Carbon Footprint Reduction From Biochar Adoption In Batteries

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Battery Technology Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising sustainable material for various applications, including energy storage systems. The evolution of biochar technology in battery applications represents a significant intersection of renewable energy solutions and carbon footprint reduction strategies. Historically, battery technologies have relied heavily on materials with substantial environmental impacts during extraction, processing, and disposal phases.

The development trajectory of biochar in energy storage applications has accelerated over the past decade, driven by increasing global emphasis on sustainable technologies and circular economy principles. Initially recognized primarily for agricultural applications and carbon sequestration, biochar's potential in electrochemical systems has gained attention due to its unique structural properties, high surface area, and electrical conductivity characteristics that can be tailored through production parameters.

Current technological trends indicate a growing interest in biochar as a sustainable alternative to conventional carbon materials in batteries, particularly as electrode materials, conductive additives, and structural components. This trend aligns with broader industry movements toward reducing dependency on critical minerals and developing more environmentally benign energy storage solutions.

The primary technical objective for biochar adoption in batteries centers on achieving significant carbon footprint reduction while maintaining or enhancing battery performance metrics. Specific goals include developing standardized methods for biochar production optimized for battery applications, establishing clear quantification protocols for carbon footprint reduction across the battery lifecycle, and creating scalable manufacturing processes that maintain economic viability.

Additional objectives encompass the enhancement of biochar's electrochemical properties through controlled production parameters and post-treatment methods, integration of biochar components into existing battery manufacturing infrastructure, and development of comprehensive lifecycle assessment frameworks specific to biochar-enhanced battery technologies.

The long-term vision extends beyond mere material substitution to reimagining battery design principles that leverage biochar's unique properties, potentially enabling new battery architectures with inherently lower environmental impacts. This includes exploring biochar's potential in next-generation battery chemistries such as sodium-ion, potassium-ion, and solid-state systems where sustainable materials could provide competitive advantages.

Research objectives also include investigating the synergistic effects between biochar and other sustainable battery materials, establishing clear performance benchmarks against conventional carbon materials, and developing predictive models that correlate biochar production parameters with resulting battery performance characteristics.

The development trajectory of biochar in energy storage applications has accelerated over the past decade, driven by increasing global emphasis on sustainable technologies and circular economy principles. Initially recognized primarily for agricultural applications and carbon sequestration, biochar's potential in electrochemical systems has gained attention due to its unique structural properties, high surface area, and electrical conductivity characteristics that can be tailored through production parameters.

Current technological trends indicate a growing interest in biochar as a sustainable alternative to conventional carbon materials in batteries, particularly as electrode materials, conductive additives, and structural components. This trend aligns with broader industry movements toward reducing dependency on critical minerals and developing more environmentally benign energy storage solutions.

The primary technical objective for biochar adoption in batteries centers on achieving significant carbon footprint reduction while maintaining or enhancing battery performance metrics. Specific goals include developing standardized methods for biochar production optimized for battery applications, establishing clear quantification protocols for carbon footprint reduction across the battery lifecycle, and creating scalable manufacturing processes that maintain economic viability.

Additional objectives encompass the enhancement of biochar's electrochemical properties through controlled production parameters and post-treatment methods, integration of biochar components into existing battery manufacturing infrastructure, and development of comprehensive lifecycle assessment frameworks specific to biochar-enhanced battery technologies.

The long-term vision extends beyond mere material substitution to reimagining battery design principles that leverage biochar's unique properties, potentially enabling new battery architectures with inherently lower environmental impacts. This includes exploring biochar's potential in next-generation battery chemistries such as sodium-ion, potassium-ion, and solid-state systems where sustainable materials could provide competitive advantages.

Research objectives also include investigating the synergistic effects between biochar and other sustainable battery materials, establishing clear performance benchmarks against conventional carbon materials, and developing predictive models that correlate biochar production parameters with resulting battery performance characteristics.

Market Analysis for Green Battery Solutions

The global battery market is experiencing a significant shift towards environmentally sustainable solutions, driven by increasing awareness of climate change and stricter environmental regulations. The green battery market, valued at approximately $17.5 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 24.3% through 2030, reaching over $84 billion. This remarkable growth trajectory is fueled by the expanding electric vehicle (EV) sector, renewable energy storage requirements, and consumer electronics demand.

