Biochar Sourcing Strategy For Sustainable Battery Manufacturing

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Technology Evolution and Battery Manufacturing Goals

Biochar technology has evolved significantly over the past decade, transitioning from traditional charcoal production methods to sophisticated pyrolysis processes optimized for specific applications. Initially developed for soil amendment and carbon sequestration in agricultural contexts, biochar production techniques have undergone substantial refinement to meet the growing demands of advanced material applications, particularly in energy storage systems.

The evolution pathway began with rudimentary kiln-based production, progressing through continuous flow reactors, and now encompasses precision-controlled pyrolysis systems capable of tailoring biochar properties at the molecular level. This technological progression has been driven by the increasing understanding of how feedstock selection, temperature profiles, and residence time affect the resulting carbon structure and electrochemical properties.

In parallel with biochar technology advancement, battery manufacturing has established ambitious sustainability goals in response to the exponential growth in energy storage demand. The industry faces mounting pressure to reduce its environmental footprint while scaling production capacity. Traditional battery materials rely heavily on mineral extraction processes with significant ecological impacts and complex supply chains vulnerable to geopolitical disruptions.

The convergence of biochar technology and battery manufacturing represents a strategic opportunity to address multiple sustainability challenges simultaneously. Battery manufacturers aim to reduce carbon emissions across the entire product lifecycle, decrease dependency on critical minerals, and establish circular economy principles within their supply chains. Biochar, as a renewable carbon source derived from waste biomass, offers a pathway to achieve these objectives.

Key technical goals for biochar in battery applications include developing consistent quality parameters, establishing scalable production methods, and optimizing electrochemical performance characteristics. The industry seeks biochar formulations that can match or exceed the performance of conventional carbon materials while delivering superior sustainability metrics. Particular attention is focused on porosity control, surface functionality, and electrical conductivity.

Recent research demonstrates biochar's potential as an anode material in lithium-ion batteries, a precursor for hard carbon in sodium-ion batteries, and a conductive additive in various battery chemistries. The material's inherent sustainability advantages are complemented by promising performance characteristics, including high specific capacity and excellent cycling stability when properly engineered.

The strategic integration of biochar into battery manufacturing requires coordinated advancement in both production technology and application-specific optimization. Industry leaders are establishing collaborative research initiatives to accelerate this integration, with particular emphasis on standardization of biochar specifications for battery applications and development of sustainable sourcing networks.

The evolution pathway began with rudimentary kiln-based production, progressing through continuous flow reactors, and now encompasses precision-controlled pyrolysis systems capable of tailoring biochar properties at the molecular level. This technological progression has been driven by the increasing understanding of how feedstock selection, temperature profiles, and residence time affect the resulting carbon structure and electrochemical properties.

In parallel with biochar technology advancement, battery manufacturing has established ambitious sustainability goals in response to the exponential growth in energy storage demand. The industry faces mounting pressure to reduce its environmental footprint while scaling production capacity. Traditional battery materials rely heavily on mineral extraction processes with significant ecological impacts and complex supply chains vulnerable to geopolitical disruptions.

The convergence of biochar technology and battery manufacturing represents a strategic opportunity to address multiple sustainability challenges simultaneously. Battery manufacturers aim to reduce carbon emissions across the entire product lifecycle, decrease dependency on critical minerals, and establish circular economy principles within their supply chains. Biochar, as a renewable carbon source derived from waste biomass, offers a pathway to achieve these objectives.

Key technical goals for biochar in battery applications include developing consistent quality parameters, establishing scalable production methods, and optimizing electrochemical performance characteristics. The industry seeks biochar formulations that can match or exceed the performance of conventional carbon materials while delivering superior sustainability metrics. Particular attention is focused on porosity control, surface functionality, and electrical conductivity.

Recent research demonstrates biochar's potential as an anode material in lithium-ion batteries, a precursor for hard carbon in sodium-ion batteries, and a conductive additive in various battery chemistries. The material's inherent sustainability advantages are complemented by promising performance characteristics, including high specific capacity and excellent cycling stability when properly engineered.

The strategic integration of biochar into battery manufacturing requires coordinated advancement in both production technology and application-specific optimization. Industry leaders are establishing collaborative research initiatives to accelerate this integration, with particular emphasis on standardization of biochar specifications for battery applications and development of sustainable sourcing networks.

Market Analysis for Biochar-Based Battery Materials

The global market for biochar-based battery materials is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the biochar materials sector specifically for battery applications reached approximately $450 million in 2022, with projections suggesting a compound annual growth rate of 12-15% through 2030. This growth trajectory is substantially higher than traditional carbon-based battery materials, reflecting the increasing prioritization of environmentally sustainable alternatives.

Consumer electronics represents the largest current application segment, accounting for nearly 40% of biochar-based battery material consumption. However, electric vehicle applications are demonstrating the most rapid growth rate at 18-20% annually, as automotive manufacturers increasingly commit to sustainable supply chain practices. Grid-scale energy storage systems are emerging as another promising market segment, particularly in regions with aggressive renewable energy targets.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, South Korea, and Japan. North America and Europe follow with 25% and 20% market shares respectively, with Europe showing particularly strong growth due to stringent environmental regulations and sustainability initiatives. Developing markets in South America and Africa represent smaller but rapidly expanding opportunities, especially given their abundant biomass resources for biochar production.

