Ultrasonic Sensor Noise Mitigation: PCB, Filtering, And Mounting Tips

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensing Technology Background and Objectives

Ultrasonic sensing technology has evolved significantly since its inception in the early 20th century, initially developed for underwater detection during World War I. The fundamental principle remains unchanged: these sensors emit high-frequency sound waves (typically 20kHz to 200kHz) and measure the time taken for echoes to return after striking objects, enabling distance calculation based on the speed of sound in the medium.

The evolution of ultrasonic sensing technology has been marked by progressive miniaturization, increased precision, and enhanced signal processing capabilities. Early systems were bulky and limited to industrial applications, while modern sensors are compact enough for integration into consumer electronics and automotive systems. This miniaturization has introduced new challenges related to noise interference, particularly in PCB design and mounting configurations.

Market adoption has accelerated dramatically in the past decade, with ultrasonic sensors becoming integral components in diverse applications including automotive parking assistance, industrial automation, healthcare diagnostics, and smart home devices. This widespread implementation has heightened the importance of noise mitigation strategies to ensure reliable performance across varied operating environments.

Current technological objectives in the field focus on addressing the persistent challenge of noise interference, which remains one of the primary limitations affecting ultrasonic sensor reliability. Environmental factors (temperature variations, humidity), electromagnetic interference (EMI), mechanical vibrations, and acoustic reflections all contribute to signal degradation. Additionally, cross-talk between multiple sensors in proximity presents significant challenges in applications requiring sensor arrays.

The industry is progressively moving toward more sophisticated signal processing techniques, including advanced filtering algorithms, machine learning-based noise cancellation, and improved hardware designs. These developments aim to enhance sensor performance in noisy environments without significantly increasing power consumption or manufacturing costs.

Recent research has demonstrated promising approaches to noise mitigation through integrated solutions that combine optimized PCB layouts, advanced filtering techniques, and strategic mounting considerations. These holistic approaches recognize that noise issues in ultrasonic sensing cannot be addressed through isolated interventions but require comprehensive strategies spanning hardware design, signal processing, and physical implementation.

The ultimate objective in this technological domain is to develop ultrasonic sensing systems that maintain high accuracy and reliability across diverse operating conditions while minimizing false readings and signal degradation. This goal necessitates innovations in PCB design to reduce electromagnetic interference, implementation of more sophisticated filtering algorithms to distinguish between genuine signals and noise, and development of mounting techniques that minimize mechanical vibration effects.

The evolution of ultrasonic sensing technology has been marked by progressive miniaturization, increased precision, and enhanced signal processing capabilities. Early systems were bulky and limited to industrial applications, while modern sensors are compact enough for integration into consumer electronics and automotive systems. This miniaturization has introduced new challenges related to noise interference, particularly in PCB design and mounting configurations.

Market adoption has accelerated dramatically in the past decade, with ultrasonic sensors becoming integral components in diverse applications including automotive parking assistance, industrial automation, healthcare diagnostics, and smart home devices. This widespread implementation has heightened the importance of noise mitigation strategies to ensure reliable performance across varied operating environments.

Current technological objectives in the field focus on addressing the persistent challenge of noise interference, which remains one of the primary limitations affecting ultrasonic sensor reliability. Environmental factors (temperature variations, humidity), electromagnetic interference (EMI), mechanical vibrations, and acoustic reflections all contribute to signal degradation. Additionally, cross-talk between multiple sensors in proximity presents significant challenges in applications requiring sensor arrays.

The industry is progressively moving toward more sophisticated signal processing techniques, including advanced filtering algorithms, machine learning-based noise cancellation, and improved hardware designs. These developments aim to enhance sensor performance in noisy environments without significantly increasing power consumption or manufacturing costs.

Recent research has demonstrated promising approaches to noise mitigation through integrated solutions that combine optimized PCB layouts, advanced filtering techniques, and strategic mounting considerations. These holistic approaches recognize that noise issues in ultrasonic sensing cannot be addressed through isolated interventions but require comprehensive strategies spanning hardware design, signal processing, and physical implementation.

The ultimate objective in this technological domain is to develop ultrasonic sensing systems that maintain high accuracy and reliability across diverse operating conditions while minimizing false readings and signal degradation. This goal necessitates innovations in PCB design to reduce electromagnetic interference, implementation of more sophisticated filtering algorithms to distinguish between genuine signals and noise, and development of mounting techniques that minimize mechanical vibration effects.

