Ultrasonic Sensors In Robotics: SLAM, Obstacle Avoidance, And Latency

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensing Evolution and Objectives

Ultrasonic sensing technology has evolved significantly since its inception in the early 20th century, initially developed for maritime applications following the Titanic disaster. The fundamental principle of ultrasonic sensing—using sound waves above human hearing range (>20kHz) to detect objects—has remained consistent, while implementation and processing capabilities have advanced dramatically. By the 1970s and 1980s, ultrasonic sensors found their way into industrial automation and early robotic systems, primarily for basic distance measurement and crude obstacle detection.

The miniaturization of electronics in the 1990s marked a pivotal shift, enabling smaller, more energy-efficient ultrasonic sensors suitable for mobile robotics. This period saw the emergence of the first commercially viable ultrasonic-based navigation systems, though they suffered from significant limitations in resolution and environmental interference. The 2000s brought digital signal processing improvements that enhanced filtering capabilities and reduced false readings, making ultrasonic sensors more reliable for robotic applications.

Recent technological advancements have focused on overcoming traditional limitations of ultrasonic sensing. Modern sensors feature improved transducer materials, sophisticated signal processing algorithms, and integration with complementary sensing technologies. Multi-element arrays and beamforming techniques have significantly improved spatial resolution, while advanced filtering algorithms have reduced susceptibility to environmental noise and cross-talk between sensors.

The primary objective of ultrasonic sensing in robotics is to provide reliable, cost-effective environmental perception for navigation tasks. Specifically, in SLAM (Simultaneous Localization and Mapping) applications, ultrasonic sensors aim to deliver sufficient spatial resolution and range accuracy to construct meaningful environmental maps while maintaining real-time performance. For obstacle avoidance, the technology seeks to detect objects with sufficient warning distance and angular resolution to enable safe navigation at practical speeds.

A critical objective in modern ultrasonic sensing development is latency reduction. Current research focuses on minimizing the delay between physical detection and data availability to the robot's decision-making systems. This includes innovations in transducer technology to reduce ring-down time, parallel processing architectures for faster signal analysis, and predictive algorithms that compensate for sensing delays.

Looking forward, ultrasonic sensing technology aims to achieve higher resolution comparable to more expensive sensing modalities while maintaining its advantages in cost, power consumption, and performance in challenging environments such as dusty, foggy, or smoky conditions where optical systems struggle. Integration with sensor fusion frameworks represents another key objective, enabling ultrasonic data to complement information from cameras, lidars, and other sensors for more robust environmental perception.

The miniaturization of electronics in the 1990s marked a pivotal shift, enabling smaller, more energy-efficient ultrasonic sensors suitable for mobile robotics. This period saw the emergence of the first commercially viable ultrasonic-based navigation systems, though they suffered from significant limitations in resolution and environmental interference. The 2000s brought digital signal processing improvements that enhanced filtering capabilities and reduced false readings, making ultrasonic sensors more reliable for robotic applications.

Recent technological advancements have focused on overcoming traditional limitations of ultrasonic sensing. Modern sensors feature improved transducer materials, sophisticated signal processing algorithms, and integration with complementary sensing technologies. Multi-element arrays and beamforming techniques have significantly improved spatial resolution, while advanced filtering algorithms have reduced susceptibility to environmental noise and cross-talk between sensors.

The primary objective of ultrasonic sensing in robotics is to provide reliable, cost-effective environmental perception for navigation tasks. Specifically, in SLAM (Simultaneous Localization and Mapping) applications, ultrasonic sensors aim to deliver sufficient spatial resolution and range accuracy to construct meaningful environmental maps while maintaining real-time performance. For obstacle avoidance, the technology seeks to detect objects with sufficient warning distance and angular resolution to enable safe navigation at practical speeds.