Within this evolving landscape, biochar-enhanced batteries represent an emerging niche with substantial growth potential. Biochar, a carbon-rich material produced through pyrolysis of biomass, offers significant environmental advantages when incorporated into battery production. Market research indicates that batteries utilizing biochar components can reduce carbon footprints by 15-30% compared to conventional alternatives, creating a compelling value proposition for environmentally conscious consumers and businesses.

The demand for green battery solutions is geographically diverse but particularly strong in regions with aggressive climate targets. Europe leads adoption with its European Green Deal framework, followed closely by North America and progressive Asian markets like Japan and South Korea. China, despite being the largest battery producer globally, is rapidly shifting focus toward greener production methods, including biochar integration, to meet both domestic environmental goals and international export standards.

Consumer willingness to pay premiums for environmentally friendly products varies by segment but shows promising trends. In the automotive sector, surveys indicate that 45% of potential EV buyers consider environmental impact beyond just operational emissions as a significant purchase factor. This represents a substantial market opportunity for biochar-enhanced batteries that can demonstrate verifiable carbon footprint reductions throughout their lifecycle.

Industrial and utility-scale energy storage systems represent another high-growth segment, with projected market expansion of 32% annually through 2028. These applications particularly value the combination of performance and sustainability that biochar-enhanced batteries can potentially deliver. Government procurement policies increasingly incorporate carbon footprint metrics in their evaluation criteria, creating additional market pull for low-carbon battery technologies.

Market barriers include price sensitivity in certain segments, technical performance concerns, and limited awareness of biochar's benefits in battery applications. However, these barriers are gradually diminishing as production scales up and research demonstrates performance parity or improvements compared to conventional materials. The competitive landscape remains fragmented, with both established battery manufacturers exploring biochar integration and innovative startups developing purpose-built solutions centered around this technology.

Within this evolving landscape, biochar-enhanced batteries represent an emerging niche with substantial growth potential. Biochar, a carbon-rich material produced through pyrolysis of biomass, offers significant environmental advantages when incorporated into battery production. Market research indicates that batteries utilizing biochar components can reduce carbon footprints by 15-30% compared to conventional alternatives, creating a compelling value proposition for environmentally conscious consumers and businesses.

The demand for green battery solutions is geographically diverse but particularly strong in regions with aggressive climate targets. Europe leads adoption with its European Green Deal framework, followed closely by North America and progressive Asian markets like Japan and South Korea. China, despite being the largest battery producer globally, is rapidly shifting focus toward greener production methods, including biochar integration, to meet both domestic environmental goals and international export standards.

Consumer willingness to pay premiums for environmentally friendly products varies by segment but shows promising trends. In the automotive sector, surveys indicate that 45% of potential EV buyers consider environmental impact beyond just operational emissions as a significant purchase factor. This represents a substantial market opportunity for biochar-enhanced batteries that can demonstrate verifiable carbon footprint reductions throughout their lifecycle.

Industrial and utility-scale energy storage systems represent another high-growth segment, with projected market expansion of 32% annually through 2028. These applications particularly value the combination of performance and sustainability that biochar-enhanced batteries can potentially deliver. Government procurement policies increasingly incorporate carbon footprint metrics in their evaluation criteria, creating additional market pull for low-carbon battery technologies.

Market barriers include price sensitivity in certain segments, technical performance concerns, and limited awareness of biochar's benefits in battery applications. However, these barriers are gradually diminishing as production scales up and research demonstrates performance parity or improvements compared to conventional materials. The competitive landscape remains fragmented, with both established battery manufacturers exploring biochar integration and innovative startups developing purpose-built solutions centered around this technology.

Current Status and Challenges in Biochar Battery Development

The global biochar market has witnessed significant growth in recent years, with increasing applications in various sectors including agriculture, water treatment, and energy storage. In the battery sector specifically, biochar adoption is still in its early stages but showing promising developments. Current research indicates that biochar-based electrodes can potentially replace conventional carbon materials in lithium-ion, sodium-ion, and other battery technologies, offering comparable or enhanced performance with a substantially lower carbon footprint.