Market dynamics are heavily influenced by sustainability certifications and carbon credit opportunities. Batteries utilizing certified sustainable biochar can command premium pricing of 15-20% over standard alternatives. Additionally, the carbon-negative potential of biochar production creates valuable carbon credit opportunities, effectively reducing the net cost of biochar for battery manufacturers by 10-30% depending on regional carbon pricing mechanisms.

Customer segmentation reveals three primary buyer categories: sustainability-focused premium manufacturers willing to pay higher prices for environmentally superior materials; cost-sensitive mass-market producers seeking regulatory compliance at minimum cost; and innovation-driven companies exploring biochar's performance advantages beyond sustainability metrics. Each segment requires tailored value propositions and pricing strategies.

Competitive analysis indicates that while traditional carbon black and synthetic graphite suppliers still dominate the broader battery materials market, specialized biochar producers are rapidly gaining market share through sustainability differentiation and performance improvements. Strategic partnerships between biochar producers and battery manufacturers have increased by 65% since 2020, indicating growing market acceptance and integration into supply chains.

Consumer electronics represents the largest current application segment, accounting for nearly 40% of biochar-based battery material consumption. However, electric vehicle applications are demonstrating the most rapid growth rate at 18-20% annually, as automotive manufacturers increasingly commit to sustainable supply chain practices. Grid-scale energy storage systems are emerging as another promising market segment, particularly in regions with aggressive renewable energy targets.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, South Korea, and Japan. North America and Europe follow with 25% and 20% market shares respectively, with Europe showing particularly strong growth due to stringent environmental regulations and sustainability initiatives. Developing markets in South America and Africa represent smaller but rapidly expanding opportunities, especially given their abundant biomass resources for biochar production.

Market dynamics are heavily influenced by sustainability certifications and carbon credit opportunities. Batteries utilizing certified sustainable biochar can command premium pricing of 15-20% over standard alternatives. Additionally, the carbon-negative potential of biochar production creates valuable carbon credit opportunities, effectively reducing the net cost of biochar for battery manufacturers by 10-30% depending on regional carbon pricing mechanisms.

Customer segmentation reveals three primary buyer categories: sustainability-focused premium manufacturers willing to pay higher prices for environmentally superior materials; cost-sensitive mass-market producers seeking regulatory compliance at minimum cost; and innovation-driven companies exploring biochar's performance advantages beyond sustainability metrics. Each segment requires tailored value propositions and pricing strategies.

Competitive analysis indicates that while traditional carbon black and synthetic graphite suppliers still dominate the broader battery materials market, specialized biochar producers are rapidly gaining market share through sustainability differentiation and performance improvements. Strategic partnerships between biochar producers and battery manufacturers have increased by 65% since 2020, indicating growing market acceptance and integration into supply chains.

Current Biochar Production Challenges and Limitations

Despite the promising potential of biochar in sustainable battery manufacturing, several significant challenges and limitations persist in current production processes. The primary obstacle remains the inconsistent quality of biochar produced across different facilities and from varying feedstocks. This inconsistency manifests in unpredictable carbon content, ash composition, surface area characteristics, and pore structure, all of which are critical parameters for battery applications. Such variability makes standardization difficult and hampers large-scale industrial adoption.

Production scale presents another substantial challenge. Current biochar production facilities typically operate at small to medium scales, producing quantities insufficient for industrial battery manufacturing demands. The disconnect between production capacity and potential market requirements creates a significant bottleneck in the supply chain, limiting biochar's integration into mainstream battery production.

Energy efficiency in the pyrolysis process remains suboptimal, with many production systems requiring substantial energy inputs that partially offset the sustainability benefits of biochar. Traditional pyrolysis technologies often operate at high temperatures (400-700°C) for extended periods, resulting in considerable energy consumption and associated carbon emissions. This contradiction undermines biochar's positioning as a sustainable alternative for battery materials.

Feedstock availability and competition represent additional constraints. High-quality biochar production requires consistent biomass inputs, yet agricultural and forestry residues face competing demands from other sectors, including bioenergy and soil amendment applications. Seasonal variations in biomass availability further complicate continuous production scheduling and quality control.

Economic viability remains questionable under current production paradigms. The combination of high production costs, energy-intensive processes, and relatively low production volumes results in biochar prices that often exceed those of conventional battery materials. Without economies of scale or technological breakthroughs to reduce production costs, biochar struggles to compete on price alone in the battery materials market.

Regulatory frameworks and standardization are notably underdeveloped. The absence of universally accepted quality standards specifically for battery-grade biochar creates uncertainty for both producers and potential users. This regulatory gap impedes investment in production facilities and slows market development, as battery manufacturers hesitate to incorporate materials without established performance benchmarks.

