Biochar For Low-Cost, Low-Carbon Stationary Storage Electrodes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Electrode Technology Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising candidate for sustainable energy storage applications. The evolution of biochar technology spans centuries, from traditional charcoal production to modern engineered carbon materials. Recent advancements in understanding biochar's electrochemical properties have positioned it as a potential game-changer in the stationary energy storage sector, where cost-effectiveness and environmental sustainability are paramount considerations.

The technological trajectory of biochar electrodes has accelerated significantly over the past decade, driven by the urgent need for grid-scale energy storage solutions to support renewable energy integration. Traditional energy storage technologies often rely on rare earth elements and environmentally problematic materials, creating a critical gap that biochar-based solutions aim to address. The inherent porosity, surface functionality, and electrical conductivity of biochar provide a foundation for developing high-performance electrodes without the environmental and economic burdens of conventional materials.

Current research trends focus on optimizing biochar properties through controlled pyrolysis conditions, feedstock selection, and post-treatment modifications to enhance electrochemical performance. The convergence of materials science, electrochemistry, and sustainable engineering has created a fertile ground for innovation in this domain. Notably, recent studies have demonstrated that biochar derived from agricultural waste can achieve competitive capacitance values when properly engineered, suggesting significant untapped potential.

The primary technical objectives for biochar electrode development include enhancing electrical conductivity, optimizing pore structure for ion transport, improving cycling stability, and scaling production methods while maintaining low environmental impact. These objectives align with broader industry goals of reducing the levelized cost of storage (LCOS) and minimizing carbon footprint across the entire life cycle of energy storage systems.

Beyond technical performance, biochar electrodes aim to address critical supply chain vulnerabilities in the energy storage sector. By utilizing locally available biomass resources, this technology offers a pathway to reduce dependence on geographically concentrated critical minerals. The potential for regional production models could democratize energy storage manufacturing, creating resilient supply chains and economic opportunities in diverse geographic contexts.

The ultimate goal of biochar electrode technology development is to establish a viable alternative to conventional electrode materials that delivers comparable performance at lower cost and with reduced environmental impact. Success in this endeavor would represent a significant step toward sustainable, accessible energy storage solutions capable of supporting the global transition to renewable energy systems.

The technological trajectory of biochar electrodes has accelerated significantly over the past decade, driven by the urgent need for grid-scale energy storage solutions to support renewable energy integration. Traditional energy storage technologies often rely on rare earth elements and environmentally problematic materials, creating a critical gap that biochar-based solutions aim to address. The inherent porosity, surface functionality, and electrical conductivity of biochar provide a foundation for developing high-performance electrodes without the environmental and economic burdens of conventional materials.

Current research trends focus on optimizing biochar properties through controlled pyrolysis conditions, feedstock selection, and post-treatment modifications to enhance electrochemical performance. The convergence of materials science, electrochemistry, and sustainable engineering has created a fertile ground for innovation in this domain. Notably, recent studies have demonstrated that biochar derived from agricultural waste can achieve competitive capacitance values when properly engineered, suggesting significant untapped potential.

The primary technical objectives for biochar electrode development include enhancing electrical conductivity, optimizing pore structure for ion transport, improving cycling stability, and scaling production methods while maintaining low environmental impact. These objectives align with broader industry goals of reducing the levelized cost of storage (LCOS) and minimizing carbon footprint across the entire life cycle of energy storage systems.

Beyond technical performance, biochar electrodes aim to address critical supply chain vulnerabilities in the energy storage sector. By utilizing locally available biomass resources, this technology offers a pathway to reduce dependence on geographically concentrated critical minerals. The potential for regional production models could democratize energy storage manufacturing, creating resilient supply chains and economic opportunities in diverse geographic contexts.

The ultimate goal of biochar electrode technology development is to establish a viable alternative to conventional electrode materials that delivers comparable performance at lower cost and with reduced environmental impact. Success in this endeavor would represent a significant step toward sustainable, accessible energy storage solutions capable of supporting the global transition to renewable energy systems.

Market Analysis for Low-Cost Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. Current projections indicate the stationary energy storage market will reach $125 billion by 2035, with a compound annual growth rate exceeding 20% over the next decade. This rapid expansion creates significant opportunities for low-cost energy storage solutions, particularly those with sustainable environmental profiles.

