Waterproofing Ultrasonic Sensors: IP Ratings, Gaskets, And Testing

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic Sensor Waterproofing Background and Objectives

Ultrasonic sensors have evolved significantly since their inception in the early 20th century, with applications expanding from simple distance measurement to sophisticated systems in automotive, industrial, medical, and consumer electronics sectors. The technology leverages the principles of sound wave propagation, where high-frequency sound waves are emitted, reflected off objects, and received back to determine distance, presence, or characteristics of targets. However, as these sensors increasingly operate in diverse and challenging environments, waterproofing has become a critical aspect of their design and functionality.

The evolution of ultrasonic sensor waterproofing technology has progressed from basic sealing methods to advanced integrated solutions. Early approaches primarily relied on rudimentary gaskets and sealants, offering limited protection against moisture. Modern solutions incorporate sophisticated materials science, precision engineering, and innovative design principles to achieve higher levels of water resistance while maintaining optimal sensor performance.

Current industry trends indicate a growing demand for ultrasonic sensors capable of operating reliably in harsh environments, including underwater applications, outdoor installations exposed to precipitation, and high-humidity industrial settings. This trend is particularly evident in the automotive sector, where ultrasonic sensors for parking assistance and autonomous driving features must function flawlessly regardless of weather conditions.

The primary technical objective of waterproofing ultrasonic sensors is to achieve a balance between environmental protection and acoustic performance. Water ingress can significantly impair sensor functionality by interfering with the transducer elements, corroding electronic components, or creating false readings due to acoustic impedance changes. Therefore, effective waterproofing solutions must prevent water penetration while minimizing impact on the sensor's acoustic properties.

Standardization through IP (Ingress Protection) ratings has become increasingly important in this field, providing a universal framework for evaluating and communicating the level of protection offered by sensor enclosures. The industry is moving toward higher IP ratings (IP67, IP68, IP69K) as applications in more demanding environments increase.

Looking forward, the technical goals in this domain include developing waterproofing solutions that are cost-effective for mass production, miniaturized to accommodate the trend toward smaller sensor packages, and capable of withstanding not just water but also other environmental challenges such as temperature extremes, chemical exposure, and mechanical stress.

Additionally, there is growing interest in self-healing waterproofing materials and active protection systems that can adapt to changing environmental conditions, representing the next frontier in ultrasonic sensor protection technology. These advancements aim to extend sensor lifespan, reduce maintenance requirements, and enable new applications in previously prohibitive environments.

The evolution of ultrasonic sensor waterproofing technology has progressed from basic sealing methods to advanced integrated solutions. Early approaches primarily relied on rudimentary gaskets and sealants, offering limited protection against moisture. Modern solutions incorporate sophisticated materials science, precision engineering, and innovative design principles to achieve higher levels of water resistance while maintaining optimal sensor performance.

Current industry trends indicate a growing demand for ultrasonic sensors capable of operating reliably in harsh environments, including underwater applications, outdoor installations exposed to precipitation, and high-humidity industrial settings. This trend is particularly evident in the automotive sector, where ultrasonic sensors for parking assistance and autonomous driving features must function flawlessly regardless of weather conditions.

The primary technical objective of waterproofing ultrasonic sensors is to achieve a balance between environmental protection and acoustic performance. Water ingress can significantly impair sensor functionality by interfering with the transducer elements, corroding electronic components, or creating false readings due to acoustic impedance changes. Therefore, effective waterproofing solutions must prevent water penetration while minimizing impact on the sensor's acoustic properties.

Standardization through IP (Ingress Protection) ratings has become increasingly important in this field, providing a universal framework for evaluating and communicating the level of protection offered by sensor enclosures. The industry is moving toward higher IP ratings (IP67, IP68, IP69K) as applications in more demanding environments increase.

Looking forward, the technical goals in this domain include developing waterproofing solutions that are cost-effective for mass production, miniaturized to accommodate the trend toward smaller sensor packages, and capable of withstanding not just water but also other environmental challenges such as temperature extremes, chemical exposure, and mechanical stress.