Technical knowledge gaps persist regarding optimal production parameters for battery-specific applications. Research connecting pyrolysis conditions to electrochemical performance remains limited, creating uncertainty about how to tailor biochar production specifically for battery applications rather than traditional uses like soil amendment.

Production scale presents another substantial challenge. Current biochar production facilities typically operate at small to medium scales, producing quantities insufficient for industrial battery manufacturing demands. The disconnect between production capacity and potential market requirements creates a significant bottleneck in the supply chain, limiting biochar's integration into mainstream battery production.

Energy efficiency in the pyrolysis process remains suboptimal, with many production systems requiring substantial energy inputs that partially offset the sustainability benefits of biochar. Traditional pyrolysis technologies often operate at high temperatures (400-700°C) for extended periods, resulting in considerable energy consumption and associated carbon emissions. This contradiction undermines biochar's positioning as a sustainable alternative for battery materials.

Feedstock availability and competition represent additional constraints. High-quality biochar production requires consistent biomass inputs, yet agricultural and forestry residues face competing demands from other sectors, including bioenergy and soil amendment applications. Seasonal variations in biomass availability further complicate continuous production scheduling and quality control.

Economic viability remains questionable under current production paradigms. The combination of high production costs, energy-intensive processes, and relatively low production volumes results in biochar prices that often exceed those of conventional battery materials. Without economies of scale or technological breakthroughs to reduce production costs, biochar struggles to compete on price alone in the battery materials market.

Regulatory frameworks and standardization are notably underdeveloped. The absence of universally accepted quality standards specifically for battery-grade biochar creates uncertainty for both producers and potential users. This regulatory gap impedes investment in production facilities and slows market development, as battery manufacturers hesitate to incorporate materials without established performance benchmarks.

Technical knowledge gaps persist regarding optimal production parameters for battery-specific applications. Research connecting pyrolysis conditions to electrochemical performance remains limited, creating uncertainty about how to tailor biochar production specifically for battery applications rather than traditional uses like soil amendment.

Current Biochar Sourcing and Processing Solutions

01 Production methods of biochar

Various methods are employed to produce biochar, including pyrolysis, gasification, and hydrothermal carbonization. These processes involve heating biomass in oxygen-limited conditions at different temperatures to convert organic materials into carbon-rich biochar. The production parameters such as temperature, residence time, and feedstock type significantly influence the properties of the resulting biochar, including surface area, porosity, and chemical composition.- Production methods of biochar: Various methods are employed to produce biochar, including pyrolysis, gasification, and hydrothermal carbonization. These processes involve heating biomass in oxygen-limited environments at different temperatures to create carbon-rich materials with specific properties. The production methods can be optimized to control biochar characteristics such as surface area, porosity, and chemical composition, which influence its effectiveness in various applications.

- Agricultural applications of biochar: Biochar serves as a soil amendment that improves soil fertility, water retention, and crop productivity. When incorporated into agricultural soils, biochar enhances nutrient availability, reduces leaching, and promotes beneficial microbial activity. It also contributes to carbon sequestration, making it a sustainable approach to improving agricultural productivity while mitigating climate change through long-term carbon storage in soil.

- Environmental remediation using biochar: Biochar is effective in environmental remediation applications, particularly for treating contaminated soil and water. Its high adsorption capacity allows it to bind heavy metals, organic pollutants, and other contaminants. Biochar can be engineered with specific surface properties to target particular pollutants, making it valuable for wastewater treatment, soil decontamination, and reducing the bioavailability of toxins in the environment.

- Biochar as carbon sequestration technology: Biochar represents a promising carbon sequestration technology that can help mitigate climate change. By converting biomass into stable carbon forms that resist decomposition, biochar can store carbon for hundreds to thousands of years when incorporated into soil. This process effectively removes carbon dioxide from the atmosphere and provides a negative emissions approach. Various methodologies have been developed to quantify and verify the carbon sequestration potential of biochar for carbon credit markets.

- Biochar-based composite materials: Innovative composite materials incorporating biochar have been developed for various applications. These include biochar-polymer composites for construction materials, biochar-enhanced filtration media, and biochar-based catalysts. The integration of biochar into these composites enhances properties such as mechanical strength, thermal stability, and functional performance. These materials find applications in building materials, water filtration systems, energy storage devices, and as supports for catalytic processes.

02 Agricultural applications of biochar

Biochar serves as a soil amendment that improves soil fertility, increases crop yields, and enhances soil water retention capacity. When incorporated into agricultural soils, biochar can modify soil physical properties, increase nutrient availability, and create favorable habitats for beneficial soil microorganisms. It also contributes to carbon sequestration in soil, making it a sustainable approach to mitigate climate change while improving agricultural productivity.Expand Specific Solutions03 Environmental remediation using biochar

Biochar is utilized for environmental remediation purposes, particularly for treating contaminated soils and water. Its high adsorption capacity allows it to effectively remove heavy metals, organic pollutants, and other contaminants from various environmental matrices. Biochar can be engineered with specific properties to target particular contaminants, making it a versatile material for environmental cleanup applications and wastewater treatment.Expand Specific Solutions04 Biochar functionalization and modification