Biochar-based electrodes represent an emerging segment within this market, positioned at the intersection of cost reduction and environmental sustainability. Traditional energy storage solutions rely heavily on lithium-ion technology, which faces challenges including high production costs, resource constraints, and environmental concerns. The average cost of lithium-ion stationary storage systems currently ranges between $250-$400 per kilowatt-hour, creating a substantial barrier to widespread adoption.

Market analysis reveals growing demand for alternative electrode materials that can reduce dependency on critical minerals while maintaining performance metrics. Biochar electrodes, derived from sustainable biomass sources, address this need by offering a carbon-negative or carbon-neutral production pathway. This aligns with the increasing corporate and governmental commitments to carbon reduction targets, creating regulatory tailwinds for such technologies.

The addressable market for low-cost stationary storage is particularly robust in developing economies, where grid infrastructure is evolving and cost sensitivity is high. These regions represent over 60% of projected global energy storage deployment growth, with particular emphasis on Southeast Asia, Sub-Saharan Africa, and Latin America. Additionally, remote and off-grid applications present significant market opportunities, with an estimated market size of $18 billion by 2030.

Consumer and industrial segments demonstrate different adoption patterns for low-cost storage solutions. Utility-scale applications prioritize long-term reliability and levelized cost of storage, while commercial and industrial users focus on payback periods and integration with existing systems. Residential markets remain price-sensitive but increasingly value sustainability credentials, creating a potential premium segment for environmentally advantageous solutions like biochar electrodes.

Competitive analysis indicates that while established energy storage providers maintain market dominance, there is increasing investment in alternative electrode technologies. Venture capital funding for novel electrode materials reached $2.7 billion in 2022, reflecting strong investor confidence in this sector. Biochar-based solutions must compete not only with traditional lithium-ion technology but also with emerging alternatives such as sodium-ion, flow batteries, and other carbon-based electrode materials.

Biochar-based electrodes represent an emerging segment within this market, positioned at the intersection of cost reduction and environmental sustainability. Traditional energy storage solutions rely heavily on lithium-ion technology, which faces challenges including high production costs, resource constraints, and environmental concerns. The average cost of lithium-ion stationary storage systems currently ranges between $250-$400 per kilowatt-hour, creating a substantial barrier to widespread adoption.

Market analysis reveals growing demand for alternative electrode materials that can reduce dependency on critical minerals while maintaining performance metrics. Biochar electrodes, derived from sustainable biomass sources, address this need by offering a carbon-negative or carbon-neutral production pathway. This aligns with the increasing corporate and governmental commitments to carbon reduction targets, creating regulatory tailwinds for such technologies.

The addressable market for low-cost stationary storage is particularly robust in developing economies, where grid infrastructure is evolving and cost sensitivity is high. These regions represent over 60% of projected global energy storage deployment growth, with particular emphasis on Southeast Asia, Sub-Saharan Africa, and Latin America. Additionally, remote and off-grid applications present significant market opportunities, with an estimated market size of $18 billion by 2030.

Consumer and industrial segments demonstrate different adoption patterns for low-cost storage solutions. Utility-scale applications prioritize long-term reliability and levelized cost of storage, while commercial and industrial users focus on payback periods and integration with existing systems. Residential markets remain price-sensitive but increasingly value sustainability credentials, creating a potential premium segment for environmentally advantageous solutions like biochar electrodes.

Competitive analysis indicates that while established energy storage providers maintain market dominance, there is increasing investment in alternative electrode technologies. Venture capital funding for novel electrode materials reached $2.7 billion in 2022, reflecting strong investor confidence in this sector. Biochar-based solutions must compete not only with traditional lithium-ion technology but also with emerging alternatives such as sodium-ion, flow batteries, and other carbon-based electrode materials.

Current Challenges in Biochar-Based Electrode Development

Despite the promising potential of biochar-based electrodes for stationary energy storage, several significant challenges impede their widespread commercial adoption. The primary obstacle lies in the inconsistent quality and properties of biochar derived from different biomass sources. Variations in feedstock composition, pyrolysis conditions, and post-processing methods result in biochar with unpredictable electrical conductivity, surface area, and pore structure—all critical parameters for electrode performance.

The electrical conductivity of raw biochar typically ranges from 10^-4 to 10^-1 S/cm, significantly lower than commercial carbon materials used in energy storage (1-100 S/cm). This inherent limitation necessitates additional processing steps such as high-temperature treatment or chemical activation, which increases production costs and carbon footprint, contradicting the low-cost, low-carbon objectives.