Additionally, there is growing interest in self-healing waterproofing materials and active protection systems that can adapt to changing environmental conditions, representing the next frontier in ultrasonic sensor protection technology. These advancements aim to extend sensor lifespan, reduce maintenance requirements, and enable new applications in previously prohibitive environments.

Market Demand Analysis for Waterproof Ultrasonic Solutions

The global market for waterproof ultrasonic sensors has experienced significant growth in recent years, driven by increasing applications across multiple industries. The demand for these specialized sensors is primarily fueled by the automotive sector, where they are extensively used in parking assistance systems, collision avoidance mechanisms, and autonomous driving technologies. With the automotive industry's rapid shift towards advanced driver-assistance systems (ADAS), the need for reliable waterproof ultrasonic sensors has become paramount.

Industrial automation represents another substantial market segment, where waterproof ultrasonic sensors are deployed in harsh environments for level measurement, object detection, and distance sensing applications. The ability to withstand moisture, chemicals, and varying temperatures makes these sensors indispensable in manufacturing facilities, chemical plants, and food processing units.

The marine and offshore industries constitute a growing market for waterproof ultrasonic sensors, particularly those with high IP ratings. These sectors require sensors that can function reliably under extreme conditions, including saltwater exposure and high-pressure environments. The demand in this segment is expected to grow as maritime operations become increasingly automated and digitized.

Consumer electronics has emerged as a rapidly expanding market for miniaturized waterproof ultrasonic sensors. Smart devices, wearables, and IoT applications require compact sensors that maintain functionality despite exposure to moisture and environmental contaminants. This segment values not only waterproofing capabilities but also energy efficiency and seamless integration possibilities.

Market analysis indicates that the healthcare sector is showing increased interest in waterproof ultrasonic solutions for medical devices that require sterilization or operate in fluid-rich environments. Applications range from non-invasive monitoring equipment to portable diagnostic devices designed for field use in various environmental conditions.

Regional market distribution shows North America and Europe leading in adoption, primarily due to stringent safety regulations and advanced industrial infrastructure. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, automotive manufacturing expansion, and increasing technological adoption across various sectors.

The market value proposition for waterproof ultrasonic sensors centers on reliability, longevity, and performance consistency across varying environmental conditions. End-users are increasingly willing to pay premium prices for sensors with higher IP ratings and proven durability, recognizing the long-term cost benefits of reduced maintenance and replacement frequencies.

Future market growth is expected to be driven by emerging applications in robotics, drone technology, and smart infrastructure, all of which require sensors capable of operating reliably in outdoor and unpredictable environments.

Industrial automation represents another substantial market segment, where waterproof ultrasonic sensors are deployed in harsh environments for level measurement, object detection, and distance sensing applications. The ability to withstand moisture, chemicals, and varying temperatures makes these sensors indispensable in manufacturing facilities, chemical plants, and food processing units.

The marine and offshore industries constitute a growing market for waterproof ultrasonic sensors, particularly those with high IP ratings. These sectors require sensors that can function reliably under extreme conditions, including saltwater exposure and high-pressure environments. The demand in this segment is expected to grow as maritime operations become increasingly automated and digitized.

Consumer electronics has emerged as a rapidly expanding market for miniaturized waterproof ultrasonic sensors. Smart devices, wearables, and IoT applications require compact sensors that maintain functionality despite exposure to moisture and environmental contaminants. This segment values not only waterproofing capabilities but also energy efficiency and seamless integration possibilities.

Market analysis indicates that the healthcare sector is showing increased interest in waterproof ultrasonic solutions for medical devices that require sterilization or operate in fluid-rich environments. Applications range from non-invasive monitoring equipment to portable diagnostic devices designed for field use in various environmental conditions.

Regional market distribution shows North America and Europe leading in adoption, primarily due to stringent safety regulations and advanced industrial infrastructure. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, automotive manufacturing expansion, and increasing technological adoption across various sectors.

