Binder Compatibility With High-Biochar Formulations

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar-Binder Integration Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising sustainable additive in various industrial applications. The integration of biochar into binder systems represents a significant technological evolution that spans several decades, with accelerated development in the past ten years due to increasing environmental concerns and sustainability initiatives.

The historical trajectory of biochar utilization began with agricultural applications, where its soil amendment properties were first recognized. However, the material science community gradually identified its potential in composite materials, particularly when combined with various binder systems. Early research in the 1990s primarily focused on low biochar content formulations (typically below 10% by weight), as higher concentrations presented significant compatibility challenges with traditional binders.

Recent technological advancements have pushed the boundaries of biochar incorporation, with researchers now exploring formulations containing up to 50-70% biochar. This dramatic increase represents both an opportunity and a technical challenge that defines the current research landscape. The primary objective in this field is to develop binder systems that can effectively accommodate these high-biochar formulations while maintaining or enhancing mechanical properties, durability, and application performance.

The technological evolution in this domain has been driven by several factors, including the push for carbon sequestration, waste valorization, and the reduction of conventional material usage. Biochar's unique properties—high surface area, porosity, and surface functionality—offer potential benefits but simultaneously create complex interactions with binder materials that must be systematically understood and optimized.

Current research objectives center around three key areas: first, understanding the fundamental interfacial interactions between biochar particles and various binder matrices; second, developing modified binder formulations specifically designed for high biochar loading; and third, establishing standardized testing and performance metrics for biochar-binder composites across different application domains.

The trajectory of this technology suggests continued growth, with projections indicating that biochar-binder systems could represent a significant market segment within sustainable materials by 2030. The ultimate technical goal is to achieve biochar loadings exceeding 70% while maintaining performance properties comparable to or better than conventional materials, thereby maximizing both environmental benefits and commercial viability.

The historical trajectory of biochar utilization began with agricultural applications, where its soil amendment properties were first recognized. However, the material science community gradually identified its potential in composite materials, particularly when combined with various binder systems. Early research in the 1990s primarily focused on low biochar content formulations (typically below 10% by weight), as higher concentrations presented significant compatibility challenges with traditional binders.

Recent technological advancements have pushed the boundaries of biochar incorporation, with researchers now exploring formulations containing up to 50-70% biochar. This dramatic increase represents both an opportunity and a technical challenge that defines the current research landscape. The primary objective in this field is to develop binder systems that can effectively accommodate these high-biochar formulations while maintaining or enhancing mechanical properties, durability, and application performance.

The technological evolution in this domain has been driven by several factors, including the push for carbon sequestration, waste valorization, and the reduction of conventional material usage. Biochar's unique properties—high surface area, porosity, and surface functionality—offer potential benefits but simultaneously create complex interactions with binder materials that must be systematically understood and optimized.

Current research objectives center around three key areas: first, understanding the fundamental interfacial interactions between biochar particles and various binder matrices; second, developing modified binder formulations specifically designed for high biochar loading; and third, establishing standardized testing and performance metrics for biochar-binder composites across different application domains.

The trajectory of this technology suggests continued growth, with projections indicating that biochar-binder systems could represent a significant market segment within sustainable materials by 2030. The ultimate technical goal is to achieve biochar loadings exceeding 70% while maintaining performance properties comparable to or better than conventional materials, thereby maximizing both environmental benefits and commercial viability.

Market Analysis for High-Biochar Products

The global biochar market is experiencing significant growth, with a market value estimated to reach $3.1 billion by 2025, growing at a CAGR of approximately 13.2% from 2020. This growth is primarily driven by increasing environmental concerns, government initiatives promoting sustainable practices, and the rising demand for organic farming. High-biochar formulations, particularly those compatible with various binders, represent an emerging segment within this market with substantial potential for expansion.