Surface functionalization presents another challenge. While biochar naturally contains various oxygen-containing functional groups that can enhance pseudocapacitive behavior, controlling the type, quantity, and distribution of these groups remains difficult. The trade-off between increased pseudocapacitance and decreased electrical conductivity due to functionalization requires careful optimization that has not been standardized across the industry.

Scalability issues further complicate commercial viability. Laboratory-scale production methods often yield high-performance biochar electrodes, but translating these processes to industrial scale introduces inconsistencies in quality and performance. The lack of standardized production protocols makes quality control particularly challenging, resulting in batch-to-batch variations that are unacceptable for commercial energy storage applications.

Long-term stability represents a critical concern for stationary storage applications. Biochar electrodes often exhibit capacity fading and structural degradation during extended cycling, with performance decreases of 15-30% after 1000 cycles being common. This falls short of the 5000+ cycles expected for commercial stationary storage solutions. The mechanisms behind this degradation, including surface group decomposition and pore structure collapse, are not fully understood.

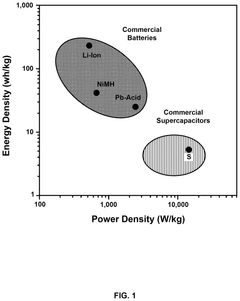

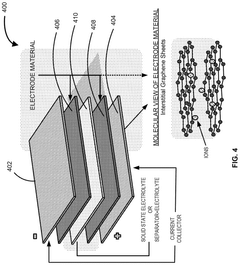

Integration challenges with existing battery and supercapacitor technologies also limit adoption. Biochar electrodes often require specialized electrolytes or cell designs that are incompatible with standard manufacturing processes. Additionally, the relatively low energy density (typically 5-20 Wh/kg) compared to commercial alternatives necessitates larger storage systems, increasing overall installation costs.

Environmental and safety concerns persist despite biochar's green credentials. Some activation processes involve hazardous chemicals like KOH or H3PO4, potentially offsetting the environmental benefits. Furthermore, the potential leaching of heavy metals or organic compounds from certain biochar sources raises questions about long-term environmental impact and safety.

The electrical conductivity of raw biochar typically ranges from 10^-4 to 10^-1 S/cm, significantly lower than commercial carbon materials used in energy storage (1-100 S/cm). This inherent limitation necessitates additional processing steps such as high-temperature treatment or chemical activation, which increases production costs and carbon footprint, contradicting the low-cost, low-carbon objectives.

Surface functionalization presents another challenge. While biochar naturally contains various oxygen-containing functional groups that can enhance pseudocapacitive behavior, controlling the type, quantity, and distribution of these groups remains difficult. The trade-off between increased pseudocapacitance and decreased electrical conductivity due to functionalization requires careful optimization that has not been standardized across the industry.

Scalability issues further complicate commercial viability. Laboratory-scale production methods often yield high-performance biochar electrodes, but translating these processes to industrial scale introduces inconsistencies in quality and performance. The lack of standardized production protocols makes quality control particularly challenging, resulting in batch-to-batch variations that are unacceptable for commercial energy storage applications.

Long-term stability represents a critical concern for stationary storage applications. Biochar electrodes often exhibit capacity fading and structural degradation during extended cycling, with performance decreases of 15-30% after 1000 cycles being common. This falls short of the 5000+ cycles expected for commercial stationary storage solutions. The mechanisms behind this degradation, including surface group decomposition and pore structure collapse, are not fully understood.

Integration challenges with existing battery and supercapacitor technologies also limit adoption. Biochar electrodes often require specialized electrolytes or cell designs that are incompatible with standard manufacturing processes. Additionally, the relatively low energy density (typically 5-20 Wh/kg) compared to commercial alternatives necessitates larger storage systems, increasing overall installation costs.

Environmental and safety concerns persist despite biochar's green credentials. Some activation processes involve hazardous chemicals like KOH or H3PO4, potentially offsetting the environmental benefits. Furthermore, the potential leaching of heavy metals or organic compounds from certain biochar sources raises questions about long-term environmental impact and safety.