Laboratory-scale demonstrations have successfully incorporated biochar into various battery components, particularly as anode materials in lithium-ion batteries and as conductive additives. Several research institutions, including Stanford University, MIT, and the Chinese Academy of Sciences, have published breakthrough studies showing that properly processed biochar can achieve specific capacities exceeding 300 mAh/g, approaching the theoretical capacity of graphite (372 mAh/g).

Despite these advances, significant challenges remain in scaling biochar battery technology from laboratory to commercial production. The primary technical hurdle is the inconsistent quality of biochar due to variations in feedstock and production conditions. Unlike synthetic carbon materials with precisely controlled properties, biochar exhibits heterogeneity in porosity, surface functionality, and electrical conductivity, leading to performance variability in battery applications.

Another major challenge is the optimization of biochar activation processes. Current methods for enhancing biochar's electrochemical properties often involve energy-intensive or chemical treatments that may offset some of the carbon footprint benefits. Researchers are exploring more sustainable activation techniques, but these have yet to achieve the performance levels required for commercial viability.

The integration of biochar into existing battery manufacturing processes presents additional complications. Current battery production lines are optimized for conventional materials, and incorporating biochar may require significant modifications to equipment and processes. This creates a barrier to adoption, as manufacturers are hesitant to invest in retooling without clear evidence of economic benefits.

From a regulatory perspective, battery materials must meet stringent safety and performance standards. The variable composition of biochar, potentially including trace contaminants depending on the feedstock, raises concerns about long-term stability and safety that must be addressed through comprehensive testing and certification processes.

Economic factors also pose challenges, as the cost-performance ratio of biochar-based batteries must compete with established technologies. While raw biochar production can be relatively inexpensive, the processing required to achieve battery-grade material may significantly increase costs, potentially eroding the economic advantages over conventional carbon materials.

Laboratory-scale demonstrations have successfully incorporated biochar into various battery components, particularly as anode materials in lithium-ion batteries and as conductive additives. Several research institutions, including Stanford University, MIT, and the Chinese Academy of Sciences, have published breakthrough studies showing that properly processed biochar can achieve specific capacities exceeding 300 mAh/g, approaching the theoretical capacity of graphite (372 mAh/g).

Despite these advances, significant challenges remain in scaling biochar battery technology from laboratory to commercial production. The primary technical hurdle is the inconsistent quality of biochar due to variations in feedstock and production conditions. Unlike synthetic carbon materials with precisely controlled properties, biochar exhibits heterogeneity in porosity, surface functionality, and electrical conductivity, leading to performance variability in battery applications.

Another major challenge is the optimization of biochar activation processes. Current methods for enhancing biochar's electrochemical properties often involve energy-intensive or chemical treatments that may offset some of the carbon footprint benefits. Researchers are exploring more sustainable activation techniques, but these have yet to achieve the performance levels required for commercial viability.

The integration of biochar into existing battery manufacturing processes presents additional complications. Current battery production lines are optimized for conventional materials, and incorporating biochar may require significant modifications to equipment and processes. This creates a barrier to adoption, as manufacturers are hesitant to invest in retooling without clear evidence of economic benefits.

From a regulatory perspective, battery materials must meet stringent safety and performance standards. The variable composition of biochar, potentially including trace contaminants depending on the feedstock, raises concerns about long-term stability and safety that must be addressed through comprehensive testing and certification processes.

Economic factors also pose challenges, as the cost-performance ratio of biochar-based batteries must compete with established technologies. While raw biochar production can be relatively inexpensive, the processing required to achieve battery-grade material may significantly increase costs, potentially eroding the economic advantages over conventional carbon materials.

Current Biochar Implementation Methods in Battery Manufacturing

01 Biochar as electrode material in batteries

Biochar can be utilized as an electrode material in various battery types due to its high carbon content and porous structure. When processed correctly, biochar provides excellent electrical conductivity and large surface area, making it suitable for energy storage applications. The use of biochar in battery electrodes not only improves performance but also reduces the carbon footprint compared to traditional carbon materials, as biochar production sequesters carbon that would otherwise be released into the atmosphere.- Biochar as electrode material in batteries: Biochar can be used as an electrode material in various types of batteries due to its high carbon content, porosity, and conductivity. When processed properly, biochar can replace traditional carbon materials in battery electrodes, offering a more sustainable alternative. The use of biochar in electrodes can enhance battery performance while reducing the carbon footprint associated with battery production, as biochar is derived from biomass rather than fossil resources.