The market value proposition for waterproof ultrasonic sensors centers on reliability, longevity, and performance consistency across varying environmental conditions. End-users are increasingly willing to pay premium prices for sensors with higher IP ratings and proven durability, recognizing the long-term cost benefits of reduced maintenance and replacement frequencies.

Future market growth is expected to be driven by emerging applications in robotics, drone technology, and smart infrastructure, all of which require sensors capable of operating reliably in outdoor and unpredictable environments.

Current Waterproofing Technologies and Challenges

Waterproofing ultrasonic sensors presents significant technical challenges due to the inherent contradiction between the need for acoustic transmission and water resistance. Current waterproofing technologies primarily utilize several approaches, each with distinct advantages and limitations in protecting these sensitive electronic components.

IP (Ingress Protection) ratings serve as the industry standard for evaluating waterproofing effectiveness, with ultrasonic sensors typically requiring IPX7 or IPX8 ratings for reliable underwater operation. These ratings guarantee protection against water immersion at specified depths and durations, providing a standardized benchmark for manufacturers and consumers alike.

Gasket-based solutions represent the most widely implemented waterproofing technology for ultrasonic sensors. Silicone, EPDM (Ethylene Propylene Diene Monomer), and fluorosilicone gaskets create compression seals between sensor components while allowing acoustic waves to pass through with minimal attenuation. The effectiveness of these gaskets depends critically on proper compression ratios, material selection, and installation precision.

Conformal coatings offer an alternative approach, with hydrophobic nano-coatings emerging as a promising technology. These ultra-thin layers (typically 2-10 microns) provide water resistance while minimizing acoustic impedance. Parylene coatings, in particular, have gained popularity for their uniform application process and excellent moisture barrier properties.

Potting compounds and encapsulation technologies represent another significant waterproofing method, where polyurethane and epoxy resins completely surround sensitive electronic components. However, these materials must be carefully formulated to maintain acoustic transparency while providing water resistance.

Despite these advances, several challenges persist in ultrasonic sensor waterproofing. Temperature cycling remains problematic as it causes differential expansion between materials, potentially compromising seals over time. Sensors operating in extreme environments face accelerated degradation of waterproofing materials, reducing effective service life.

Acoustic impedance matching presents perhaps the most fundamental challenge, as waterproofing materials inevitably affect signal transmission and reception quality. Engineers must carefully balance water resistance against signal integrity, often accepting compromises in performance.

Manufacturing consistency also remains difficult to achieve, with variations in gasket compression, coating thickness, and material properties leading to inconsistent waterproofing performance across production batches. This necessitates rigorous quality control protocols and testing methodologies.

Recent innovations focus on developing acoustically transparent hydrophobic materials and advanced manufacturing techniques like ultrasonic welding and laser bonding to create hermetic seals without compromising sensor functionality. These developments show promise for overcoming the current limitations in ultrasonic sensor waterproofing technology.

IP (Ingress Protection) ratings serve as the industry standard for evaluating waterproofing effectiveness, with ultrasonic sensors typically requiring IPX7 or IPX8 ratings for reliable underwater operation. These ratings guarantee protection against water immersion at specified depths and durations, providing a standardized benchmark for manufacturers and consumers alike.

Gasket-based solutions represent the most widely implemented waterproofing technology for ultrasonic sensors. Silicone, EPDM (Ethylene Propylene Diene Monomer), and fluorosilicone gaskets create compression seals between sensor components while allowing acoustic waves to pass through with minimal attenuation. The effectiveness of these gaskets depends critically on proper compression ratios, material selection, and installation precision.

Conformal coatings offer an alternative approach, with hydrophobic nano-coatings emerging as a promising technology. These ultra-thin layers (typically 2-10 microns) provide water resistance while minimizing acoustic impedance. Parylene coatings, in particular, have gained popularity for their uniform application process and excellent moisture barrier properties.