The construction materials sector presents the largest market opportunity for high-biochar products, accounting for approximately 40% of the total biochar market. The integration of biochar into concrete, mortar, and other building materials not only improves carbon sequestration but also enhances material properties such as thermal insulation and moisture regulation. This application is gaining traction in green building certifications like LEED and BREEAM, further driving market demand.

Agricultural applications constitute the second-largest market segment, representing about 30% of the biochar market. Farmers are increasingly adopting biochar-amended soils to improve crop yields, enhance soil health, and reduce fertilizer requirements. The compatibility of biochar with organic binders creates products that offer controlled nutrient release and improved soil structure, commanding premium prices in organic farming markets.

Environmental remediation represents a rapidly growing niche, currently at 15% of the market but expected to double within five years. High-biochar formulations with compatible binders are proving effective in soil remediation projects, wastewater treatment, and contaminated land restoration. Government contracts and environmental compliance requirements are driving this segment's expansion.

Consumer products incorporating high-biochar formulations are emerging as a high-margin segment. These include filtration systems, odor control products, and specialty gardening supplies. This segment currently represents 10% of the market but shows the highest growth rate at 18% annually, particularly in developed economies where environmental consciousness is high.

Regional analysis indicates North America leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is projected to witness the fastest growth due to rapid industrialization, increasing environmental regulations, and growing agricultural modernization efforts.

Key customer segments include construction companies seeking sustainable building materials, agricultural suppliers, environmental service providers, and increasingly, direct-to-consumer brands marketing eco-friendly products. The willingness to pay premium prices varies significantly across these segments, with environmental remediation clients showing the highest price tolerance due to regulatory compliance requirements.

The construction materials sector presents the largest market opportunity for high-biochar products, accounting for approximately 40% of the total biochar market. The integration of biochar into concrete, mortar, and other building materials not only improves carbon sequestration but also enhances material properties such as thermal insulation and moisture regulation. This application is gaining traction in green building certifications like LEED and BREEAM, further driving market demand.

Agricultural applications constitute the second-largest market segment, representing about 30% of the biochar market. Farmers are increasingly adopting biochar-amended soils to improve crop yields, enhance soil health, and reduce fertilizer requirements. The compatibility of biochar with organic binders creates products that offer controlled nutrient release and improved soil structure, commanding premium prices in organic farming markets.

Environmental remediation represents a rapidly growing niche, currently at 15% of the market but expected to double within five years. High-biochar formulations with compatible binders are proving effective in soil remediation projects, wastewater treatment, and contaminated land restoration. Government contracts and environmental compliance requirements are driving this segment's expansion.

Consumer products incorporating high-biochar formulations are emerging as a high-margin segment. These include filtration systems, odor control products, and specialty gardening supplies. This segment currently represents 10% of the market but shows the highest growth rate at 18% annually, particularly in developed economies where environmental consciousness is high.

Regional analysis indicates North America leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is projected to witness the fastest growth due to rapid industrialization, increasing environmental regulations, and growing agricultural modernization efforts.

Key customer segments include construction companies seeking sustainable building materials, agricultural suppliers, environmental service providers, and increasingly, direct-to-consumer brands marketing eco-friendly products. The willingness to pay premium prices varies significantly across these segments, with environmental remediation clients showing the highest price tolerance due to regulatory compliance requirements.

Technical Challenges in Biochar-Binder Compatibility

The integration of high biochar content in various formulations presents significant technical challenges related to binder compatibility. The heterogeneous nature of biochar, with its variable physical and chemical properties depending on feedstock and pyrolysis conditions, creates inconsistent interaction patterns with binding agents. Surface chemistry variations, particularly in functional groups like carboxylic acids, phenolic hydroxides, and lactones, directly impact adhesion mechanisms and bonding efficiency.

Porosity characteristics of biochar particles create substantial hurdles for effective binding. The highly porous structure absorbs significant amounts of liquid binders, altering viscosity profiles and setting times of composite mixtures. This absorption behavior often necessitates increased binder quantities, negatively affecting production economics and potentially compromising the environmental benefits that biochar incorporation aims to achieve.