A critical objective in modern ultrasonic sensing development is latency reduction. Current research focuses on minimizing the delay between physical detection and data availability to the robot's decision-making systems. This includes innovations in transducer technology to reduce ring-down time, parallel processing architectures for faster signal analysis, and predictive algorithms that compensate for sensing delays.

Looking forward, ultrasonic sensing technology aims to achieve higher resolution comparable to more expensive sensing modalities while maintaining its advantages in cost, power consumption, and performance in challenging environments such as dusty, foggy, or smoky conditions where optical systems struggle. Integration with sensor fusion frameworks represents another key objective, enabling ultrasonic data to complement information from cameras, lidars, and other sensors for more robust environmental perception.

Market Analysis for Robotic Ultrasonic Applications

The global market for ultrasonic sensors in robotics is experiencing robust growth, driven by increasing automation across multiple industries. Currently valued at approximately $3.2 billion in 2023, this segment is projected to reach $5.7 billion by 2028, representing a compound annual growth rate (CAGR) of 12.3%. This growth trajectory significantly outpaces the broader sensor market, indicating the rising importance of ultrasonic technology in robotic applications.

Industrial robotics represents the largest application segment, accounting for 41% of the market share. Within this segment, manufacturing automation leads demand, particularly in automotive production, electronics assembly, and food processing industries. The warehouse and logistics sector follows closely, with a rapidly expanding 37% market share, fueled by the e-commerce boom and the need for efficient inventory management systems.

Consumer robotics, including vacuum cleaners and home assistance robots, constitutes 15% of the market but shows the fastest growth rate at 18.7% annually. This surge reflects increasing consumer acceptance of home automation technologies and declining unit costs. The remaining market share is distributed across specialized applications including agricultural robotics, security systems, and medical robotics.

Geographically, Asia-Pacific dominates with 42% of the global market, led by manufacturing powerhouses China, Japan, and South Korea. North America follows with 31%, where advanced research in SLAM technologies drives innovation. Europe accounts for 22%, with Germany and France leading in industrial automation applications.

Key market drivers include the decreasing cost of ultrasonic sensor technology, with average unit prices falling by 8.3% annually over the past five years. Improved performance metrics, particularly in terms of accuracy and latency reduction, have expanded application possibilities. The integration of ultrasonic sensors with complementary technologies such as LiDAR and computer vision has created hybrid sensing systems that overcome individual technology limitations.

Market challenges include competition from alternative sensing technologies, particularly optical and infrared systems that offer higher resolution in certain applications. Technical limitations in extreme environmental conditions and interference issues in complex environments remain obstacles to broader adoption. Additionally, standardization gaps across different robotic platforms create integration challenges for sensor manufacturers.

The market shows strong segmentation based on performance tiers, with premium sensors featuring sub-millisecond latency commanding price premiums of 300-400% over standard models. This price-performance relationship creates distinct market segments catering to different robotic applications based on their precision requirements and operational constraints.

Industrial robotics represents the largest application segment, accounting for 41% of the market share. Within this segment, manufacturing automation leads demand, particularly in automotive production, electronics assembly, and food processing industries. The warehouse and logistics sector follows closely, with a rapidly expanding 37% market share, fueled by the e-commerce boom and the need for efficient inventory management systems.

Consumer robotics, including vacuum cleaners and home assistance robots, constitutes 15% of the market but shows the fastest growth rate at 18.7% annually. This surge reflects increasing consumer acceptance of home automation technologies and declining unit costs. The remaining market share is distributed across specialized applications including agricultural robotics, security systems, and medical robotics.

Geographically, Asia-Pacific dominates with 42% of the global market, led by manufacturing powerhouses China, Japan, and South Korea. North America follows with 31%, where advanced research in SLAM technologies drives innovation. Europe accounts for 22%, with Germany and France leading in industrial automation applications.

Key market drivers include the decreasing cost of ultrasonic sensor technology, with average unit prices falling by 8.3% annually over the past five years. Improved performance metrics, particularly in terms of accuracy and latency reduction, have expanded application possibilities. The integration of ultrasonic sensors with complementary technologies such as LiDAR and computer vision has created hybrid sensing systems that overcome individual technology limitations.