Biochar can be functionalized or modified to enhance its properties for specific applications. Modification techniques include chemical activation, surface oxidation, mineral impregnation, and magnetic functionalization. These processes can increase the surface area, introduce specific functional groups, or incorporate additional elements to improve biochar's performance in various applications such as catalysis, adsorption, and energy storage.Expand Specific Solutions05 Biochar for carbon sequestration and climate change mitigation

Biochar represents a promising approach for carbon sequestration and climate change mitigation. When produced from sustainable biomass sources and applied to soils, biochar can store carbon for hundreds to thousands of years, effectively removing CO2 from the atmosphere. This carbon negative technology offers potential for generating carbon credits and contributing to greenhouse gas reduction targets while providing additional benefits such as improved soil health and waste management.Expand Specific Solutions

Key Industry Players in Biochar and Battery Manufacturing

The biochar sourcing market for sustainable battery manufacturing is in an early growth stage, characterized by increasing demand driven by the shift towards green energy solutions. The market size is expanding as battery manufacturers seek sustainable carbon sources to reduce environmental impact. Technologically, the field is evolving rapidly with varying levels of maturity across players. Academic institutions like Beijing Institute of Technology, Tianjin University, and Harbin Institute of Technology are advancing fundamental research, while specialized companies such as Carbon Gold Ltd., Aries Clean Technologies, and Honeycomb Battery Co. are developing commercial applications. Chinese enterprises like Shanghai Mek Sheng Energy Technology and Jinan Shengquan Group are emerging as significant players, leveraging their manufacturing capabilities to scale biochar production for battery applications.

Carbon Gold Ltd.

Technical Solution: Carbon Gold has developed a specialized biochar production system targeting the battery materials market. Their technology employs a controlled pyrolysis process using sustainably sourced woody biomass, operating at precisely controlled temperatures between 450-650°C to optimize electrical conductivity properties. The company's proprietary "TriChar" process incorporates three distinct treatment stages: initial pyrolysis, steam activation to develop porosity, and a final functionalization step using proprietary mineral additives. This results in biochar with tailored surface chemistry and pore structure specifically designed for battery applications. Carbon Gold has established partnerships with battery manufacturers to integrate their biochar into lithium-ion battery anodes, where it serves as a partial replacement for synthetic graphite. Testing has demonstrated that batteries incorporating up to 30% biochar maintain 92% of the energy density while reducing carbon emissions by approximately 25% in the anode material production process.

Strengths: Established supply chain for consistent biomass feedstock; comprehensive quality control system ensures batch-to-batch consistency. Weaknesses: Limited production scale compared to conventional carbon material suppliers; higher cost structure than petroleum-derived alternatives.

Shanghai Mek Sheng Energy Technology Co. Ltd.

Technical Solution: Shanghai Mek Sheng Energy Technology has developed a proprietary biochar production system specifically optimized for battery applications. Their technology utilizes agricultural waste streams (primarily rice husks and corn stalks) to produce high-purity carbon materials through a controlled pyrolysis process at temperatures between 500-700°C. The resulting biochar undergoes a multi-stage activation process using potassium hydroxide to create microporous structures with surface areas exceeding 2000 m²/g. This activated biochar is then functionalized with nitrogen-containing compounds to enhance electrical conductivity and electrochemical performance. The company has integrated this biochar into lithium-sulfur battery cathodes, demonstrating capacity retention of over 85% after 500 cycles, significantly outperforming conventional carbon materials.

Strengths: Vertically integrated supply chain from agricultural waste collection to final battery material production; proprietary activation process creates highly tailored pore structures. Weaknesses: Production capacity remains limited compared to synthetic graphite manufacturers; quality consistency challenges when sourcing from diverse agricultural waste streams.

Critical Patents and Research in Biochar for Battery Applications

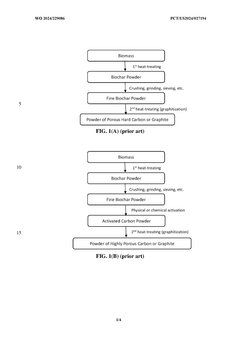

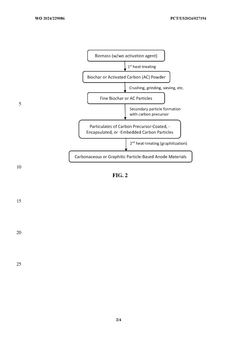

Production of carbon- or graphite-based anode active materials from biomass feedstock

