maintain competitive pricing in high-volume applications.

Current Technical Limitations and Challenges

Despite the widespread adoption of ultrasonic and infrared sensing technologies, both face significant technical limitations that impact their performance in various applications. Ultrasonic sensors struggle with environmental interference, particularly in environments with high ambient noise levels or extreme temperature fluctuations. Sound wave propagation is notably affected by air density variations, leading to inconsistent readings in environments with temperature gradients or high humidity. Additionally, ultrasonic sensors exhibit a "blind zone" - a minimum detection distance typically ranging from 2-15cm depending on the model, where objects cannot be reliably detected.

Cross-talk interference presents another challenge for ultrasonic sensors when multiple units operate in close proximity, as the sound waves from one sensor can trigger false readings in adjacent sensors. This limitation restricts their deployment density in complex systems requiring multiple proximity sensors.

Infrared sensors face their own set of challenges, with ambient light interference being the most significant. Direct sunlight or strong artificial lighting can overwhelm IR receivers, causing erroneous readings or complete sensor failure. This makes outdoor applications particularly problematic without sophisticated filtering mechanisms.

Material properties significantly impact IR sensor performance, as dark or non-reflective surfaces absorb infrared light rather than reflecting it back to the sensor, resulting in detection failures or range reduction. Conversely, highly reflective or transparent surfaces can cause false readings through unexpected reflection patterns.

Both technologies exhibit angular sensitivity issues, with detection accuracy decreasing as the target moves away from the sensor's central axis. This creates "cone-shaped" detection zones rather than precise linear measurements, complicating applications requiring exact spatial awareness.

Power consumption remains a concern for both technologies in battery-operated devices, though infrared typically offers better energy efficiency than ultrasonic solutions. However, this advantage is often offset by the need for additional processing to filter noise and compensate for environmental variables.

Manufacturing consistency presents challenges for both technologies, with sensor-to-sensor variations requiring individual calibration to achieve uniform performance across production batches. This calibration requirement increases production costs and complexity, particularly for high-precision applications.

Weather and environmental robustness also differ significantly between the technologies. Ultrasonic sensors are vulnerable to wind conditions that can disperse sound waves, while infrared sensors struggle in fog, smoke, or dusty environments that scatter or block light transmission. These environmental limitations restrict deployment options and necessitate redundant sensing systems in critical applications.

Cross-talk interference presents another challenge for ultrasonic sensors when multiple units operate in close proximity, as the sound waves from one sensor can trigger false readings in adjacent sensors. This limitation restricts their deployment density in complex systems requiring multiple proximity sensors.

Infrared sensors face their own set of challenges, with ambient light interference being the most significant. Direct sunlight or strong artificial lighting can overwhelm IR receivers, causing erroneous readings or complete sensor failure. This makes outdoor applications particularly problematic without sophisticated filtering mechanisms.

Material properties significantly impact IR sensor performance, as dark or non-reflective surfaces absorb infrared light rather than reflecting it back to the sensor, resulting in detection failures or range reduction. Conversely, highly reflective or transparent surfaces can cause false readings through unexpected reflection patterns.

Both technologies exhibit angular sensitivity issues, with detection accuracy decreasing as the target moves away from the sensor's central axis. This creates "cone-shaped" detection zones rather than precise linear measurements, complicating applications requiring exact spatial awareness.

Power consumption remains a concern for both technologies in battery-operated devices, though infrared typically offers better energy efficiency than ultrasonic solutions. However, this advantage is often offset by the need for additional processing to filter noise and compensate for environmental variables.

Manufacturing consistency presents challenges for both technologies, with sensor-to-sensor variations requiring individual calibration to achieve uniform performance across production batches. This calibration requirement increases production costs and complexity, particularly for high-precision applications.

Weather and environmental robustness also differ significantly between the technologies. Ultrasonic sensors are vulnerable to wind conditions that can disperse sound waves, while infrared sensors struggle in fog, smoke, or dusty environments that scatter or block light transmission. These environmental limitations restrict deployment options and necessitate redundant sensing systems in critical applications.

Comparative Analysis of Current Sensing Solutions

01 Accuracy comparison between ultrasonic and infrared sensors

Ultrasonic sensors generally provide higher accuracy in distance measurement compared to infrared sensors, especially in varying environmental conditions. Ultrasonic sensors are less affected by surface colors and textures, while infrared sensors may have accuracy issues with reflective or dark surfaces. However, infrared sensors can offer better precision for short-range detection and in applications requiring rapid response times. The accuracy of both sensor types can be improved through calibration algorithms and signal processing techniques.- Accuracy comparison between ultrasonic and infrared sensors: Ultrasonic sensors generally provide higher accuracy in distance measurement compared to infrared sensors, especially in varying environmental conditions. Ultrasonic sensors are less affected by surface colors and textures, while infrared sensors may have accuracy issues with reflective or dark surfaces. However, infrared sensors can be more precise for short-range detection and in controlled environments. The accuracy of both sensor types can be improved through calibration algorithms and signal processing techniques.