Market challenges include competition from alternative sensing technologies, particularly optical and infrared systems that offer higher resolution in certain applications. Technical limitations in extreme environmental conditions and interference issues in complex environments remain obstacles to broader adoption. Additionally, standardization gaps across different robotic platforms create integration challenges for sensor manufacturers.

The market shows strong segmentation based on performance tiers, with premium sensors featuring sub-millisecond latency commanding price premiums of 300-400% over standard models. This price-performance relationship creates distinct market segments catering to different robotic applications based on their precision requirements and operational constraints.

Current Ultrasonic Technology Limitations in Robotics

Despite significant advancements in ultrasonic sensor technology for robotics applications, several critical limitations continue to impede their optimal performance in SLAM, obstacle avoidance, and real-time navigation systems. The most prominent constraint remains the relatively low resolution compared to optical and LiDAR systems. Ultrasonic sensors typically provide distance measurements with centimeter-level accuracy, which proves insufficient for precise mapping and fine object detection required in complex environments.

Signal interference presents another substantial challenge, particularly in environments with multiple robots operating simultaneously. When multiple ultrasonic sensors function in close proximity, cross-talk between devices can lead to erroneous readings and phantom obstacles. This limitation becomes especially problematic in warehouse automation and multi-robot collaborative settings where numerous units operate within confined spaces.

Environmental factors significantly impact ultrasonic sensor performance. Soft, sound-absorbing materials often go undetected or appear at incorrect distances due to weak echo returns. Conversely, highly reflective surfaces can cause multipath reflections, resulting in ghost readings and distance calculation errors. Temperature and humidity variations also affect sound propagation speed, introducing measurement inaccuracies without proper calibration mechanisms.

The inherent latency in ultrasonic sensing systems represents a critical bottleneck for high-speed robotic applications. The physical constraints of sound propagation (approximately 343 m/s at standard conditions) impose fundamental limits on measurement frequency. This latency becomes particularly problematic when robots operate at higher speeds, as the environment may change significantly between measurements, leading to delayed obstacle detection and potential collision risks.

Beam width limitations further restrict ultrasonic sensor capabilities. The typical conical detection pattern creates significant blind spots and makes it difficult to precisely locate small objects within the detection zone. This characteristic necessitates complex sensor arrays and fusion algorithms to achieve comprehensive environmental coverage, increasing system complexity and cost.

Power consumption remains a concern for battery-operated robotic platforms. While ultrasonic sensors are generally more energy-efficient than LiDAR systems, the need for multiple sensors to overcome coverage limitations can collectively drain power resources, especially in long-duration operations where energy efficiency is paramount.

Integration challenges with other sensing modalities also persist. Achieving seamless sensor fusion between ultrasonic data and information from cameras, LiDAR, or radar requires sophisticated algorithms to reconcile different data formats, resolutions, and update rates. The computational overhead of these fusion processes can strain onboard processing resources, particularly in compact or low-cost robotic platforms.

Signal interference presents another substantial challenge, particularly in environments with multiple robots operating simultaneously. When multiple ultrasonic sensors function in close proximity, cross-talk between devices can lead to erroneous readings and phantom obstacles. This limitation becomes especially problematic in warehouse automation and multi-robot collaborative settings where numerous units operate within confined spaces.

Environmental factors significantly impact ultrasonic sensor performance. Soft, sound-absorbing materials often go undetected or appear at incorrect distances due to weak echo returns. Conversely, highly reflective surfaces can cause multipath reflections, resulting in ghost readings and distance calculation errors. Temperature and humidity variations also affect sound propagation speed, introducing measurement inaccuracies without proper calibration mechanisms.