PatentWO2024229086A1

Innovation

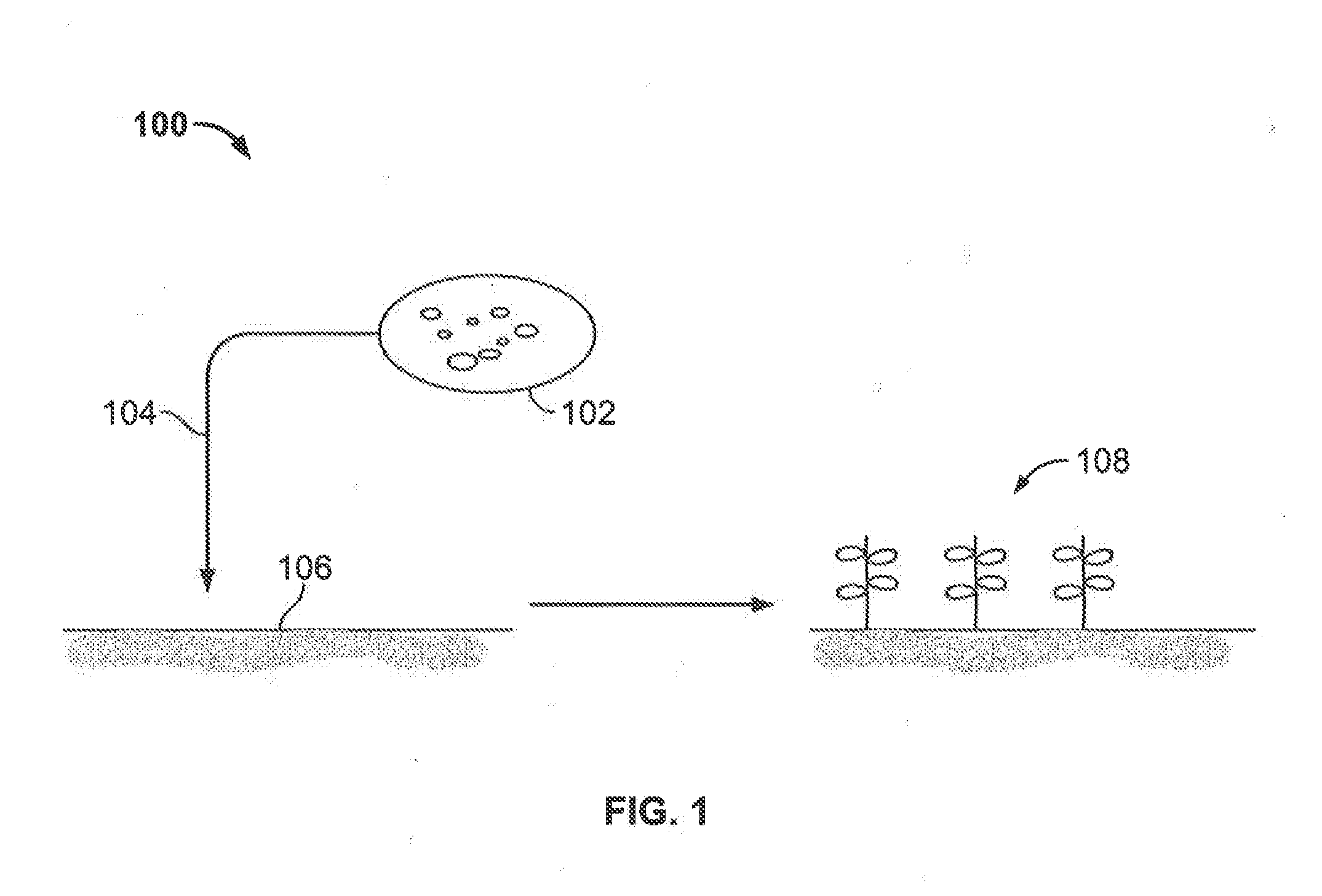

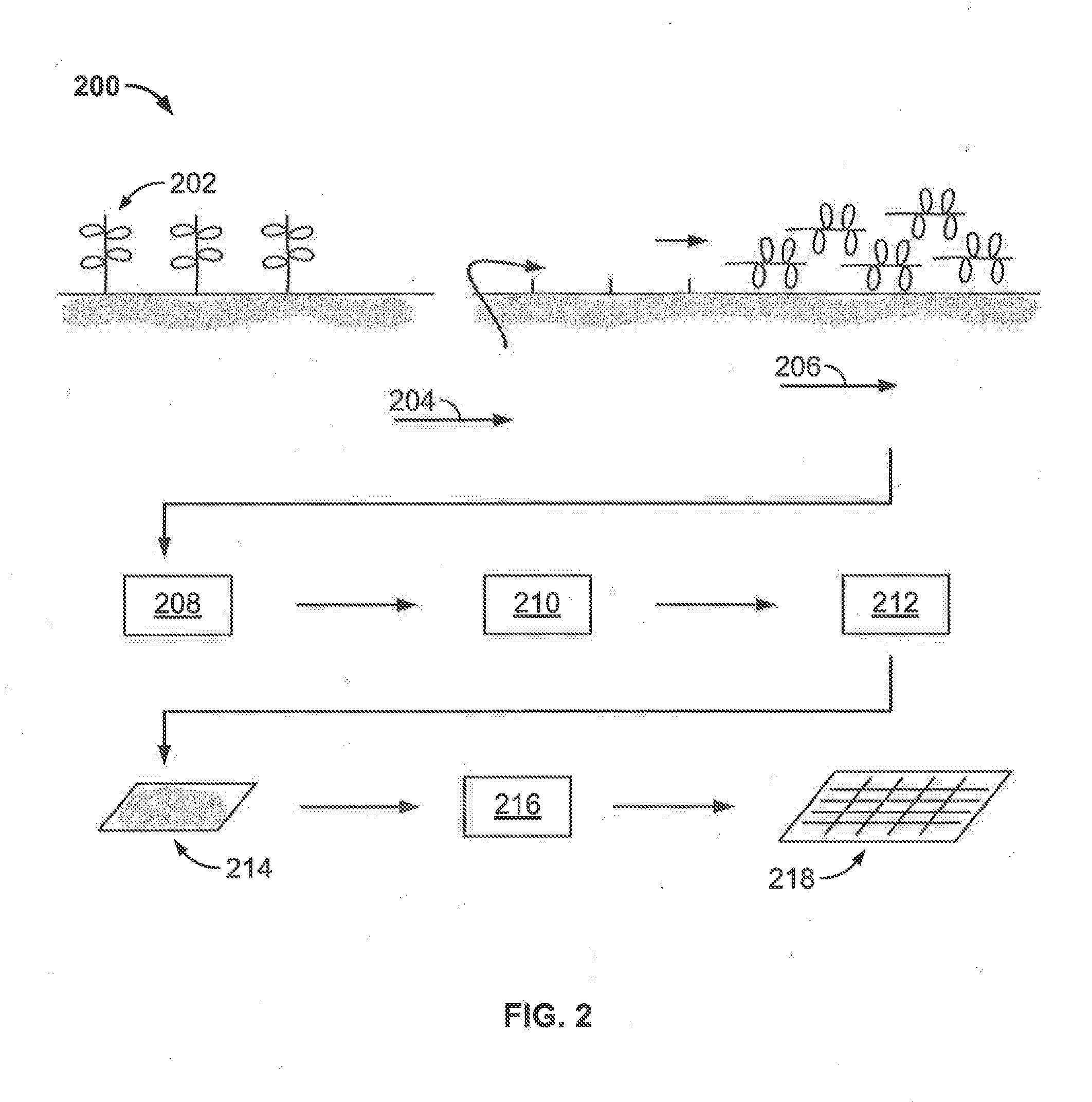

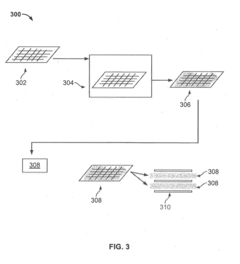

- A scalable, cost-effective process involving the production of biochar from biomass feedstocks, followed by mixing with a carbon precursor and subsequent heat-treating to form graphitic or carbonaceous particles with controlled density and structure, reducing the amount of solid-electrolyte interface (SEI) and improving charge-discharge characteristics.