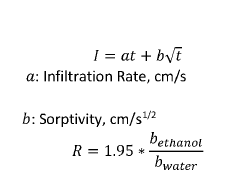

Hydrophobicity presents another critical challenge, especially with high-temperature produced biochars that exhibit water-repellent properties. This characteristic fundamentally conflicts with water-based binding systems, resulting in phase separation, poor dispersion, and ultimately weak structural integrity in the final product. Manufacturers have documented up to 40% reduction in mechanical strength when biochar content exceeds certain thresholds without specialized binding modifications.

Particle size distribution and morphology of biochar significantly influence binder performance. Irregular shapes and wide size distributions create variable surface area exposure, leading to inconsistent binder coverage and weak points in the material matrix. Research indicates that binding efficiency decreases exponentially as biochar content increases beyond 15-20% by weight in most conventional formulations.

Chemical incompatibility manifests through interference with curing mechanisms in various binder systems. For instance, alkaline biochars disrupt acid-catalyzed polymerization processes in certain resins, while acidic biochars can neutralize alkaline hardeners in epoxy systems. These interactions often result in incomplete curing, extended setting times, or compromised final properties.

Aging and weathering stability represent long-term challenges, as biochar-binder interfaces may degrade differently than conventional materials when exposed to environmental factors. Differential thermal expansion between biochar particles and surrounding binder matrices creates micro-cracks during temperature cycling, progressively weakening structural integrity over time.

Advanced characterization techniques including FTIR spectroscopy, contact angle measurements, and rheological analysis have revealed that traditional binding approaches become increasingly ineffective as biochar content exceeds 25% by volume. This technical barrier has become the primary limiting factor preventing wider industrial adoption of high-biochar formulations despite their promising environmental benefits.

Porosity characteristics of biochar particles create substantial hurdles for effective binding. The highly porous structure absorbs significant amounts of liquid binders, altering viscosity profiles and setting times of composite mixtures. This absorption behavior often necessitates increased binder quantities, negatively affecting production economics and potentially compromising the environmental benefits that biochar incorporation aims to achieve.

Hydrophobicity presents another critical challenge, especially with high-temperature produced biochars that exhibit water-repellent properties. This characteristic fundamentally conflicts with water-based binding systems, resulting in phase separation, poor dispersion, and ultimately weak structural integrity in the final product. Manufacturers have documented up to 40% reduction in mechanical strength when biochar content exceeds certain thresholds without specialized binding modifications.

Particle size distribution and morphology of biochar significantly influence binder performance. Irregular shapes and wide size distributions create variable surface area exposure, leading to inconsistent binder coverage and weak points in the material matrix. Research indicates that binding efficiency decreases exponentially as biochar content increases beyond 15-20% by weight in most conventional formulations.

Chemical incompatibility manifests through interference with curing mechanisms in various binder systems. For instance, alkaline biochars disrupt acid-catalyzed polymerization processes in certain resins, while acidic biochars can neutralize alkaline hardeners in epoxy systems. These interactions often result in incomplete curing, extended setting times, or compromised final properties.

Aging and weathering stability represent long-term challenges, as biochar-binder interfaces may degrade differently than conventional materials when exposed to environmental factors. Differential thermal expansion between biochar particles and surrounding binder matrices creates micro-cracks during temperature cycling, progressively weakening structural integrity over time.

Advanced characterization techniques including FTIR spectroscopy, contact angle measurements, and rheological analysis have revealed that traditional binding approaches become increasingly ineffective as biochar content exceeds 25% by volume. This technical barrier has become the primary limiting factor preventing wider industrial adoption of high-biochar formulations despite their promising environmental benefits.