Potting compounds and encapsulation technologies represent another significant waterproofing method, where polyurethane and epoxy resins completely surround sensitive electronic components. However, these materials must be carefully formulated to maintain acoustic transparency while providing water resistance.

Despite these advances, several challenges persist in ultrasonic sensor waterproofing. Temperature cycling remains problematic as it causes differential expansion between materials, potentially compromising seals over time. Sensors operating in extreme environments face accelerated degradation of waterproofing materials, reducing effective service life.

Acoustic impedance matching presents perhaps the most fundamental challenge, as waterproofing materials inevitably affect signal transmission and reception quality. Engineers must carefully balance water resistance against signal integrity, often accepting compromises in performance.

Manufacturing consistency also remains difficult to achieve, with variations in gasket compression, coating thickness, and material properties leading to inconsistent waterproofing performance across production batches. This necessitates rigorous quality control protocols and testing methodologies.

Recent innovations focus on developing acoustically transparent hydrophobic materials and advanced manufacturing techniques like ultrasonic welding and laser bonding to create hermetic seals without compromising sensor functionality. These developments show promise for overcoming the current limitations in ultrasonic sensor waterproofing technology.

IP Rating Standards and Implementation Approaches

01 Encapsulation techniques for waterproofing ultrasonic sensors

Various encapsulation methods are used to protect ultrasonic sensors from water and moisture. These include using waterproof materials like silicone, epoxy resins, or specialized polymers to fully encapsulate the sensor components. The encapsulation creates a protective barrier that prevents water infiltration while allowing ultrasonic waves to transmit effectively. This approach is particularly important for sensors used in outdoor environments or underwater applications.- Waterproof housing designs for ultrasonic sensors: Various housing designs can be implemented to protect ultrasonic sensors from water ingress. These designs include sealed enclosures with waterproof materials, specialized casings with rubber gaskets, and integrated waterproof membranes that allow sound transmission while blocking water. These housings are engineered to maintain the sensor's functionality while providing protection against moisture in various environmental conditions.

- Protective coating and encapsulation techniques: Ultrasonic sensors can be waterproofed through various coating and encapsulation methods. These include applying hydrophobic coatings, using potting compounds, encapsulating with silicone or epoxy resins, and utilizing conformal coatings. These techniques create a protective barrier around the sensor components while maintaining acoustic transparency, ensuring the sensor remains functional in wet environments.

- Waterproof membrane technology for ultrasonic transmission: Specialized waterproof membranes can be integrated into ultrasonic sensor designs to allow sound waves to pass through while preventing water penetration. These membranes are made from materials that offer minimal acoustic impedance while maintaining water resistance. The technology includes microporous structures, composite materials, and specially designed films that balance acoustic transparency with waterproofing capabilities.

- Sealing methods for electrical connections: Waterproofing ultrasonic sensors requires protecting electrical connections from moisture. Various sealing methods are employed, including hermetic sealing techniques, waterproof connectors, cable glands, and specialized junction designs. These methods ensure that water cannot penetrate through cable entry points or electrical interfaces, maintaining the integrity of the sensor system in wet environments.

- Testing and validation methods for waterproof ultrasonic sensors: Various testing and validation methods are used to ensure ultrasonic sensors meet waterproofing standards. These include immersion testing, pressure testing, environmental cycling, and long-term reliability assessments. Standardized protocols such as IP rating tests verify the sensor's ability to withstand water exposure while maintaining functionality. These methods help validate the effectiveness of waterproofing solutions in real-world applications.