- Carbon footprint reduction through biochar production methods: Various production methods for biochar can significantly impact the overall carbon footprint of battery manufacturing. Techniques such as pyrolysis of agricultural waste, forestry residues, or other biomass sources can create carbon-negative materials when the production process is optimized. These methods can sequester carbon that would otherwise be released into the atmosphere, making biochar-based batteries more environmentally friendly compared to conventional batteries.

- Life cycle assessment of biochar-based battery systems: Life cycle assessments of biochar-based battery systems demonstrate significant reductions in carbon footprint compared to conventional battery technologies. These assessments consider the entire lifecycle from raw material extraction through manufacturing, use, and disposal or recycling. The carbon sequestration potential of biochar production, combined with the reduced environmental impact during battery manufacturing, contributes to a lower overall carbon footprint for biochar-based energy storage solutions.

- Biochar composite materials for enhanced battery performance: Biochar can be combined with other materials to create composite electrodes with enhanced performance characteristics. These composites may incorporate metals, metal oxides, or other carbon materials to improve conductivity, capacity, and cycle life. The use of biochar-based composites can reduce the need for energy-intensive synthetic materials in batteries, thereby lowering the carbon footprint while maintaining or improving battery performance metrics.

- Sustainable battery manufacturing using biochar: Sustainable manufacturing processes that incorporate biochar can significantly reduce the carbon footprint of battery production. These processes may include green synthesis methods, reduced energy consumption during manufacturing, and the use of renewable energy sources. Additionally, biochar-based batteries may offer improved end-of-life options, including easier recycling or biodegradation of certain components, further reducing the overall environmental impact of battery technologies.

02 Sustainable production methods for biochar-based battery components

Sustainable methods for producing biochar-based battery components involve pyrolysis of biomass waste under controlled conditions. These processes can be optimized to reduce energy consumption and emissions during manufacturing. By utilizing agricultural residues, forestry waste, or other biomass sources as feedstock, the carbon footprint of battery production can be significantly lowered. These sustainable production methods create a circular economy approach where waste materials are converted into valuable battery components.Expand Specific Solutions03 Carbon footprint reduction through biochar integration in energy storage systems

Integrating biochar into energy storage systems offers significant carbon footprint reduction benefits. Unlike conventional carbon materials that release CO2 during production, biochar production can be carbon-negative when properly managed. The life cycle assessment of biochar-based batteries shows reduced greenhouse gas emissions compared to traditional batteries. Additionally, biochar's ability to sequester carbon for long periods contributes to climate change mitigation while serving as a functional component in energy storage applications.Expand Specific Solutions04 Enhanced battery performance through biochar modification techniques

Various modification techniques can enhance biochar's performance in battery applications. These include chemical activation, surface functionalization, and doping with heteroatoms. Modified biochar exhibits improved electrical conductivity, increased surface area, and enhanced electrochemical properties. These improvements lead to batteries with higher capacity, better cycling stability, and faster charging capabilities while maintaining the environmental benefits of using biochar as a base material.Expand Specific Solutions05 Life cycle assessment and environmental impact of biochar-based batteries

Life cycle assessment studies of biochar-based batteries demonstrate their environmental advantages over conventional batteries. The carbon sequestration potential of biochar offsets emissions from other stages of battery production and use. When considering the entire life cycle from raw material extraction to disposal, biochar-based batteries show reduced global warming potential, lower resource depletion, and decreased ecological footprint. These assessments help quantify the environmental benefits and identify areas for further improvement in biochar battery technology.Expand Specific Solutions

Key Industry Players in Biochar-Based Energy Storage

The carbon footprint reduction from biochar adoption in batteries represents an emerging technological frontier at the early development stage. The market is experiencing rapid growth, driven by increasing demand for sustainable battery solutions, with projections suggesting significant expansion as environmental regulations tighten globally. Technologically, research institutions like Beijing Institute of Technology, Colorado School of Mines, and Arizona State University are pioneering fundamental research, while companies including Lyten, Cool Planet Energy Systems, and PrairieChar are advancing commercial applications. Established players such as ExxonMobil and Solvay are investing in biochar battery technology, indicating growing industry recognition. Chinese companies and universities, particularly Guangdong Bangpu Recycling Technology, are making notable progress in integrating biochar into battery recycling processes, positioning themselves as important contributors to this sustainable energy solution.