The inherent latency in ultrasonic sensing systems represents a critical bottleneck for high-speed robotic applications. The physical constraints of sound propagation (approximately 343 m/s at standard conditions) impose fundamental limits on measurement frequency. This latency becomes particularly problematic when robots operate at higher speeds, as the environment may change significantly between measurements, leading to delayed obstacle detection and potential collision risks.

Beam width limitations further restrict ultrasonic sensor capabilities. The typical conical detection pattern creates significant blind spots and makes it difficult to precisely locate small objects within the detection zone. This characteristic necessitates complex sensor arrays and fusion algorithms to achieve comprehensive environmental coverage, increasing system complexity and cost.

Power consumption remains a concern for battery-operated robotic platforms. While ultrasonic sensors are generally more energy-efficient than LiDAR systems, the need for multiple sensors to overcome coverage limitations can collectively drain power resources, especially in long-duration operations where energy efficiency is paramount.

Integration challenges with other sensing modalities also persist. Achieving seamless sensor fusion between ultrasonic data and information from cameras, LiDAR, or radar requires sophisticated algorithms to reconcile different data formats, resolutions, and update rates. The computational overhead of these fusion processes can strain onboard processing resources, particularly in compact or low-cost robotic platforms.

SLAM and Obstacle Avoidance Implementation Approaches

01 Latency reduction techniques in ultrasonic sensor systems

Various techniques can be implemented to reduce latency in ultrasonic sensor systems, including optimized signal processing algorithms, hardware acceleration, and improved transducer designs. These approaches minimize the time delay between signal transmission and reception, allowing for faster response times in applications requiring real-time feedback. Advanced digital signal processors and specialized circuitry can significantly decrease computational delays in ultrasonic measurement systems.- Latency reduction techniques in ultrasonic sensor systems: Various methods can be employed to reduce latency in ultrasonic sensor systems, including optimized signal processing algorithms, hardware acceleration, and improved transducer designs. These techniques focus on minimizing the time delay between signal transmission and reception, enabling faster response times for applications requiring real-time feedback. Advanced digital signal processing techniques can filter noise more efficiently while maintaining signal integrity, contributing to overall latency reduction.

- Automotive applications addressing ultrasonic sensor latency: In automotive systems, ultrasonic sensor latency is particularly critical for applications such as parking assistance, collision avoidance, and autonomous driving. Specialized implementations focus on reducing processing time through dedicated microcontrollers, parallel processing architectures, and predictive algorithms that compensate for inherent sensor delays. These systems often incorporate multiple sensors with synchronized timing to provide comprehensive environmental awareness while minimizing response delays.

- Time-of-flight measurement optimization for ultrasonic sensors: Time-of-flight measurement is fundamental to ultrasonic sensing, and optimizing this process directly impacts latency. Advanced techniques include phase-shift detection, frequency modulation, and pulse compression methods that improve timing accuracy while reducing measurement delays. By implementing precise clock synchronization and calibration routines, these systems can achieve microsecond-level timing precision, significantly reducing the overall latency in distance measurement applications.

- Multi-sensor fusion approaches to compensate for ultrasonic latency: Combining ultrasonic sensors with other sensing modalities such as cameras, radar, or LiDAR can help compensate for the inherent latency of ultrasonic systems. These fusion approaches use faster sensors to provide immediate feedback while ultrasonic data is being processed, or implement predictive algorithms that anticipate changes based on historical sensor data. The integration of multiple sensor types with different latency characteristics enables more responsive and reliable sensing systems.

- Environmental adaptation for ultrasonic sensor latency management: Ultrasonic sensor latency can vary significantly based on environmental conditions such as temperature, humidity, and air pressure. Advanced systems incorporate environmental sensors and adaptive algorithms that dynamically adjust processing parameters to maintain consistent performance across varying conditions. These systems may include temperature compensation circuits, adaptive filtering based on ambient noise levels, and dynamic power management to optimize sensor performance while managing latency under changing environmental conditions.