Current Biochar Electrode Fabrication Techniques

01 Biochar production cost factors

The cost of biochar production is influenced by several factors including feedstock selection, processing technology, and scale of operation. Lower-cost feedstocks such as agricultural waste and forestry residues can significantly reduce production expenses. Advanced pyrolysis technologies that optimize energy efficiency and throughput rates help minimize operational costs. Additionally, economies of scale play a crucial role, with larger production facilities generally achieving lower per-unit costs through improved efficiency and reduced overhead expenses.- Biochar production cost factors: The cost of biochar production is influenced by various factors including feedstock selection, production technology, scale of operation, and energy requirements. Different feedstocks such as agricultural waste, forestry residues, and municipal solid waste have varying costs and availability. Production technologies like pyrolysis, gasification, and hydrothermal carbonization each have different capital and operational expenses. Economies of scale significantly impact the unit cost, with larger operations generally achieving lower production costs per ton of biochar.

- Carbon footprint reduction through biochar application: Biochar application in soil serves as a carbon sequestration method, effectively reducing carbon footprint by storing carbon that would otherwise be released as CO2. The carbon stability in biochar allows for long-term carbon storage, with residence times potentially spanning centuries to millennia. When incorporated into agricultural practices, biochar can reduce greenhouse gas emissions from soil, particularly nitrous oxide and methane. The carbon negative potential of biochar systems makes them valuable for climate change mitigation strategies and carbon credit generation.

- Economic viability and market considerations: The economic viability of biochar depends on multiple revenue streams beyond the sale of biochar itself, including carbon credits, agricultural yield improvements, and waste management cost reductions. Market development for biochar is influenced by policy incentives, carbon pricing mechanisms, and recognition of its environmental benefits. Price points vary significantly based on biochar quality, certification, and intended application. The integration of biochar production with renewable energy generation can improve overall economic feasibility through the sale of bio-oil, syngas, or electricity as co-products.

- Life cycle assessment of biochar systems: Life cycle assessments of biochar systems evaluate the net environmental impact from feedstock collection through production and application. These assessments consider energy inputs, transportation emissions, production emissions, and carbon sequestration benefits. Different production methods show varying carbon footprints, with optimized pyrolysis systems potentially achieving carbon-negative outcomes. The choice of feedstock significantly affects the overall carbon balance, with waste biomass generally providing better environmental outcomes than purpose-grown feedstocks. System boundaries and allocation methods in life cycle assessments can significantly influence the calculated carbon footprint.

- Technological innovations reducing costs and carbon footprint: Emerging technologies are addressing cost and carbon footprint challenges in biochar production. Mobile and modular biochar production units reduce transportation emissions and enable on-site processing of biomass. Process optimization techniques improve energy efficiency and reduce greenhouse gas emissions during production. Integration with existing industrial processes allows for waste heat utilization and improved overall efficiency. Advanced monitoring and control systems optimize production parameters to enhance biochar quality while minimizing energy consumption and emissions.

02 Carbon footprint reduction through biochar application

Biochar application offers significant carbon footprint reduction through multiple mechanisms. When incorporated into soil, biochar serves as a stable carbon sink, sequestering carbon for hundreds to thousands of years. The production process can be carbon-negative when combined with renewable energy sources or when capturing byproduct gases for energy generation. Additionally, biochar application reduces the need for chemical fertilizers, decreasing associated emissions from fertilizer production and application, while also potentially reducing nitrous oxide emissions from soil.Expand Specific Solutions03 Economic viability and carbon credit opportunities

The economic viability of biochar is enhanced through carbon credit markets and environmental incentives. Biochar projects can generate carbon credits through verified carbon sequestration, providing additional revenue streams beyond the direct sale of biochar products. Various carbon credit methodologies have been developed specifically for biochar, recognizing its long-term carbon storage potential. Government incentives, including tax benefits and subsidies for climate-friendly agricultural practices, further improve the economic case for biochar adoption and help offset initial production costs.Expand Specific Solutions04 Technological innovations reducing biochar production costs

Recent technological innovations have significantly reduced biochar production costs. Modular and mobile pyrolysis units enable on-site processing of biomass, eliminating transportation costs of bulky feedstock. Continuous-feed systems improve efficiency compared to batch processing methods. Heat recovery systems capture and utilize thermal energy from the pyrolysis process, reducing overall energy requirements. Additionally, integrated systems that combine biochar production with bioenergy generation create valuable co-products like bio-oil and syngas, improving the economic feasibility of biochar production.Expand Specific Solutions05 Life cycle assessment of biochar's carbon footprint