Current Binding Mechanisms for High-Biochar Formulations

01 Polymer binder compatibility in coating formulations

Compatibility between different polymer binders is crucial in coating formulations to ensure proper film formation and performance. Various polymers such as acrylics, polyurethanes, and epoxies can be combined to achieve desired properties. The compatibility of these binders affects adhesion, durability, and appearance of the final coating. Formulation techniques include using compatibilizers or selecting polymers with similar solubility parameters to prevent phase separation.- Polymer binder compatibility in coating formulations: Polymer binders play a crucial role in coating formulations, where compatibility between different polymers affects the final product properties. Certain polymer combinations demonstrate enhanced compatibility, leading to improved adhesion, durability, and performance. Factors affecting polymer compatibility include molecular weight, functional groups, and polarity. Compatible polymer binders can create homogeneous mixtures that prevent phase separation and ensure consistent application properties.

- Binder compatibility in construction materials: In construction materials, binder compatibility is essential for structural integrity and longevity. Various binders such as cement, lime, and polymeric additives must be compatible to ensure proper curing, strength development, and resistance to environmental factors. Incompatible binders can lead to premature deterioration, cracking, or failure of the construction material. Testing protocols have been developed to assess the compatibility of different binders before their application in construction projects.

- Compatibility of binders in electronic and optical applications: Binders used in electronic and optical applications require specific compatibility characteristics to maintain functionality. These binders must be compatible with electronic components, substrates, and other materials while providing necessary insulation, protection, or conductivity properties. Compatibility issues in these applications can lead to signal interference, component failure, or degradation of optical properties. Advanced testing methods help determine the suitability of binders for specific electronic or optical applications.

- Chemical compatibility of binders in industrial formulations: Chemical compatibility between binders and other components in industrial formulations is critical for product stability and performance. Factors such as pH, solvent systems, and reactive functional groups can affect how binders interact with active ingredients and additives. Incompatible combinations may result in precipitation, phase separation, or unwanted chemical reactions. Formulation scientists must carefully select binders that maintain chemical stability throughout the product's lifecycle while delivering the desired functional properties.

- Software and data binding compatibility systems: In software development, data binding compatibility refers to the ability of different software components to effectively communicate and share data. This includes compatibility between different programming languages, frameworks, and data structures. Systems have been developed to ensure seamless data binding across platforms, reducing integration issues and improving efficiency. These compatibility systems often include middleware solutions, standardized protocols, and automated testing frameworks to verify proper data binding functionality.

02 Binder systems for composite materials

Binder systems play a critical role in composite material manufacturing, where compatibility between the binder and reinforcement materials determines the mechanical properties of the final product. These systems often involve thermosetting resins that must be compatible with fibers or particulate fillers. The binder composition affects processing parameters such as cure time, viscosity, and wetting behavior, which ultimately influence the structural integrity and performance of the composite.Expand Specific Solutions03 Compatibility of binders in pharmaceutical formulations

In pharmaceutical applications, binder compatibility with active pharmaceutical ingredients (APIs) and other excipients is essential for drug stability and efficacy. The selection of compatible binders affects tablet hardness, disintegration time, and drug release profiles. Considerations include chemical interactions between binders and APIs, moisture sensitivity, and processing conditions. Incompatibilities can lead to degradation of the active ingredient or changes in bioavailability.Expand Specific Solutions04 Digital system compatibility for binding operations

Digital systems for managing binding operations require compatibility between hardware, software, and network components. These systems coordinate binding processes in manufacturing or information management contexts. Compatibility issues can arise between different versions of software, communication protocols, or data formats. Solutions include standardized interfaces, middleware applications, and compatibility layers that enable seamless integration of diverse components in binding operations.Expand Specific Solutions05 Mechanical binding systems compatibility

Mechanical binding systems require compatibility between binding components and the materials being bound. This includes considerations for different types of binding mechanisms such as ring binders, spiral binding, or comb binding systems. The compatibility affects the durability of the binding, ease of use, and functionality. Design factors include material thickness capacity, binding strength, and interoperability between different binding system components.Expand Specific Solutions