Market Applications and Demand Analysis

The ultrasonic sensor market has experienced significant growth across multiple industries, driven by increasing demand for non-contact sensing technologies in automation, robotics, and IoT applications. The global ultrasonic sensor market was valued at approximately 4.9 billion USD in 2022 and is projected to reach 7.6 billion USD by 2028, growing at a CAGR of 7.8% during the forecast period.

Automotive applications represent the largest market segment, with ultrasonic sensors being essential components in parking assistance systems, blind spot detection, and autonomous driving technologies. The automotive industry's shift toward advanced driver assistance systems (ADAS) and autonomous vehicles has substantially increased demand for high-precision ultrasonic sensors with improved noise mitigation capabilities.

Industrial automation constitutes another significant market segment, where ultrasonic sensors are deployed for object detection, distance measurement, and level sensing in manufacturing processes. The Industry 4.0 revolution has accelerated adoption rates, with manufacturers seeking sensors that can operate reliably in electrically noisy factory environments where PCB design and filtering techniques become critical differentiators.

Consumer electronics applications have emerged as a rapidly growing segment, incorporating ultrasonic sensors in smartphones for fingerprint recognition, gesture control systems, and proximity detection. This market demands miniaturized sensors with sophisticated noise filtering algorithms to function in varied consumer environments.

Healthcare applications utilize ultrasonic technology for medical imaging, therapeutic devices, and monitoring systems. These applications require exceptionally high signal-to-noise ratios, driving demand for advanced mounting techniques and specialized filtering solutions to eliminate artifacts and interference.

Market research indicates that customers across all segments increasingly prioritize noise immunity as a key purchasing criterion, with 68% of industrial customers citing noise performance as "very important" or "critical" in their selection process. This trend is particularly pronounced in environments with multiple ultrasonic devices operating simultaneously, where cross-talk interference presents significant challenges.

Regional analysis shows North America and Europe leading in adoption of premium ultrasonic sensors with advanced noise mitigation features, while the Asia-Pacific region represents the fastest-growing market with increasing implementation in manufacturing and automotive sectors. Chinese manufacturers are rapidly closing the technology gap in noise filtering capabilities, intensifying global competition.

The market demonstrates strong price sensitivity to performance improvements, with customers willing to pay 15-30% premium for sensors demonstrating superior noise immunity in challenging environments. This price elasticity underscores the significant market opportunity for innovations in PCB design, filtering algorithms, and mounting techniques that effectively address noise mitigation challenges.

Automotive applications represent the largest market segment, with ultrasonic sensors being essential components in parking assistance systems, blind spot detection, and autonomous driving technologies. The automotive industry's shift toward advanced driver assistance systems (ADAS) and autonomous vehicles has substantially increased demand for high-precision ultrasonic sensors with improved noise mitigation capabilities.

Industrial automation constitutes another significant market segment, where ultrasonic sensors are deployed for object detection, distance measurement, and level sensing in manufacturing processes. The Industry 4.0 revolution has accelerated adoption rates, with manufacturers seeking sensors that can operate reliably in electrically noisy factory environments where PCB design and filtering techniques become critical differentiators.

Consumer electronics applications have emerged as a rapidly growing segment, incorporating ultrasonic sensors in smartphones for fingerprint recognition, gesture control systems, and proximity detection. This market demands miniaturized sensors with sophisticated noise filtering algorithms to function in varied consumer environments.

Healthcare applications utilize ultrasonic technology for medical imaging, therapeutic devices, and monitoring systems. These applications require exceptionally high signal-to-noise ratios, driving demand for advanced mounting techniques and specialized filtering solutions to eliminate artifacts and interference.

Market research indicates that customers across all segments increasingly prioritize noise immunity as a key purchasing criterion, with 68% of industrial customers citing noise performance as "very important" or "critical" in their selection process. This trend is particularly pronounced in environments with multiple ultrasonic devices operating simultaneously, where cross-talk interference presents significant challenges.

Regional analysis shows North America and Europe leading in adoption of premium ultrasonic sensors with advanced noise mitigation features, while the Asia-Pacific region represents the fastest-growing market with increasing implementation in manufacturing and automotive sectors. Chinese manufacturers are rapidly closing the technology gap in noise filtering capabilities, intensifying global competition.