Life cycle assessments of biochar reveal varying carbon footprints depending on production methods and applications. The carbon intensity of biochar is influenced by feedstock sourcing, transportation distances, pyrolysis conditions, and end-use applications. Sustainable practices such as using waste biomass and renewable energy for processing can result in carbon-negative outcomes. The stability of biochar carbon in soil environments affects long-term sequestration potential, with high-temperature biochar typically offering greater stability. Comprehensive life cycle analyses consider both direct emissions from production and indirect effects on agricultural systems.Expand Specific Solutions

Key Industry Players in Sustainable Energy Storage

The biochar-based low-cost, low-carbon stationary storage electrode market is in its early growth phase, characterized by significant research activity but limited commercial deployment. The global market for sustainable energy storage solutions is expanding rapidly, projected to reach $100+ billion by 2030, with biochar electrodes representing an emerging niche. Research institutions like Fraunhofer-Gesellschaft, Max Planck Society, and universities in China (Harbin Institute of Technology, Zhejiang University of Technology) are leading fundamental research, while specialized companies such as Florrent, Inc. and KYOCERA AVX Components are advancing commercialization efforts. Large industrial players including Siemens Energy, thyssenkrupp, and Applied Materials are exploring integration opportunities, indicating growing interest in this sustainable technology that leverages biomass waste conversion for energy storage applications.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed an advanced biochar-based electrode system called "BioElectrode" specifically designed for stationary energy storage applications. Their approach utilizes a two-stage thermochemical conversion process of agricultural and forestry residues. The first stage involves hydrothermal carbonization (180-250°C) under pressurized conditions to create hydrochar, followed by controlled pyrolysis (500-800°C) to produce highly structured biochar. Fraunhofer's innovation includes a proprietary surface modification technique using ionic liquids that creates tailored pore distributions and surface functionalities. Their electrodes demonstrate exceptional performance metrics, including specific capacities of 280-350 mAh/g in sodium-ion batteries and volumetric capacities exceeding 200 F/cm³ in supercapacitor configurations. The technology has been implemented in 50 kWh grid-connected storage systems across several pilot sites in Germany, showing 88% round-trip efficiency and minimal capacity fade (less than 12% after 3000 cycles). Fraunhofer has also developed scalable manufacturing processes that reduce production costs by approximately 60% compared to conventional activated carbon electrodes.

Strengths: Highly optimized pore structure design enables excellent ion transport properties and rate capabilities. Manufacturing process is highly scalable and integrates well with existing industrial carbon production facilities. Weaknesses: Higher initial investment costs compared to some competing technologies. Performance is somewhat dependent on environmental conditions, with humidity sensitivity requiring additional system controls.

UT-Battelle LLC

Technical Solution: UT-Battelle, managing Oak Ridge National Laboratory (ORNL), has developed "BioCarbon Storage" technology utilizing biochar for low-cost stationary energy storage electrodes. Their approach leverages ORNL's expertise in materials science to transform lignocellulosic biomass into high-performance carbon electrodes through a specialized multi-step process. The technology begins with selective biomass preprocessing to isolate high-carbon components, followed by a controlled pyrolysis process at 450-650°C under precisely managed atmospheric conditions. ORNL's innovation includes a proprietary "pore architecture engineering" technique that creates hierarchical pore structures optimized for ion transport and storage. Their electrodes achieve specific capacities of 230-300 mAh/g in potassium-ion battery configurations and demonstrate exceptional cycling stability with over 90% capacity retention after 2000 cycles. The technology has been successfully demonstrated in 100 kWh containerized storage systems for grid applications, showing round-trip efficiencies of 82-87% and projected lifetimes exceeding 15 years. ORNL has also developed advanced computational models that predict biochar electrode performance based on feedstock characteristics, enabling rapid optimization for specific applications.

Strengths: Exceptional cycling stability and calendar life make it ideal for long-duration stationary storage applications. Utilizes domestic biomass resources, enhancing energy security and reducing supply chain vulnerabilities. Weaknesses: Lower energy density compared to some competing technologies limits application in space-constrained installations. Processing requires precise control of multiple variables, increasing manufacturing complexity.