02 Automotive applications of low-latency ultrasonic sensors

Low-latency ultrasonic sensors are crucial for automotive safety and autonomous driving systems where rapid detection and response to obstacles is essential. These sensors provide distance measurements and object detection with minimal delay for applications such as parking assistance, collision avoidance, and adaptive cruise control. The reduced latency enables vehicles to make split-second decisions based on environmental conditions, enhancing overall safety and performance.Expand Specific Solutions03 Multi-sensor fusion for latency compensation

Combining ultrasonic sensors with other sensing technologies such as cameras, radar, or LiDAR can help compensate for inherent latency issues. Sensor fusion algorithms integrate data from multiple sources to provide more accurate and timely information. This approach allows the system to predict object movements and positions during the ultrasonic measurement delay period, effectively reducing the perceived latency in critical applications.Expand Specific Solutions04 Time-of-flight optimization for ultrasonic sensors

Optimizing time-of-flight measurements is essential for minimizing latency in ultrasonic sensing systems. Advanced timing circuits, precise clock synchronization, and improved echo detection algorithms contribute to more accurate and faster distance calculations. By reducing uncertainties in the measurement process and implementing predictive algorithms, the overall system latency can be significantly decreased while maintaining measurement accuracy.Expand Specific Solutions05 Environmental compensation for ultrasonic sensor latency

Environmental factors such as temperature, humidity, and air pressure can affect ultrasonic wave propagation speed, introducing variable latency in measurements. Advanced ultrasonic sensor systems implement real-time environmental compensation algorithms that adjust calculations based on ambient conditions. These systems may include additional sensors to monitor environmental parameters and dynamically calibrate the ultrasonic measurements, ensuring consistent performance across varying conditions.Expand Specific Solutions

Leading Ultrasonic Sensor Manufacturers and Integrators

The ultrasonic sensor market in robotics is currently in a growth phase, with increasing applications in SLAM and obstacle avoidance technologies. The market is expanding rapidly due to rising adoption of autonomous robots across industrial, consumer, and commercial sectors. Leading players include established electronics giants like Samsung Electronics, LG Electronics, and Robert Bosch GmbH, who leverage their manufacturing expertise, alongside specialized robotics companies such as iRobot Corp. and UBTECH Robotics. Automotive companies including Toyota, DENSO, and Valeo are also significant contributors, particularly in navigation applications. The technology is approaching maturity for basic obstacle detection but continues to evolve for complex SLAM implementations, with companies like Trifo and TRX Systems advancing solutions to address latency challenges in real-time navigation.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated ultrasonic sensor ecosystem for robotics applications focusing on high-precision SLAM and obstacle avoidance. Their system employs arrays of miniaturized ultrasonic transducers operating at multiple frequencies (typically 40-200 kHz) to optimize performance across different environmental conditions. Bosch's approach includes advanced signal processing techniques such as pulse compression and adaptive filtering to improve range resolution and reduce false detections. Their proprietary ASIC (Application-Specific Integrated Circuit) design enables parallel processing of ultrasonic signals, reducing latency to approximately 15ms in their latest generation sensors[2]. Bosch has implemented a distributed architecture where preprocessing occurs at the sensor level before data fusion, significantly reducing the computational load on the main processor. Their ultrasonic SLAM implementation incorporates probabilistic mapping techniques that account for sensor uncertainty, particularly important for ultrasonic sensors where beam width can create ambiguity in obstacle location.

Strengths: Exceptional reliability in harsh industrial environments; robust performance in dusty, smoky, or poorly lit conditions; low power consumption suitable for battery-operated robots; mature manufacturing processes ensuring consistent quality. Weaknesses: Higher cost compared to basic ultrasonic solutions; requires careful calibration for optimal performance; limited effectiveness for very small obstacle detection.

iRobot Corp.