The market demonstrates strong price sensitivity to performance improvements, with customers willing to pay 15-30% premium for sensors demonstrating superior noise immunity in challenging environments. This price elasticity underscores the significant market opportunity for innovations in PCB design, filtering algorithms, and mounting techniques that effectively address noise mitigation challenges.

Current Noise Challenges in Ultrasonic Sensing

Ultrasonic sensing technology faces significant noise challenges that impede its performance across various applications. Electromagnetic interference (EMI) represents one of the most prevalent issues, originating from nearby electronic components, power supplies, and external devices. This interference can manifest as random spikes or consistent background noise in sensor readings, particularly problematic in densely packed electronic environments where multiple systems operate in close proximity.

Mechanical vibrations constitute another major noise source, affecting ultrasonic sensors through physical disturbances that propagate through mounting structures. These vibrations can originate from motors, fans, or environmental factors like wind or vehicle movement, creating false echoes or distorting legitimate signal returns. The challenge intensifies in mobile applications where constant movement generates unpredictable vibration patterns.

Acoustic reflections and multipath effects significantly complicate signal interpretation in ultrasonic sensing systems. When ultrasonic waves encounter multiple reflective surfaces, they create secondary echoes that arrive at the receiver at different times, causing signal confusion and false distance readings. This phenomenon is especially problematic in complex environments with numerous objects or irregular surfaces.

Temperature and humidity variations introduce additional complications by altering the speed of sound in air, directly affecting distance calculations. Without proper compensation mechanisms, these environmental factors can cause measurement drift of up to 0.6 meters per second per degree Celsius change, rendering readings unreliable in fluctuating conditions.

Cross-talk between multiple ultrasonic sensors operating simultaneously presents a growing challenge as systems become more sophisticated. When sensors detect signals emitted by neighboring units rather than their own reflected signals, measurement errors occur that can be difficult to isolate and address through conventional filtering methods.

PCB design limitations further exacerbate noise issues, with inadequate isolation between analog and digital circuits creating interference pathways. Poor grounding schemes and improper component placement can introduce noise directly into sensitive amplification stages, while insufficient shielding leaves sensors vulnerable to external electromagnetic fields.

Current filtering approaches often struggle to distinguish between legitimate signal variations and noise, particularly in dynamic environments where target characteristics change rapidly. Traditional band-pass filters may eliminate useful signal components along with noise, while more sophisticated adaptive filtering requires significant computational resources that may not be available in cost-sensitive applications.

Mechanical vibrations constitute another major noise source, affecting ultrasonic sensors through physical disturbances that propagate through mounting structures. These vibrations can originate from motors, fans, or environmental factors like wind or vehicle movement, creating false echoes or distorting legitimate signal returns. The challenge intensifies in mobile applications where constant movement generates unpredictable vibration patterns.

Acoustic reflections and multipath effects significantly complicate signal interpretation in ultrasonic sensing systems. When ultrasonic waves encounter multiple reflective surfaces, they create secondary echoes that arrive at the receiver at different times, causing signal confusion and false distance readings. This phenomenon is especially problematic in complex environments with numerous objects or irregular surfaces.

Temperature and humidity variations introduce additional complications by altering the speed of sound in air, directly affecting distance calculations. Without proper compensation mechanisms, these environmental factors can cause measurement drift of up to 0.6 meters per second per degree Celsius change, rendering readings unreliable in fluctuating conditions.

Cross-talk between multiple ultrasonic sensors operating simultaneously presents a growing challenge as systems become more sophisticated. When sensors detect signals emitted by neighboring units rather than their own reflected signals, measurement errors occur that can be difficult to isolate and address through conventional filtering methods.

PCB design limitations further exacerbate noise issues, with inadequate isolation between analog and digital circuits creating interference pathways. Poor grounding schemes and improper component placement can introduce noise directly into sensitive amplification stages, while insufficient shielding leaves sensors vulnerable to external electromagnetic fields.

Current filtering approaches often struggle to distinguish between legitimate signal variations and noise, particularly in dynamic environments where target characteristics change rapidly. Traditional band-pass filters may eliminate useful signal components along with noise, while more sophisticated adaptive filtering requires significant computational resources that may not be available in cost-sensitive applications.