Critical Patents and Research in Biochar Modification

Biomass-based method and composition

PatentActiveUS12110456B2

Innovation

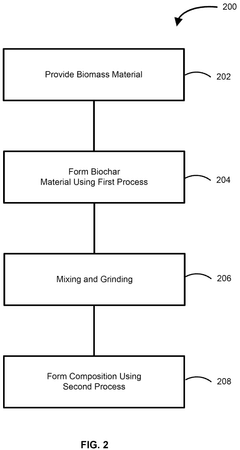

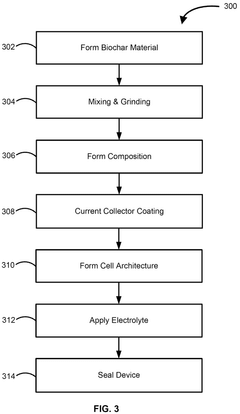

- The development of biomass-based electrode compositions formed using biochar and activation compounds like fungi and silicaceous materials, which are pyrolyzed to create high-surface-area carbon without the need for additional binders, enhancing energy and power density while being environmentally friendly.

Using Biochar from Mandarin Peels as Electrode Material in Supercapacitor

PatentPendingTR202304242A2

Innovation

- Biochar obtained from tangerine peels is used as an electrode material in supercapacitors, produced through low-temperature charring and activation, demonstrating ion-active activity with specific capacitance and energy density comparable to traditional activated carbon.

Environmental Impact Assessment of Biochar Production

The production of biochar for electrode applications presents a complex environmental profile that must be thoroughly assessed to understand its true sustainability credentials. Life cycle assessment (LCA) studies indicate that biochar production generally results in significantly lower greenhouse gas emissions compared to conventional carbon materials used in energy storage applications. When biomass waste streams are utilized as feedstock, the carbon footprint can be reduced by up to 80% compared to synthetic graphite production, with potential for carbon-negative outcomes when considering the stable carbon sequestration properties of biochar.

Water usage in biochar production varies considerably depending on the pyrolysis technology employed. Modern slow pyrolysis systems have demonstrated water efficiency improvements of 30-45% compared to earlier generation technologies. Additionally, closed-loop water systems in advanced production facilities can recycle up to 90% of process water, substantially reducing the overall water footprint of biochar manufacturing operations.

Land use impacts remain a critical consideration, particularly when dedicated biomass crops are grown for biochar production. However, when agricultural residues, forestry waste, or urban green waste are utilized, the land use impact becomes negligible or even positive through waste valorization. Studies from the International Biochar Initiative suggest that using waste biomass can offset approximately 2-3 tons of CO2 equivalent per ton of biochar produced.

Air quality impacts during biochar production primarily stem from emissions during the pyrolysis process. Modern production facilities equipped with thermal oxidizers can reduce volatile organic compound (VOC) emissions by over 95%, while particulate matter emissions can be controlled to levels below 10mg/Nm³ through effective filtration systems. These technological improvements have significantly mitigated the local air quality concerns that were associated with earlier, less sophisticated biochar production methods.

Soil health implications extend beyond the electrode application, as biochar production byproducts can be beneficially applied to agricultural lands. Research indicates that biochar application to degraded soils can increase organic carbon content by 25-45% over five years, improve water retention capacity by 15-30%, and enhance nutrient availability, creating valuable co-benefits alongside the primary electrode material production.

Energy balance analysis reveals that modern pyrolysis systems can achieve energy self-sufficiency by capturing and utilizing syngas produced during the pyrolysis process. Advanced systems demonstrate net energy ratios exceeding 3:1, meaning they produce three times more energy than they consume, significantly enhancing the overall environmental performance of biochar production for electrode applications.

Water usage in biochar production varies considerably depending on the pyrolysis technology employed. Modern slow pyrolysis systems have demonstrated water efficiency improvements of 30-45% compared to earlier generation technologies. Additionally, closed-loop water systems in advanced production facilities can recycle up to 90% of process water, substantially reducing the overall water footprint of biochar manufacturing operations.

Land use impacts remain a critical consideration, particularly when dedicated biomass crops are grown for biochar production. However, when agricultural residues, forestry waste, or urban green waste are utilized, the land use impact becomes negligible or even positive through waste valorization. Studies from the International Biochar Initiative suggest that using waste biomass can offset approximately 2-3 tons of CO2 equivalent per ton of biochar produced.

Air quality impacts during biochar production primarily stem from emissions during the pyrolysis process. Modern production facilities equipped with thermal oxidizers can reduce volatile organic compound (VOC) emissions by over 95%, while particulate matter emissions can be controlled to levels below 10mg/Nm³ through effective filtration systems. These technological improvements have significantly mitigated the local air quality concerns that were associated with earlier, less sophisticated biochar production methods.