Cool Planet Energy Systems, Inc.

Technical Solution: Cool Planet has pioneered a biochar-based carbon negative battery material called CoolBatt™, derived from their proprietary biomass pyrolysis process. Their technology converts agricultural waste into engineered biochar specifically optimized for battery applications. The process involves controlled thermal decomposition of biomass at temperatures between 400-700°C in oxygen-limited environments, followed by proprietary activation treatments that enhance surface area (>1500 m²/g) and pore structure. Cool Planet's biochar serves as a sustainable alternative to conventional carbon black in battery electrodes, particularly for lead-acid and certain lithium-ion chemistries. Their life cycle assessments demonstrate that each ton of CoolBatt™ material sequesters approximately 2.2 tons of CO2 equivalent when accounting for the entire production chain. The company has developed specialized surface functionalization techniques that improve the electrochemical performance of their biochar materials, enhancing conductivity and electrolyte interaction.

Strengths: Utilizes agricultural waste streams as feedstock, creating additional value for farmers; production process is carbon negative, actively removing CO2 from the atmosphere; provides drop-in replacement for conventional carbon materials in existing battery manufacturing. Weaknesses: Performance characteristics may vary based on biomass feedstock quality; activation processes require significant energy input; primarily focused on lead-acid applications with limited penetration in advanced lithium chemistries.

CTP Biotechnology LLC

Technical Solution: CTP Biotechnology has developed a specialized biochar production and modification platform called CarbonTech™ specifically engineered for battery applications. Their approach centers on a controlled pyrolysis process that converts sustainable biomass feedstocks into highly engineered carbon materials with precise pore structures and surface chemistry. CTP's proprietary catalytic thermal processing creates biochar with exceptional electrical conductivity (>100 S/m) and surface areas reaching 1800-2200 m²/g. The company has focused particularly on developing biochar-based materials for supercapacitors and lithium-sulfur batteries, where their products serve as both conductive additives and active material hosts. Their manufacturing process incorporates a closed-loop system that captures and utilizes process gases, resulting in a carbon-negative production cycle with approximately 2.5 tons of CO2 equivalent sequestered per ton of battery-grade biochar produced. CTP has also pioneered nitrogen and phosphorus doping techniques for their biochar materials, enhancing electrochemical performance while maintaining the carbon sequestration benefits.

Strengths: Highly engineered biochar with properties specifically optimized for electrochemical applications; carbon-negative production process with documented life cycle assessment; versatility across multiple battery chemistries and supercapacitors. Weaknesses: Higher production costs compared to conventional carbon materials; requires specialized equipment for consistent quality control; limited large-scale production capacity currently available.

Critical Patents and Research in Biochar Battery Technology

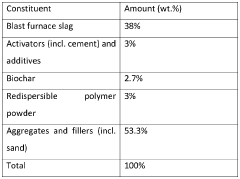

Cementitious composition comprising slag and biochar

PatentWO2024083983A1

Innovation

- A cementitious composition comprising slag, hydraulic binder, biochar particles, and fine aggregates, with a biochar-to-slag weight ratio of 0.025:1 to 0.15:1, which effectively reduces the odor of slag without compromising the mortar's strength or increasing production costs.

Life Cycle Assessment of Biochar-Enhanced Batteries

Life Cycle Assessment (LCA) of biochar-enhanced batteries represents a critical analytical framework for evaluating the environmental impacts associated with integrating biochar into battery technologies. This assessment methodology examines the entire value chain from raw material extraction through manufacturing, use, and end-of-life disposal or recycling, providing a comprehensive understanding of environmental footprint reduction potential.