Industry Leaders in Biochar Binding Solutions

The biochar binder compatibility market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for biochar-based materials is expanding rapidly, projected to reach significant value as industries seek sustainable alternatives. Technologically, the field shows moderate maturity with ongoing innovations addressing compatibility challenges between traditional binders and high-biochar formulations. Leading players include BASF, which has developed specialized coating technologies adaptable to biochar composites, and Wacker Chemie AG, offering silicone-based solutions for improved adhesion. Henkel and Arkema are advancing polymer-based binder systems, while research institutions like Fraunhofer-Gesellschaft and The Regents of the University of California are pioneering novel biochar-binder interfaces. Made of Air GmbH represents innovative startups developing carbon-negative thermoplastics incorporating high biochar content.

Arkema France SA

Technical Solution: Arkema has developed innovative binder systems specifically designed for high-biochar formulations, focusing on their Kynar® PVDF (polyvinylidene fluoride) technology. Their approach involves modifying polymer chains with functional groups that can effectively interact with biochar's surface functional groups, creating stronger interfacial bonding. The company has engineered specialized copolymers that maintain adhesion properties even with biochar loadings exceeding 30% by weight. Their research demonstrates that incorporating silane coupling agents into their binder formulations significantly improves the mechanical integrity of biochar-rich composites. Arkema's water-based acrylic binder systems have been specifically modified to accommodate the high porosity and surface area of biochar particles, ensuring proper wetting and adhesion. Their technology enables biochar incorporation in various applications including coatings, adhesives, and construction materials while maintaining performance properties.

Strengths: Superior chemical resistance and thermal stability of their PVDF-based binders allow for high-temperature applications. Their water-based systems reduce VOC emissions compared to solvent-based alternatives. Weaknesses: Higher cost compared to conventional binders, potentially limiting widespread adoption in price-sensitive markets. Some formulations may require specialized processing equipment for optimal dispersion of biochar particles.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered advanced binder technologies compatible with high-biochar formulations through their Loctite® and Technomelt® product lines. Their approach centers on modified polyurethane and polyolefin-based binders specifically engineered to accommodate biochar's unique surface chemistry and porosity. Henkel's technology involves pre-treating biochar with proprietary surfactants that improve wettability and compatibility with their binder systems. Their research has demonstrated successful incorporation of up to 40% biochar content while maintaining adhesive performance. Henkel has developed hybrid binder systems combining synthetic polymers with bio-based components that show enhanced compatibility with biochar's heterogeneous structure. Their water-based adhesive formulations utilize specialized dispersants to prevent biochar agglomeration, ensuring uniform distribution throughout the matrix. Henkel's technology enables applications in construction adhesives, packaging, and industrial assembly where sustainability metrics are increasingly important.

Strengths: Extensive formulation expertise allows for customization across diverse applications and biochar types. Their global manufacturing capabilities ensure consistent quality and supply chain reliability. Weaknesses: Some formulations may exhibit reduced shelf stability when biochar content exceeds certain thresholds. Water resistance properties can be compromised at very high biochar loadings without additional waterproofing additives.

Key Patents in Biochar-Binder Interface Engineering

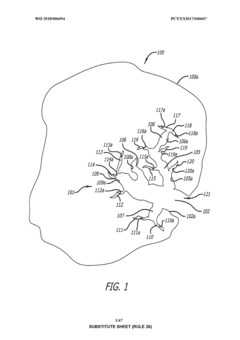

Treated biochar for use in water treatment systems

PatentWO2018006094A1

Innovation

- Treated biochar is produced through methods such as vacuum impregnation and surfactant treatment to enhance its ability to adsorb contaminants, adjust pH, and increase water retention, making it more effective for water treatment and agricultural applications.