02 Membrane and diaphragm designs for waterproof ultrasonic transducers

Specialized membrane and diaphragm designs are implemented to create waterproof ultrasonic sensors. These membranes are typically made of water-resistant materials that can vibrate to transmit ultrasonic waves while preventing water penetration. The design often includes a thin, flexible layer that maintains acoustic properties while providing a waterproof seal. Some designs incorporate multiple layers or composite materials to optimize both waterproofing and acoustic performance.Expand Specific Solutions03 Housing and sealing solutions for ultrasonic sensor protection

Protective housings and sealing solutions are developed specifically for ultrasonic sensors to ensure waterproofing. These include specialized casings with rubber gaskets, O-rings, or other sealing mechanisms that create watertight compartments for the sensor electronics. The housings are designed to allow ultrasonic signals to pass through while keeping water out. Some designs incorporate pressure-equalizing elements to prevent damage when used at varying depths or pressure conditions.Expand Specific Solutions04 Waterproof coating technologies for ultrasonic sensors

Advanced coating technologies are applied to ultrasonic sensors to provide waterproofing without significantly affecting sensor performance. These include hydrophobic nano-coatings, conformal coatings, and specialized water-repellent treatments that can be applied to the sensor components. The coatings create a microscopic barrier that repels water while allowing ultrasonic waves to propagate effectively. This approach is particularly useful for retrofitting existing sensors or for applications where minimal dimensional changes are required.Expand Specific Solutions05 Integrated waterproofing solutions for ultrasonic sensor systems

Comprehensive waterproofing approaches that integrate multiple techniques are developed for ultrasonic sensor systems. These solutions combine structural design elements, material selection, and manufacturing processes to create inherently waterproof sensors. The integrated approach considers the entire sensor system, including electronics, transducer elements, and connection points. Some designs incorporate self-healing materials or redundant waterproofing features to ensure long-term reliability in wet environments.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The waterproofing ultrasonic sensor market is in a growth phase, with increasing demand across automotive, medical, and industrial sectors driving a projected market expansion. Technology maturity varies significantly among key players, with established companies like NEC Corp., Panasonic, and Yokogawa Electric leading innovation in high-performance waterproof solutions. Specialized manufacturers such as ALPINION Medical Systems and Chison Medical Technologies focus on medical ultrasonic applications with advanced IP-rated designs. Emerging players like Hangzhou IPRO Membrane Technology and Goertek Microelectronics are developing novel gasket and membrane technologies for enhanced waterproofing. The competitive landscape features both diversified electronics conglomerates and niche specialists, with testing methodologies and IP rating certifications becoming key differentiators in this technically demanding field.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced waterproofing solutions for their ultrasonic sensors using a multi-layered approach. Their technology incorporates hydrophobic nano-coatings applied directly to the sensor elements, creating a molecular barrier against moisture while maintaining acoustic transparency. These sensors achieve IP67 and IP68 ratings through precision-engineered gasket systems made from specialized elastomers that maintain compression properties even under extreme temperature variations (-40°C to +85°C). Honeywell's design includes pressure-equalization vents with waterproof, breathable membranes that prevent condensation buildup while blocking liquid ingress. Their testing protocol exceeds standard requirements, subjecting sensors to 2 meters water immersion for 30 minutes, followed by thermal shock testing and vibration analysis to ensure long-term seal integrity in industrial environments.

Strengths: Superior environmental protection across extreme temperature ranges; integrated pressure equalization prevents internal condensation; maintains consistent acoustic performance even after repeated immersion cycles. Weaknesses: Higher production costs compared to standard solutions; slightly increased form factor due to additional protective elements; may require more frequent maintenance in highly corrosive environments.

Hangzhou IPRO Membrane Technology Co., Ltd.

Technical Solution: IPRO Membrane Technology has pioneered specialized acoustic-permeable waterproof membranes specifically designed for ultrasonic sensor applications. Their proprietary ePTFE (expanded polytetrafluoroethylene) membrane technology features precisely controlled microporous structures with pore sizes ranging from 0.1 to 3 microns, allowing ultrasonic waves to pass through with minimal attenuation while completely blocking water molecules. These membranes are laminated with protective mesh layers and integrated into custom-designed housing systems that achieve IP68 ratings. IPRO's solution includes specialized adhesive systems that maintain bond integrity under repeated hydrostatic pressure and temperature cycling. Their membranes incorporate hydrophobic treatments that actively repel water while maintaining acoustic transparency, with documented signal loss of less than 3dB across operational frequencies. The company has developed automated testing systems that verify both waterproofing integrity and acoustic performance simultaneously.