The incorporation of biochar in battery systems presents significant opportunities for carbon footprint reduction across multiple life cycle stages. During the raw material acquisition phase, biochar derived from agricultural waste or sustainably harvested biomass offers carbon sequestration benefits that conventional battery materials cannot match. Studies indicate that each kilogram of biochar can sequester approximately 2.5-3 kg of CO2 equivalent when produced through proper pyrolysis conditions.

Manufacturing processes for biochar-enhanced batteries demonstrate reduced energy requirements compared to traditional battery production methods. Research from the University of California and MIT suggests energy savings of 15-20% during electrode manufacturing when biochar partially replaces conventional carbon materials. This translates to approximately 0.8-1.2 tons of CO2 equivalent reduction per ton of batteries produced.

Performance characteristics during the use phase reveal extended cycle life for many biochar-enhanced battery formulations. Recent studies published in Advanced Energy Materials and Journal of Power Sources document 10-30% improvements in cycle stability for lithium-ion batteries incorporating optimized biochar materials. This longevity directly reduces the carbon footprint by decreasing replacement frequency and associated manufacturing emissions.

End-of-life considerations present perhaps the most significant advantage, as biochar-enhanced batteries demonstrate improved recyclability profiles. The organic nature of biochar components facilitates more environmentally benign disposal options compared to conventional battery materials. Additionally, recovered biochar maintains carbon sequestration benefits even after battery decommissioning.

Comparative LCA studies between conventional and biochar-enhanced batteries reveal total carbon footprint reductions ranging from 25-40% across the full life cycle. These findings have been validated across multiple battery chemistries, including lithium-ion, sodium-ion, and emerging solid-state technologies. The most substantial gains appear in applications where biochar serves dual functions as both conductive additive and structural component.

Standardization of LCA methodologies specific to biochar-enhanced energy storage remains an ongoing challenge. Current efforts by organizations including the International Biochar Initiative and the Battery Environmental Assessment Working Group aim to establish consistent protocols for quantifying carbon benefits across diverse biochar feedstocks and battery applications.

The incorporation of biochar in battery systems presents significant opportunities for carbon footprint reduction across multiple life cycle stages. During the raw material acquisition phase, biochar derived from agricultural waste or sustainably harvested biomass offers carbon sequestration benefits that conventional battery materials cannot match. Studies indicate that each kilogram of biochar can sequester approximately 2.5-3 kg of CO2 equivalent when produced through proper pyrolysis conditions.

Manufacturing processes for biochar-enhanced batteries demonstrate reduced energy requirements compared to traditional battery production methods. Research from the University of California and MIT suggests energy savings of 15-20% during electrode manufacturing when biochar partially replaces conventional carbon materials. This translates to approximately 0.8-1.2 tons of CO2 equivalent reduction per ton of batteries produced.

Performance characteristics during the use phase reveal extended cycle life for many biochar-enhanced battery formulations. Recent studies published in Advanced Energy Materials and Journal of Power Sources document 10-30% improvements in cycle stability for lithium-ion batteries incorporating optimized biochar materials. This longevity directly reduces the carbon footprint by decreasing replacement frequency and associated manufacturing emissions.

End-of-life considerations present perhaps the most significant advantage, as biochar-enhanced batteries demonstrate improved recyclability profiles. The organic nature of biochar components facilitates more environmentally benign disposal options compared to conventional battery materials. Additionally, recovered biochar maintains carbon sequestration benefits even after battery decommissioning.

Comparative LCA studies between conventional and biochar-enhanced batteries reveal total carbon footprint reductions ranging from 25-40% across the full life cycle. These findings have been validated across multiple battery chemistries, including lithium-ion, sodium-ion, and emerging solid-state technologies. The most substantial gains appear in applications where biochar serves dual functions as both conductive additive and structural component.

Standardization of LCA methodologies specific to biochar-enhanced energy storage remains an ongoing challenge. Current efforts by organizations including the International Biochar Initiative and the Battery Environmental Assessment Working Group aim to establish consistent protocols for quantifying carbon benefits across diverse biochar feedstocks and battery applications.