Technical Solution: iRobot's ultrasonic sensor technology for robotics focuses on advanced SLAM (Simultaneous Localization and Mapping) implementation in their Roomba series. Their approach combines multiple ultrasonic sensors positioned strategically around the robot's perimeter to create a comprehensive spatial awareness system. The company has developed proprietary algorithms that process ultrasonic data with minimal latency (typically under 20ms) by employing specialized signal processing hardware. Their latest systems utilize frequency-modulated continuous wave (FMCW) ultrasonic sensing rather than simple time-of-flight measurements, allowing for more accurate distance calculations and better discrimination between different types of obstacles[1]. iRobot has also pioneered sensor fusion techniques that combine ultrasonic data with other sensor inputs (infrared, optical) to overcome the inherent limitations of ultrasonic technology in certain environments.

Strengths: Superior obstacle detection in varied lighting conditions; excellent performance in detecting transparent and reflective surfaces that challenge optical systems; low computational requirements compared to vision-based systems. Weaknesses: Limited range (typically under 3 meters); susceptibility to acoustic interference in noisy environments; lower resolution compared to LiDAR or camera-based systems.

Key Patents in Low-Latency Ultrasonic Sensing

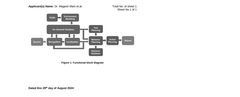

Autonomous robotic navigation system utilizing real-time environmental mapping

PatentPendingIN202441065496A

Innovation

- The integration of advanced sensor technologies and machine learning algorithms enables real-time environmental mapping and simultaneous localization and mapping (SLAM), allowing robots to create detailed maps of their surroundings, predict object movement, and adapt navigation strategies, while ensuring safety and versatility across various industries.

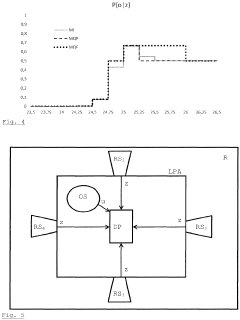

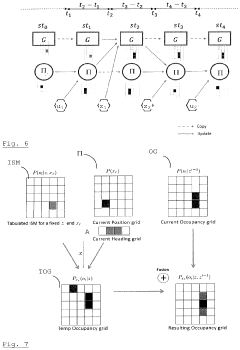

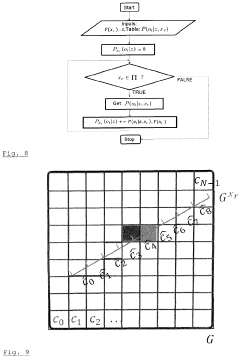

Method and apparatus for performing simultaneous localization and mapping

PatentActiveEP3734388A1

Innovation

- A method that uses an occupancy grid and a pose grid, updated by distance and odometry measurements, which accounts for sensor measurement uncertainties and has a probabilistic model to handle finite precision and errors, allowing for efficient simultaneous localization and mapping.

Environmental Factors Affecting Ultrasonic Performance

Ultrasonic sensors in robotics operate within diverse environments that significantly impact their performance characteristics. Temperature variations constitute a primary environmental factor affecting these sensors, as sound waves travel faster in warmer air and slower in colder conditions. This velocity differential can lead to measurement inaccuracies of up to 0.35 meters per second per degree Celsius change, requiring sophisticated compensation algorithms in robotic navigation systems operating across varying thermal environments.

Humidity levels similarly influence ultrasonic performance by altering air density and consequently sound propagation speed. Higher humidity typically increases sound velocity, though the relationship is non-linear and depends on temperature interactions. For precision robotics applications such as warehouse automation or medical robots, these humidity-induced variations necessitate calibration protocols that account for environmental moisture content.

Atmospheric pressure fluctuations, while less impactful in indoor environments, become significant considerations for outdoor robotic applications. Barometric pressure changes affect air density, subsequently modifying ultrasonic wave propagation characteristics. Research indicates measurement errors of approximately 0.1% per kilopascal pressure deviation, potentially compromising navigation accuracy in applications like agricultural robotics or autonomous delivery vehicles operating across elevation changes.