PCB Design Solutions for Noise Reduction

01 Noise reduction techniques in ultrasonic sensors

Various techniques can be employed to reduce noise in ultrasonic sensors, including signal filtering, frequency modulation, and advanced signal processing algorithms. These methods help to distinguish between actual signals and background noise, improving the accuracy and reliability of ultrasonic measurements. Implementing these noise reduction techniques can significantly enhance the performance of ultrasonic sensors in various applications.- Noise reduction techniques in ultrasonic sensors: Various techniques can be employed to reduce noise in ultrasonic sensors, including signal filtering, frequency modulation, and digital signal processing. These methods help to isolate the desired ultrasonic signal from background noise, improving the accuracy and reliability of measurements. Advanced algorithms can be implemented to distinguish between actual signals and noise patterns, enhancing the overall performance of ultrasonic sensing systems.

- Acoustic isolation and shielding for ultrasonic sensors: Physical design elements such as acoustic isolation materials and shielding can significantly reduce noise interference in ultrasonic sensors. These approaches involve strategically placing dampening materials around the sensor, creating barriers against external noise sources, and designing enclosures that minimize sound reflections and reverberations. Proper mounting techniques also help to reduce vibration-induced noise that can affect sensor readings.

- Signal processing and amplification techniques: Advanced signal processing and amplification techniques can be used to enhance the signal-to-noise ratio in ultrasonic sensors. These include adaptive filtering, phase-locked loop systems, and specialized amplifier circuits designed to minimize electronic noise. By carefully conditioning the signal before analysis, these methods can extract meaningful data even in noisy environments, making ultrasonic sensors more reliable for various applications.

- Environmental noise compensation in ultrasonic sensing: Methods for compensating for environmental noise factors such as temperature variations, humidity, and air turbulence can improve ultrasonic sensor performance. These approaches often involve calibration routines, reference measurements, and environmental monitoring to adjust sensor parameters dynamically. Some systems incorporate multiple sensors to create differential measurements that can cancel out common-mode noise affecting all sensors in the array.

- Frequency optimization and pulse shaping: Optimizing the operating frequency and shaping the ultrasonic pulse can minimize susceptibility to noise interference. By selecting frequencies that avoid known noise sources and designing pulse characteristics (duration, amplitude, and shape) to maximize signal clarity, these techniques improve detection capabilities. Some advanced systems employ frequency hopping or spread spectrum techniques to distribute the signal energy across multiple frequencies, reducing the impact of narrowband noise sources.

02 Structural design modifications for noise mitigation

The physical design of ultrasonic sensors can be modified to minimize noise interference. This includes using acoustic insulation materials, optimizing the sensor housing design, and implementing vibration dampening structures. By addressing noise at the structural level, these modifications help to isolate the sensor from environmental vibrations and acoustic interference, resulting in cleaner signal output and more accurate measurements.Expand Specific Solutions03 Environmental noise compensation systems

Systems designed to compensate for environmental noise factors that affect ultrasonic sensor performance. These systems may include adaptive algorithms that adjust sensor parameters based on ambient conditions, calibration mechanisms that account for changing environmental factors, and noise mapping techniques that identify and filter out specific environmental noise patterns. Such compensation systems are particularly valuable in dynamic or harsh environments where noise conditions frequently change.Expand Specific Solutions04 Signal processing algorithms for noise filtering

Advanced signal processing algorithms specifically designed to filter out noise from ultrasonic sensor data. These may include digital filtering techniques, wavelet transforms, neural network-based noise cancellation, and statistical methods for signal enhancement. By applying sophisticated mathematical approaches to the raw sensor data, these algorithms can effectively separate meaningful signals from various types of noise, improving detection accuracy and range.Expand Specific Solutions05 Multi-sensor fusion for noise resilience