- Range capabilities of ultrasonic and infrared sensing technologies: Ultrasonic sensors typically offer longer detection ranges compared to infrared sensors, with some industrial models capable of measuring distances up to several meters. Infrared sensors generally have shorter effective ranges but can be more suitable for precise short-distance measurements. Environmental factors such as humidity, temperature, and air pressure can affect the maximum range of ultrasonic sensors, while ambient light conditions and object reflectivity impact infrared sensor range performance.

- Cost considerations for sensor implementation: Infrared sensors are generally more cost-effective than ultrasonic sensors, making them preferable for budget-constrained applications or when multiple sensors are needed. The cost difference is attributed to simpler manufacturing processes and components for infrared sensors. However, ultrasonic sensors often provide better value in applications requiring higher accuracy and reliability. The total implementation cost should consider not only the sensor unit price but also installation requirements, supporting electronics, and maintenance needs.

- Application-specific sensor selection criteria: The selection between ultrasonic and infrared sensors depends on specific application requirements. Ultrasonic sensors are preferred for applications involving transparent objects, liquid level detection, or environments with dust and smoke. Infrared sensors perform better in applications requiring fast response times, detection of human presence, or where acoustic noise might interfere with ultrasonic operation. Some advanced systems utilize both sensor types in combination to leverage their complementary strengths and overcome individual limitations.

- Environmental factors affecting sensor performance: Environmental conditions significantly impact the performance of both sensor types. Ultrasonic sensors are sensitive to temperature variations, air turbulence, and acoustic noise, which can affect wave propagation. Infrared sensors are influenced by ambient light conditions, smoke, fog, and extreme temperatures that can distort readings. Proper sensor selection should account for the operating environment, with weatherproof housings and temperature compensation algorithms being essential for outdoor applications or harsh industrial environments.

02 Range capabilities of ultrasonic and infrared sensing technologies

Ultrasonic sensors typically offer longer detection ranges, often extending from a few centimeters to several meters, making them suitable for applications requiring medium to long-distance sensing. Infrared sensors generally have shorter effective ranges but can be more precise within those limits. Environmental factors such as humidity, temperature, and air pressure can affect the maximum range of ultrasonic sensors, while ambient light conditions and atmospheric absorption can impact infrared sensor range performance. Some advanced models incorporate dual-technology approaches to maximize effective detection range.Expand Specific Solutions03 Cost considerations for sensor implementation

Infrared sensors are generally more cost-effective for basic applications, with lower manufacturing and implementation costs compared to ultrasonic sensors. Ultrasonic sensors typically require more complex circuitry and components, resulting in higher unit costs. However, when considering total system cost, ultrasonic sensors may offer better value in applications where their superior performance justifies the additional expense. The cost difference becomes less significant in high-volume production scenarios or when considering specialized versions of either technology with enhanced capabilities.Expand Specific Solutions04 Environmental factors affecting sensor performance

Ultrasonic sensors are susceptible to interference from air currents, temperature variations, and acoustic noise, while performing well in dusty or foggy environments. Infrared sensors are more affected by ambient light conditions, smoke, and certain weather conditions, but are less sensitive to sound interference. Temperature fluctuations can affect the accuracy of both sensor types, though ultrasonic sensors typically show greater sensitivity to temperature changes. Understanding these environmental limitations is crucial when selecting the appropriate sensor technology for specific applications and operating conditions.Expand Specific Solutions05 Hybrid and complementary sensing systems