Air turbulence and wind conditions present substantial challenges for ultrasonic-based robotic systems deployed outdoors. Wind speeds exceeding 10 m/s can deflect ultrasonic waves, creating signal distortion and false readings. This phenomenon particularly affects SLAM (Simultaneous Localization and Mapping) algorithms that rely on consistent sensor data for environmental mapping and self-localization.

Surface characteristics of detected objects significantly influence echo quality and measurement reliability. Smooth, hard surfaces typically provide optimal reflection conditions, while soft, porous, or angled surfaces may absorb or scatter ultrasonic waves, reducing detection reliability. This variability necessitates multi-sensor fusion approaches in complex environments where surface properties cannot be controlled or predicted.

Ambient noise pollution, particularly in industrial settings, can interfere with ultrasonic signal reception. High-frequency mechanical noise from machinery, compressed air systems, or other robots operating in proximity can create false positives or mask genuine obstacle detections. Advanced filtering algorithms and frequency modulation techniques have emerged as countermeasures, though they often introduce additional computational overhead and latency.

Dust, fog, and airborne particulates present variable challenges depending on particle size and concentration. While ultrasonic sensors generally outperform optical systems in dusty or foggy conditions, extreme particulate concentrations can attenuate signals and reduce effective sensing range by up to 25% in heavily contaminated environments.

Humidity levels similarly influence ultrasonic performance by altering air density and consequently sound propagation speed. Higher humidity typically increases sound velocity, though the relationship is non-linear and depends on temperature interactions. For precision robotics applications such as warehouse automation or medical robots, these humidity-induced variations necessitate calibration protocols that account for environmental moisture content.

Atmospheric pressure fluctuations, while less impactful in indoor environments, become significant considerations for outdoor robotic applications. Barometric pressure changes affect air density, subsequently modifying ultrasonic wave propagation characteristics. Research indicates measurement errors of approximately 0.1% per kilopascal pressure deviation, potentially compromising navigation accuracy in applications like agricultural robotics or autonomous delivery vehicles operating across elevation changes.

Air turbulence and wind conditions present substantial challenges for ultrasonic-based robotic systems deployed outdoors. Wind speeds exceeding 10 m/s can deflect ultrasonic waves, creating signal distortion and false readings. This phenomenon particularly affects SLAM (Simultaneous Localization and Mapping) algorithms that rely on consistent sensor data for environmental mapping and self-localization.

Surface characteristics of detected objects significantly influence echo quality and measurement reliability. Smooth, hard surfaces typically provide optimal reflection conditions, while soft, porous, or angled surfaces may absorb or scatter ultrasonic waves, reducing detection reliability. This variability necessitates multi-sensor fusion approaches in complex environments where surface properties cannot be controlled or predicted.

Ambient noise pollution, particularly in industrial settings, can interfere with ultrasonic signal reception. High-frequency mechanical noise from machinery, compressed air systems, or other robots operating in proximity can create false positives or mask genuine obstacle detections. Advanced filtering algorithms and frequency modulation techniques have emerged as countermeasures, though they often introduce additional computational overhead and latency.

Dust, fog, and airborne particulates present variable challenges depending on particle size and concentration. While ultrasonic sensors generally outperform optical systems in dusty or foggy conditions, extreme particulate concentrations can attenuate signals and reduce effective sensing range by up to 25% in heavily contaminated environments.

Safety Standards for Robotic Navigation Systems

The integration of robotic systems into various environments necessitates comprehensive safety standards to ensure reliable navigation, particularly when utilizing ultrasonic sensor technology. International safety standards such as ISO 10218 and ISO/TS 15066 establish fundamental requirements for collaborative robots, with specific provisions addressing sensor-based navigation systems. These standards mandate minimum detection ranges, response times, and failure mode behaviors for ultrasonic-based obstacle detection systems.