Integration of multiple sensors or sensor types to create systems that are more resilient to noise. By combining data from different ultrasonic sensors or complementing ultrasonic data with information from other sensor types (such as optical or infrared), these systems can cross-validate measurements and identify noise-affected data. This fusion approach allows for more robust operation in noisy environments and can compensate for the limitations of individual sensor technologies.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ultrasonic sensor noise mitigation market is currently in a growth phase, with increasing applications across automotive, industrial, and consumer electronics sectors. The global market size is estimated to exceed $1.5 billion, driven by rising demand for advanced driver assistance systems and industrial automation. Technologically, the field shows varying maturity levels, with established players like Robert Bosch GmbH, Valeo, and DENSO leading innovation in automotive applications. Murata Manufacturing and Nippon Ceramic dominate the component manufacturing space with advanced filtering technologies. Meanwhile, companies like Canon Medical Systems and Hitachi are pushing boundaries in high-precision applications requiring sophisticated noise reduction. Emerging players such as Goertek Microelectronics are focusing on specialized MEMS-based solutions, indicating a trend toward miniaturization and integration of noise mitigation technologies directly into sensor designs.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed specialized ultrasonic sensor noise mitigation techniques focusing on miniaturization and integration. Their PCB designs feature high-density integration with carefully engineered ground planes and power distribution networks to minimize electrical noise. They employ advanced materials science in their PCB substrate selection, using materials with specific dielectric properties to reduce signal degradation. Murata's filtering approach combines analog front-end filtering with digital signal processing, implementing matched filters optimized for specific ultrasonic frequencies. Their sensors incorporate proprietary ceramic materials with superior piezoelectric properties that provide inherently better signal-to-noise ratios. For mounting solutions, Murata has developed micro-machined structures that provide mechanical isolation while maintaining precise positioning. Their packaging technology includes acoustic chambers designed to enhance desired ultrasonic frequencies while attenuating noise across broader spectrum ranges.

Strengths: Industry-leading miniaturization capabilities; excellent integration potential for space-constrained applications; superior materials science approach to noise reduction. Weaknesses: Higher component costs due to specialized materials and manufacturing processes; may require more complex integration support compared to simpler solutions.

Hyundai Mobis Co., Ltd.

Technical Solution: Hyundai Mobis has developed an integrated approach to ultrasonic sensor noise mitigation focusing on automotive applications. Their PCB design methodology incorporates specialized shielding techniques with segmented ground planes to isolate sensitive analog components from digital noise sources. They implement controlled impedance routing for critical signal paths to maintain signal integrity. On the filtering front, Hyundai Mobis employs a multi-stage approach combining analog bandpass filters with digital adaptive filtering algorithms that continuously adjust to changing noise environments. Their signal processing includes statistical pattern recognition to identify and remove common automotive noise signatures. For physical mounting, they've developed composite mounting brackets that combine rigid structural support with vibration-dampening materials strategically placed at key interface points. Their sensor housings incorporate acoustic baffling designed to minimize interference from wind noise and other environmental factors common in automotive applications.

Strengths: Highly optimized for automotive environments; excellent integration with existing vehicle systems; robust performance in harsh environmental conditions. Weaknesses: Solutions primarily focused on automotive applications; may require significant customization for other use cases; relatively higher implementation costs for non-automotive applications.

Signal Filtering Techniques and Algorithms

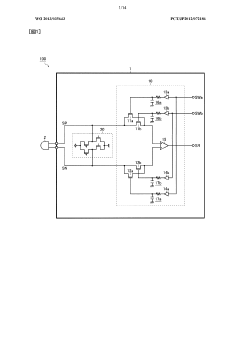

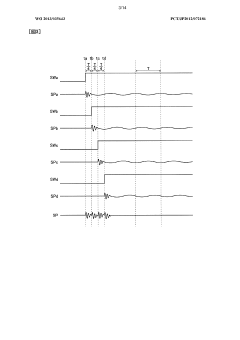

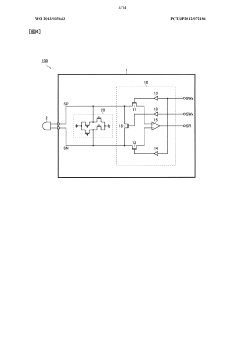

Receiving circuit, semiconductor device, and sensor device

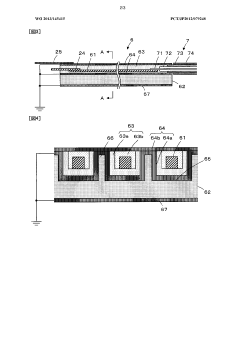

PatentWO2013035643A1

Innovation

- A receiving circuit configuration that includes parallel transistors with phase shifts and filters to suppress noise, differential signal transmission, and a switch for short-circuiting transmission paths, along with a semiconductor device integrating these features to improve signal quality during ultrasonic wave reception.