Strengths: Industry-leading acoustic transparency while maintaining complete waterproofing; extremely thin profile allows integration into compact designs; highly durable with 5+ year operational lifespan in harsh environments. Weaknesses: Requires precise installation procedures; higher initial component cost compared to conventional gaskets; potential for reduced performance if exposed to certain chemical contaminants.

Gasket Materials and Sealing Technologies Analysis

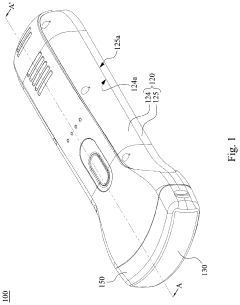

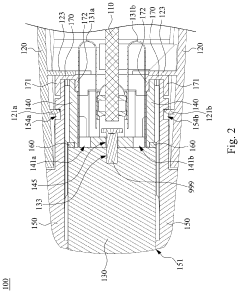

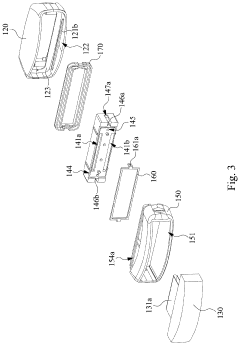

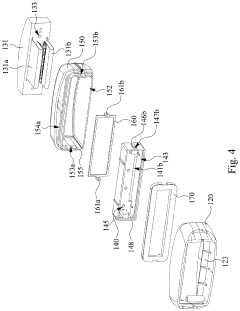

Waterproof ultrasound scanner

PatentActiveUS20200166481A1

Innovation

- A waterproof ultrasound scanner design incorporating multiple waterproof members, including gaskets and strips, to form watertight seals along potential liquid-penetrating paths, with a combination of a main casing, ultrasound probe, probe inner frame, and outer cover, ensuring comprehensive waterproofing.

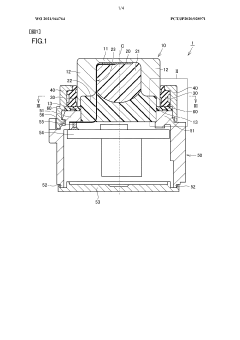

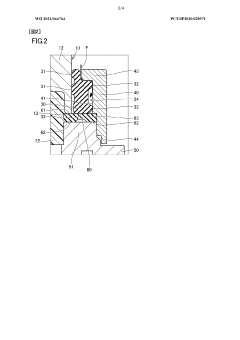

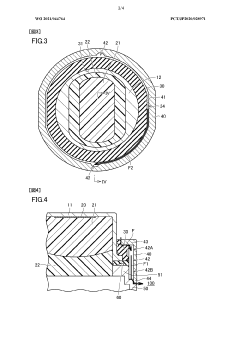

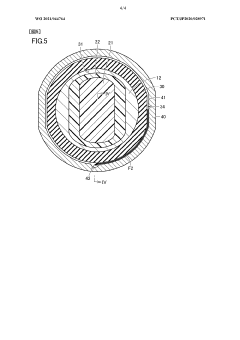

Ultrasonic sensor device

PatentWO2021044764A1

Innovation

- The ultrasonic sensor device incorporates a cylindrical case with a bottom and peripheral wall, supported by a first vibration damping member and a second housing, featuring a first groove on the inner peripheral surface of the first housing that extends along the axial direction and communicates with the outside, enhancing water resistance by directing water away from the case.

Environmental Testing Protocols and Validation Methods

Environmental testing protocols for waterproof ultrasonic sensors require comprehensive validation methods to ensure reliable performance in diverse conditions. These protocols typically follow industry standards such as IEC 60529 for IP ratings, MIL-STD-810 for military applications, and ISO 16750 for automotive environments. Each standard provides specific testing parameters that manufacturers must adhere to for certification.