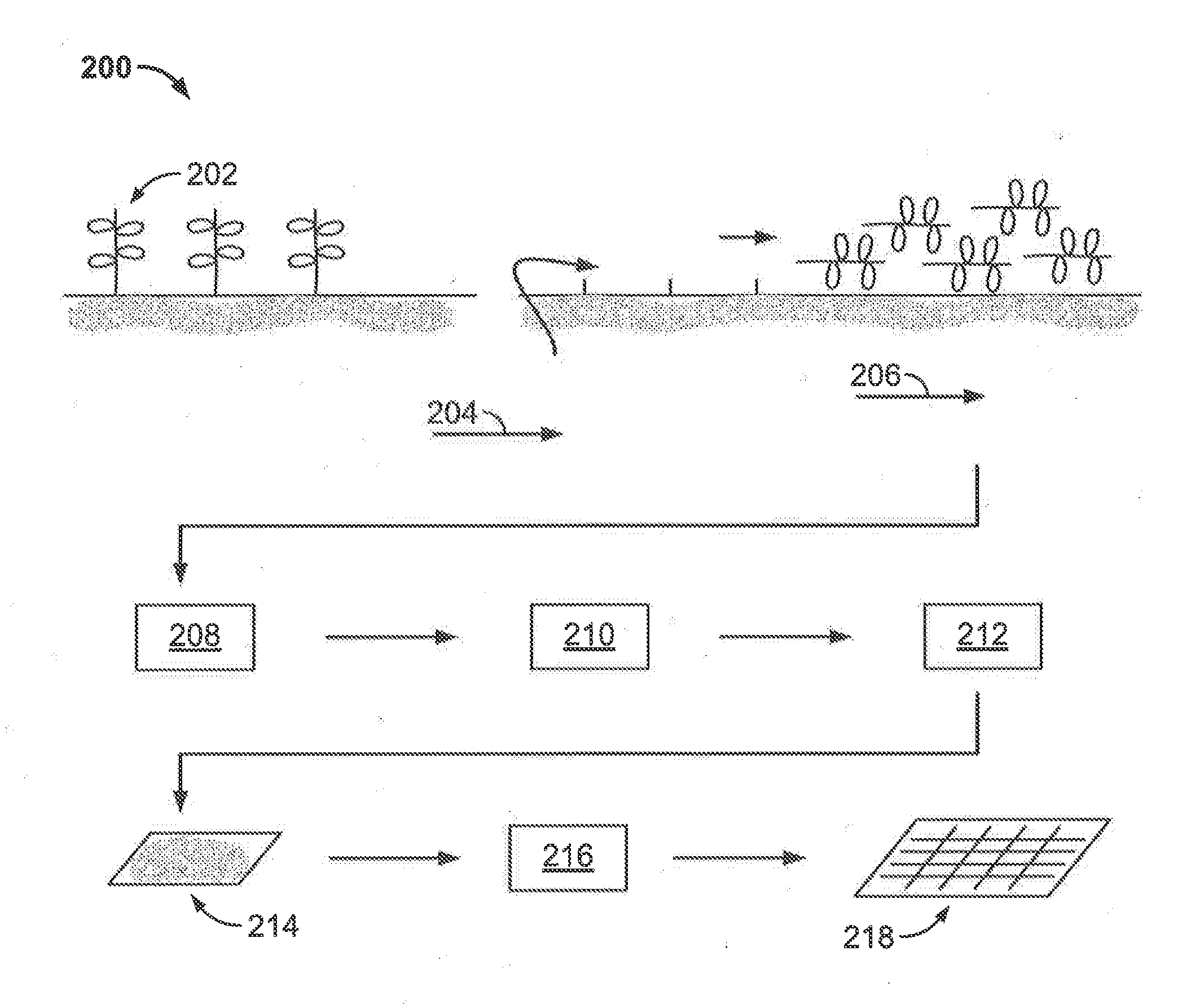

Systems and Methods for Producing Biochar-Based Products

PatentActiveUS20170040083A1

Innovation

- A system and method for producing biochar-based products, specifically tailored ultra-capacitor electrodes and battery components, by selecting and processing biomass to create biochar with controlled properties through thermal and chemical processing, utilizing a 'net-shaping' method that eliminates the need for toxic materials and mining, and integrates renewable and sustainable practices.

Supply Chain Optimization for Biochar Materials

The optimization of biochar supply chains represents a critical component in sustainable battery manufacturing. Current supply chain structures for biochar materials face significant challenges including fragmented production networks, inconsistent quality standards, and logistical inefficiencies that impede large-scale adoption in battery applications.

Primary biochar sources for battery manufacturing include agricultural waste (corn stover, rice husks), forestry residues (sawdust, bark), and dedicated biomass crops. Each source presents distinct advantages and limitations regarding carbon content, purity, and availability. Agricultural waste offers seasonal abundance but variable quality, while forestry residues provide more consistent properties but face competing industrial demands.

Regional availability mapping indicates that optimal biochar sourcing hubs exist in areas with concentrated agricultural or forestry activities. North America, Southeast Asia, and parts of Europe demonstrate particularly favorable conditions for establishing integrated biochar production facilities near battery manufacturing centers, potentially reducing transportation emissions by 30-45%.

Quality control mechanisms represent a significant challenge in biochar supply chains. Implementing standardized testing protocols and certification systems across supplier networks can reduce quality variations that currently range from 15-40% between batches. Advanced characterization techniques including thermogravimetric analysis and surface area measurements are becoming essential components of supplier qualification processes.

Vertical integration strategies have demonstrated success in pilot programs, with battery manufacturers investing in dedicated biochar production facilities. This approach has shown potential to reduce supply chain costs by 18-25% while ensuring consistent material specifications. Alternative models include strategic partnerships with agricultural cooperatives and forestry management organizations to secure stable feedstock supplies.

Digital tracking systems utilizing blockchain technology are emerging as valuable tools for biochar supply chain transparency. These systems enable verification of sustainable sourcing practices and provide complete material traceability from biomass origin through processing to battery integration. Early implementations have demonstrated improved supplier compliance with sustainability metrics and enhanced reporting capabilities for regulatory requirements.

Transportation optimization models suggest that regional processing hubs located within 200-300 kilometers of major battery manufacturing facilities represent the optimal configuration for minimizing both costs and environmental impacts. Multi-modal transportation strategies combining rail and electric vehicle delivery fleets can further reduce the carbon footprint of biochar logistics by up to 60% compared to conventional distribution methods.

Primary biochar sources for battery manufacturing include agricultural waste (corn stover, rice husks), forestry residues (sawdust, bark), and dedicated biomass crops. Each source presents distinct advantages and limitations regarding carbon content, purity, and availability. Agricultural waste offers seasonal abundance but variable quality, while forestry residues provide more consistent properties but face competing industrial demands.

Regional availability mapping indicates that optimal biochar sourcing hubs exist in areas with concentrated agricultural or forestry activities. North America, Southeast Asia, and parts of Europe demonstrate particularly favorable conditions for establishing integrated biochar production facilities near battery manufacturing centers, potentially reducing transportation emissions by 30-45%.

Quality control mechanisms represent a significant challenge in biochar supply chains. Implementing standardized testing protocols and certification systems across supplier networks can reduce quality variations that currently range from 15-40% between batches. Advanced characterization techniques including thermogravimetric analysis and surface area measurements are becoming essential components of supplier qualification processes.