Combining ultrasonic and infrared sensing technologies in hybrid systems can overcome the limitations of each individual technology. These complementary systems leverage the strengths of both sensor types: the longer range and weather resistance of ultrasonic sensors with the faster response and better short-range accuracy of infrared sensors. Fusion algorithms integrate data from multiple sensor types to provide more reliable detection across varying conditions. This approach, while more complex and potentially more expensive, offers enhanced performance in critical applications where reliability and accuracy are paramount.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ultrasonic sensor versus infrared technology market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and industrial applications. The global market size for these sensing technologies is projected to reach approximately $18-20 billion by 2025, driven by automation trends and IoT integration. Leading players like Robert Bosch GmbH, Samsung Electronics, and Toyota Motor Corp. have established strong positions through extensive R&D investments, while Panasonic, DENSO, and Raytheon demonstrate technological maturity in specialized applications. Emerging competitors such as Sonicmems and Boundless Sensor Technology are introducing innovations in cost reduction and miniaturization. The technology landscape shows ultrasonic sensors offering superior accuracy in variable conditions, while infrared solutions maintain advantages in cost-efficiency and specific detection scenarios.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced ultrasonic and infrared sensing technologies for automotive and industrial applications. Their ultrasonic sensors utilize piezoelectric transducers operating at frequencies between 40-50 kHz, achieving detection ranges up to 8 meters with accuracy within ±1cm. For infrared sensing, Bosch employs both passive infrared (PIR) and active time-of-flight (ToF) technologies. Their automotive ultrasonic parking sensors feature temperature compensation algorithms and multi-sensor fusion techniques to minimize environmental interference. Bosch's MEMS-based infrared sensors offer response times under 10ms, while their ultrasonic sensors typically operate at 20-30ms response times. The company has integrated these technologies into comprehensive ADAS (Advanced Driver Assistance Systems) solutions that combine multiple sensor types for redundancy and enhanced performance across varying environmental conditions.

Strengths: Superior manufacturing quality with high durability in harsh environments; comprehensive sensor fusion algorithms that enhance accuracy; extensive automotive qualification testing. Weaknesses: Higher cost compared to competitors; ultrasonic sensors show reduced performance in heavy rain or snow conditions; infrared sensors require more complex signal processing for reliable operation in varying lighting conditions.

Raytheon Co.

Technical Solution: Raytheon has pioneered military-grade ultrasonic and infrared sensing technologies with applications extending to commercial sectors. Their ultrasonic sensing solutions employ advanced array configurations with multiple transducers operating at precisely controlled frequencies (typically 30-60 kHz), enabling beam-forming capabilities for enhanced directional sensitivity and range up to 15 meters in optimal conditions. For infrared detection, Raytheon utilizes cooled and uncooled focal plane arrays with sensitivity across multiple IR bands (near, mid, and far infrared). Their proprietary signal processing algorithms implement adaptive filtering techniques to distinguish targets from background noise in complex environments. Raytheon's sensors incorporate hardened electronics designed to withstand extreme temperatures (-40°C to +85°C) and electromagnetic interference, making them suitable for defense, aerospace, and industrial applications requiring high reliability.

Strengths: Exceptional range and accuracy in adverse conditions; military-grade reliability and durability; advanced signal processing capabilities for noise rejection. Weaknesses: Significantly higher cost than commercial-grade alternatives; larger form factors that may limit integration options; higher power consumption requirements that constrain battery-powered applications.

Core Patents and Technical Innovations

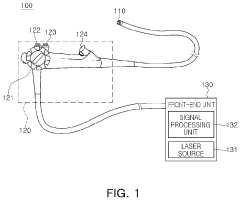

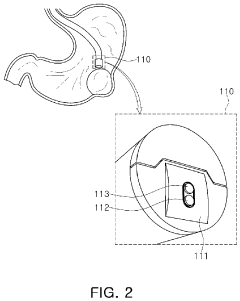

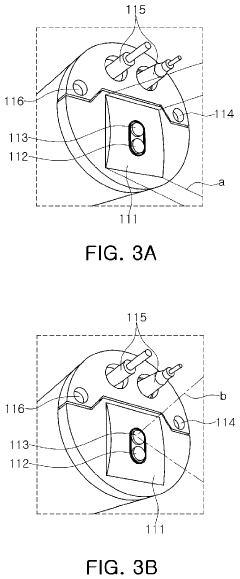

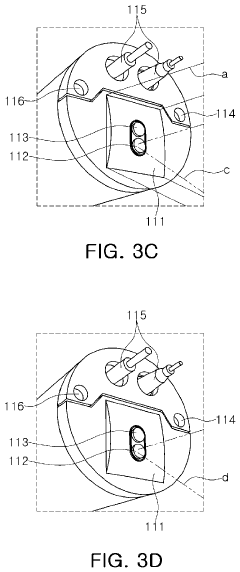

Transparent-ultrasonic-sensor-based optical-ultrasonic integrated endoscopic probe, endoscope apparatus, and catheter apparatus

PatentPendingEP4324401A1

Innovation

- A transparent ultrasonic sensor is used, allowing for coaxial alignment of optical and ultrasonic paths, enabling the integration of optical and ultrasonic imaging systems within a miniaturized endoscopic probe or catheter, with an optical fiber laser unit and a camera that transmit and receive light and ultrasonic waves through the transparent sensor.