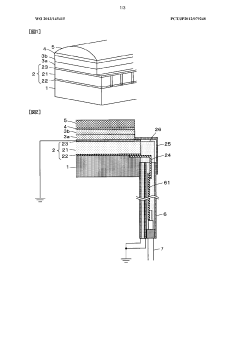

Connection method for ultrasonic probe and signal line

PatentWO2013145415A1

Innovation

- The ultrasonic probe employs a printed circuit board with insulating and grounding layers to shield connection conductors and signal lines, aligning core wires with guide grooves to ensure proper impedance matching and reduce external noise interference, thereby preventing signal degradation.

Environmental Factors Affecting Sensor Performance

Ultrasonic sensors operate by emitting sound waves and measuring the time taken for echoes to return, but their performance is significantly influenced by various environmental factors. Temperature fluctuations represent one of the most critical variables affecting these sensors, as sound velocity in air changes approximately 0.6 meters per second for each degree Celsius change. This relationship necessitates temperature compensation mechanisms in precision applications to maintain measurement accuracy across varying thermal conditions.

Humidity levels similarly impact ultrasonic wave propagation, with higher humidity generally increasing sound velocity. This effect, while less pronounced than temperature variations, becomes particularly relevant in environments with rapid humidity changes or in applications requiring high precision measurements.

Atmospheric pressure variations also affect ultrasonic sensor performance by altering the density of the medium through which sound waves travel. Lower pressure at higher altitudes results in decreased air density, consequently reducing the effective range and sensitivity of ultrasonic sensors.

Air turbulence and wind conditions create additional challenges by disrupting the path of ultrasonic waves. Strong air currents can deflect sound waves away from their intended trajectory, potentially causing signal loss or erroneous readings. Industrial environments with ventilation systems or outdoor applications in windy conditions are particularly susceptible to these effects.

Ambient noise presents another significant challenge, especially in industrial settings where machinery, pneumatic systems, or other ultrasonic sources may operate at frequencies overlapping with the sensor's operational range. These competing signals can interfere with the sensor's ability to distinguish its own emitted signal from background noise, resulting in false readings or reduced detection reliability.

Particulate matter suspended in air, such as dust, smoke, or mist, can absorb or scatter ultrasonic waves, diminishing signal strength and potentially reducing the sensor's effective range. This factor becomes particularly relevant in manufacturing environments, construction sites, or outdoor applications in adverse weather conditions.

Surface characteristics of target objects also influence measurement accuracy. Smooth, hard surfaces typically provide stronger echo returns compared to soft, irregular, or sound-absorbing materials. The angle of incidence between the ultrasonic wave and the target surface further affects echo strength, with perpendicular surfaces providing optimal reflection conditions.

Understanding these environmental factors is essential for implementing effective noise mitigation strategies in ultrasonic sensing applications, as they form the foundation upon which filtering algorithms, mounting considerations, and PCB design decisions must be based.

Humidity levels similarly impact ultrasonic wave propagation, with higher humidity generally increasing sound velocity. This effect, while less pronounced than temperature variations, becomes particularly relevant in environments with rapid humidity changes or in applications requiring high precision measurements.

Atmospheric pressure variations also affect ultrasonic sensor performance by altering the density of the medium through which sound waves travel. Lower pressure at higher altitudes results in decreased air density, consequently reducing the effective range and sensitivity of ultrasonic sensors.

Air turbulence and wind conditions create additional challenges by disrupting the path of ultrasonic waves. Strong air currents can deflect sound waves away from their intended trajectory, potentially causing signal loss or erroneous readings. Industrial environments with ventilation systems or outdoor applications in windy conditions are particularly susceptible to these effects.

Ambient noise presents another significant challenge, especially in industrial settings where machinery, pneumatic systems, or other ultrasonic sources may operate at frequencies overlapping with the sensor's operational range. These competing signals can interfere with the sensor's ability to distinguish its own emitted signal from background noise, resulting in false readings or reduced detection reliability.

Particulate matter suspended in air, such as dust, smoke, or mist, can absorb or scatter ultrasonic waves, diminishing signal strength and potentially reducing the sensor's effective range. This factor becomes particularly relevant in manufacturing environments, construction sites, or outdoor applications in adverse weather conditions.