Biomass carbon-based lightweight environmentally friendly composite material

PatentActiveZA202201876A

Innovation

- A biomass carbon-based lightweight composite material is prepared by mixing biochar with water glass, a water-resistant agent, and a coupling agent, then curing to create a fire-resistant, water-resistant, and high-strength composite that leverages biochar's pore structure for adsorption without blocking, using water saturation to prevent dust and simplify processing, and employing water glass for bonding and high-temperature resistance.

Environmental Impact Assessment of Biochar-Binder Systems

The environmental implications of integrating biochar into binder systems represent a critical area of assessment for sustainable construction and manufacturing practices. When evaluating biochar-binder systems, lifecycle analysis reveals significant carbon sequestration potential, with high-biochar formulations capable of storing between 0.5-1.5 tons of CO2 equivalent per ton of material used, depending on biochar concentration and production methods.

Water quality impacts show promising results, as biochar-binder composites demonstrate reduced leaching of heavy metals compared to conventional materials. Studies indicate up to 70% reduction in metal ion release in aqueous environments, particularly when biochar is properly activated and integrated with compatible binders. This characteristic makes these systems particularly valuable in environmentally sensitive applications.

Air quality considerations during production and application phases show mixed results. While biochar production can generate particulate matter and volatile organic compounds, the integration with binders typically reduces dust emissions during handling. However, compatibility issues between certain binders and high-biochar formulations may require additional processing steps that increase energy consumption and associated emissions.

Soil interaction assessments demonstrate that biochar-binder systems, particularly those using clay or organic binders, can contribute positively to soil health when used in ground-contact applications. The slow release of beneficial minerals and improved water retention characteristics have been documented in field trials, though long-term studies remain limited.

Energy efficiency metrics reveal that high-biochar formulations generally require 15-30% less energy during curing processes compared to conventional binder systems, representing significant operational carbon savings. However, this advantage may be partially offset by increased mixing energy requirements when biochar content exceeds 40% by volume due to viscosity challenges.

Waste reduction potential is substantial, with biochar-binder systems offering dual benefits of utilizing waste biomass for biochar production and reducing end-of-life disposal impacts. Research indicates that properly formulated systems can maintain structural integrity for extended periods while remaining biodegradable or recyclable, depending on binder selection.

Regulatory compliance analysis shows varying regional acceptance, with European standards generally more accommodating of biochar-binder innovations than North American frameworks. Recent policy developments suggest increasing recognition of these systems' environmental benefits, though certification pathways remain complex for high-biochar formulations exceeding traditional material classification parameters.

Water quality impacts show promising results, as biochar-binder composites demonstrate reduced leaching of heavy metals compared to conventional materials. Studies indicate up to 70% reduction in metal ion release in aqueous environments, particularly when biochar is properly activated and integrated with compatible binders. This characteristic makes these systems particularly valuable in environmentally sensitive applications.

Air quality considerations during production and application phases show mixed results. While biochar production can generate particulate matter and volatile organic compounds, the integration with binders typically reduces dust emissions during handling. However, compatibility issues between certain binders and high-biochar formulations may require additional processing steps that increase energy consumption and associated emissions.

Soil interaction assessments demonstrate that biochar-binder systems, particularly those using clay or organic binders, can contribute positively to soil health when used in ground-contact applications. The slow release of beneficial minerals and improved water retention characteristics have been documented in field trials, though long-term studies remain limited.

Energy efficiency metrics reveal that high-biochar formulations generally require 15-30% less energy during curing processes compared to conventional binder systems, representing significant operational carbon savings. However, this advantage may be partially offset by increased mixing energy requirements when biochar content exceeds 40% by volume due to viscosity challenges.

Waste reduction potential is substantial, with biochar-binder systems offering dual benefits of utilizing waste biomass for biochar production and reducing end-of-life disposal impacts. Research indicates that properly formulated systems can maintain structural integrity for extended periods while remaining biodegradable or recyclable, depending on binder selection.