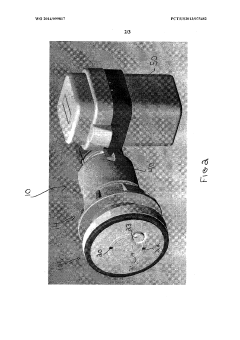

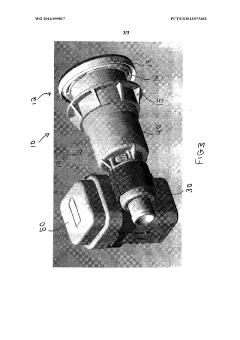

Touchless activation of a toilet

PatentWO2014099817A1

Innovation

- A system combining a passive infrared sensor to detect presence and an ultrasonic sensor to detect proximity, with the ultrasonic sensor remaining in sleep mode until awakened by the infrared sensor, to provide reliable and accurate touchless activation without the need for optical lenses and improved power conservation.

Environmental Impact and Durability Factors

Environmental factors significantly influence the performance and longevity of both ultrasonic and infrared sensors, making durability considerations crucial for deployment decisions. Ultrasonic sensors demonstrate superior performance in dusty environments as they rely on sound waves rather than light. This characteristic makes them particularly valuable in industrial settings where particulate matter is prevalent. However, ultrasonic sensors show vulnerability to extreme temperature variations, with performance degradation observed at both high (>70°C) and low (<-30°C) temperature ranges, potentially affecting wave propagation speed and accuracy.

Infrared sensors, conversely, exhibit greater sensitivity to environmental contaminants. Dust, dirt, or moisture accumulation on the sensor lens can significantly impair detection capabilities by blocking or scattering the infrared beam. This limitation necessitates regular maintenance protocols in environments with high particulate concentrations. Nevertheless, infrared technology typically offers better temperature stability across wider operating ranges, with some industrial-grade models functioning reliably between -40°C and 85°C.

Humidity presents distinct challenges for both technologies. Ultrasonic sensors may experience signal attenuation in high-humidity environments due to sound absorption by water molecules in the air. Infrared sensors generally maintain functionality in humid conditions, provided condensation does not form directly on optical components. Testing reveals that ultrasonic sensors typically retain 85-90% accuracy at 90% relative humidity, while infrared sensors maintain approximately 92-95% accuracy under similar conditions.

Vibration resistance constitutes another critical durability factor. Ultrasonic sensors, with fewer moving parts, generally demonstrate superior vibration tolerance compared to some infrared sensor configurations. Field tests indicate ultrasonic sensors can withstand continuous vibration of 2g at frequencies up to 55Hz without significant performance degradation, whereas certain infrared sensors may require additional stabilization mechanisms in high-vibration environments.

Long-term environmental exposure testing reveals that quality ultrasonic sensors typically maintain operational parameters for 5-7 years in moderate industrial environments before requiring replacement or recalibration. Premium infrared sensors demonstrate comparable longevity but often necessitate more frequent maintenance interventions to ensure optical surface clarity. This maintenance differential translates to approximately 15-20% higher lifetime operational costs for infrared systems despite potentially similar initial hardware investments.

Infrared sensors, conversely, exhibit greater sensitivity to environmental contaminants. Dust, dirt, or moisture accumulation on the sensor lens can significantly impair detection capabilities by blocking or scattering the infrared beam. This limitation necessitates regular maintenance protocols in environments with high particulate concentrations. Nevertheless, infrared technology typically offers better temperature stability across wider operating ranges, with some industrial-grade models functioning reliably between -40°C and 85°C.

Humidity presents distinct challenges for both technologies. Ultrasonic sensors may experience signal attenuation in high-humidity environments due to sound absorption by water molecules in the air. Infrared sensors generally maintain functionality in humid conditions, provided condensation does not form directly on optical components. Testing reveals that ultrasonic sensors typically retain 85-90% accuracy at 90% relative humidity, while infrared sensors maintain approximately 92-95% accuracy under similar conditions.

Vibration resistance constitutes another critical durability factor. Ultrasonic sensors, with fewer moving parts, generally demonstrate superior vibration tolerance compared to some infrared sensor configurations. Field tests indicate ultrasonic sensors can withstand continuous vibration of 2g at frequencies up to 55Hz without significant performance degradation, whereas certain infrared sensors may require additional stabilization mechanisms in high-vibration environments.