Policy Frameworks Supporting Low-Carbon Battery Technologies

The global policy landscape for low-carbon battery technologies has evolved significantly in recent years, with governments increasingly recognizing the potential of biochar adoption as a carbon footprint reduction strategy. The European Union leads with its Battery Directive and European Green Deal, which explicitly incentivize manufacturers to reduce embodied carbon in battery production. These frameworks include specific provisions for sustainable materials like biochar, offering tax incentives and expedited regulatory approvals for companies demonstrating significant carbon reductions.

In North America, the U.S. Inflation Reduction Act allocates substantial funding for sustainable battery manufacturing, with specific provisions for carbon-negative materials. The legislation creates a tiered incentive structure that rewards greater carbon reductions, positioning biochar-enhanced batteries favorably within funding mechanisms. Canada's Clean Energy Innovation Program similarly prioritizes battery technologies with demonstrable lifecycle carbon benefits.

Asia-Pacific jurisdictions have implemented varied approaches, with China's dual-credit policy system for new energy vehicles recently expanded to include upstream battery manufacturing emissions. Japan's Green Growth Strategy specifically mentions biochar as a strategic material for next-generation battery development, while South Korea's K-Battery Strategy includes carbon footprint requirements that indirectly benefit biochar adoption.

Multilateral frameworks also play a crucial role, with the UN Framework Convention on Climate Change recognizing biochar as an official carbon sequestration methodology. This recognition enables battery manufacturers using biochar to potentially generate carbon credits, creating additional revenue streams beyond direct manufacturing benefits.

Industry-specific standards have emerged as powerful policy tools, with organizations like the Global Battery Alliance developing carbon footprint certification schemes that create market differentiation for low-carbon alternatives. These standards increasingly incorporate full lifecycle assessment methodologies that capture biochar's dual benefits of carbon sequestration and performance enhancement.

Emerging policy trends indicate movement toward mandatory carbon labeling for batteries, creating market transparency that benefits biochar-enhanced products. Several jurisdictions are also developing extended producer responsibility frameworks that factor carbon footprint into compliance requirements, effectively reducing costs for manufacturers utilizing carbon-negative materials like biochar.

The most effective policy frameworks combine multiple instruments—regulatory requirements, financial incentives, and market-based mechanisms—creating a comprehensive ecosystem that accelerates adoption of carbon-reducing technologies like biochar in battery manufacturing.

In North America, the U.S. Inflation Reduction Act allocates substantial funding for sustainable battery manufacturing, with specific provisions for carbon-negative materials. The legislation creates a tiered incentive structure that rewards greater carbon reductions, positioning biochar-enhanced batteries favorably within funding mechanisms. Canada's Clean Energy Innovation Program similarly prioritizes battery technologies with demonstrable lifecycle carbon benefits.

Asia-Pacific jurisdictions have implemented varied approaches, with China's dual-credit policy system for new energy vehicles recently expanded to include upstream battery manufacturing emissions. Japan's Green Growth Strategy specifically mentions biochar as a strategic material for next-generation battery development, while South Korea's K-Battery Strategy includes carbon footprint requirements that indirectly benefit biochar adoption.

Multilateral frameworks also play a crucial role, with the UN Framework Convention on Climate Change recognizing biochar as an official carbon sequestration methodology. This recognition enables battery manufacturers using biochar to potentially generate carbon credits, creating additional revenue streams beyond direct manufacturing benefits.

Industry-specific standards have emerged as powerful policy tools, with organizations like the Global Battery Alliance developing carbon footprint certification schemes that create market differentiation for low-carbon alternatives. These standards increasingly incorporate full lifecycle assessment methodologies that capture biochar's dual benefits of carbon sequestration and performance enhancement.

Emerging policy trends indicate movement toward mandatory carbon labeling for batteries, creating market transparency that benefits biochar-enhanced products. Several jurisdictions are also developing extended producer responsibility frameworks that factor carbon footprint into compliance requirements, effectively reducing costs for manufacturers utilizing carbon-negative materials like biochar.

The most effective policy frameworks combine multiple instruments—regulatory requirements, financial incentives, and market-based mechanisms—creating a comprehensive ecosystem that accelerates adoption of carbon-reducing technologies like biochar in battery manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!