Soil health implications extend beyond the electrode application, as biochar production byproducts can be beneficially applied to agricultural lands. Research indicates that biochar application to degraded soils can increase organic carbon content by 25-45% over five years, improve water retention capacity by 15-30%, and enhance nutrient availability, creating valuable co-benefits alongside the primary electrode material production.

Energy balance analysis reveals that modern pyrolysis systems can achieve energy self-sufficiency by capturing and utilizing syngas produced during the pyrolysis process. Advanced systems demonstrate net energy ratios exceeding 3:1, meaning they produce three times more energy than they consume, significantly enhancing the overall environmental performance of biochar production for electrode applications.

Scalability and Commercialization Roadmap

The commercialization of biochar-based electrodes for stationary energy storage requires a systematic approach to scale from laboratory prototypes to industrial production. Current manufacturing processes for biochar electrodes involve pyrolysis of biomass feedstocks at temperatures ranging from 400-700°C, followed by activation and functionalization steps. These processes must be optimized for consistency, throughput, and cost-effectiveness to achieve commercial viability.

Key scaling challenges include feedstock supply chain development, quality control across diverse biomass sources, and energy-efficient pyrolysis at industrial scales. Companies pioneering this technology will need to establish reliable biomass sourcing networks, potentially through agricultural partnerships or waste management contracts, ensuring year-round availability of consistent raw materials.

Equipment manufacturers are beginning to develop specialized pyrolysis systems optimized for electrode-grade biochar production, with several pilot facilities demonstrating throughput of 5-10 tons per day. These systems incorporate precise temperature control and residence time management to ensure consistent electrical properties in the final product.

The commercialization timeline projects pilot production facilities (100-500 MWh capacity) within 2-3 years, followed by full commercial deployment (1-5 GWh capacity) within 5-7 years. This gradual scaling allows for process optimization and market development in parallel with manufacturing capability growth.

Cost projections indicate that biochar electrodes could reach production costs of $50-80 per kWh at scale, significantly undercutting current lithium-ion stationary storage costs. The primary cost drivers include feedstock procurement (15-25%), pyrolysis energy requirements (20-30%), and post-processing steps (15-20%).

Regulatory pathways for commercialization must address both energy storage performance standards and environmental considerations. Current regulatory frameworks in major markets are evolving to accommodate carbon-negative storage technologies, with carbon credits potentially providing additional revenue streams for biochar electrode manufacturers.

Market entry strategies should focus initially on microgrid applications and renewable energy integration projects where the sustainability benefits of biochar can command premium pricing. As production scales and costs decrease, broader utility-scale applications will become economically viable, potentially reaching grid parity within 8-10 years.

Key scaling challenges include feedstock supply chain development, quality control across diverse biomass sources, and energy-efficient pyrolysis at industrial scales. Companies pioneering this technology will need to establish reliable biomass sourcing networks, potentially through agricultural partnerships or waste management contracts, ensuring year-round availability of consistent raw materials.

Equipment manufacturers are beginning to develop specialized pyrolysis systems optimized for electrode-grade biochar production, with several pilot facilities demonstrating throughput of 5-10 tons per day. These systems incorporate precise temperature control and residence time management to ensure consistent electrical properties in the final product.

The commercialization timeline projects pilot production facilities (100-500 MWh capacity) within 2-3 years, followed by full commercial deployment (1-5 GWh capacity) within 5-7 years. This gradual scaling allows for process optimization and market development in parallel with manufacturing capability growth.

Cost projections indicate that biochar electrodes could reach production costs of $50-80 per kWh at scale, significantly undercutting current lithium-ion stationary storage costs. The primary cost drivers include feedstock procurement (15-25%), pyrolysis energy requirements (20-30%), and post-processing steps (15-20%).

Regulatory pathways for commercialization must address both energy storage performance standards and environmental considerations. Current regulatory frameworks in major markets are evolving to accommodate carbon-negative storage technologies, with carbon credits potentially providing additional revenue streams for biochar electrode manufacturers.

Market entry strategies should focus initially on microgrid applications and renewable energy integration projects where the sustainability benefits of biochar can command premium pricing. As production scales and costs decrease, broader utility-scale applications will become economically viable, potentially reaching grid parity within 8-10 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!