Long-term environmental exposure testing reveals that quality ultrasonic sensors typically maintain operational parameters for 5-7 years in moderate industrial environments before requiring replacement or recalibration. Premium infrared sensors demonstrate comparable longevity but often necessitate more frequent maintenance interventions to ensure optical surface clarity. This maintenance differential translates to approximately 15-20% higher lifetime operational costs for infrared systems despite potentially similar initial hardware investments.

Integration Complexity and System Compatibility

The integration of sensor technologies into existing systems represents a critical consideration when evaluating ultrasonic versus infrared sensors. Ultrasonic sensors typically offer more straightforward integration pathways due to their standardized output signals, which are commonly compatible with most microcontrollers and processing units. These sensors generally provide analog voltage outputs or digital signals through standard protocols such as UART, I2C, or SPI, facilitating seamless connection with various control systems.

In contrast, infrared sensors often require additional signal conditioning circuitry, particularly when dealing with the non-linear relationship between distance and output voltage. This non-linearity necessitates calibration algorithms or lookup tables to achieve accurate distance measurements, potentially increasing the complexity of system integration. However, modern infrared sensor modules increasingly incorporate built-in signal processing capabilities, mitigating some of these challenges.

From a physical integration perspective, ultrasonic sensors typically demand specific mounting considerations to avoid acoustic interference. Their performance can be compromised when installed in confined spaces or environments with sound-absorbing materials. The sensor's beam angle and potential for side-lobe detection must be carefully evaluated during system design to prevent false readings.

Infrared sensors present different physical integration challenges, primarily related to optical path requirements. These sensors need a clear line of sight to function effectively and may require protective windows that maintain optical transparency while providing environmental protection. Additionally, ambient light interference must be addressed through proper shielding or filtering mechanisms.

Power requirements constitute another significant compatibility factor. Ultrasonic sensors generally consume more power during operation due to the energy needed for generating acoustic pulses, making them potentially less suitable for battery-powered applications. Infrared sensors typically offer lower power consumption profiles, though advanced models with built-in processing capabilities may approach ultrasonic sensors in energy demands.

Regarding software compatibility, both sensor types require driver development and integration with existing software architectures. Ultrasonic sensors often benefit from more mature software libraries and development resources due to their longer history in industrial applications. Infrared sensors, particularly newer models with enhanced capabilities, may require more specialized software development efforts to fully leverage their features.

Environmental compatibility also influences integration decisions. Ultrasonic sensors maintain consistent performance across varying light conditions but may struggle in environments with extreme temperature fluctuations or high humidity. Conversely, infrared sensors perform reliably across temperature ranges but require additional considerations for environments with varying reflective properties or potential infrared interference sources.

In contrast, infrared sensors often require additional signal conditioning circuitry, particularly when dealing with the non-linear relationship between distance and output voltage. This non-linearity necessitates calibration algorithms or lookup tables to achieve accurate distance measurements, potentially increasing the complexity of system integration. However, modern infrared sensor modules increasingly incorporate built-in signal processing capabilities, mitigating some of these challenges.

From a physical integration perspective, ultrasonic sensors typically demand specific mounting considerations to avoid acoustic interference. Their performance can be compromised when installed in confined spaces or environments with sound-absorbing materials. The sensor's beam angle and potential for side-lobe detection must be carefully evaluated during system design to prevent false readings.

Infrared sensors present different physical integration challenges, primarily related to optical path requirements. These sensors need a clear line of sight to function effectively and may require protective windows that maintain optical transparency while providing environmental protection. Additionally, ambient light interference must be addressed through proper shielding or filtering mechanisms.

Power requirements constitute another significant compatibility factor. Ultrasonic sensors generally consume more power during operation due to the energy needed for generating acoustic pulses, making them potentially less suitable for battery-powered applications. Infrared sensors typically offer lower power consumption profiles, though advanced models with built-in processing capabilities may approach ultrasonic sensors in energy demands.

Regarding software compatibility, both sensor types require driver development and integration with existing software architectures. Ultrasonic sensors often benefit from more mature software libraries and development resources due to their longer history in industrial applications. Infrared sensors, particularly newer models with enhanced capabilities, may require more specialized software development efforts to fully leverage their features.

Environmental compatibility also influences integration decisions. Ultrasonic sensors maintain consistent performance across varying light conditions but may struggle in environments with extreme temperature fluctuations or high humidity. Conversely, infrared sensors perform reliably across temperature ranges but require additional considerations for environments with varying reflective properties or potential infrared interference sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!