Regulatory compliance analysis shows varying regional acceptance, with European standards generally more accommodating of biochar-binder innovations than North American frameworks. Recent policy developments suggest increasing recognition of these systems' environmental benefits, though certification pathways remain complex for high-biochar formulations exceeding traditional material classification parameters.

Scalability and Cost Analysis of High-Biochar Formulations

The economic viability of high-biochar formulations depends significantly on their scalability and cost-effectiveness. Current production methods for biochar-binder systems face several challenges when scaling from laboratory to industrial levels. Production capacity limitations exist primarily in biochar manufacturing, where traditional pyrolysis methods struggle to maintain consistent quality at higher volumes. This inconsistency directly impacts binder compatibility and final product performance.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for high-biochar formulations. Biochar itself varies from $500-2,000 per ton depending on feedstock quality and production method, while compatible binders range from $1,200-3,500 per ton. The economic equation becomes more favorable when waste biomass serves as feedstock, potentially reducing biochar costs by 30-45%.

Processing equipment represents another significant cost factor. Specialized mixing equipment capable of handling high-biochar formulations (>30% biochar content) requires capital investments of $100,000-500,000 depending on production scale. These systems must overcome the inherent challenges of biochar's hydrophobicity and variable particle size distribution when mixing with binders.

Energy consumption during processing presents both a cost and sustainability concern. High-biochar formulations typically require 15-25% more mixing energy than conventional materials due to increased viscosity and complex rheological properties. However, this can be partially offset through process optimization and equipment modifications specifically designed for biochar-rich mixtures.

Supply chain considerations significantly impact scalability. The distributed nature of biomass resources often necessitates decentralized biochar production facilities to minimize transportation costs. This creates challenges for maintaining consistent binder compatibility across production sites. Establishing regional processing hubs near biomass sources could reduce logistics costs by 20-35%.

Economies of scale become evident at production volumes exceeding 5,000 tons annually, where unit costs may decrease by 15-30%. However, these economies are less pronounced than in conventional materials due to the specialized nature of biochar-binder interactions and quality control requirements. Manufacturers must carefully balance batch size optimization against quality consistency.

Regulatory compliance adds another layer of cost consideration. Certification processes for high-biochar products can add 5-15% to overall costs, though these expenses typically decrease on a per-unit basis with increased production volume. These certifications are essential for market acceptance and may eventually become standardized as the industry matures.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for high-biochar formulations. Biochar itself varies from $500-2,000 per ton depending on feedstock quality and production method, while compatible binders range from $1,200-3,500 per ton. The economic equation becomes more favorable when waste biomass serves as feedstock, potentially reducing biochar costs by 30-45%.

Processing equipment represents another significant cost factor. Specialized mixing equipment capable of handling high-biochar formulations (>30% biochar content) requires capital investments of $100,000-500,000 depending on production scale. These systems must overcome the inherent challenges of biochar's hydrophobicity and variable particle size distribution when mixing with binders.

Energy consumption during processing presents both a cost and sustainability concern. High-biochar formulations typically require 15-25% more mixing energy than conventional materials due to increased viscosity and complex rheological properties. However, this can be partially offset through process optimization and equipment modifications specifically designed for biochar-rich mixtures.

Supply chain considerations significantly impact scalability. The distributed nature of biomass resources often necessitates decentralized biochar production facilities to minimize transportation costs. This creates challenges for maintaining consistent binder compatibility across production sites. Establishing regional processing hubs near biomass sources could reduce logistics costs by 20-35%.

Economies of scale become evident at production volumes exceeding 5,000 tons annually, where unit costs may decrease by 15-30%. However, these economies are less pronounced than in conventional materials due to the specialized nature of biochar-binder interactions and quality control requirements. Manufacturers must carefully balance batch size optimization against quality consistency.

Regulatory compliance adds another layer of cost consideration. Certification processes for high-biochar products can add 5-15% to overall costs, though these expenses typically decrease on a per-unit basis with increased production volume. These certifications are essential for market acceptance and may eventually become standardized as the industry matures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!