Water immersion testing represents the cornerstone of validation protocols, with sensors subjected to specified depths for predetermined durations. Progressive testing methodologies often begin with spray testing at various angles and pressures, followed by immersion at increasing depths. Advanced facilities utilize pressure chambers to simulate deep-water conditions without requiring actual depth testing.

Temperature cycling tests are equally critical, as thermal expansion and contraction can compromise waterproof seals. Standard protocols require sensors to function properly through multiple cycles between extreme temperatures (-40°C to +85°C for automotive applications, with even wider ranges for specialized industrial uses). During these cycles, sensors must maintain their waterproof integrity while simultaneously demonstrating consistent performance metrics.

Vibration and shock testing protocols simulate real-world mechanical stresses that could compromise gasket seals or housing integrity. These tests typically employ multi-axis vibration tables programmed with application-specific profiles. For automotive sensors, road vibration profiles are used, while industrial applications might employ machinery vibration signatures. Shock testing involves controlled impacts at specified G-forces to validate structural integrity.

Chemical resistance validation has become increasingly important as sensors face exposure to diverse substances. Standard protocols include immersion in or exposure to saltwater, automotive fluids, cleaning chemicals, and industrial solvents. These tests must verify that gasket materials maintain their elasticity and sealing properties without degradation or swelling that could compromise the waterproof barrier.

Accelerated aging tests provide crucial data on long-term reliability. These protocols subject sensors to intensified environmental conditions to simulate years of use within compressed timeframes. UV exposure chambers, humidity cycling, and salt fog testing are commonly employed to predict seal degradation over time. The correlation between accelerated testing and real-world performance requires careful calibration based on field data.

Validation documentation must include detailed test procedures, environmental parameters, measurement methodologies, and acceptance criteria. This documentation forms the foundation for certification and quality assurance programs. Modern testing increasingly incorporates real-time monitoring during environmental exposure, allowing engineers to observe performance degradation patterns rather than simple pass/fail results.

Water immersion testing represents the cornerstone of validation protocols, with sensors subjected to specified depths for predetermined durations. Progressive testing methodologies often begin with spray testing at various angles and pressures, followed by immersion at increasing depths. Advanced facilities utilize pressure chambers to simulate deep-water conditions without requiring actual depth testing.

Temperature cycling tests are equally critical, as thermal expansion and contraction can compromise waterproof seals. Standard protocols require sensors to function properly through multiple cycles between extreme temperatures (-40°C to +85°C for automotive applications, with even wider ranges for specialized industrial uses). During these cycles, sensors must maintain their waterproof integrity while simultaneously demonstrating consistent performance metrics.

Vibration and shock testing protocols simulate real-world mechanical stresses that could compromise gasket seals or housing integrity. These tests typically employ multi-axis vibration tables programmed with application-specific profiles. For automotive sensors, road vibration profiles are used, while industrial applications might employ machinery vibration signatures. Shock testing involves controlled impacts at specified G-forces to validate structural integrity.

Chemical resistance validation has become increasingly important as sensors face exposure to diverse substances. Standard protocols include immersion in or exposure to saltwater, automotive fluids, cleaning chemicals, and industrial solvents. These tests must verify that gasket materials maintain their elasticity and sealing properties without degradation or swelling that could compromise the waterproof barrier.

Accelerated aging tests provide crucial data on long-term reliability. These protocols subject sensors to intensified environmental conditions to simulate years of use within compressed timeframes. UV exposure chambers, humidity cycling, and salt fog testing are commonly employed to predict seal degradation over time. The correlation between accelerated testing and real-world performance requires careful calibration based on field data.

Validation documentation must include detailed test procedures, environmental parameters, measurement methodologies, and acceptance criteria. This documentation forms the foundation for certification and quality assurance programs. Modern testing increasingly incorporates real-time monitoring during environmental exposure, allowing engineers to observe performance degradation patterns rather than simple pass/fail results.