Surface characteristics of target objects also influence measurement accuracy. Smooth, hard surfaces typically provide stronger echo returns compared to soft, irregular, or sound-absorbing materials. The angle of incidence between the ultrasonic wave and the target surface further affects echo strength, with perpendicular surfaces providing optimal reflection conditions.

Understanding these environmental factors is essential for implementing effective noise mitigation strategies in ultrasonic sensing applications, as they form the foundation upon which filtering algorithms, mounting considerations, and PCB design decisions must be based.

Mounting Optimization and Mechanical Considerations

The mounting configuration of ultrasonic sensors significantly impacts their noise performance and overall reliability. Proper mechanical integration requires careful consideration of several factors to minimize unwanted vibrations and acoustic interference. Sensor positioning should avoid proximity to mechanical resonance points on the host structure, as these can amplify vibrations and introduce noise artifacts in the sensor readings.

Material selection for mounting brackets plays a crucial role in noise mitigation. Materials with high damping properties such as rubber compounds or specialized polymers can effectively absorb vibrations before they reach the sensor. Conversely, rigid metal mounts may transmit vibrations directly to the sensor, degrading performance. A hybrid approach using stiff materials with strategic damping elements often yields optimal results.

Decoupling techniques represent another essential aspect of mounting optimization. Implementing isolation mounts using silicone grommets or specialized vibration-absorbing washers can significantly reduce mechanical noise transmission. These components act as mechanical low-pass filters, attenuating high-frequency vibrations while maintaining structural integrity. For applications with severe vibration environments, multi-stage isolation systems may be necessary.

Geometric considerations in mount design also warrant attention. The orientation of the sensor relative to potential noise sources can dramatically affect performance. Directional shielding through strategic placement of acoustic baffles or reflectors can redirect unwanted acoustic energy away from the sensor. Additionally, the shape and size of mounting brackets should be optimized to avoid creating resonant cavities that might amplify specific frequencies.

Environmental sealing represents another critical dimension of mounting design. Proper gaskets and seals not only protect the sensor from environmental contaminants but also help maintain consistent acoustic properties around the sensor. Variations in air pressure, humidity, or the presence of particulates can all affect ultrasonic wave propagation. Standardized IP-rated enclosures provide a systematic approach to environmental protection while ensuring consistent performance.

Temperature management through mounting design requires careful consideration, as ultrasonic sensors exhibit temperature-dependent behavior. Thermal isolation from heat-generating components and strategic placement of thermal paths can help maintain stable operating temperatures. In extreme environments, active temperature control mechanisms may be integrated into the mounting structure to ensure optimal sensor performance across varying ambient conditions.

Material selection for mounting brackets plays a crucial role in noise mitigation. Materials with high damping properties such as rubber compounds or specialized polymers can effectively absorb vibrations before they reach the sensor. Conversely, rigid metal mounts may transmit vibrations directly to the sensor, degrading performance. A hybrid approach using stiff materials with strategic damping elements often yields optimal results.

Decoupling techniques represent another essential aspect of mounting optimization. Implementing isolation mounts using silicone grommets or specialized vibration-absorbing washers can significantly reduce mechanical noise transmission. These components act as mechanical low-pass filters, attenuating high-frequency vibrations while maintaining structural integrity. For applications with severe vibration environments, multi-stage isolation systems may be necessary.

Geometric considerations in mount design also warrant attention. The orientation of the sensor relative to potential noise sources can dramatically affect performance. Directional shielding through strategic placement of acoustic baffles or reflectors can redirect unwanted acoustic energy away from the sensor. Additionally, the shape and size of mounting brackets should be optimized to avoid creating resonant cavities that might amplify specific frequencies.

Environmental sealing represents another critical dimension of mounting design. Proper gaskets and seals not only protect the sensor from environmental contaminants but also help maintain consistent acoustic properties around the sensor. Variations in air pressure, humidity, or the presence of particulates can all affect ultrasonic wave propagation. Standardized IP-rated enclosures provide a systematic approach to environmental protection while ensuring consistent performance.

Temperature management through mounting design requires careful consideration, as ultrasonic sensors exhibit temperature-dependent behavior. Thermal isolation from heat-generating components and strategic placement of thermal paths can help maintain stable operating temperatures. In extreme environments, active temperature control mechanisms may be integrated into the mounting structure to ensure optimal sensor performance across varying ambient conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!