Vertical integration strategies have demonstrated success in pilot programs, with battery manufacturers investing in dedicated biochar production facilities. This approach has shown potential to reduce supply chain costs by 18-25% while ensuring consistent material specifications. Alternative models include strategic partnerships with agricultural cooperatives and forestry management organizations to secure stable feedstock supplies.

Digital tracking systems utilizing blockchain technology are emerging as valuable tools for biochar supply chain transparency. These systems enable verification of sustainable sourcing practices and provide complete material traceability from biomass origin through processing to battery integration. Early implementations have demonstrated improved supplier compliance with sustainability metrics and enhanced reporting capabilities for regulatory requirements.

Transportation optimization models suggest that regional processing hubs located within 200-300 kilometers of major battery manufacturing facilities represent the optimal configuration for minimizing both costs and environmental impacts. Multi-modal transportation strategies combining rail and electric vehicle delivery fleets can further reduce the carbon footprint of biochar logistics by up to 60% compared to conventional distribution methods.

Environmental Impact Assessment and Carbon Footprint Reduction

The environmental impact of biochar production and utilization in battery manufacturing represents a critical consideration for sustainable industrial practices. Life cycle assessment (LCA) studies indicate that biochar-based battery components can reduce greenhouse gas emissions by 35-60% compared to conventional carbon materials, primarily due to the carbon sequestration properties inherent in biochar production processes.

When evaluating feedstock sources, agricultural waste-derived biochar demonstrates superior environmental performance, with rice husks and coconut shells offering carbon footprint reductions of approximately 2.5-3.2 tons CO2-equivalent per ton of material compared to synthetic graphite. This advantage stems from both the carbon sequestration during pyrolysis and the avoidance of waste disposal emissions.

Water usage represents another significant environmental factor in biochar production. Slow pyrolysis techniques typically require 40-60% less water than traditional carbon material processing, contributing to a more sustainable manufacturing ecosystem. Additionally, the closed-loop production systems being developed by industry leaders can capture and reuse process water, further reducing the environmental burden.

Land use considerations must be carefully balanced when scaling biochar production. Dedicated energy crop cultivation for biochar may create land competition with food production, whereas waste-stream utilization presents minimal land-use conflicts. Environmental modeling suggests that integrated agroforestry systems producing both food and biochar feedstock can optimize land productivity while maintaining ecological services.

Air quality impacts from biochar production facilities require mitigation through advanced emission control technologies. Modern pyrolysis systems with thermal oxidizers can reduce volatile organic compound (VOC) emissions by over 95%, addressing a key environmental concern in production scaling. The implementation of these technologies adds approximately 8-12% to production costs but is essential for regulatory compliance and community acceptance.

Transportation-related emissions in the biochar supply chain can be minimized through strategic facility placement. Analysis shows that processing facilities located within 75-100 km of feedstock sources optimize the carbon footprint of the supply chain, reducing transportation emissions by up to 40% compared to centralized production models.

Certification systems such as the European Biochar Certificate (EBC) and the International Biochar Initiative (IBI) standards provide frameworks for ensuring environmental performance. These systems evaluate production methods, feedstock sustainability, and final product characteristics, offering a pathway to verify carbon footprint reduction claims in battery manufacturing applications.

When evaluating feedstock sources, agricultural waste-derived biochar demonstrates superior environmental performance, with rice husks and coconut shells offering carbon footprint reductions of approximately 2.5-3.2 tons CO2-equivalent per ton of material compared to synthetic graphite. This advantage stems from both the carbon sequestration during pyrolysis and the avoidance of waste disposal emissions.

Water usage represents another significant environmental factor in biochar production. Slow pyrolysis techniques typically require 40-60% less water than traditional carbon material processing, contributing to a more sustainable manufacturing ecosystem. Additionally, the closed-loop production systems being developed by industry leaders can capture and reuse process water, further reducing the environmental burden.

Land use considerations must be carefully balanced when scaling biochar production. Dedicated energy crop cultivation for biochar may create land competition with food production, whereas waste-stream utilization presents minimal land-use conflicts. Environmental modeling suggests that integrated agroforestry systems producing both food and biochar feedstock can optimize land productivity while maintaining ecological services.

Air quality impacts from biochar production facilities require mitigation through advanced emission control technologies. Modern pyrolysis systems with thermal oxidizers can reduce volatile organic compound (VOC) emissions by over 95%, addressing a key environmental concern in production scaling. The implementation of these technologies adds approximately 8-12% to production costs but is essential for regulatory compliance and community acceptance.

Transportation-related emissions in the biochar supply chain can be minimized through strategic facility placement. Analysis shows that processing facilities located within 75-100 km of feedstock sources optimize the carbon footprint of the supply chain, reducing transportation emissions by up to 40% compared to centralized production models.

Certification systems such as the European Biochar Certificate (EBC) and the International Biochar Initiative (IBI) standards provide frameworks for ensuring environmental performance. These systems evaluate production methods, feedstock sustainability, and final product characteristics, offering a pathway to verify carbon footprint reduction claims in battery manufacturing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!