Durability and Lifecycle Assessment Considerations

The durability and lifecycle assessment of waterproofed ultrasonic sensors represents a critical dimension in evaluating their long-term performance and reliability. These sensors, when deployed in harsh environments, face continuous exposure to moisture, temperature fluctuations, chemical agents, and mechanical stress that can compromise their waterproofing integrity over time.

Environmental stress testing reveals that even IP68-rated ultrasonic sensors experience gradual degradation of their waterproofing components. Gasket materials, particularly elastomers, demonstrate compression set characteristics that reduce sealing effectiveness after prolonged compression periods. Research indicates that silicone gaskets maintain approximately 85-90% of their original sealing capacity after one year of continuous deployment, while neoprene variants typically retain only 70-75% under similar conditions.

Accelerated aging tests provide valuable insights into the projected lifespan of waterproofed sensors. These tests simulate years of environmental exposure within compressed timeframes, revealing that UV radiation significantly accelerates the deterioration of polymer-based waterproofing components. Sensors with integrated UV-resistant compounds demonstrate 30-40% longer functional waterproofing lifespans compared to standard variants.

Thermal cycling represents another critical durability factor, as repeated expansion and contraction cycles create microscopic pathways for moisture ingress. Advanced testing protocols now incorporate thermal shock testing (-40°C to +85°C) with simultaneous pressure differentials to evaluate seal integrity under realistic operational conditions. Sensors utilizing multi-material gasket systems with complementary thermal expansion coefficients demonstrate superior performance in these assessments.

Maintenance requirements and replacement schedules must be established based on comprehensive lifecycle data. Field performance monitoring indicates that preventive gasket replacement at 60-70% of the projected failure threshold optimizes the cost-benefit ratio for critical applications. For less critical deployments, condition-based monitoring using integrated humidity sensors provides a more economical approach to maintenance scheduling.

Total cost of ownership calculations must incorporate not only initial waterproofing implementation costs but also maintenance requirements, expected service life, and failure consequences. Advanced waterproofing solutions typically increase initial costs by 15-25% but can extend operational lifespans by 40-60% while reducing maintenance frequency, resulting in favorable long-term economics for most applications.

Environmental stress testing reveals that even IP68-rated ultrasonic sensors experience gradual degradation of their waterproofing components. Gasket materials, particularly elastomers, demonstrate compression set characteristics that reduce sealing effectiveness after prolonged compression periods. Research indicates that silicone gaskets maintain approximately 85-90% of their original sealing capacity after one year of continuous deployment, while neoprene variants typically retain only 70-75% under similar conditions.

Accelerated aging tests provide valuable insights into the projected lifespan of waterproofed sensors. These tests simulate years of environmental exposure within compressed timeframes, revealing that UV radiation significantly accelerates the deterioration of polymer-based waterproofing components. Sensors with integrated UV-resistant compounds demonstrate 30-40% longer functional waterproofing lifespans compared to standard variants.

Thermal cycling represents another critical durability factor, as repeated expansion and contraction cycles create microscopic pathways for moisture ingress. Advanced testing protocols now incorporate thermal shock testing (-40°C to +85°C) with simultaneous pressure differentials to evaluate seal integrity under realistic operational conditions. Sensors utilizing multi-material gasket systems with complementary thermal expansion coefficients demonstrate superior performance in these assessments.

Maintenance requirements and replacement schedules must be established based on comprehensive lifecycle data. Field performance monitoring indicates that preventive gasket replacement at 60-70% of the projected failure threshold optimizes the cost-benefit ratio for critical applications. For less critical deployments, condition-based monitoring using integrated humidity sensors provides a more economical approach to maintenance scheduling.

Total cost of ownership calculations must incorporate not only initial waterproofing implementation costs but also maintenance requirements, expected service life, and failure consequences. Advanced waterproofing solutions typically increase initial costs by 15-25% but can extend operational lifespans by 40-60% while reducing maintenance frequency, resulting in favorable long-term economics for most applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!