For SLAM applications utilizing ultrasonic sensors, safety standards require redundant sensing mechanisms to compensate for the inherent limitations in ultrasonic technology, such as specular reflections and environmental interference. The IEC 61496 standard specifically addresses the safety requirements for presence-sensing devices, including those based on ultrasonic principles, establishing performance levels that correlate with risk assessment outcomes.

Latency considerations are explicitly addressed in safety frameworks, with maximum permissible response times defined based on the robot's operational speed and stopping distance. For ultrasonic sensor implementations, standards typically require system latency not to exceed 100ms for critical obstacle avoidance functions, ensuring timely response to dynamic obstacles. This becomes particularly crucial in human-robot collaborative environments where ISO/TS 15066 imposes stringent requirements on collision detection and avoidance capabilities.

Certification processes for robotic navigation systems incorporating ultrasonic sensors involve rigorous testing under various environmental conditions. These tests evaluate sensor performance across temperature ranges, humidity levels, and in the presence of acoustic interference. The ANSI/RIA R15.06 standard provides specific guidelines for risk assessment methodologies applicable to ultrasonic-based navigation systems, requiring manufacturers to document sensor limitations and implement appropriate safety measures.

Emerging standards are beginning to address the specific challenges of ultrasonic sensor integration in advanced robotic applications. The UL 3100 framework for autonomous mobile robots includes provisions for multi-sensor fusion approaches, recognizing the complementary role ultrasonic sensors play alongside other sensing modalities. These standards increasingly emphasize fail-safe design principles, requiring systems to maintain safe operation even when ultrasonic sensors experience temporary performance degradation.

Regional variations in safety standards present challenges for global deployment of ultrasonic-equipped robotic systems. While European standards (EN ISO 13849) focus on performance levels and safety integrity, North American standards (ANSI/RIA) emphasize risk assessment methodologies. Harmonization efforts are underway through organizations like the International Federation of Robotics to establish consistent global safety benchmarks for sensor-based navigation technologies.

For SLAM applications utilizing ultrasonic sensors, safety standards require redundant sensing mechanisms to compensate for the inherent limitations in ultrasonic technology, such as specular reflections and environmental interference. The IEC 61496 standard specifically addresses the safety requirements for presence-sensing devices, including those based on ultrasonic principles, establishing performance levels that correlate with risk assessment outcomes.

Latency considerations are explicitly addressed in safety frameworks, with maximum permissible response times defined based on the robot's operational speed and stopping distance. For ultrasonic sensor implementations, standards typically require system latency not to exceed 100ms for critical obstacle avoidance functions, ensuring timely response to dynamic obstacles. This becomes particularly crucial in human-robot collaborative environments where ISO/TS 15066 imposes stringent requirements on collision detection and avoidance capabilities.

Certification processes for robotic navigation systems incorporating ultrasonic sensors involve rigorous testing under various environmental conditions. These tests evaluate sensor performance across temperature ranges, humidity levels, and in the presence of acoustic interference. The ANSI/RIA R15.06 standard provides specific guidelines for risk assessment methodologies applicable to ultrasonic-based navigation systems, requiring manufacturers to document sensor limitations and implement appropriate safety measures.

Emerging standards are beginning to address the specific challenges of ultrasonic sensor integration in advanced robotic applications. The UL 3100 framework for autonomous mobile robots includes provisions for multi-sensor fusion approaches, recognizing the complementary role ultrasonic sensors play alongside other sensing modalities. These standards increasingly emphasize fail-safe design principles, requiring systems to maintain safe operation even when ultrasonic sensors experience temporary performance degradation.

Regional variations in safety standards present challenges for global deployment of ultrasonic-equipped robotic systems. While European standards (EN ISO 13849) focus on performance levels and safety integrity, North American standards (ANSI/RIA) emphasize risk assessment methodologies. Harmonization efforts are underway through organizations like the International Federation of Robotics to establish consistent global safety benchmarks for sensor-based navigation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!